Patents

Literature

32results about How to "Play the role of anti-leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

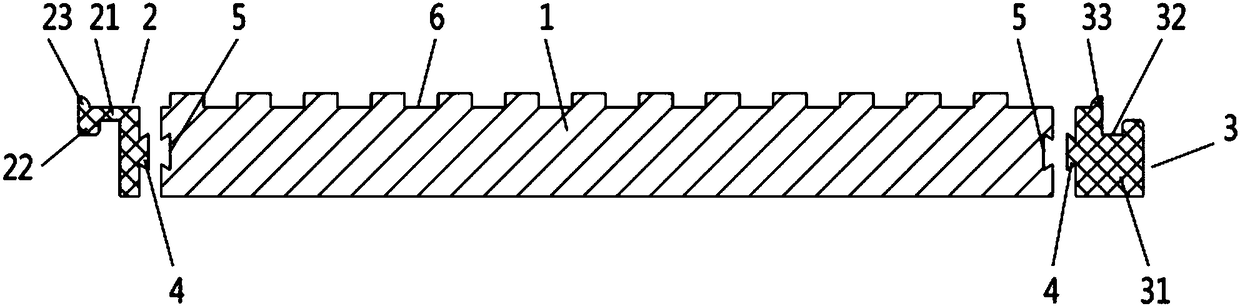

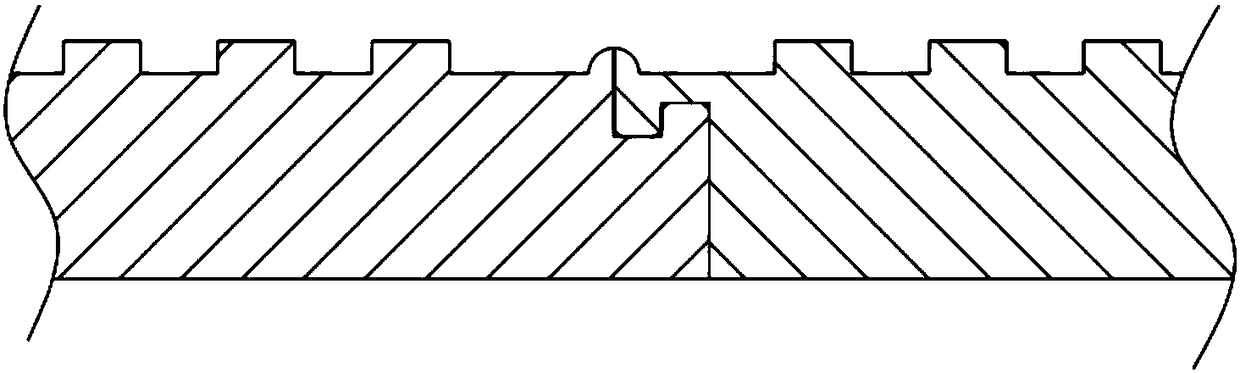

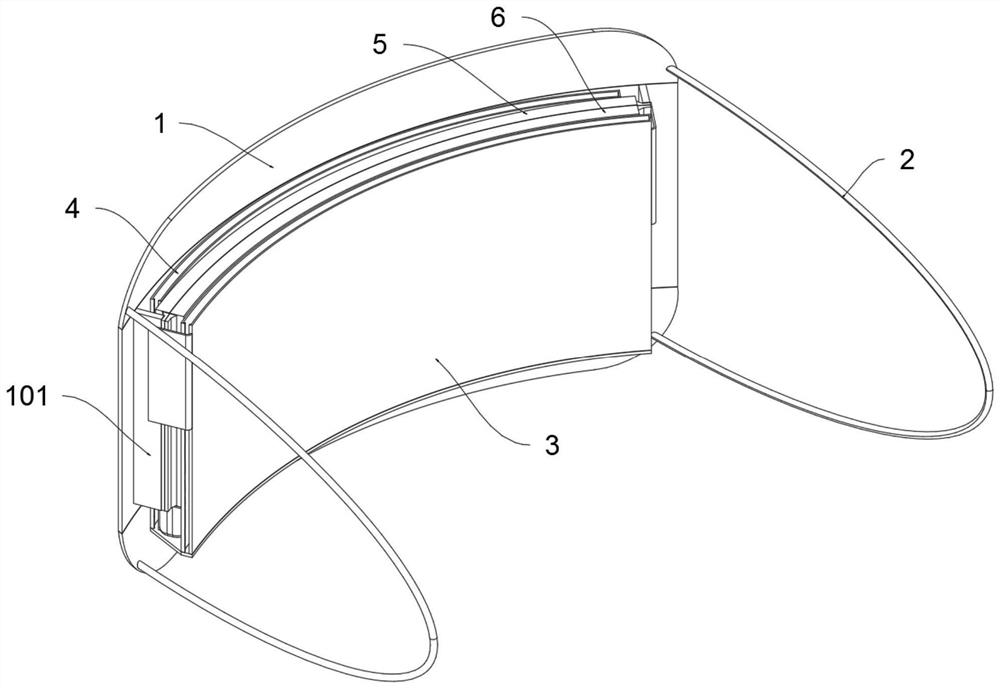

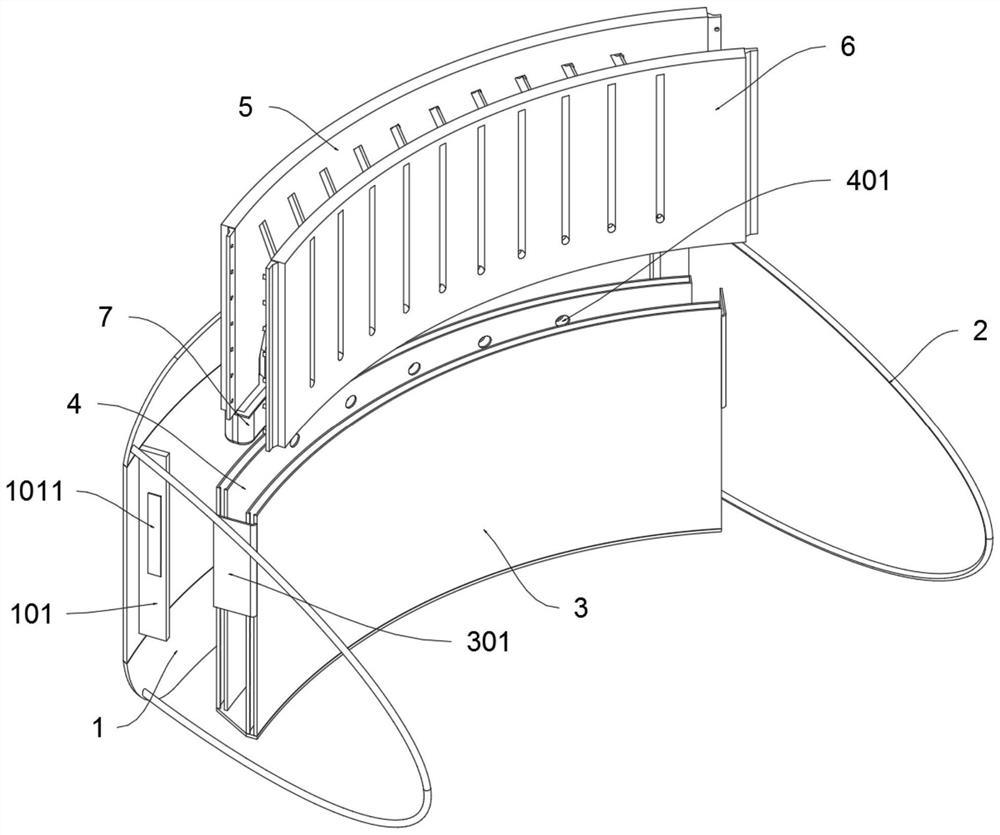

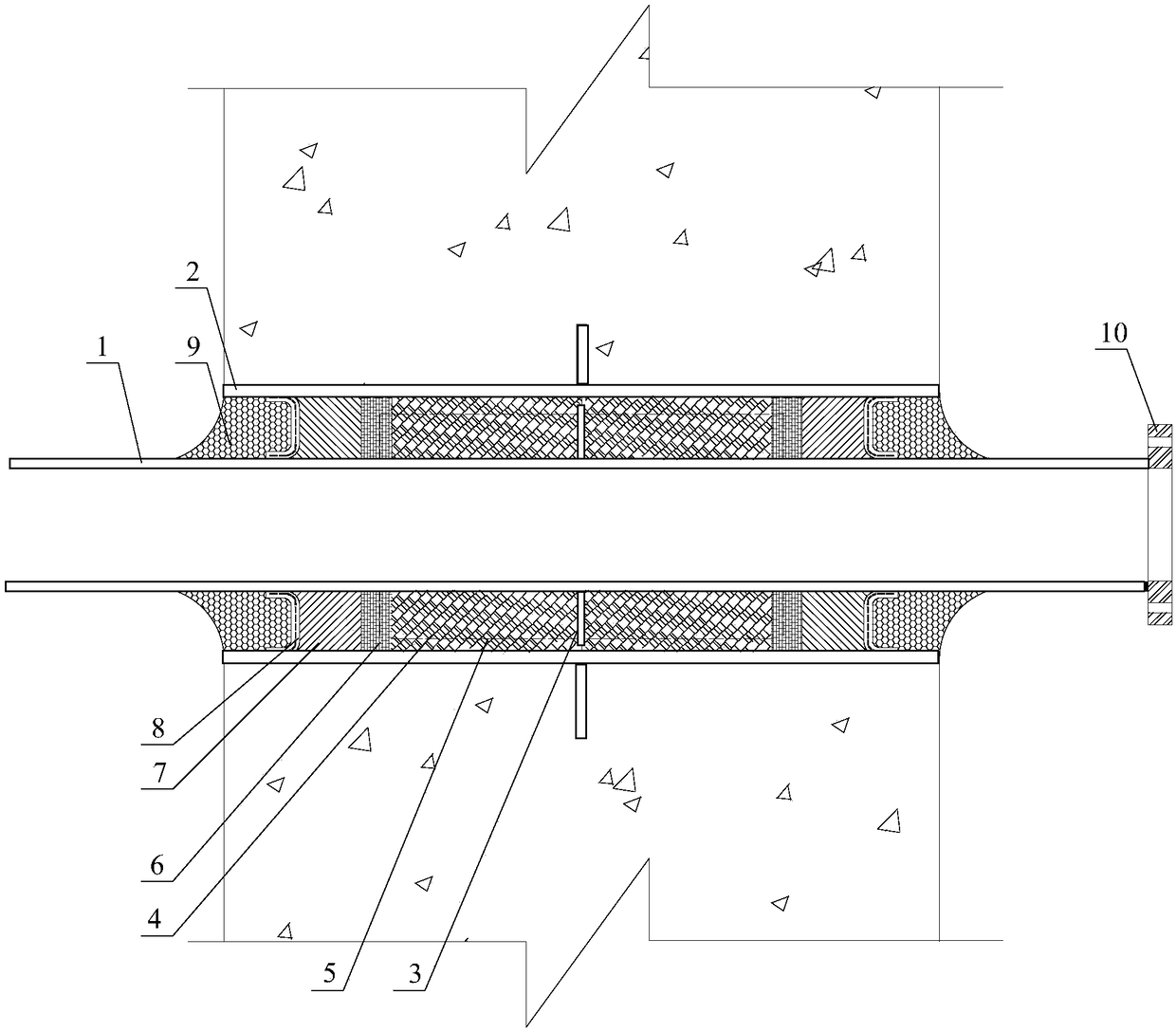

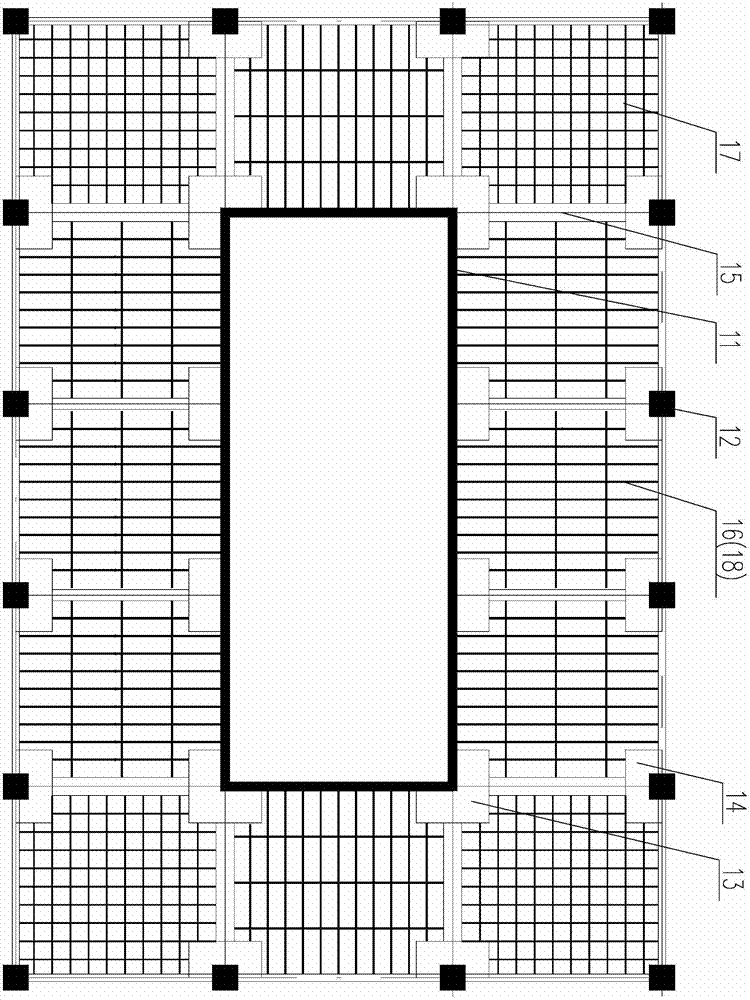

Hollow floor using steel mesh and thin plate combination for hole forming

InactiveCN104631679ARealize multifunctional applicationReinforced top surface against construction loadsFloorsCalcium silicateThin slab

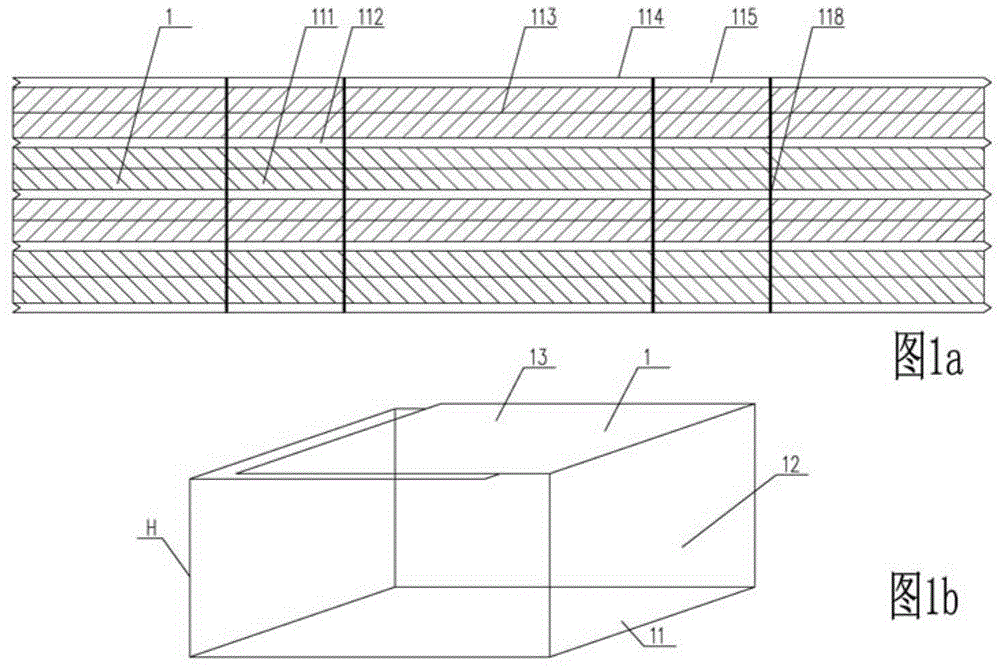

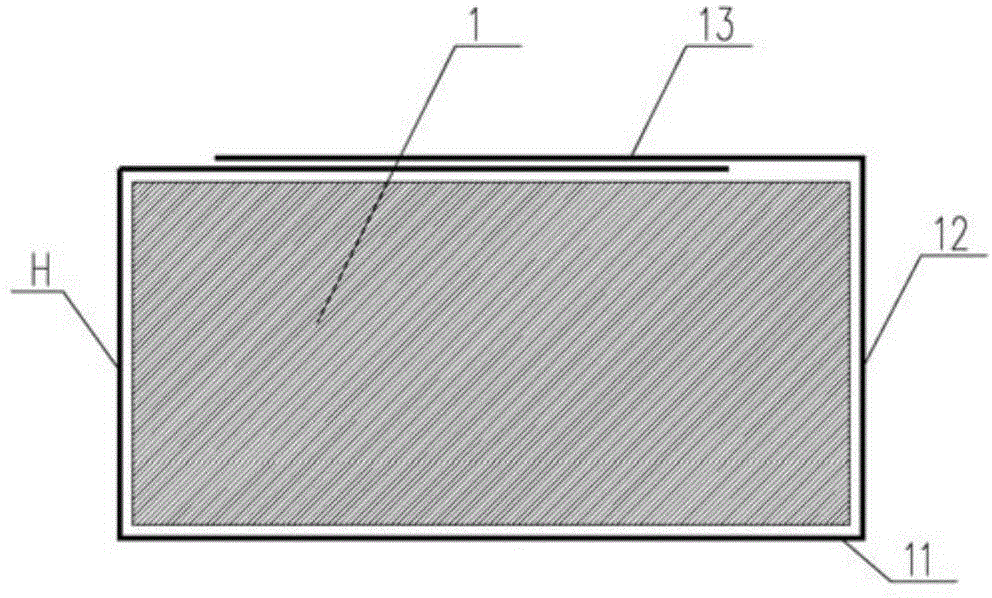

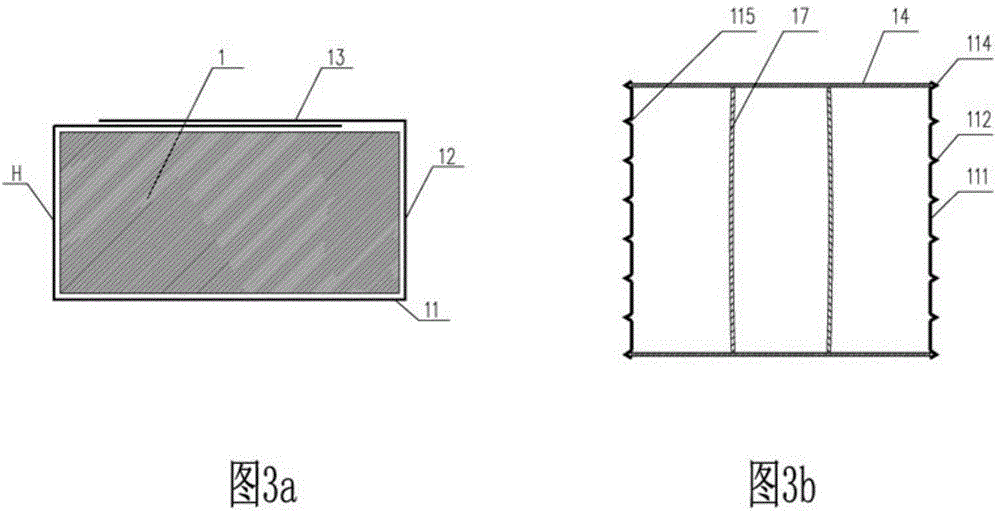

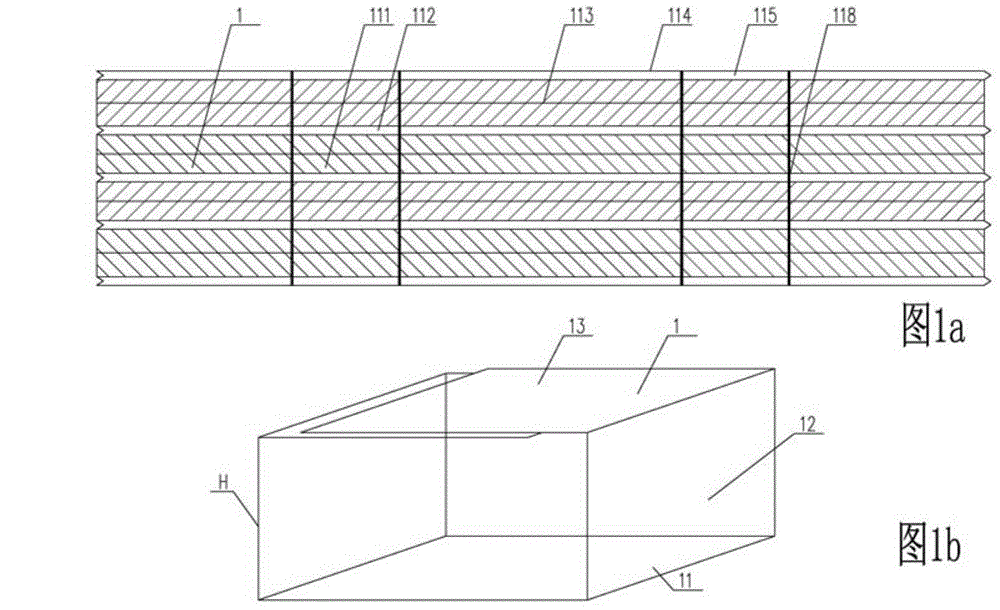

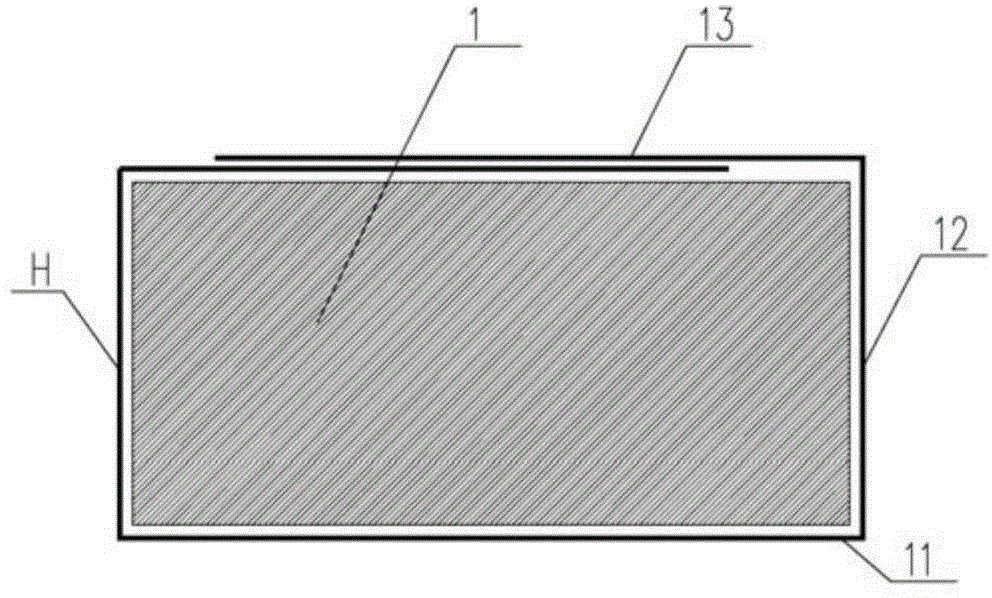

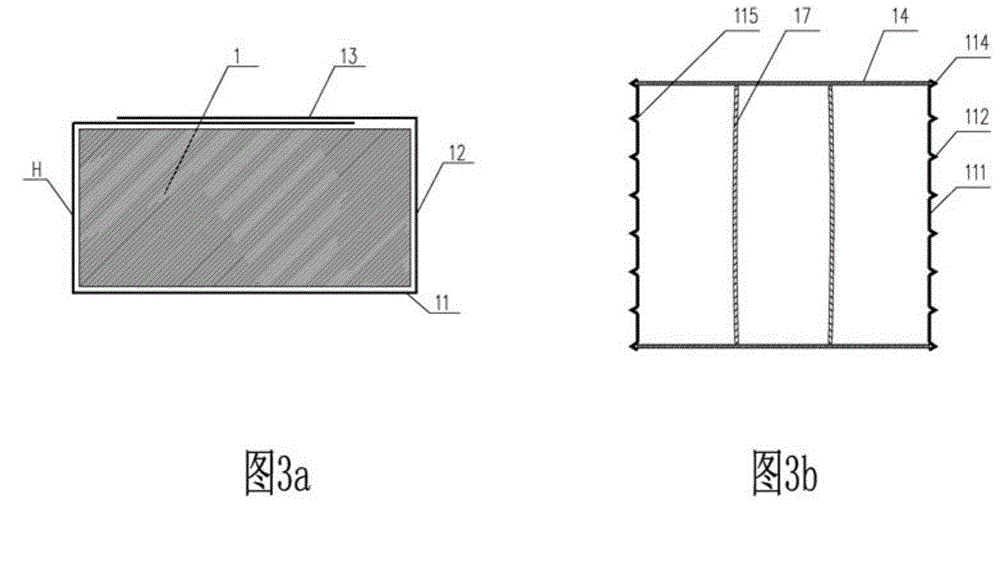

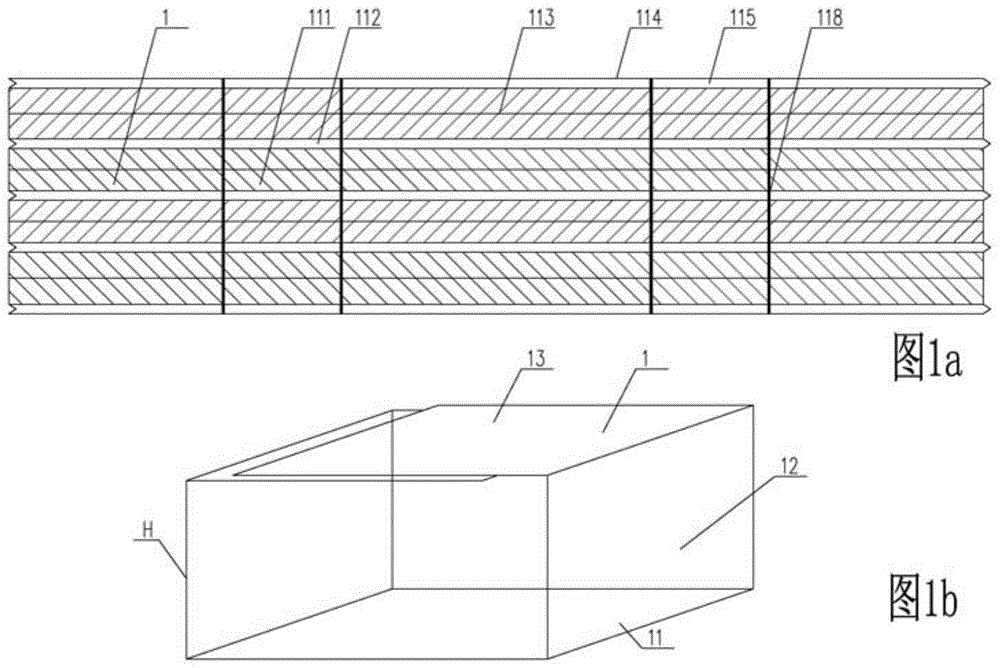

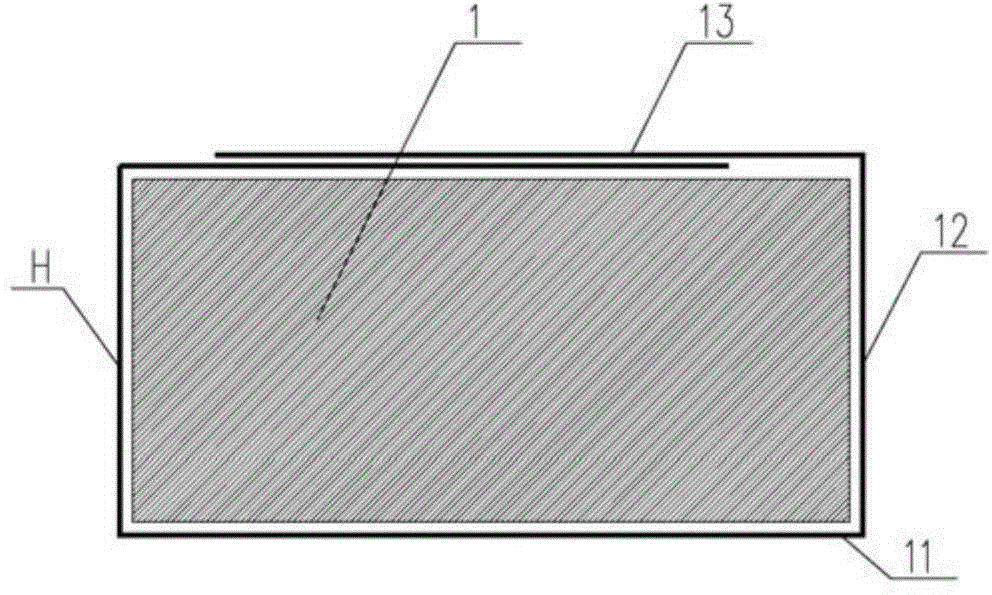

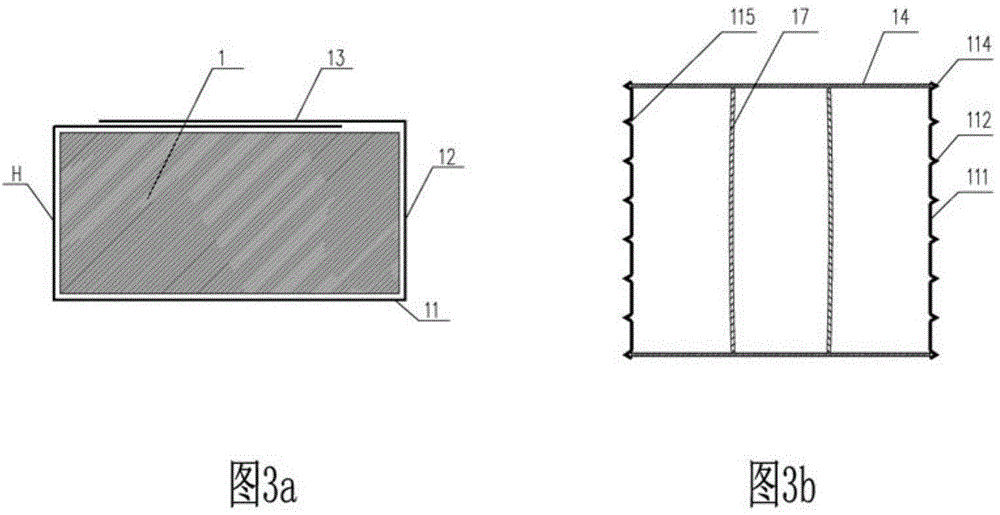

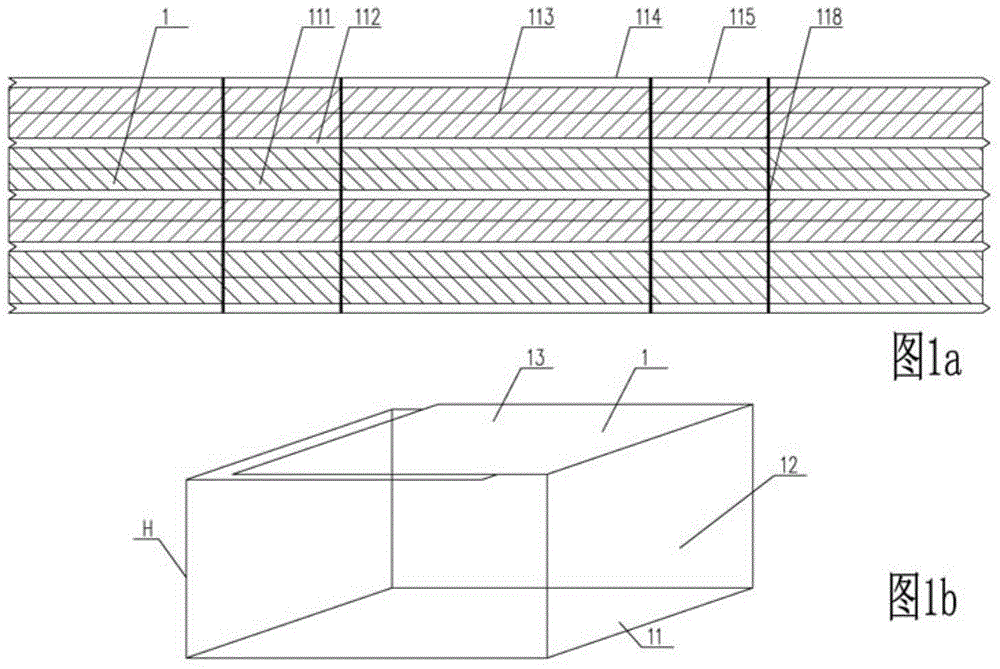

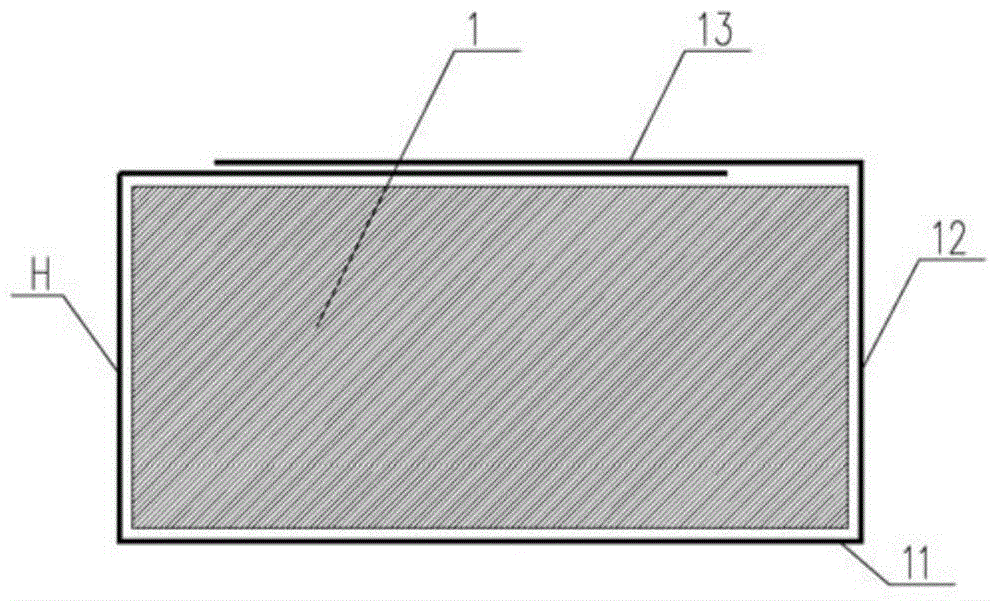

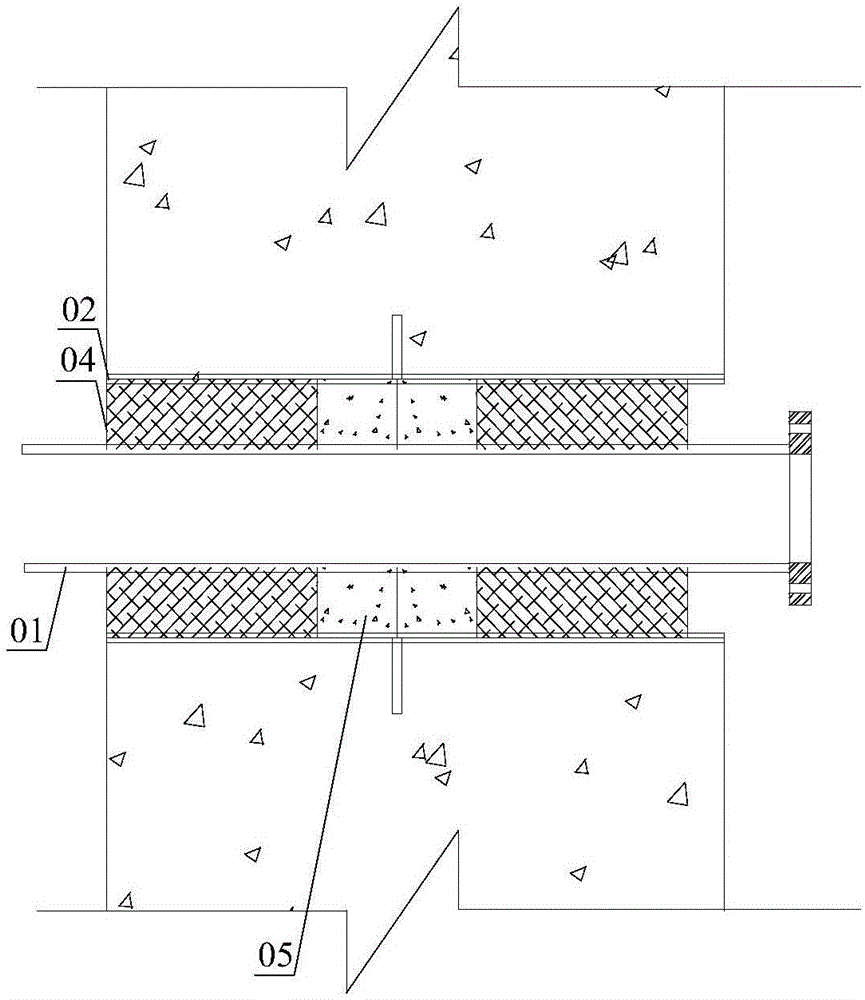

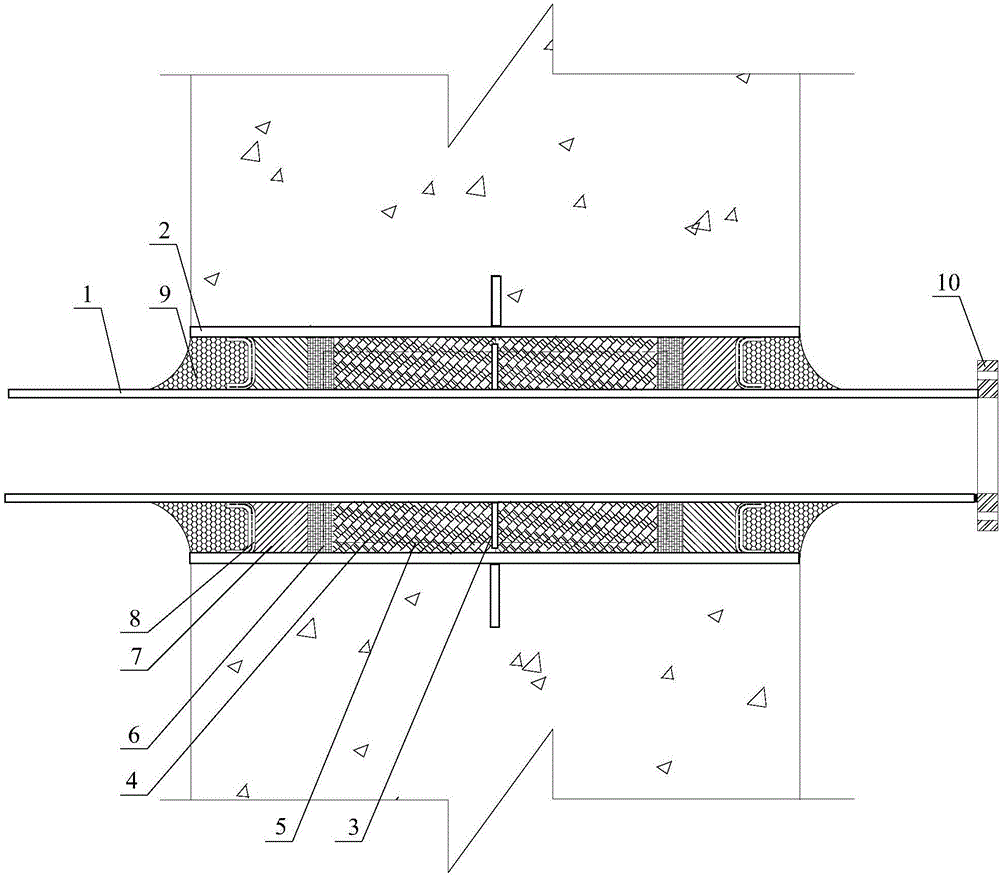

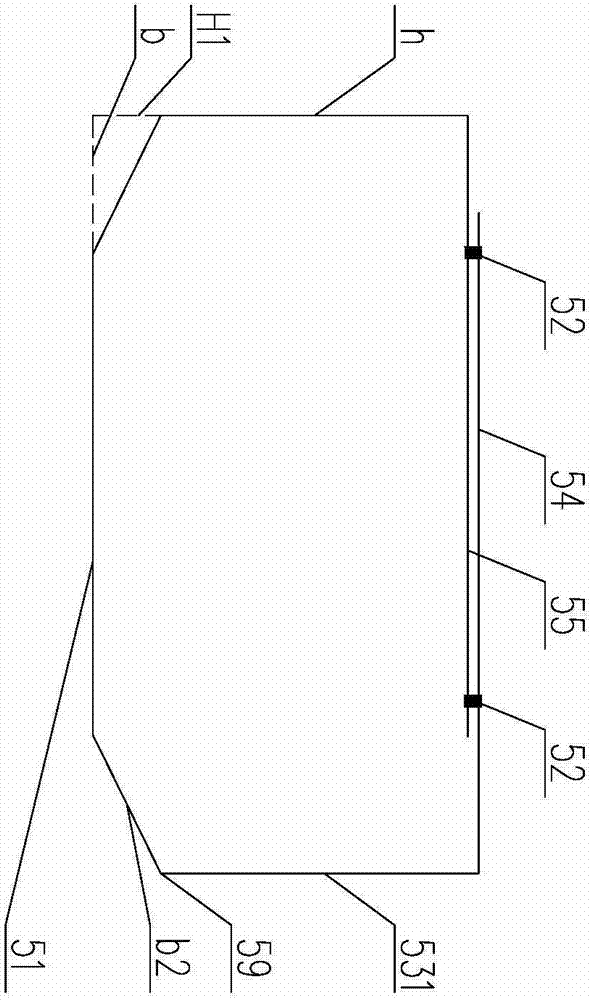

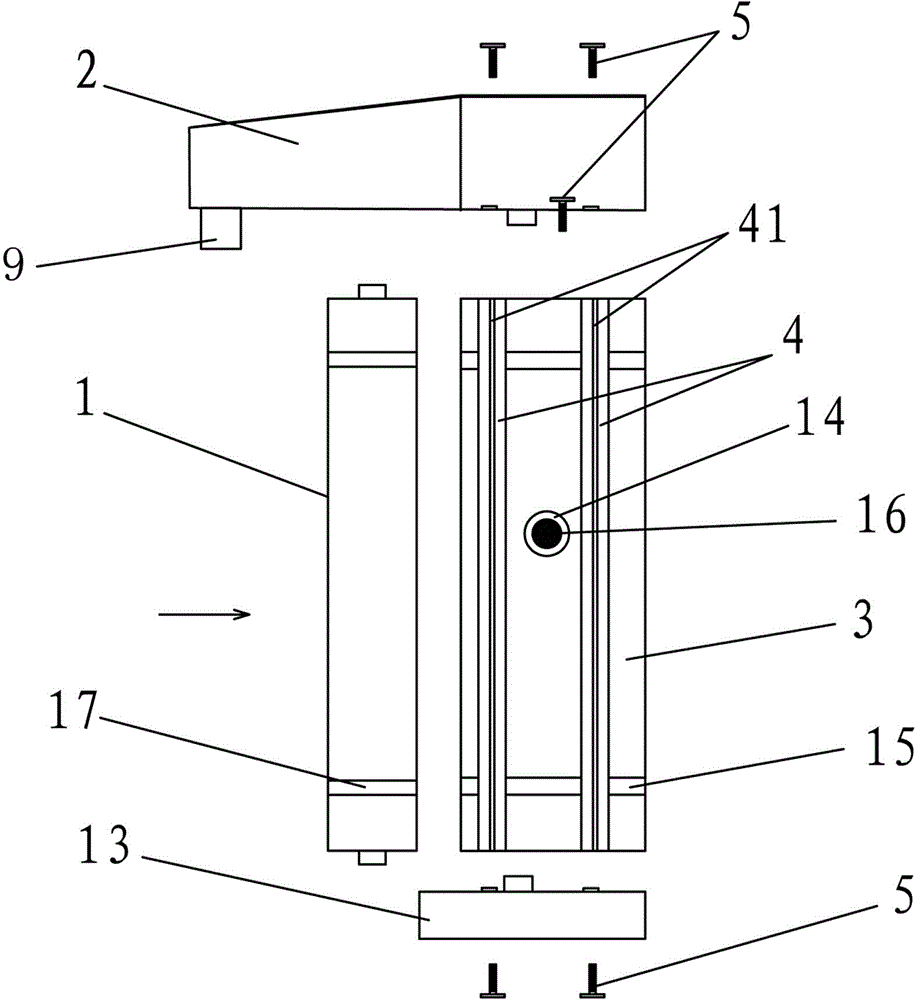

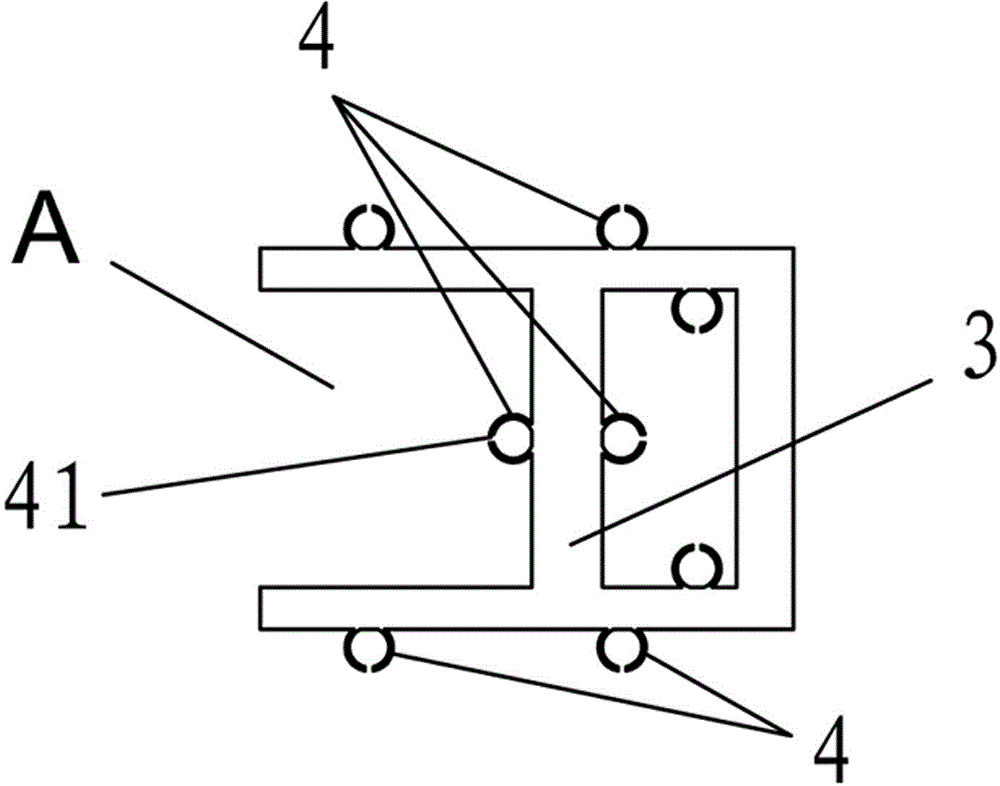

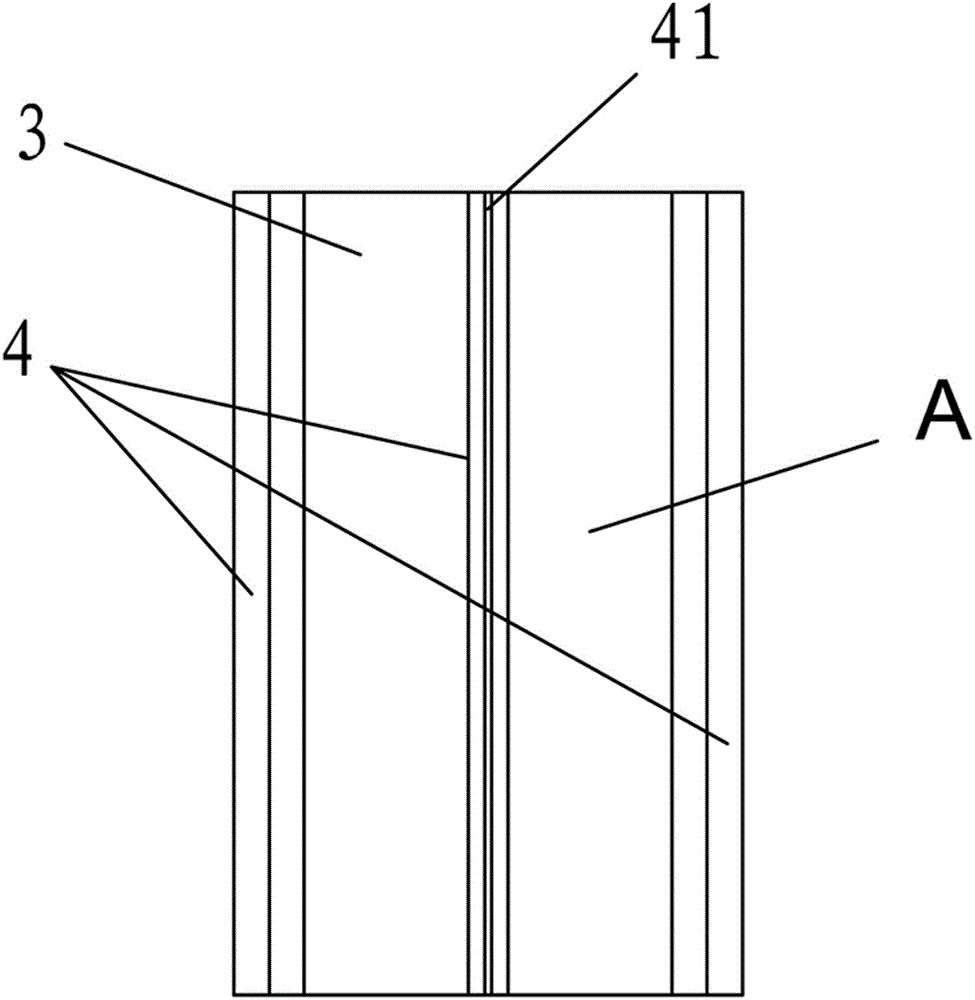

A hollow floor using steel mesh and thin plate combination for hole forming comprises columns, beams, flange plates, and a cavity component formed by steel meshes and thin plates, wherein the beams are reinforced concrete beams or steel reinforced concrete combined beams; the flange plates are I-shaped section plates or T-shaped section plates; the cavity component is formed by the steel meshes and the thin plates which acts on each other; the steel meshes form the overall forming tetrahedron of the top plate, the bottom plate and two lateral walls of the hexahedron cavity component; the head and tail ends of the steel meshes overlap on one optional face of the tetrahedron; the thin plates include calcium silicate plates, plastic plates, composite plates, gypsum plates or corrugated plates; the thin plates form the other two lateral wall plates of the cavity component and the support plates between the top plate and the bottom plate of the cavity component; the two lateral wall plates formed by the thin plates are placed in edge reinforcing rib grooves at two edges of the steel meshes; in-situ concrete pouring is performed on the columns, the beams and the flange plates.

Owner:王本淼 +2

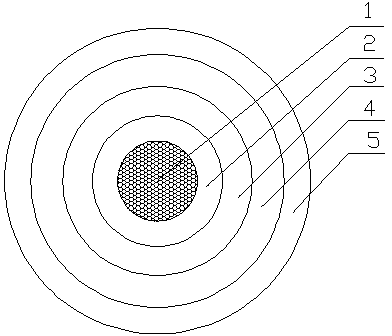

Manufacturing method of once-formed graphite crucible

The invention relates to a manufacturing method of a once-formed graphite crucible. The manufacturing method is characterized by comprising the following steps: (1) batching: preparing the following components in percentage by mass: 70%-90% grinding powder prepared by grinding graphite scrap and 10%-30% of medium temperature coal pitch; (2) mixing kneading; (3) compression; (4) roasting; and (5) processing. The major material adopted in the manufacturing method is the graphite scrap which is waste obtained during the production of an electrode, so that the waste reutilization is realized, the average cost of each same-scale product is lowered by 800-1000 yuan, the energy source is saved, the environment is protected, and meanwhile, the manufacturing cost of the graphite crucible is lowered. Compared with a graphite crucible produced from a traditional graphite electrode, two procedures of impregnation and graphitization in which the environmental pollution may be caused and the energy sources are greatly consumed are reduced; and compared with a graphite electrode crucible, the average production cycle is shortened by 30-40 days, the energy conservation and emission reduction are achieved, and the production efficiency is greatly improved. According to the graphite crucible produced by virtue of the technical scheme, the longitudinal layout of aggregate particles is avoided, the structure of a product is isotropic, an anti-seepage effect is achieved, and the smelting use requirements of heavy and noble metals are well met.

Owner:吉林科工碳业有限公司

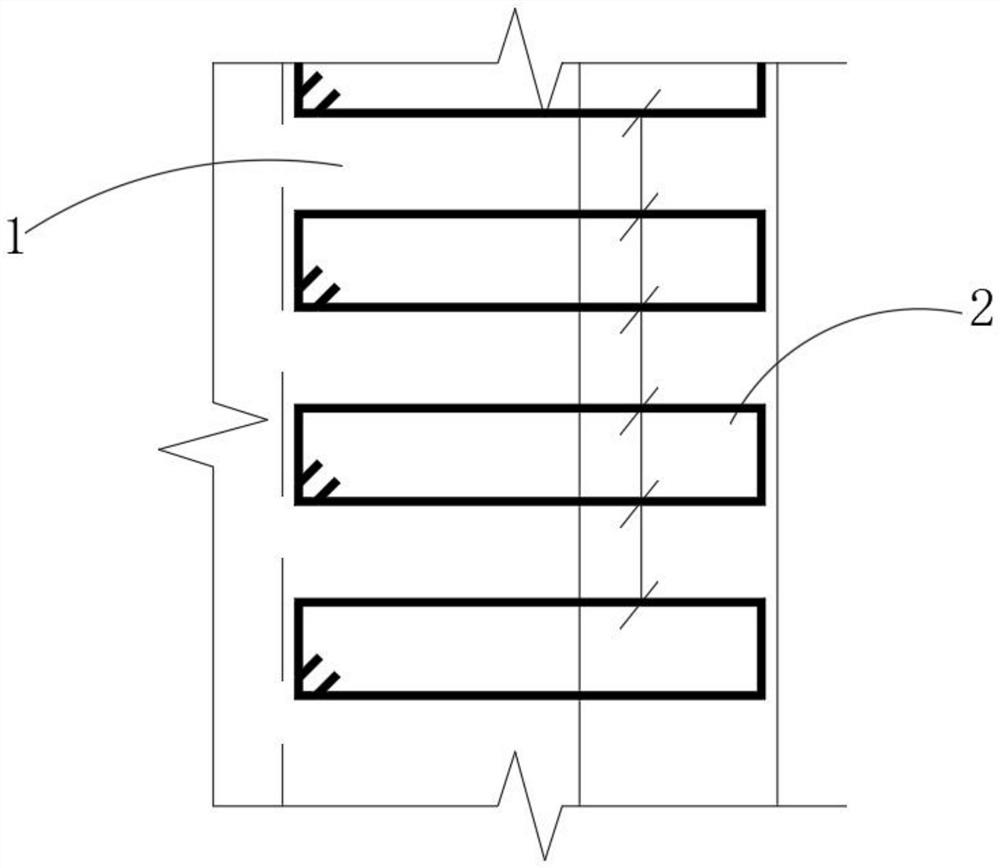

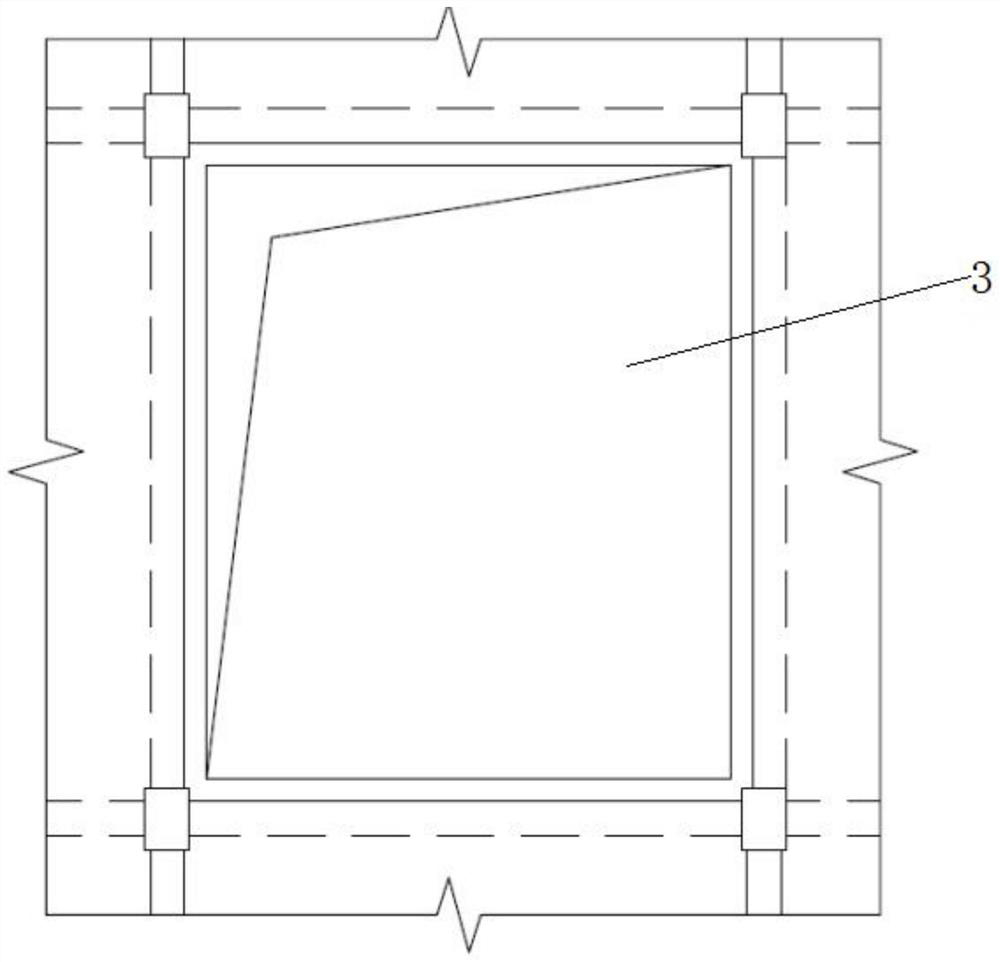

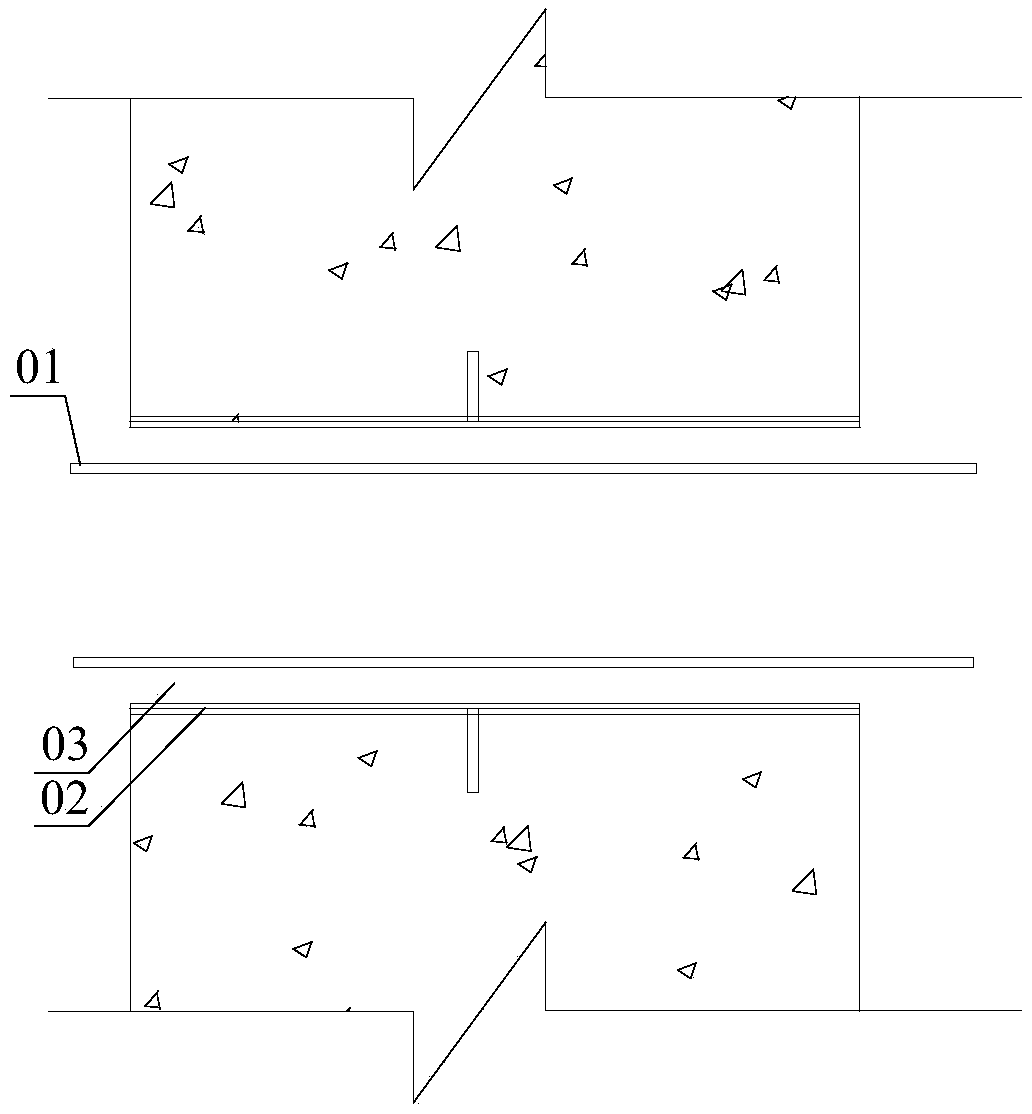

Hollow floor using steel mesh and plate combination for hole forming

InactiveCN104631678ARealize multifunctional applicationReinforced top surface against construction loadsFloorsCalcium silicateReinforced concrete

A hollow floor using steel mesh and plate combination for hole forming comprises columns, beams, flange plates, and a cavity component formed by steel meshes and thin plates, wherein a solid part column cap larger than 500mm is disposed at the outer edge of each column; the beams are reinforced concrete beams or steel reinforced concrete combined beams; the flange plates are I-shaped section plates or T-shaped section plates; the cavity component is formed by the steel meshes and the thin plates which acts on each other; the steel meshes form the overall forming tetrahedron of the top plate, the bottom plate and two lateral walls of the hexahedron cavity component; the head and tail ends of the steel meshes overlap on one optional face of the tetrahedron; the thin plates include calcium silicate plates, plastic plates, composite plates, gypsum plates or corrugated plates; the thin plates form the other two lateral wall plates of the cavity component and the support plates between the top plate and the bottom plate of the cavity component; the two lateral wall plates formed by the thin plates are placed in edge reinforcing rib grooves at two edges of the steel meshes.

Owner:王本淼 +2

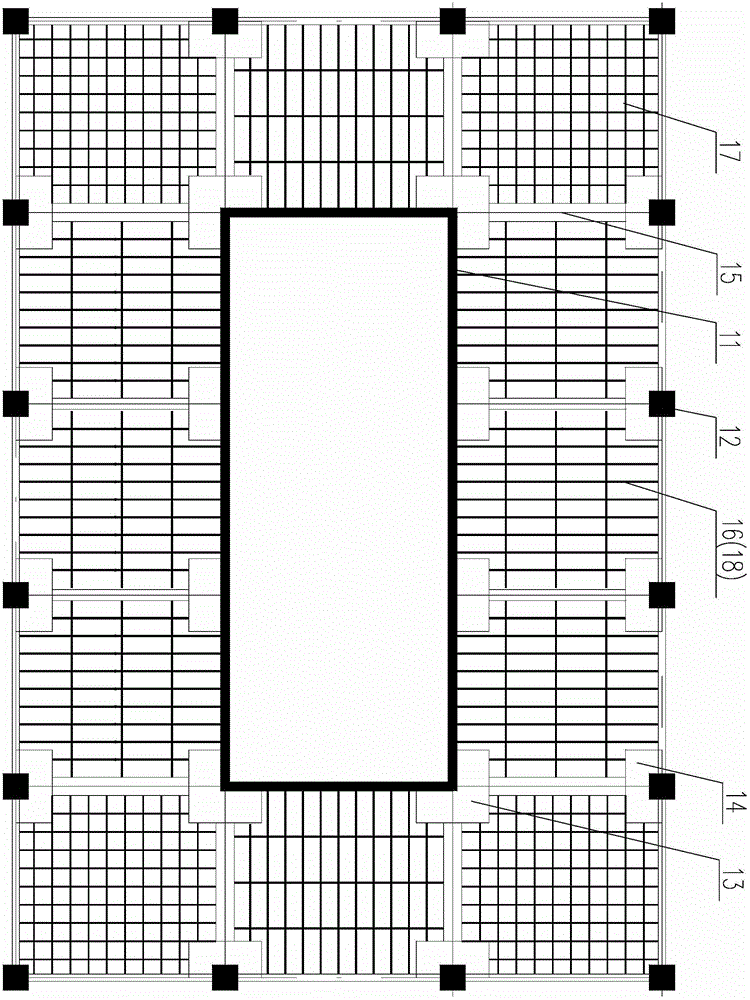

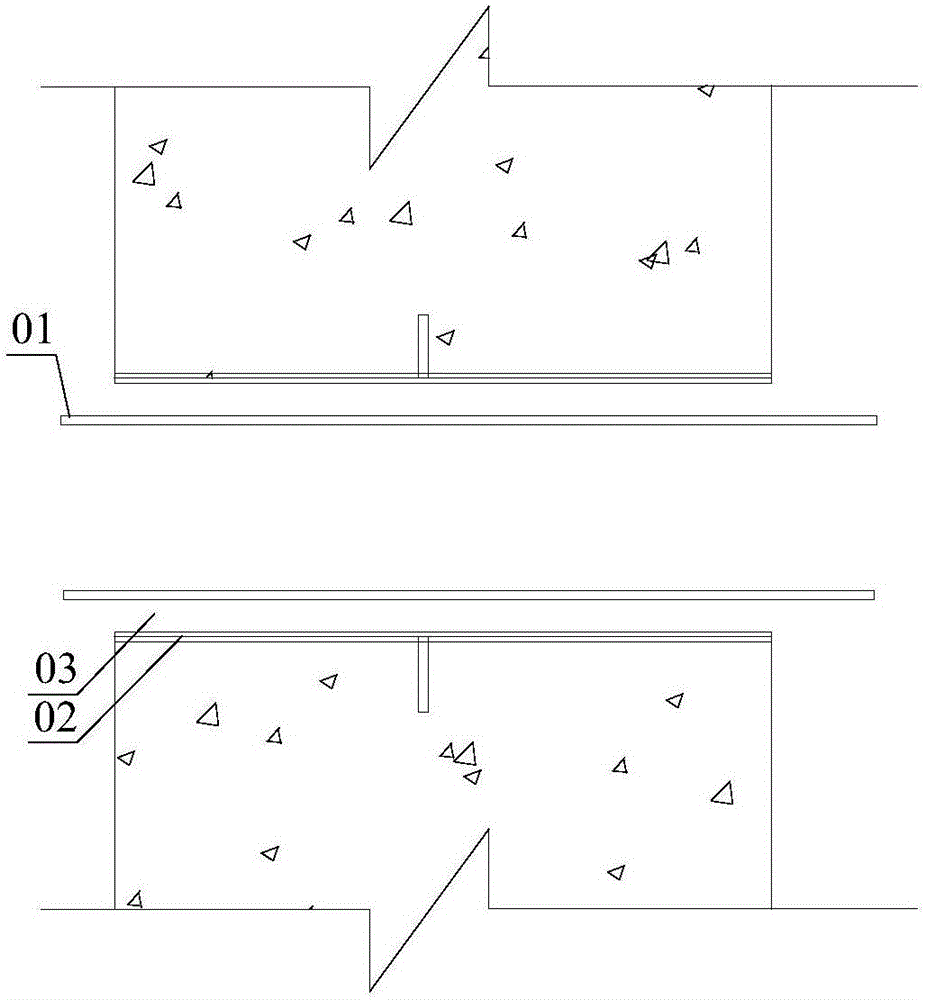

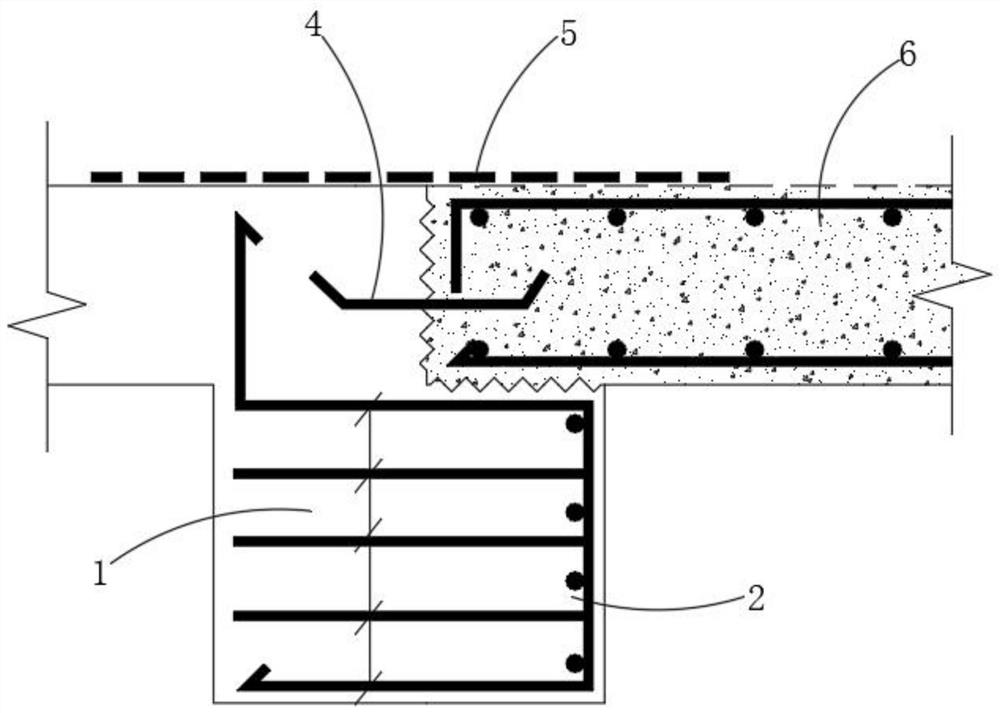

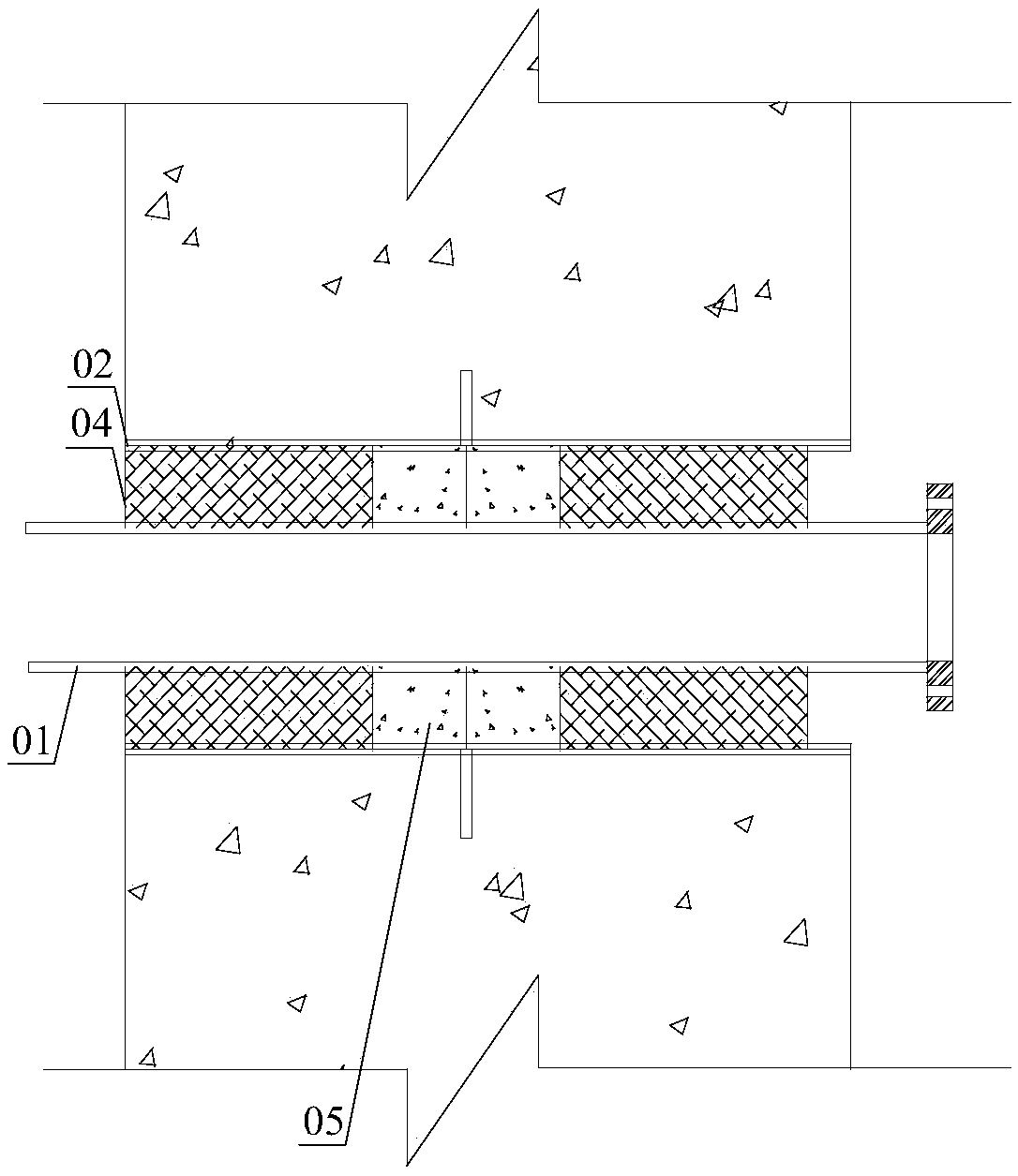

High-rise building adopting cast-in-place hollow floors

InactiveCN103981944AEasy constructionFilled with light weightFloorsReinforced concreteSpatial structure

The invention provides a high-rise building adopting cast-in-place hollow floors. The high-rise building is formed by a core tube, an outer frame, hollow floors, and a steel mesh and organic object combined cavity; the core tube is of a closed space structure formed by shear walls in four directions at the central part of a building plane; the outer frame is a frame stress component formed by outer edge beam columns of the building plane; main beams are reinforced concrete combined beams or profiled-steel beams; steel meshes and organic objects act upon each other; the steel meshes form the cavity top surface and the cavity bottom surface of the combined cavity and two side walls of the cavity side faces; the organic objects comprise air bags or polyphenyl blocks; the organic objects form the other two side walls of the side faces of the combined cavity of the steel meshes, are supported between the cavity top surface and the cavity bottom surface, and are used for controlling the height of the combined cavity of the steel meshes. After the steel mesh and organic object combined cavity is put in place, concrete is deposited, vibration and ramming and maintenance are carried out, and floor templates are dismantled, so that the application of the cast-in-place hollow floors in the high-rise building is realized.

Owner:王本淼 +2

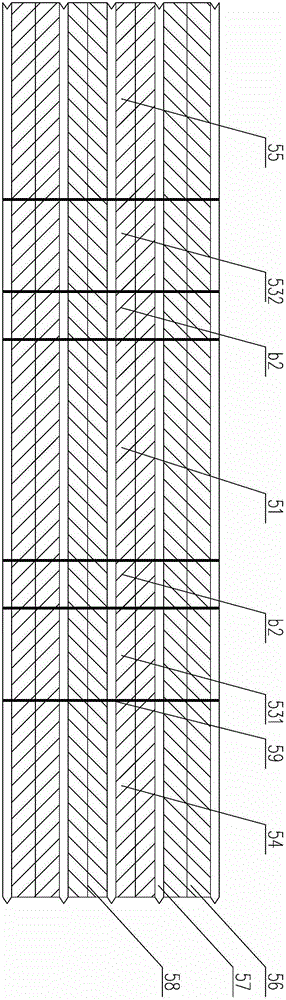

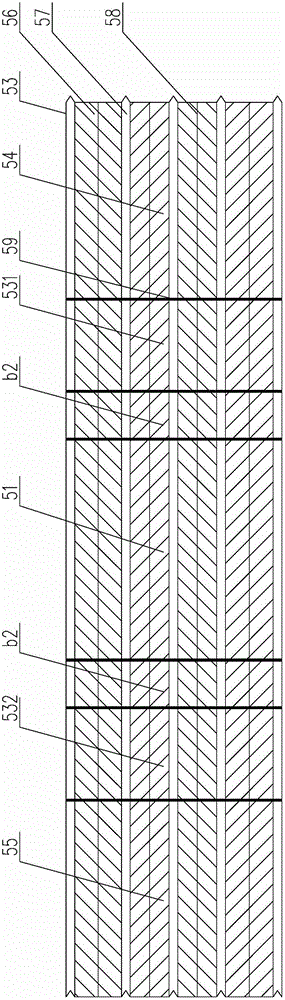

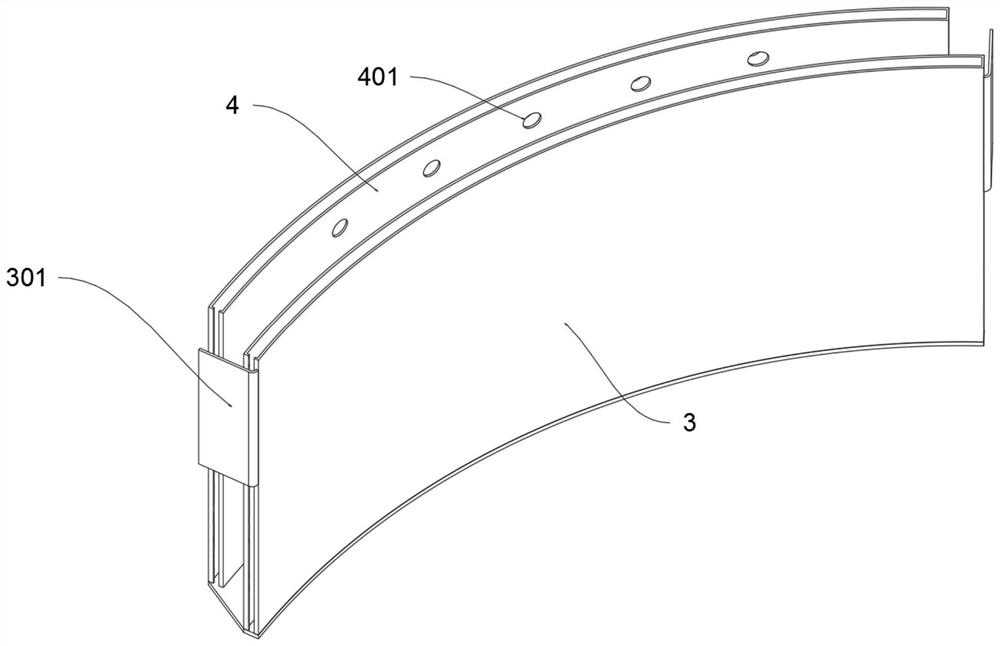

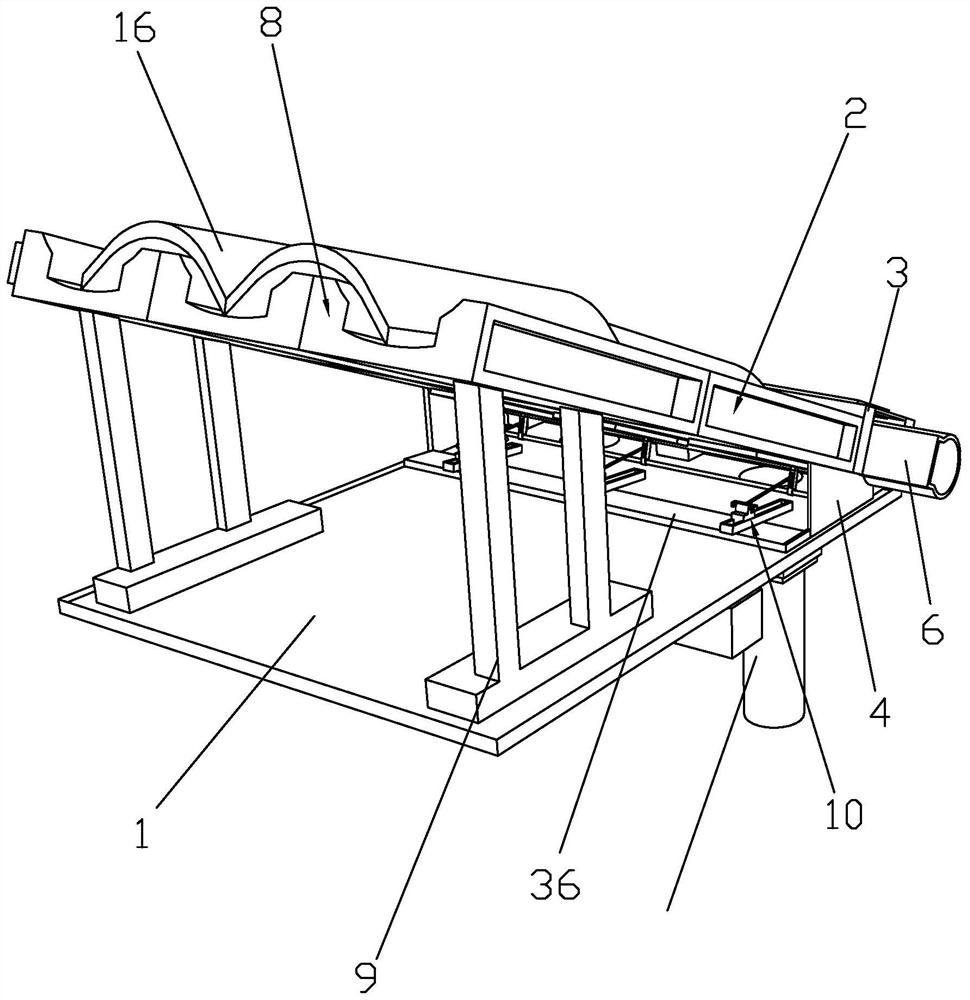

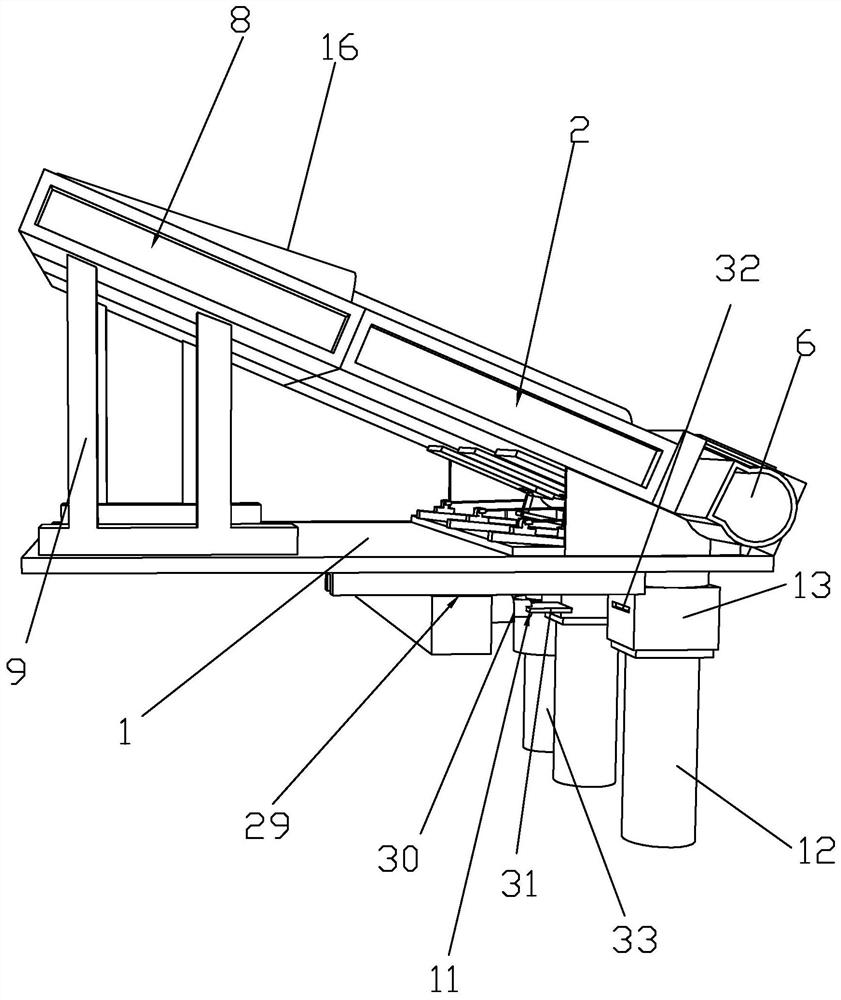

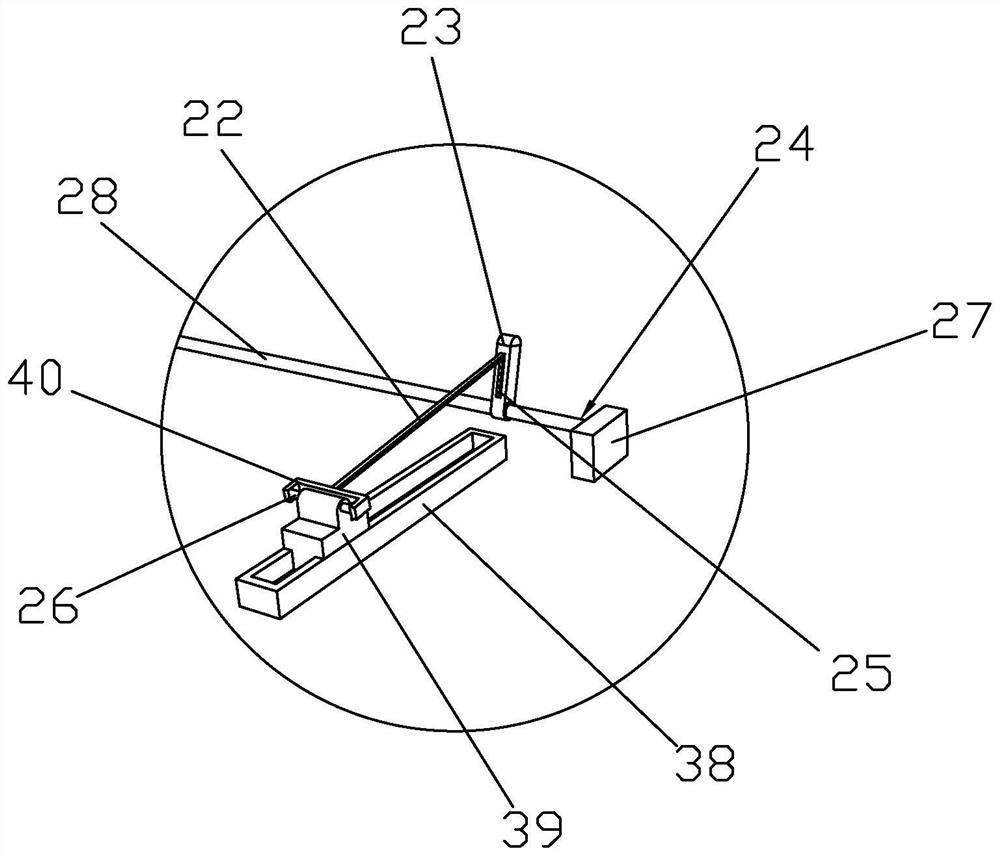

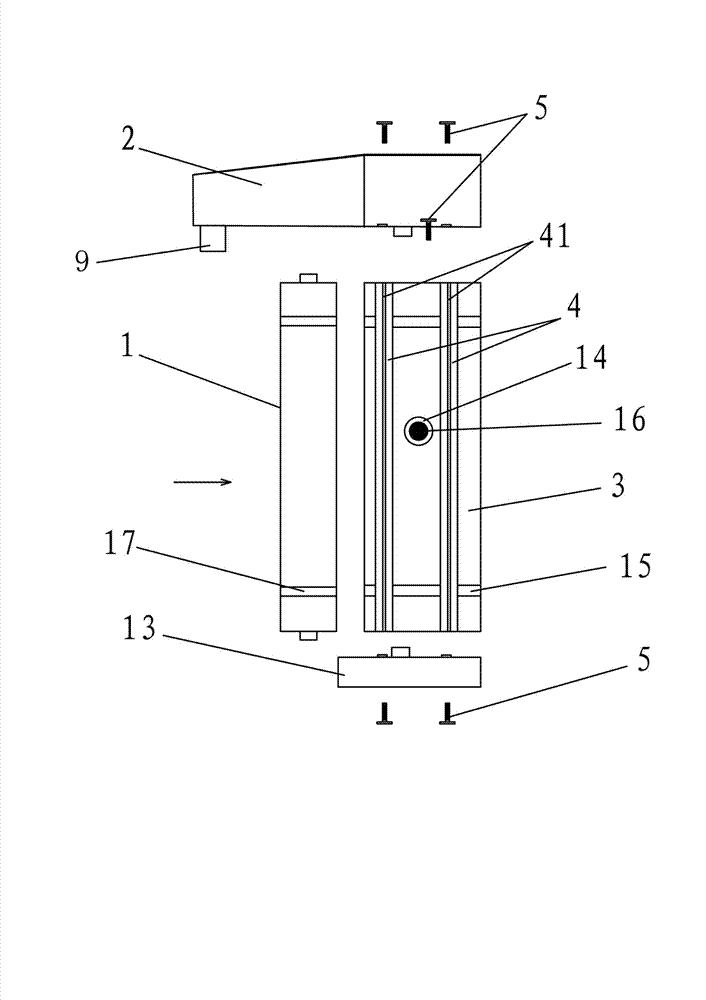

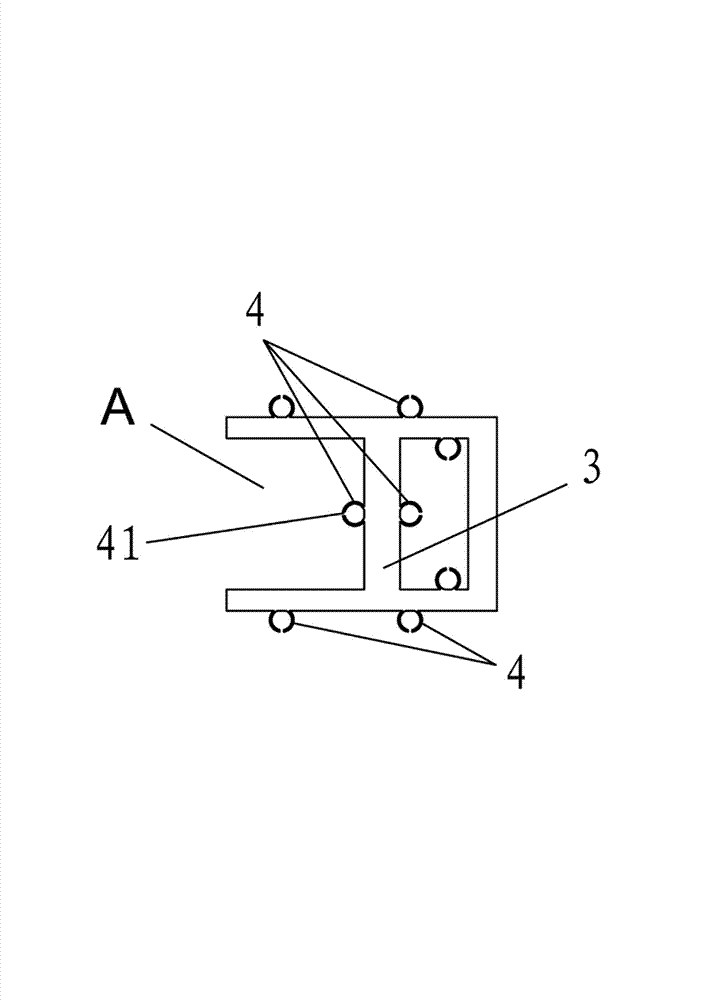

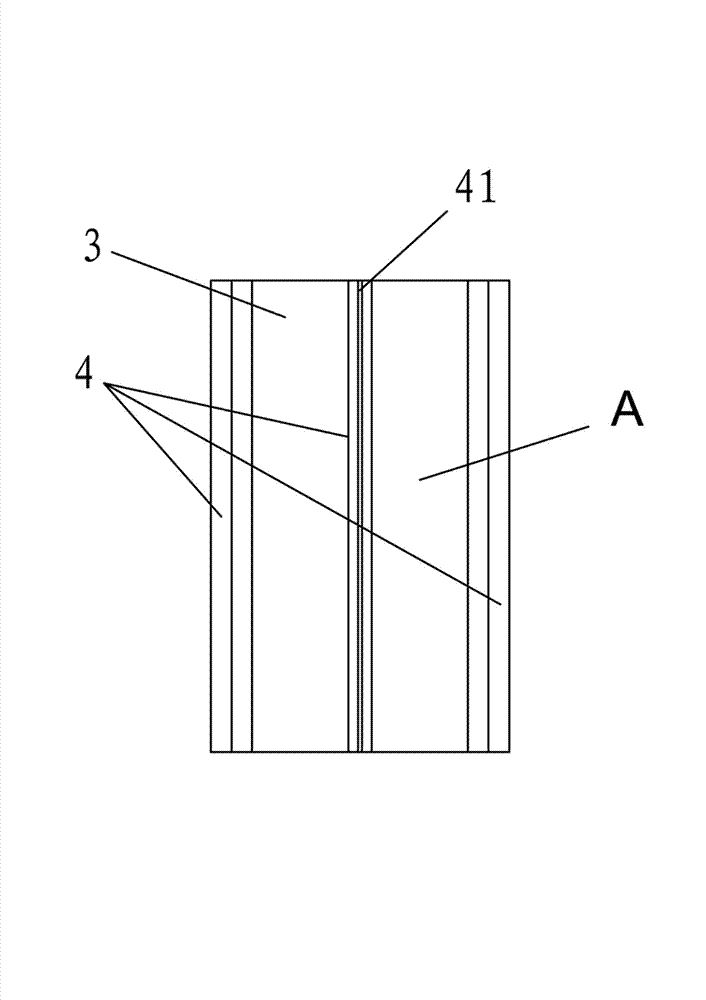

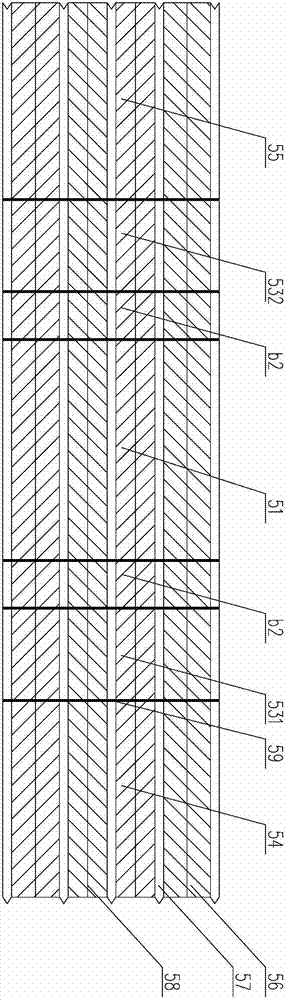

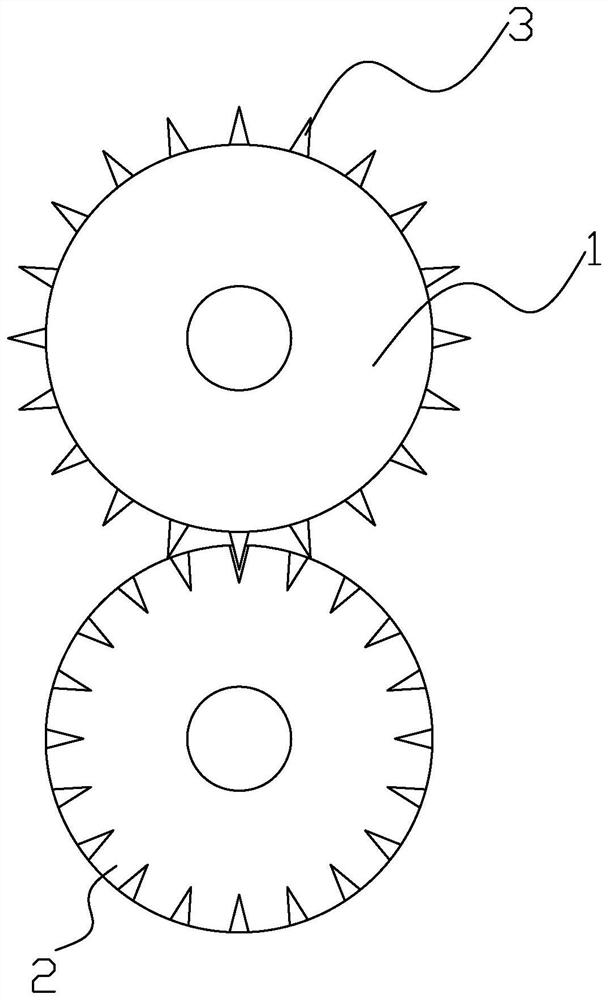

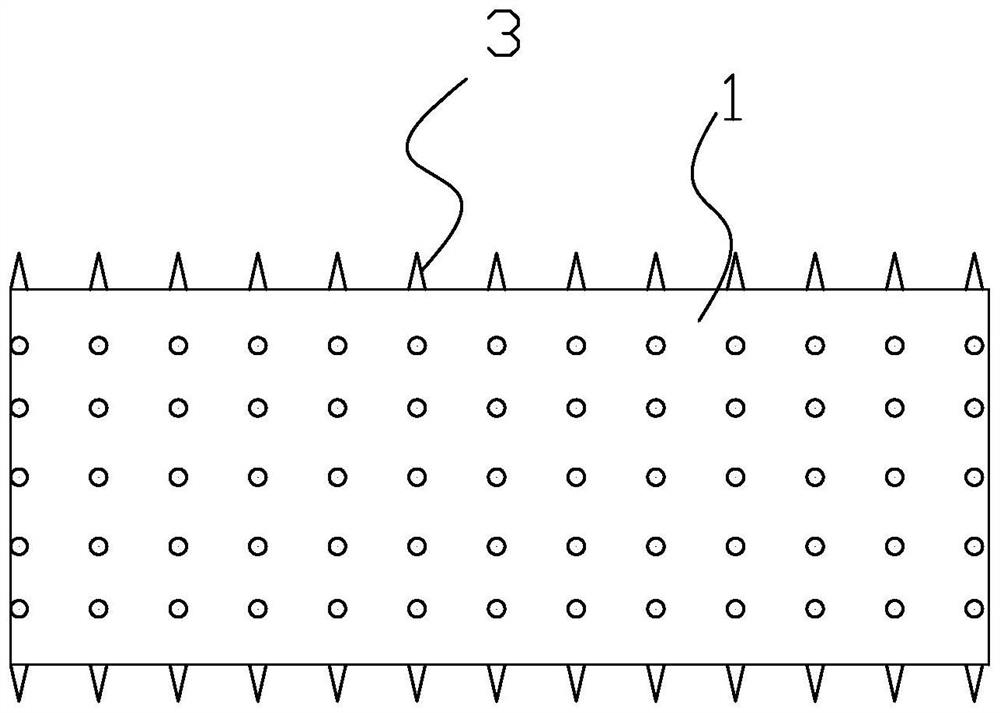

Manufacturing method of steel mesh member used for forming holes of hollow floor slab

InactiveCN104631682AReinforced top surface against construction loadsPlay the role of anti-leakageFloorsCalcium silicateSheet steel

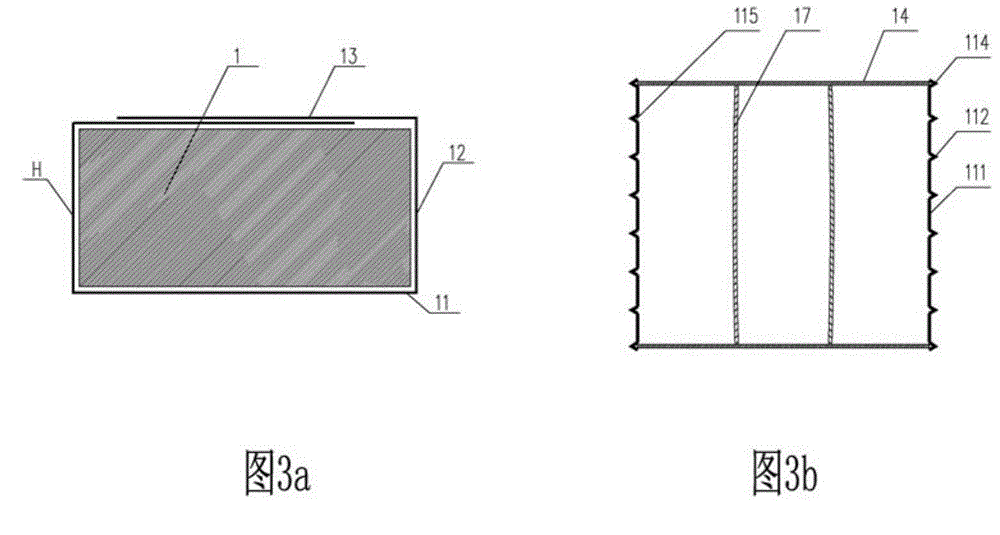

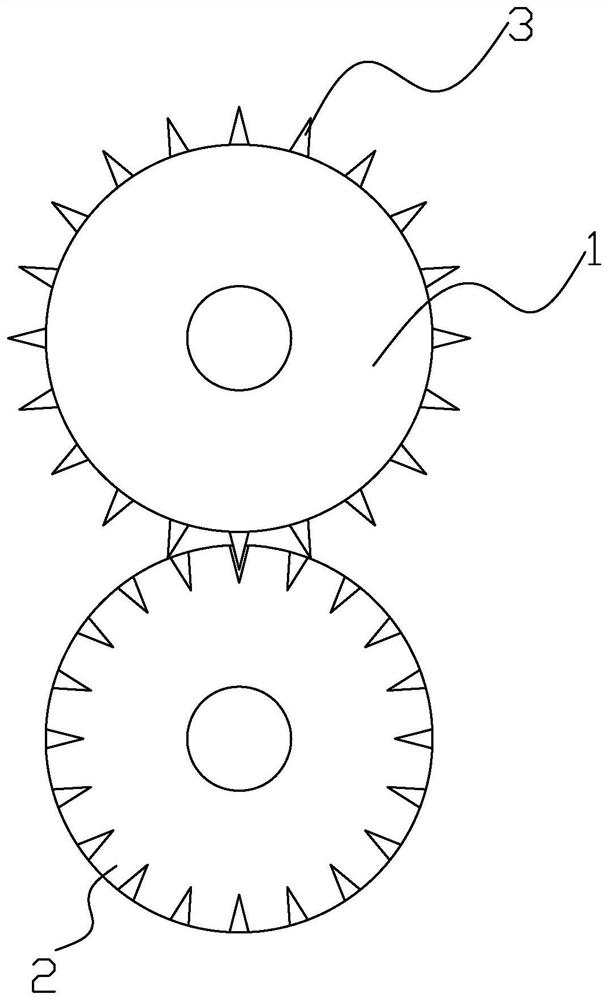

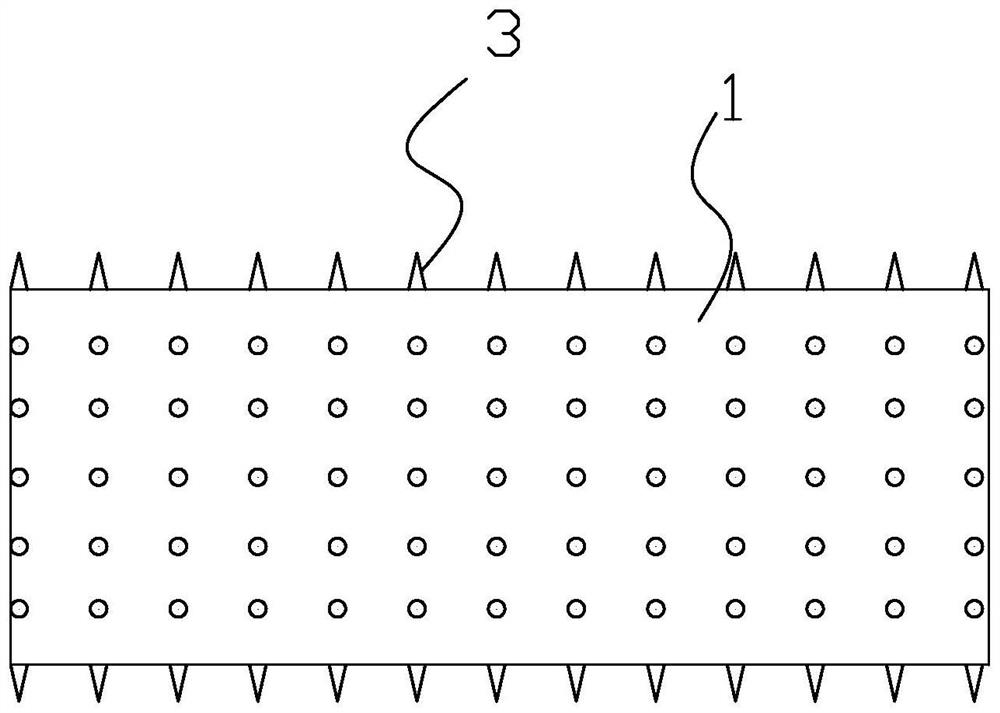

The invention provides a manufacturing method of a steel mesh member used for forming holes of a hollow floor slab. The manufacturing method includes manufacturing a specially made steel mesh with a mesh board, reinforcing ribs, a connecting board and side reinforcing ribs by punching and drawing a thin steel roll, and pressing bent lines on the steel mesh reinforcing ribs in the vertical direction; cutting a thin sheet into a side panel and a support board in required specification; transporting the steel mesh and the thin sheet to a hollow floor slab construction site to be assembled, bending the steel mesh along the bent lines to form a top panel, a bottom panel and tetrahedrons of two side walls of a hexahedron steel mesh member, wherein the thin sheet comprises a calcium silicate board, a plastic board, a composite board, a plasterboard or a corrugated board; the thin sheet constitutes another two side wallboards and a support board between the top panel and the bottom panel of the steel mesh; the thin sheet used for the side wallboards is disposed in side reinforcing rib grooves of two edges of the steel mesh, the length of the support board is larger than or equal to that of the inner clearance of the steel mesh, and the support board directly supports the top side wallboard; the head and tail ends of the steel mesh are overlapped on the top surface of the steel mesh member and welded by electric welding to form the steel mesh member.

Owner:王本淼 +2

Hollow slab floor adopting steel nets and plastic plates for combined hole forming

InactiveCN104652676ARealize multifunctional applicationReinforced top surface against construction loadsFloorsReinforced concreteEngineering

The invention provides a hollow slab floor adopting steel nets and plastic plates for combined hole forming. The hollow slab floor consists of posts, beams, flange plates and cavity components formed by the steel nets and the plastic plates, wherein the beams are reinforced concrete beams or sectional steel concrete combined beam, the flange plates are I-shaped cross section plates or T-shaped cross section plates, the cavity components formed by the steel nets and the plastic plates are formed by the steel nets and the plastic plates through mutual action, the steel nets form tetrahedrons of the top surface plates, the bottom surface plates and the two side walls of the hexahedron cavity components, the head and tail ends of the steel nets are overlapped at any one side of the tetrahedrons, the plastic plates form the other two side wall plates of the steel net cavity components and support plates between the top surface plates and the bottom surface plates of the cavity components, and the plastic plates are arranged in edge reinforcing rib grooves formed in the two edges of the steel nets.

Owner:王本淼 +2

Casing gap blocking device and blocking method

The invention discloses a casing gap blocking device. The casing gap blocking device comprises a pipeline, a reinforcing plate, a backing ring and a casing, wherein the casing is sheathed at the exterior of a pipeline; the backing ring is sheathed at the outer wall of the pipeline; the side surface of the reinforcing plate is fixedly connected with the outer wall of the pipeline; the length direction of the reinforcing plate extends along the axial direction of the pipeline; an epoxy mortar filling layer is filled between the backing ring and the external of the reinforcing plate; both sides of the epoxy mortar filling layer are in sealed connection with the inner wall of the casing and the outer wall of the pipeline; epoxy grout sealing layers are sealed at the two ends of the epoxy mortar filling layer; a leakage-blocking rigid waterproof layer is sealed at the outer side of each epoxy grout sealing layer; the epoxy grout sealing layer and the leakage-blocking rigid waterproof layers are in sealed connection with the outer wall of the pipeline and the inner wall of the casing. The sealing property of the casing gap in the casing gap blocking device is improved. The invention also discloses a casing gap blocking method.

Owner:北京燕化天钲建筑工程有限责任公司

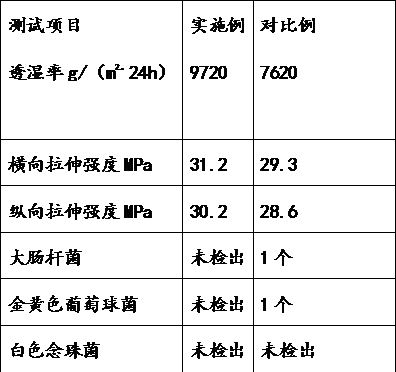

Preparation method of anti-microorganism baby paper diaper

ActiveCN112618169AImprove hydrophilicityNot easy to reverse osmosisAbsorbent padsBaby linensBiotechnologyBiochemical engineering

The invention relates to the field of hygienic products, provides a preparation method of anti-microorganism baby paper diaper, and overcomes defects of a poor anti-microorganism effect and poor air permeability of anti-microorganism baby paper diaper in the prior art. The preparation method comprises the following steps: preparing an anti-microorganism breathable composite layer, preparing an absorber, preparing a liquid-tight bottom layer and compounding the anti-microorganism breathable composite layer, the absorber and the liquid-tight bottom layer into a whole.

Owner:GUANGDONG YINYIN CO LTD

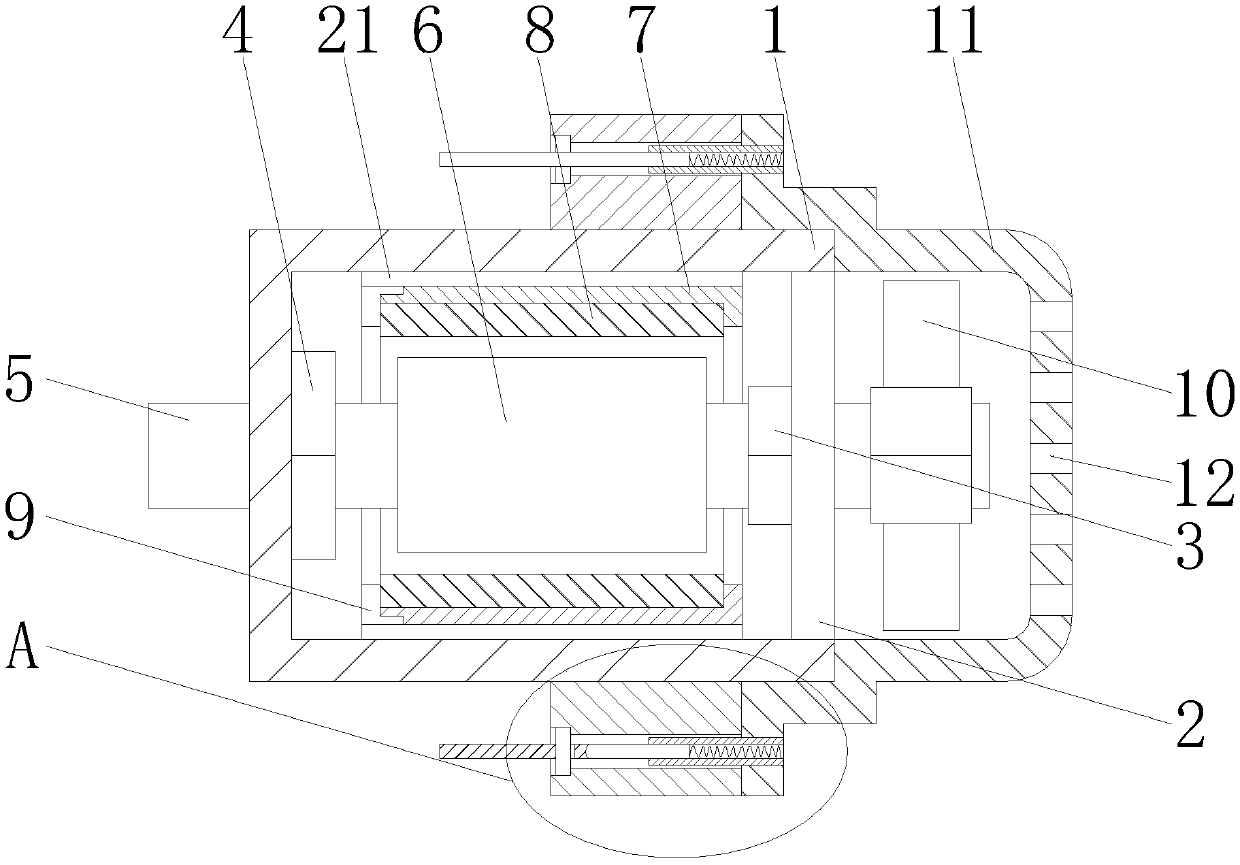

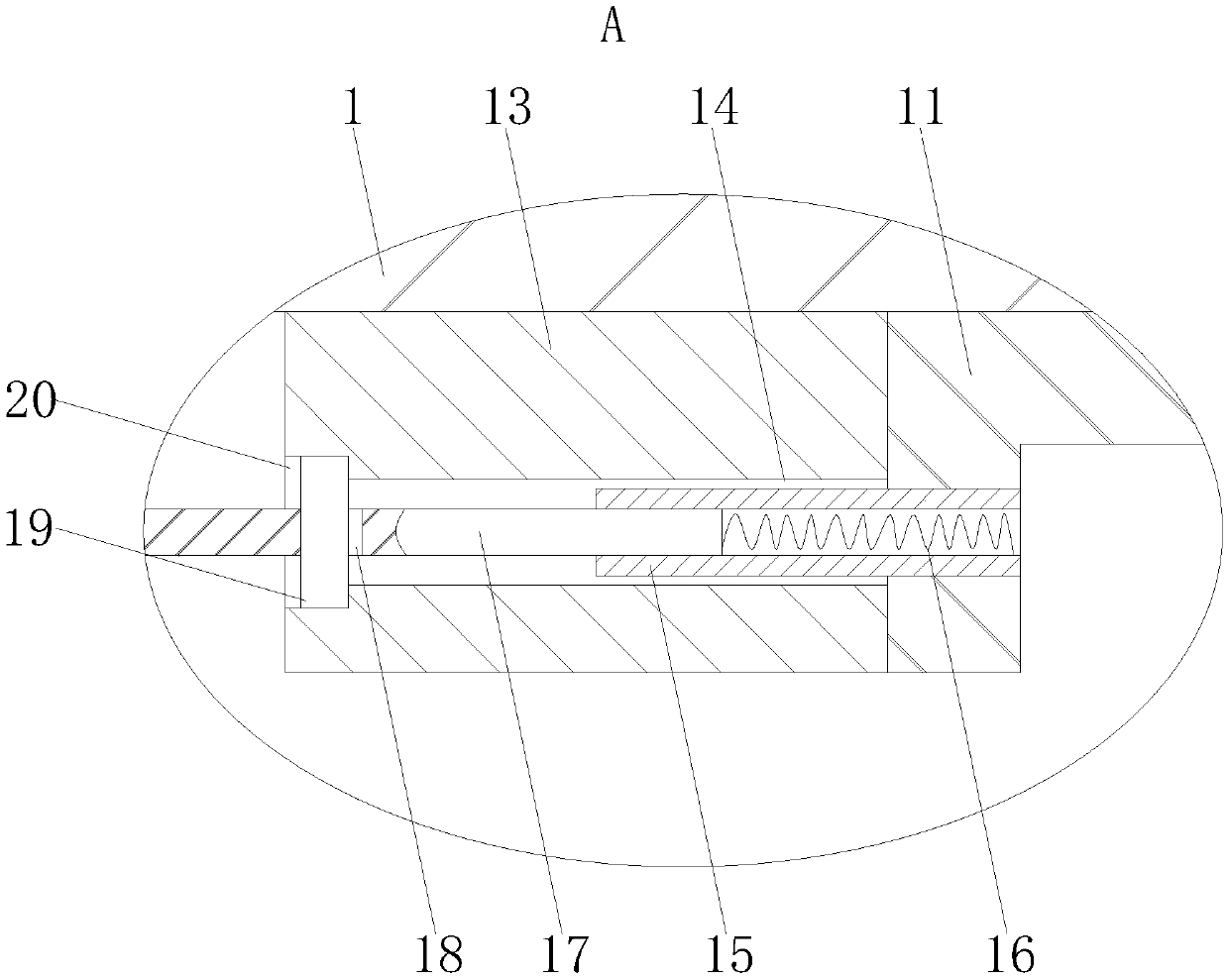

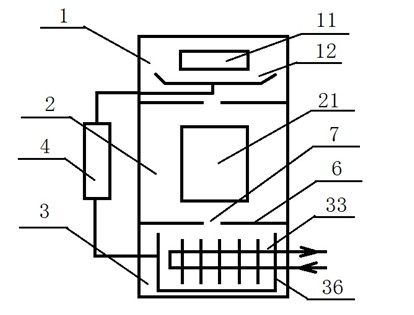

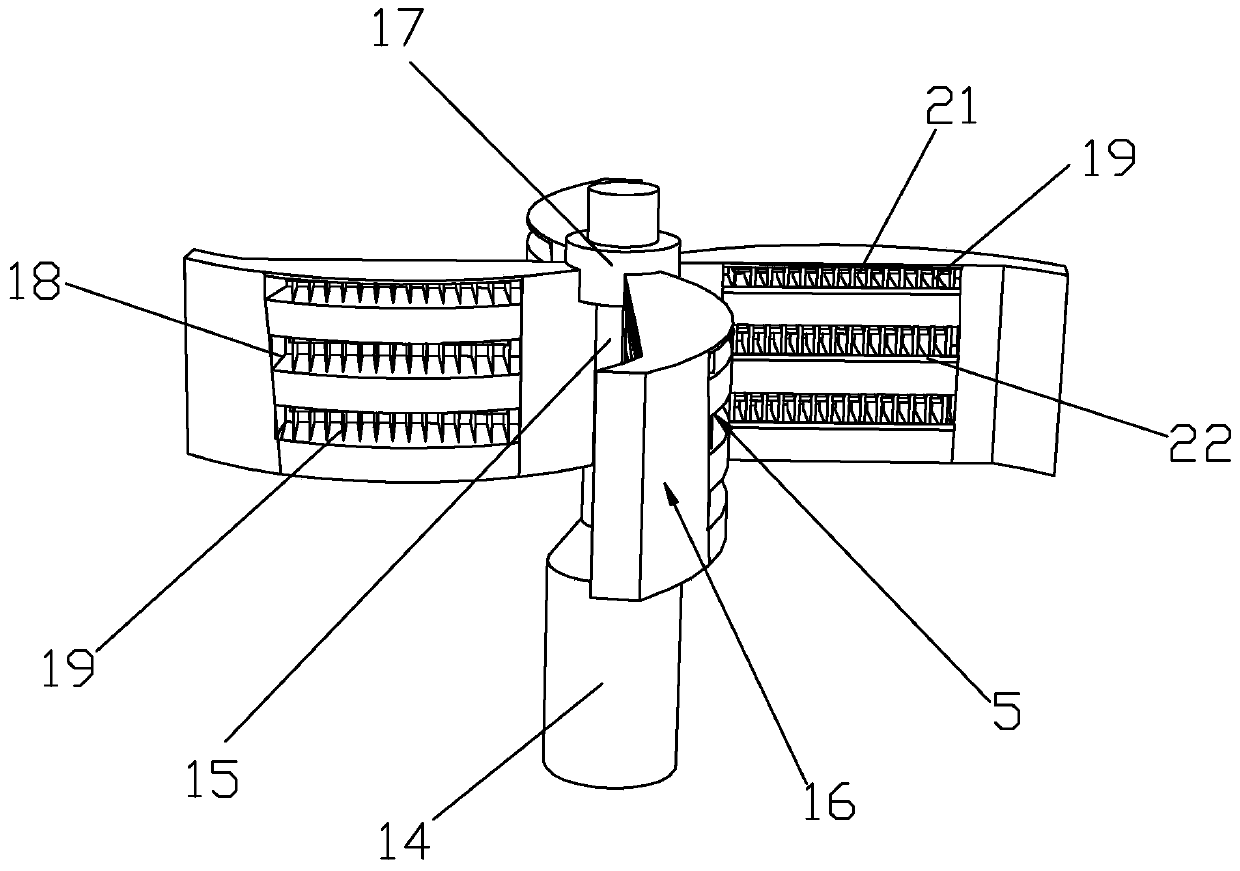

Anti-creeping permanent magnet synchronous motor

ActiveCN109687622AEasy to cleanEasy maintenanceMagnetic circuit stationary partsCooling/ventillation arrangementPermanent magnet synchronous motorUltimate tensile strength

The invention belongs to the technical field of motors, and particularly relates to an anti-creeping permanent magnet synchronous motor. The anti-creeping permanent magnet synchronous motor comprisesa case, a partition plate, heat dissipating holes, a first bearing, a second bearing, a rotating shaft, a rotor, an insulating plastic sleeve, a stator, an insulating plastic mounting ring, a coolingfan, a fan hood, through holes, fixing blocks, circular holes, cylinders, springs, a movable rod, a through groove, limiting strips, strip-shaped grooves and a ceramic sleeve. The anti-creeping permanent magnet synchronous motor is reasonable in structure, through the cooperation effect of the cylinders, the springs, the movable rod, the fixing blocks, the circular holes, the limiting strips and the strip-shaped grooves, the anti-creeping permanent magnet synchronous motor and the case can be mounted, compared with a traditional mounting mode, the anti-creeping permanent magnet synchronous motor is convenient and quick to mount and demount, the labor strength is low, and thus the interior of the fan hood can be cleaned and maintained conveniently; and the insulating plastic sleeve, the ceramic sleeve and the insulating plastic mounting ring are arranged between the stator and the case, direct contact between the stator and the case can be avoided, and the anti-creeping effect is achieved through the insulating effect of the insulating plastic sleeve, the ceramic sleeve and the insulating plastic mounting ring.

Owner:广州仿真机器人有限公司

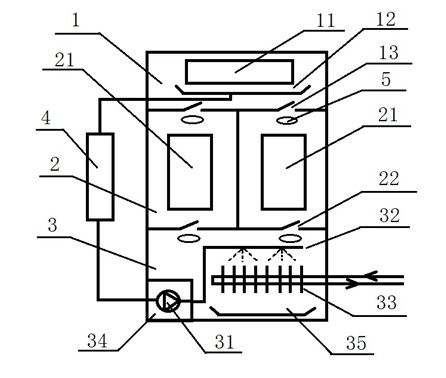

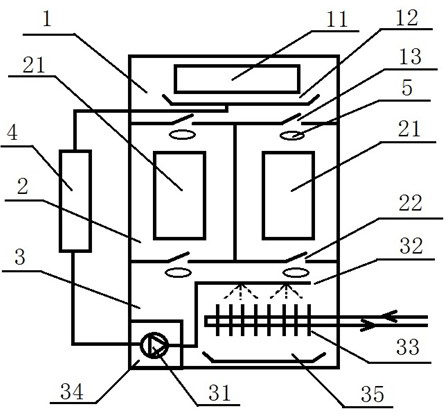

Adsorption type water-cooling machine

InactiveCN101988774ASpeed up the cyclePlay a non-return roleEnergy efficient heating/coolingClimate change adaptationLiquid storage tankEngineering

The invention discloses an adsorption type water-cooling machine, comprising a condensation chamber, an absorption chamber, an evaporation chamber, a liquid storage tank, a booster pump and a spraying tube. Sealing turnover plates are arranged among the chambers, and blowers are arranged below the turnover plates, the booster pump is arranged between the liquid storage tank and the spraying tube and connected with the liquid storage tank and the spraying tube through pipelines, the spraying tube is arranged above an evaporator, the booster pump is arranged in a sealing chamber, and a condenser and the evaporator are shared by a group of absorption beds. The adsorption type water-cooling machine has the advantages of small size, high refrigeration and low manufacture cost.

Owner:苏州新亚科技有限公司

Preparation method of graphite crucible

The invention discloses a preparation method of a graphite crucible. The preparation method comprises the following steps: S1, raw material preparation: raw materials comprise graphite scraps, an Acheson furnace petroleum coke resistance material, an Acheson furnace petroleum coke thermal insulation material and medium-temperature coal pitch; s2, burdening: graphite is crushed and ground into graphite powder, then the graphite powder is mixed with the Acheson furnace petroleum coke resistance material, the Acheson furnace petroleum coke resistance material and the Acheson furnace petroleum coke heat preservation material according to the mass ratio of 3: 2: 5, the mixture is ground into mixed powder, the mixed powder is mixed with medium-temperature coal pitch, the mass percent of the mixed powder in the mixing process is 65%-85%, and the medium-temperature coal pitch is obtained; the mass percent of the medium-temperature coal pitch is 15%-35%; s3, mixing and kneading; s4, profiling is conducted; s5, roasting; and S6, processing. A hot-pressing cold-out one-time forming method is adopted, the obtained product is excellent in performance and shows good thermal shock resistance, ablation performance, leakage-proof performance and mechanical strength, and the preparation process has the advantages in the aspects of saving energy, protecting the environment, shortening the period and improving the aging efficiency.

Owner:吉林科工碳业有限公司

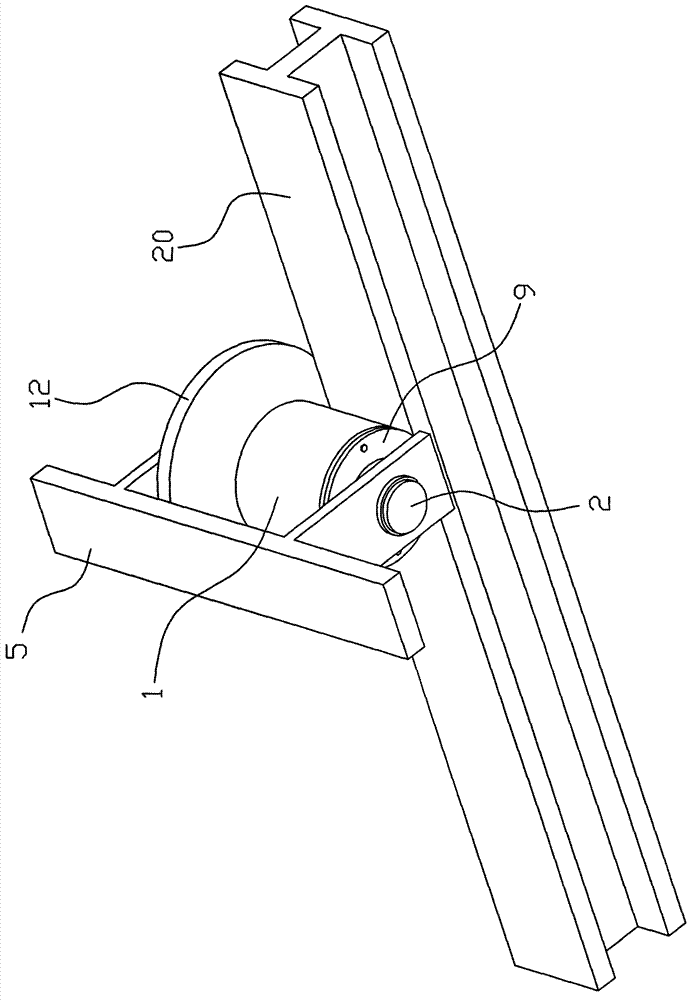

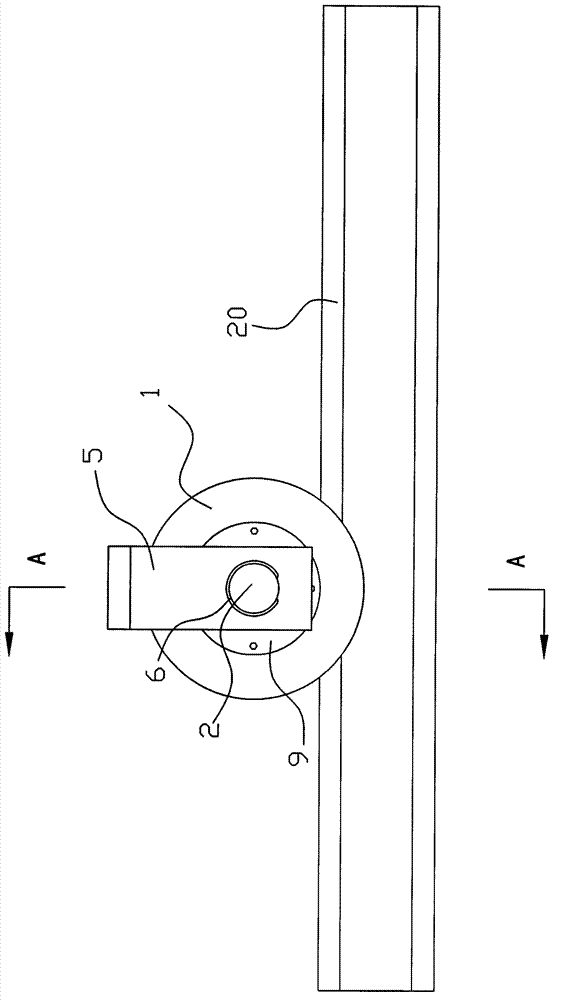

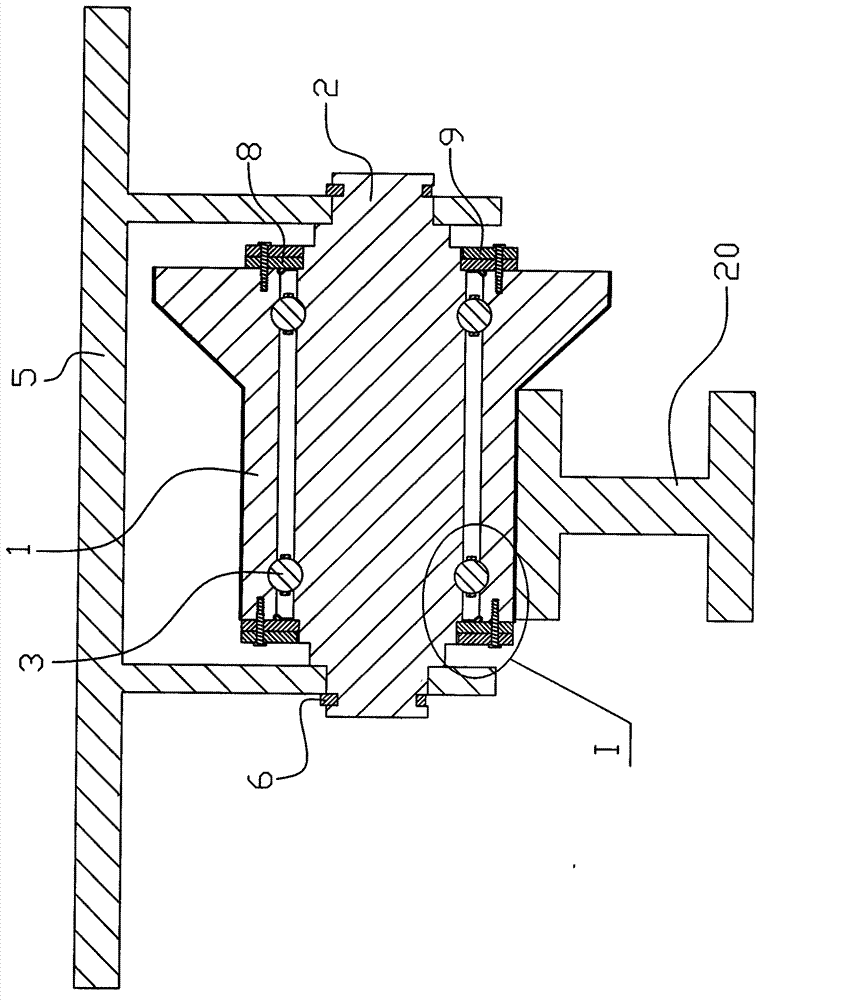

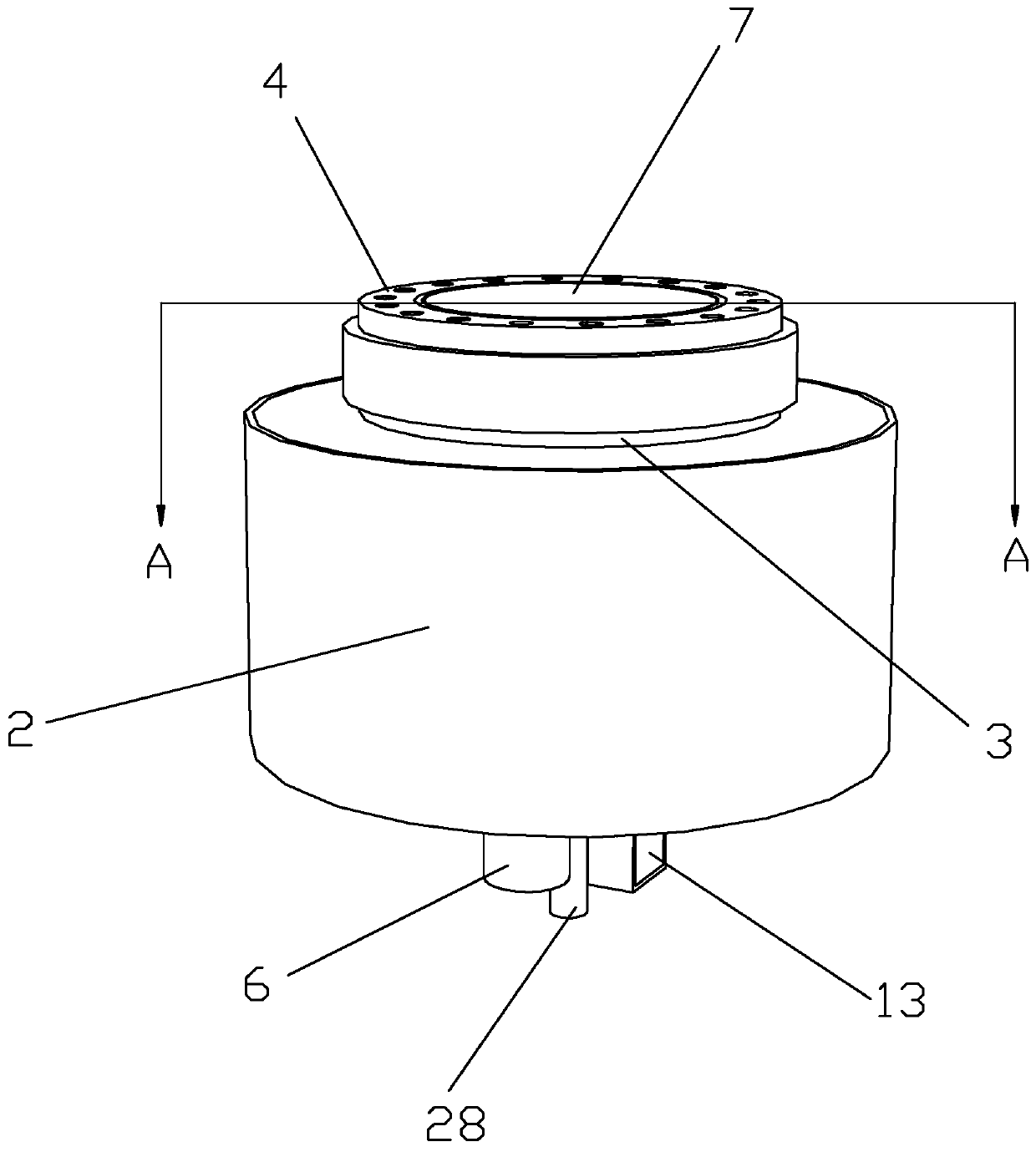

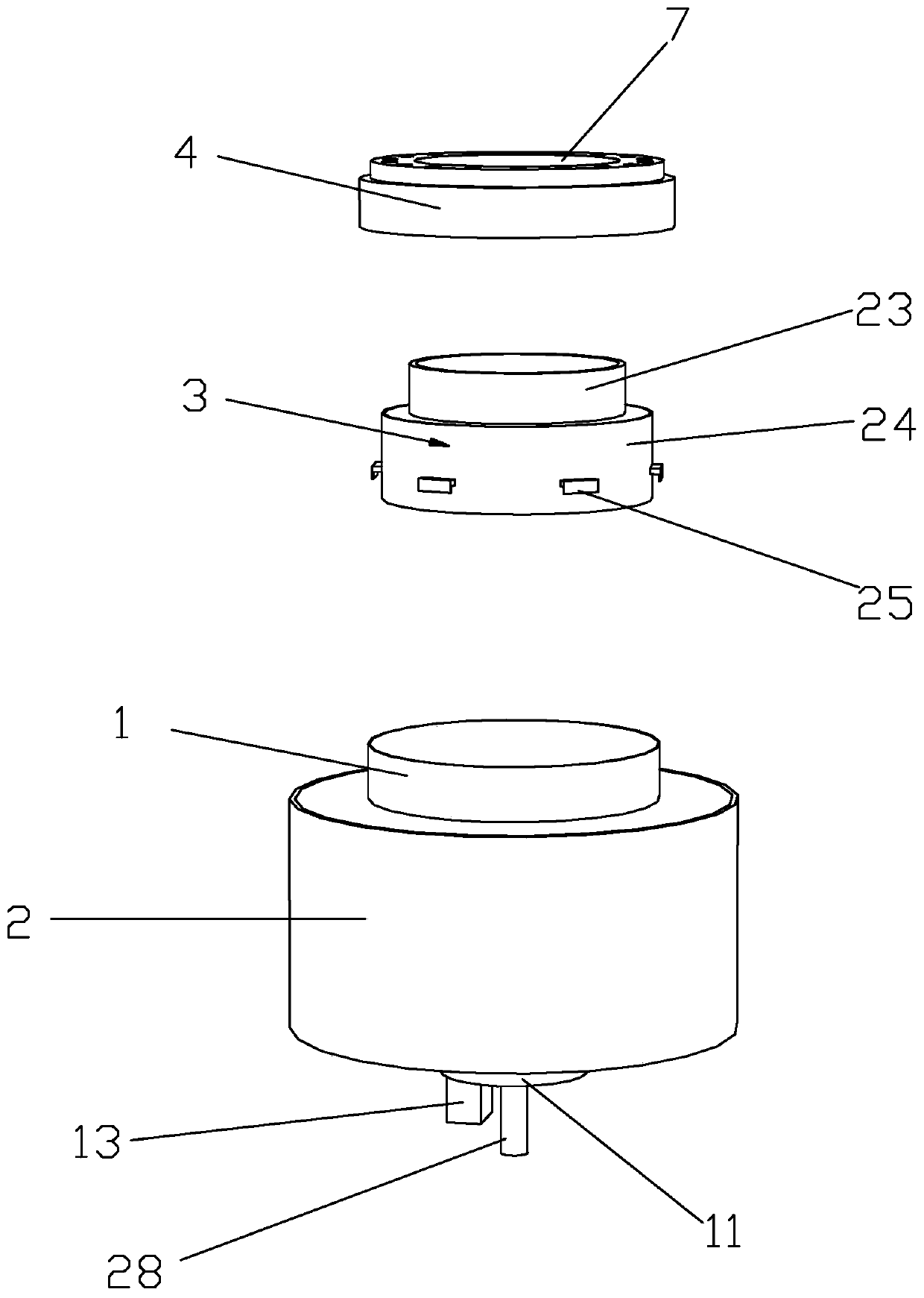

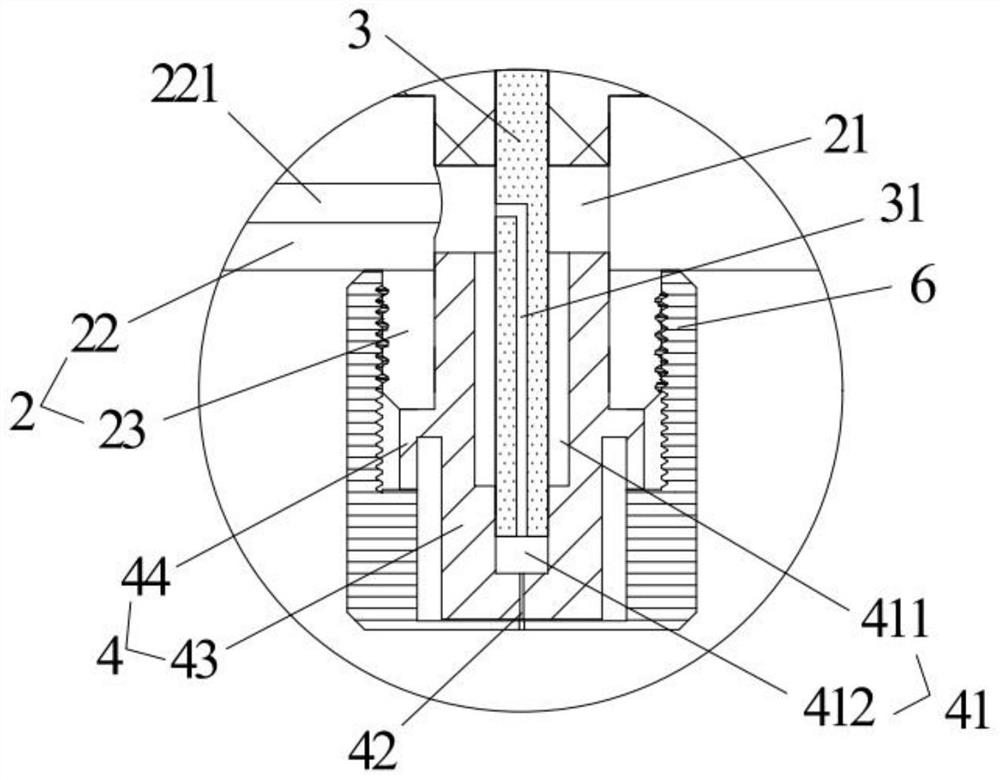

Bearing device for track wheel

ActiveCN102922948ACompact structureGuaranteed uptimeBall bearingsBearing componentsEngineeringMechanical engineering

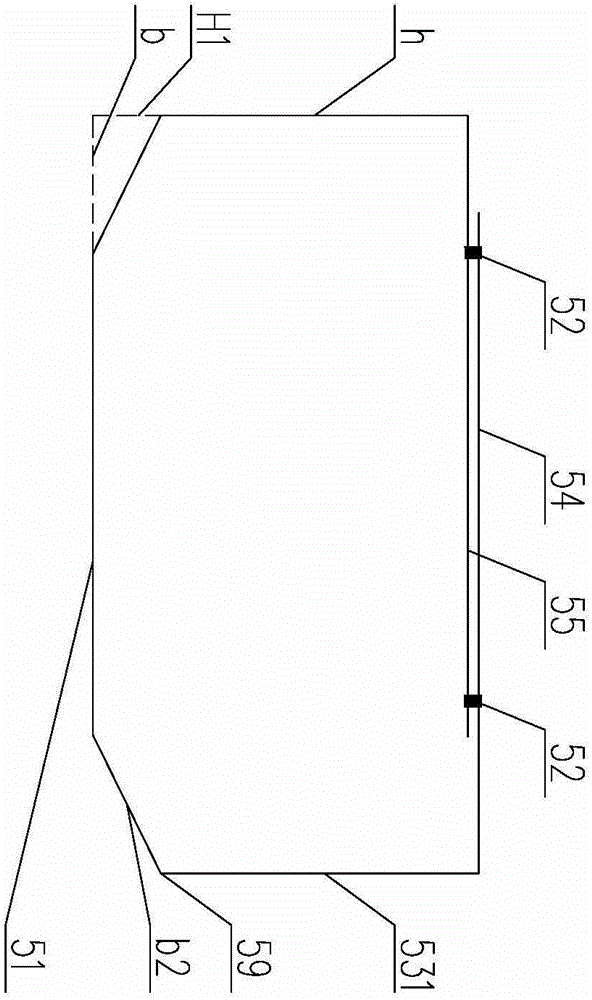

A bearing device for a track wheel comprises a wheel body (1) and a rotary shaft (2) and is characterized in that balls (3) are arranged between the wheel body (1) and the rotary shaft (2), an inner wall of the wheel body (1) is provided with an inner annular groove (11), an outer annular groove (21) is arranged at the corresponding position of the rotary shaft (2), the balls (3) can arranged on a retainer (4) in a rolling mode and can be movably arranged between the wheel body (1) and the rotary shaft (2) together with the retainer (4), the outer surfaces of the balls (3) are contacted with the surfaces of the inner annular groove (11) and the outer annular groove (21), and two ends of the rotary shaft (2) are arranged on a support (5) at the bottom of a vehicle body. The bearing device for the track wheel has the advantages that the bearing device is compact in structure, double rows of balls are arranged between the wheel body and the rotary shaft and can enable wheel to be stable in running, a dust-proof cover and a rubber sealing ring can have double sealing effects, and accordingly the service life of the wheel is prolonged.

Owner:徐州宇之阳市场营销策划有限公司

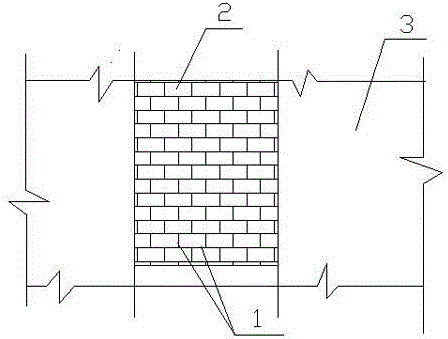

Anti-seeping treatment method of wall between windows of high-rise building external wall

InactiveCN105971132ASeamlessNo crackBuilding material handlingBuilding insulationsNinetieth percentileHigh rise

The invention discloses an anti-seeping treatment method of a wall between windows of a high-rise building external wall. Mortar joints, the wall between windows and a concrete shear wall are adopted in the method. The method comprises the following steps of 1, material selection: selecting cement bricks or fly ash concrete aerated blocks, and insisting a strict sampling inspection test system on the cement bricks or fly ash concrete aerated blocks conveyed into the field; 2, building: strictly preparing masonry mortar according to the mixture ratio; during the building, performing building by using a full mortar spreading and mortar extruding process; strictly controlling the mortar joint thickness to be 10 to 12mm; enabling the mortar full degree to reach 90 percent or above; certainly enabling a vertical joint in positions of the cement bricks or fly ash concrete aerated blocks and the concrete shear wall to be 15 to 20mm; immediately performing cleaning, joint pressing and joint pointing after the building completion; and remaining concave joints being about 4 to 6mm; and 3, painting: executing the painting procedure strictly according to the process operation regulations so as to achieve the effects that the inside and outside are compact, smooth and flat, no seam, no crack and no pore exist, and the like. During the rainstorm invasion, the anti-seepage effect is achieved.

Owner:CHINA MCC17 GRP

Combined frame of steel meshed body and organic object for pore forming of cast-in-place hollow floor

The invention provides a combined frame of a steel meshed body and an organic object for the pore forming of a cast-in-place hollow floor. According to the combined frame, the steel meshed body comprises a meshed plate, reinforcing ribs, a connecting plate and edge reinforcements, wherein the meshed plate, the reinforcing ribs, the connecting plate and the edge reinforcements which interact with each other form an integral structure; a row of bending lines are pressed in the vertical direction of the reinforcing ribs of the steel meshed body; when the steel meshed body is in lap joint end to end on the surface of the top of the frame, the lap joint amount is less than or equal to the surface area of the surface of the frame top, and a surface reinforced layer is formed directly; the organic object comprises air bags or polyphenyl blocks; the organic object forms the other two side walls on the side of the combined frame and is supported in inner space between the surface of the frame top and the surface of the bottom of the frame to control the height of the combined frame of the steel meshed body. According to the combined frame, the non-sealed combined frame of the steel meshed body and the organic object replaces the conventional full-sealing hollow filling body and solid filling body as the pore-forming technology of the cast-in-place hollow floor to solve the problems of difficulties in the blocking and supporting of the other two side walls on the side of the steel meshed body frame and facilitate the implementation of the cast-in-place hollow floor.

Owner:王本淼 +1

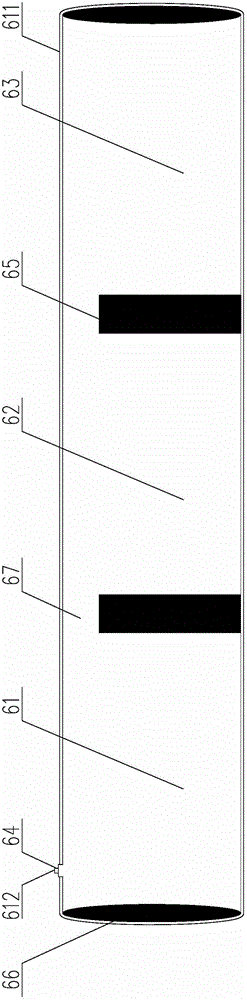

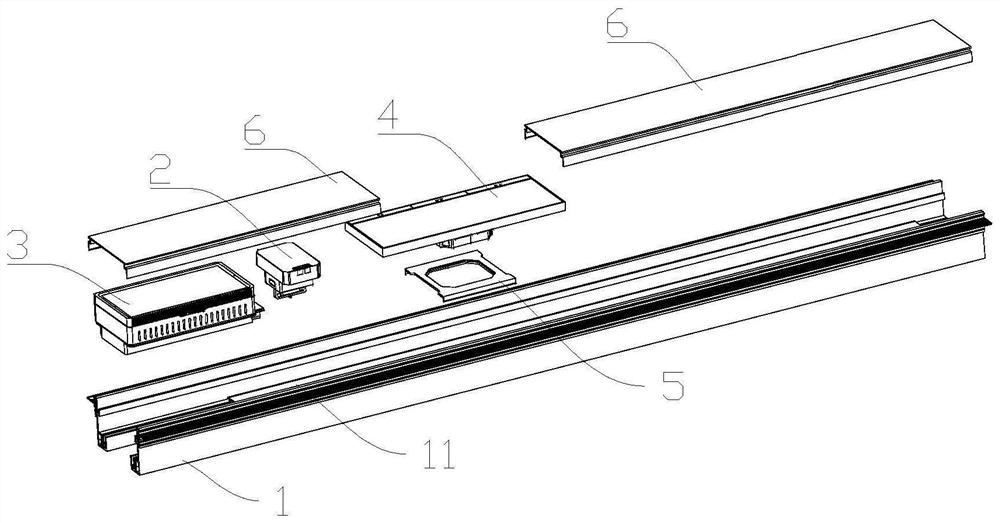

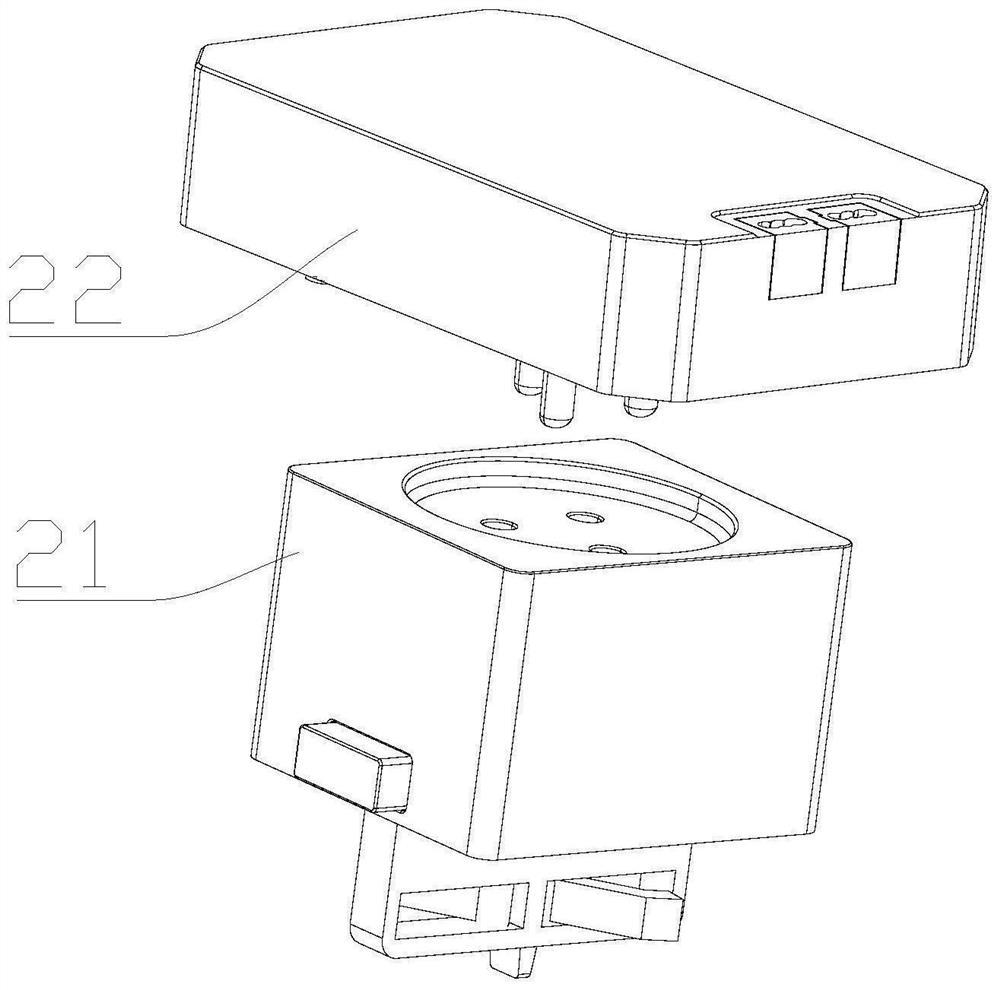

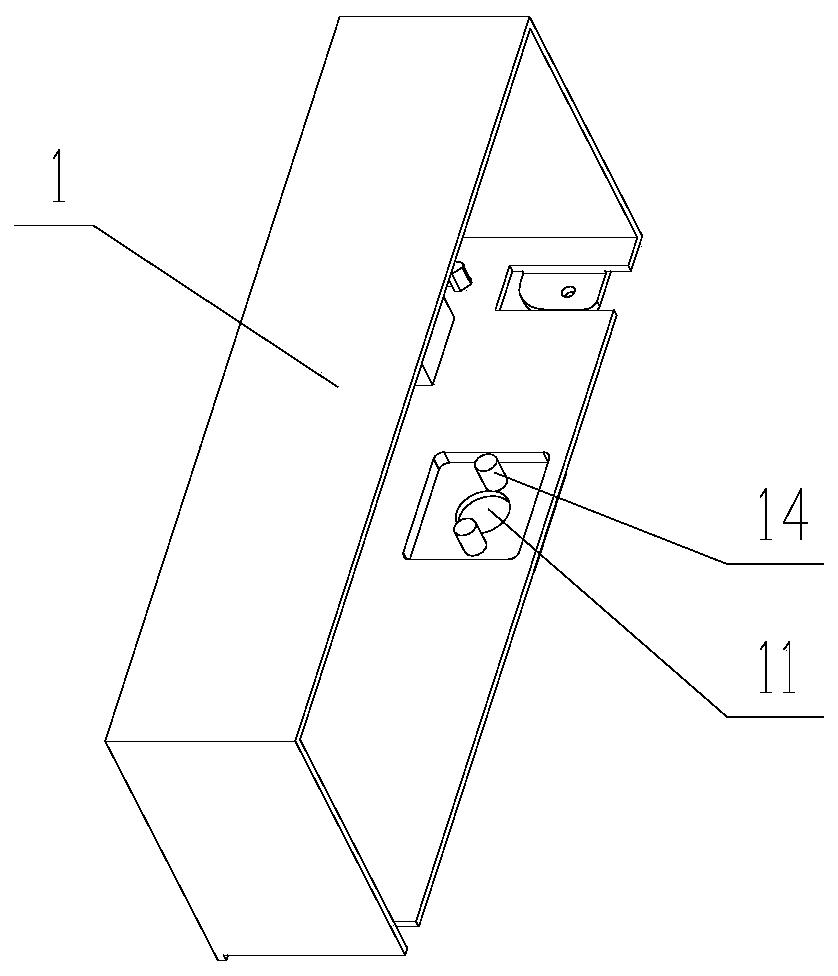

Track socket convenient to install

The invention provides a track socket convenient to install. The track socket comprises a power track, an adapter, a power management module and a fixing support used for installing a terminal. A channel is formed in the power track in the length direction; the adapter comprises an electricity-taking connector and a converter connected with the electricity-taking connector; the electricity-taking connector is matched with the electric power track; one end, far away from the electricity-taking connector, of the converter extends out of the channel and then is connected with the terminal through a wire; and the power management module is also arranged in the channel. Through the arrangement of a button and an elastic sheet structure on the power taking connector, the adapter can be flexibly and conveniently installed and stably fixed on the power track, and the problem caused by poor contact between the adapter and the power track is eliminated. The positions of baffles are adjusted through the adjusting tooth grooves formed in a first support and a second support of the power track, so that the track socket can be suitable for various installation environments, and the practicability is high.

Owner:深圳市云图数字科技有限公司

Novel fireproof cable

The invention provides a novel fireproof cable. An insulation cover is wrapped outside a conductor, a water blocking yarn is arranged outside the insulation layer, and a sheath layer is wrapped outside the water blocking yarn. The novel fireproof cable has the advantages that the insulation layer is wrapped outside the cable conductor, an electricity leakage prevention effect is achieved on the cable conductor, the cable can be protected through the water blocking yarn, the influence on the use of the cable caused when the cable is affected with damp is prevented, the service life of the cable is prolonged, asbestos is added into the insulation layer, and the cable combustion can be better prevented, so the cable cannot easily facture through folding, and the toughness of the cable is improved.

Owner:YANGZHOU DEBAO CABLE

Solid floor with anti-corrosion and anti-seepage functions

The invention discloses a solid floor with anti-corrosion and anti-seepage functions. The solid floor includes a floor main body, the floor main body is composed of a solid wood middle plate, a son auxiliary strip fixedly connected to the left side of the solid wood middle plate, and a mother auxiliary strip fixedly connected to the right side of the solid wood middle plate; the upper position ofthe side surface of the son auxiliary strip is provided with a first protrusion extending in the side direction, and the first protrusion is further provided with a second protrusion facing downwards;the lower position of the side surface of the mother auxiliary strip is provided with a third protrusion extending in the side direction, the third protrusion is further provided with a groove with anotch facing upwards, and the groove is matched with the second protrusion; the upper surface of the son auxiliary strip is provided with a first quarter circle protruding block, and the first quarter circle protruding block is located at the back side of the second protrusion; and the upper surface of the mother auxiliary strip is provided with a second quarter circle protruding block, and the second quarter circle protruding block is located above the groove. The solid floor with the anti-corrosion and anti-seepage functions has the characteristics of anti-leakage and anti-corrosion at thesplicing place and long service life, the overall function is perfect, and the practicality is strong.

Owner:ZHEJIANG CHENGCHENG NEW MATERIAL TECH CO LTD

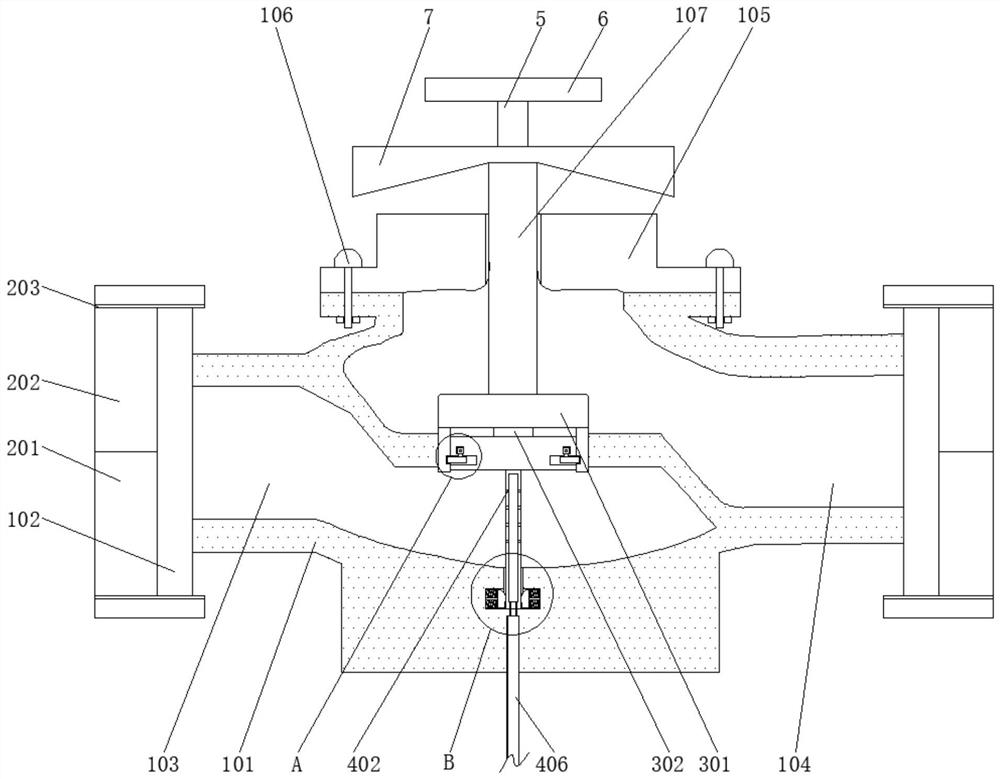

Anti-leakage low-temperature valve

PendingCN113864460AImprove pressure relief efficiencyImprove stabilityFlanged jointsEqualizing valvesPhysicsElectric machinery

The invention discloses an anti-leakage low-temperature valve, comprising a main body mechanism and an anti-bursting mechanism. The main body mechanism comprises a valve body, a flange, a feeding channel, a discharging channel, a valve cover, a first connecting piece, a valve rod and a clamping ring; the feeding channel and the discharging channel are formed in the valve body; the anti-bursting mechanism is connected with the bottom of a valve plate assembly; and the anti-bursting mechanism comprises a pressure relief rod, an air inlet hole, a cavity, an exhaust hole, an exhaust channel, a pressure relief pipeline, a rubber block, a spring and a pressure relief valve. The anti-leakage low-temperature valve is provided with an anti-leakage plate, the anti-leakage plate can block a circulating medium leaked from a gap between the valve plate and the clamping ring when the valve plate shrinks and deforms when encountering cold, namely when the outer wall of the valve plate cannot make contact with the clamping ring, so that the anti-leakage effect can be achieved to a certain extent; meanwhile, a motor and a cam are arranged, the motor can drive the cam to rotate to be clamped with the clamping ring, so that the stability of the valve plate is improved conveniently, and the phenomenon that the valve plate vibrates due to too large pressure during use is prevented conveniently.

Owner:YANCHENG FANGDING LOW TEMPERATURE VALVE CO LTD

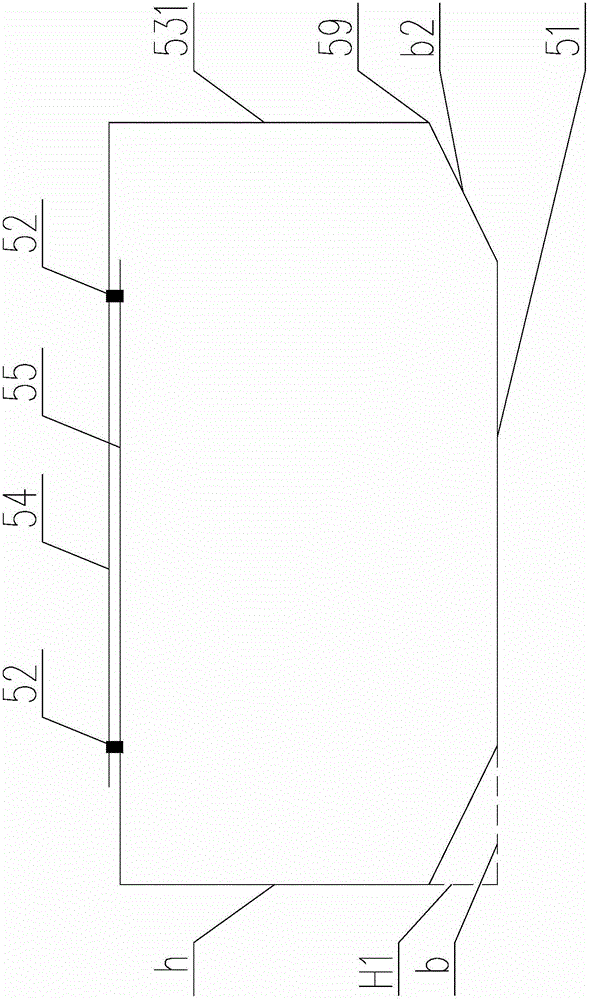

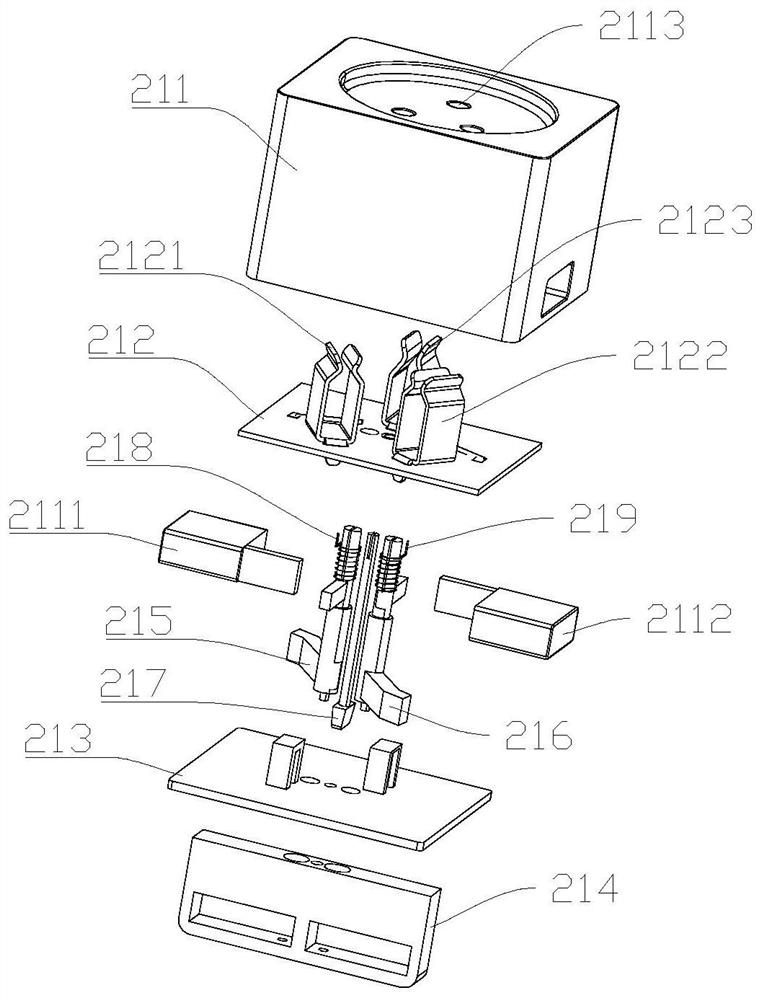

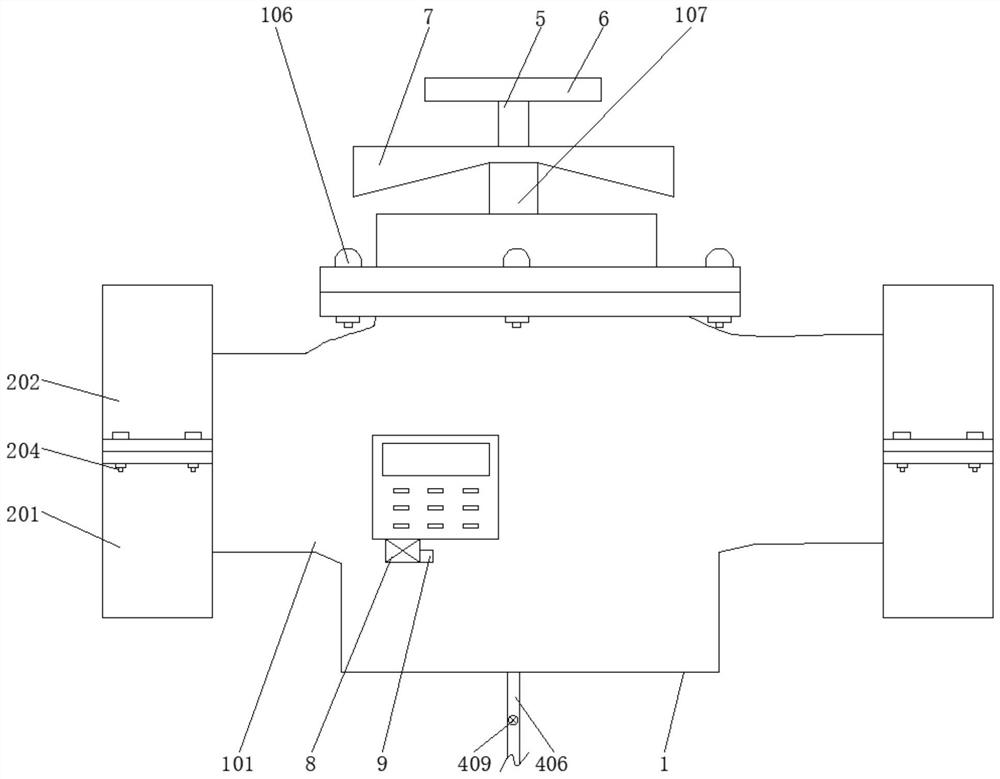

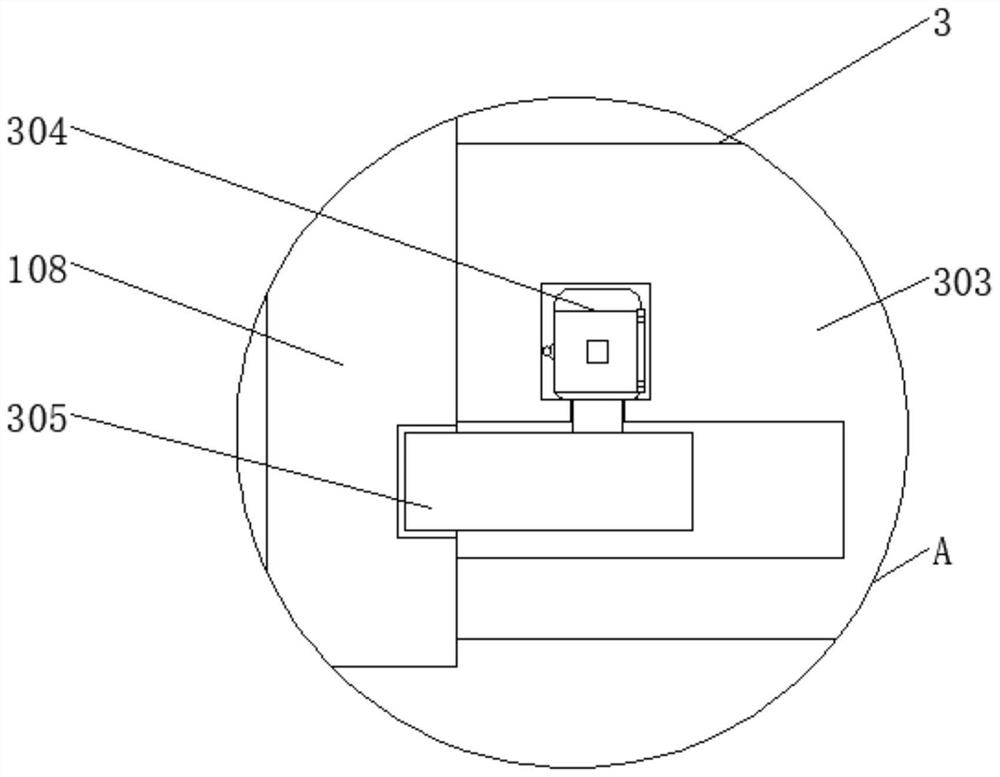

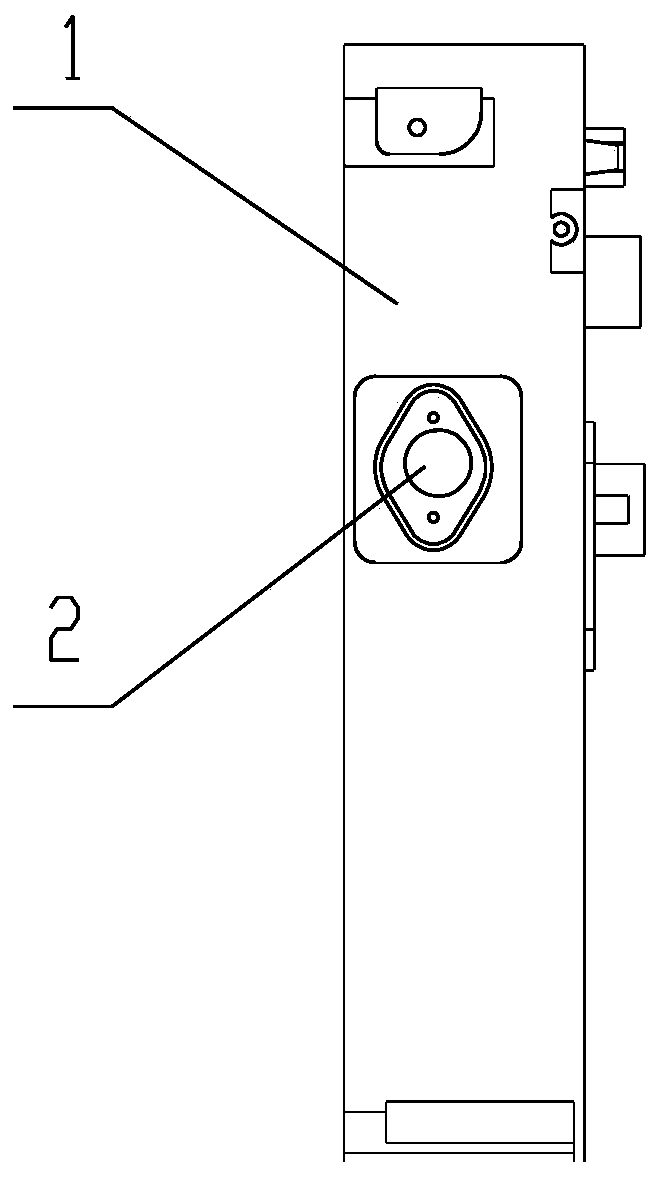

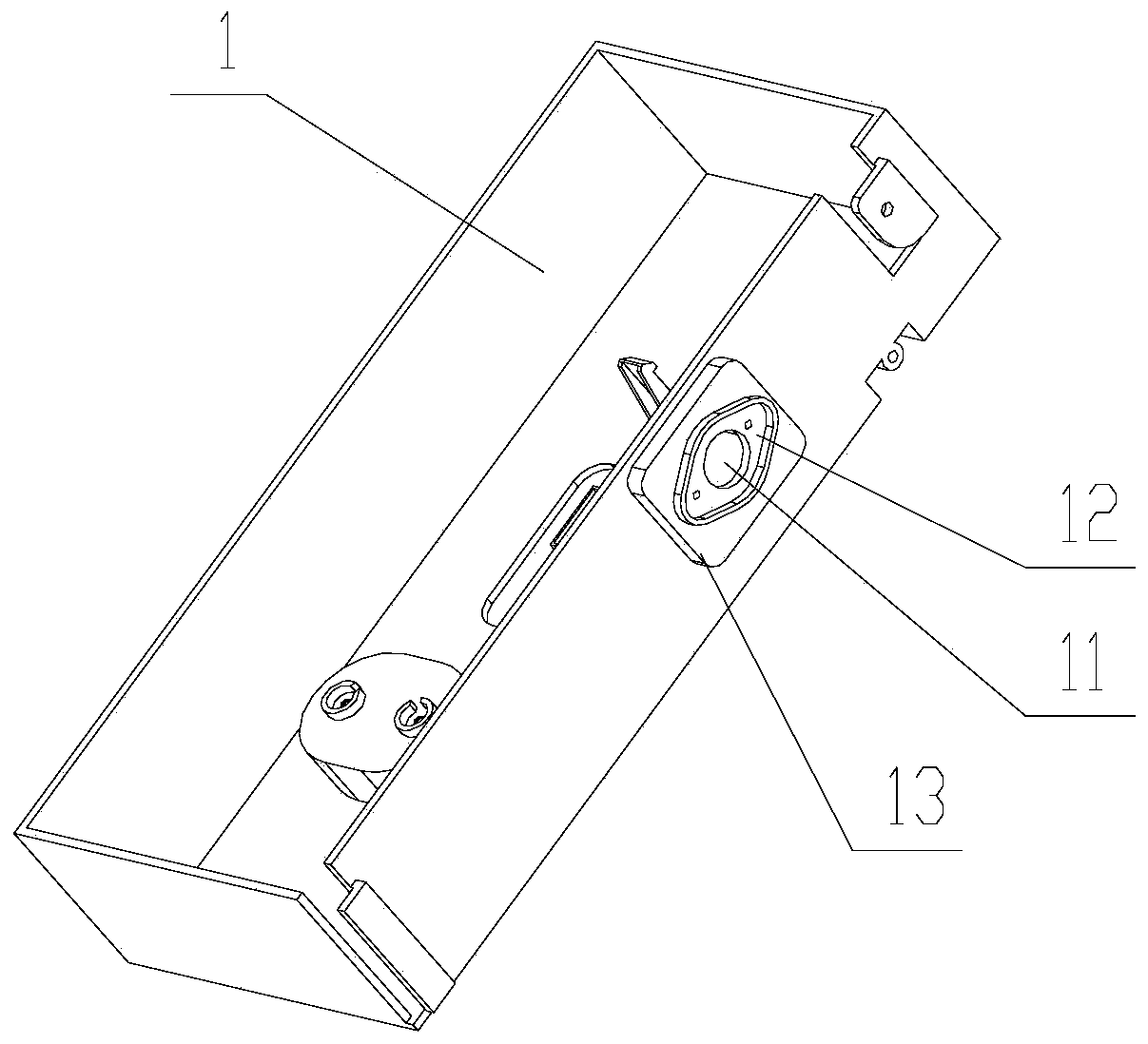

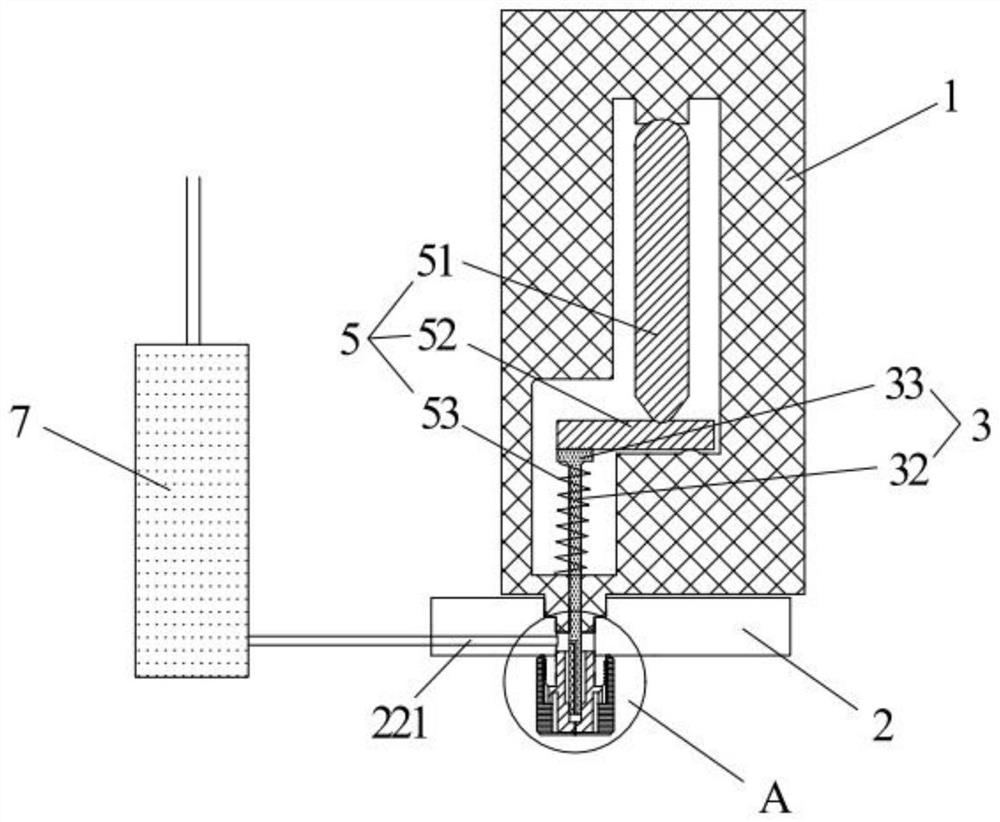

Safety protection device and electric heater

PendingCN109737496AEasy to assemblePlay the role of anti-leakageLighting and heating apparatusElectric heating systemLimiter

The invention provides a safety protection device and an electric heater. The safety protection device comprises a fixing plate and a temperature limiter (2), wherein a through hole is formed in the fixing plate, at least part of the temperature limiter (2) penetrates through the through hole (11), and the temperature limiter is in seal connection with the through hole (11). The safety protectiondevice comprises the fixing plate and the temperature limiter, the through hole is formed in the fixing plate, and the temperature limiter is fixed into the through hole in a sealing mode. The temperature limiter is fixed onto the fixing plate in the sealing mode, the fixing plate can isolate the electric leakage part of the temperature limiter to play a role of preventing electric leakage. Meanwhile, by the arrangement of the through hole, the temperature limiter is conveniently assembled. The operation is convenient, and mounting is firm.

Owner:GREE ELECTRIC APPLIANCES INC

Residue separating device for dish washing machine and mounting method of residue separating device

PendingCN110353604AEasy to installThe connection structure is stableTableware washing/rinsing machine detailsWater pipeEngineering

The invention discloses a residue separating device for a dish washing machine and a mounting method of the residue separating device. The residue separating device for the dish washing machine comprises a separating pipe, a water passing pipe, a connecting pipe and a top cover, wherein the connecting pipe is mounted in the separating pipe; the separating pipe is connected with the water passing pipe; the separating pipe is mounted in the water passing pipe; the connecting pipe is connected with a top cover; a separating mechanism is mounted inside the connecting pipe; the separating mechanismrotates in the separating pipe; a drain pipe is arranged at the bottom of the water passing pipe; a residue inlet is formed in the top cover; a connecting rod is arranged below the separating mechanism; and the connecting rod is connected with the bottom of the water passing pipe. The mounting method comprises the following steps: 1) mounting the separating mechanism; 2) mounting the connecting pipe and the separating pipe; 3) mounting the connecting pipe and the top cover; and 4) mounting the water passing pipe and the separating pipe. According to the residue separating device, the problemthat a pipeline is blocked due to the fact that food residues are easily carried in the process of discharging sewage by an existing dish washing machine is solved.

Owner:浙江蓝炬星电器有限公司

Mask manufacturing process and mask

PendingCN113040442AAvoid failurePlay the role of anti-leakageProtective garmentSpecial outerwear garmentsEngineeringCotton cloth

The invention provides a mask manufacturing process and a mask, and the mask is characterized in that the mask comprises a mask body, an outer cotton cloth bearing layer, an outer moisture absorption plate and a water accumulation box; the inner side surface of the mask body is connected with an inner cotton cloth bearing layer through hook-and-loop fasteners, and the two sides of the mask body are fixedly connected with mask fixing ropes; the bottom of the outer cotton cloth bearing layer is fixedly connected with the bottom of the inner cotton cloth bearing layer, and the outer cotton cloth bearing layer is located on the outer side of the inner cotton cloth bearing layer. The two sides of the outer moisture absorption plate are connected with the inner moisture absorption plate through buckles, and the outer moisture absorption plate and the inner moisture absorption plate are located between the outer cotton cloth bearing layer and the inner cotton cloth bearing layer. The outer side of the upper end of the water accumulation box is fixedly connected to the bottom of the outer moisture absorption plate, and it can be seen that a built-in structure with the drying function is additionally arranged on an existing medical mask, and the problems that during expiration in winter, water is liquefied, a mask filtering layer is soaked, the function of adsorbing viruses through static electricity is lost, and the medical mask loses efficacy are solved.

Owner:宜春市绘梦技术服务有限公司

Construction method of basement roof

The invention relates to the technical field of basement roof construction, and provides a construction method of a basement roof. The basement roof comprises hole edge beams and brackets, the brackets are connected to the vertical faces of the hole edge beams and extend in the direction away from the hole edge beams, the brackets define holes of hoisting holes, the holes are covered with cover plates, and the cover plates are placed on the brackets. According to the construction method of the basement roof, the hoisting holes are formed through the brackets, on one hand, hoisting is convenient, on the other hand, the brackets can stably support the cover plates, and the structure is more stable; and a waterproof structure is adopted, and the anti-seepage effect can be achieved.

Owner:中冶南方武汉建筑设计有限公司

Drainage structure and construction method of a wooden arch ancient corridor bridge

The invention discloses a drainage structure and a construction method of a wooden arch ancient gallery bridge, comprising a support plate, a water guide block and a waterproof plate are arranged on the support plate, the water guide block is installed on the waterproof plate, the water guide block is installed obliquely, and the water guide block is installed on the water guide plate. The water block is provided with a water guide groove, the inside of the water guide block is provided with a water collection pipe, the water collection pipe is provided with a water inlet, the waterproof board is provided with a first structural plate, the supporting plate is provided with a support frame, and the support frame is provided with a second structural plate , the support plate is provided with a sliding mechanism, the bottom of the support plate is provided with a connecting mechanism and a first drain pipe, the first drain pipe is provided with a connection box, and the connection mechanism is connected with the connection box. The construction method includes: 1) the basic structure of the wooden arch ancient corridor bridge; 2) the installation of the sliding mechanism; 3) the installation of the first construction plate and the second construction plate; 4) the installation of the waterproof structure; 5) the installation of the eaves. The invention solves the problem that the drainage efficiency of the existing wooden arch ancient corridor bridge is not high, and the rainwater is easily blown to the inside of the corridor bridge by strong wind, thus affecting the use.

Owner:金华市广和古建筑技术研发有限公司

Casing gap sealing device and sealing method

The invention discloses a casing gap blocking device. The casing gap blocking device comprises a pipeline, a reinforcing plate, a backing ring and a casing, wherein the casing is sheathed at the exterior of a pipeline; the backing ring is sheathed at the outer wall of the pipeline; the side surface of the reinforcing plate is fixedly connected with the outer wall of the pipeline; the length direction of the reinforcing plate extends along the axial direction of the pipeline; an epoxy mortar filling layer is filled between the backing ring and the external of the reinforcing plate; both sides of the epoxy mortar filling layer are in sealed connection with the inner wall of the casing and the outer wall of the pipeline; epoxy grout sealing layers are sealed at the two ends of the epoxy mortar filling layer; a leakage-blocking rigid waterproof layer is sealed at the outer side of each epoxy grout sealing layer; the epoxy grout sealing layer and the leakage-blocking rigid waterproof layers are in sealed connection with the outer wall of the pipeline and the inner wall of the casing. The sealing property of the casing gap in the casing gap blocking device is improved. The invention also discloses a casing gap blocking method.

Owner:北京燕化天钲建筑工程有限责任公司

Instant heating type heater subassembly

The invention discloses an instant heating type heater subassembly which comprises an instant heating type heater and a water outlet end base of the instant heating type heater, wherein the instant heating type heater subassembly is characterized by also comprising a section shell; the instant heating type heater is arranged at the inner side of the section shell; the wall surface of the section shell is stretched to form a rib with a hole; and two ends of the rib with the hole respectively extend to the upper end surface and lower end surface of the section shell, and a bolt passes through the hole of the water outlet end base and is connected with the rib with the hole on the upper end surface of the section shell, so that the water outlet end base is arranged at the upper end surface of the section shell. According to the heater subassembly, the operations of adding a bent turned edge and tapping are not needed because the section shell is integrally stretched and molded once and the rib with the hole is formed during stretching, therefore, the processing procedure is simplified and the processing efficiency is improved. Furthermore, the bolt is screwed from top to bottom, a screwing tool is not limited by the section shell, and the screwing operation is convenient, moreover, the rib with the hole and the section shell are integrally molded once, and the water outlet end base and the section shell can not loosen easily.

Owner:冯海涛

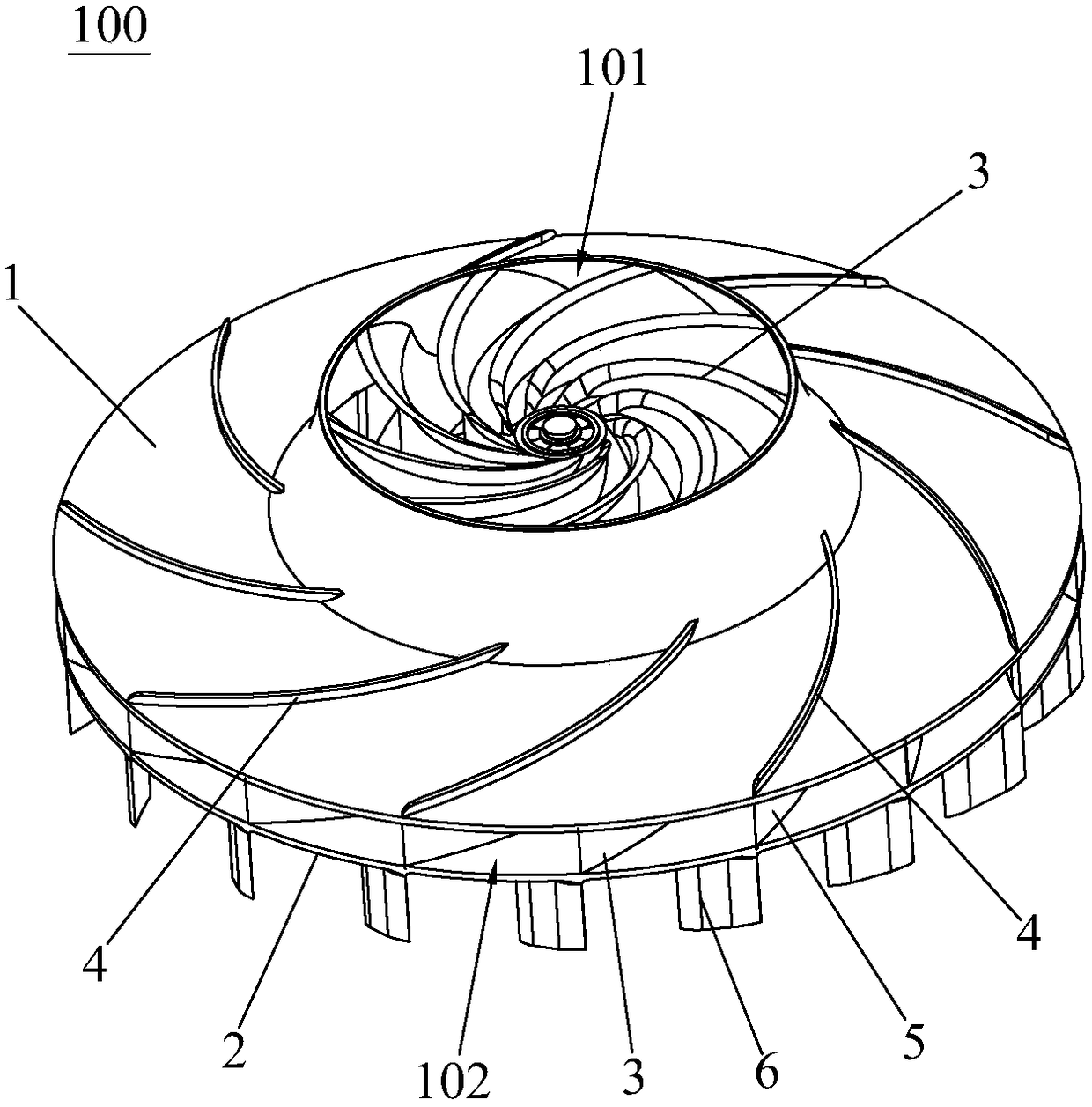

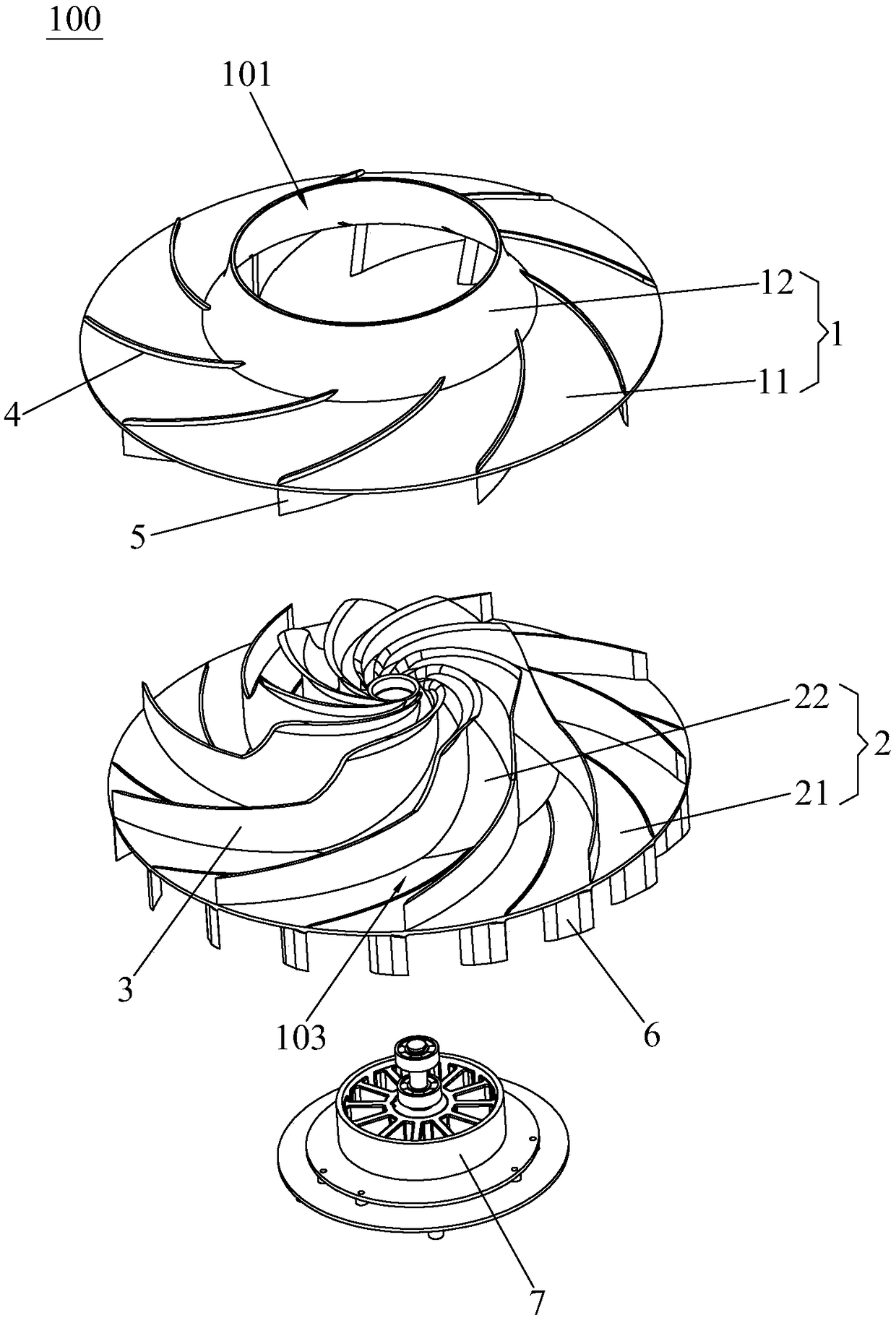

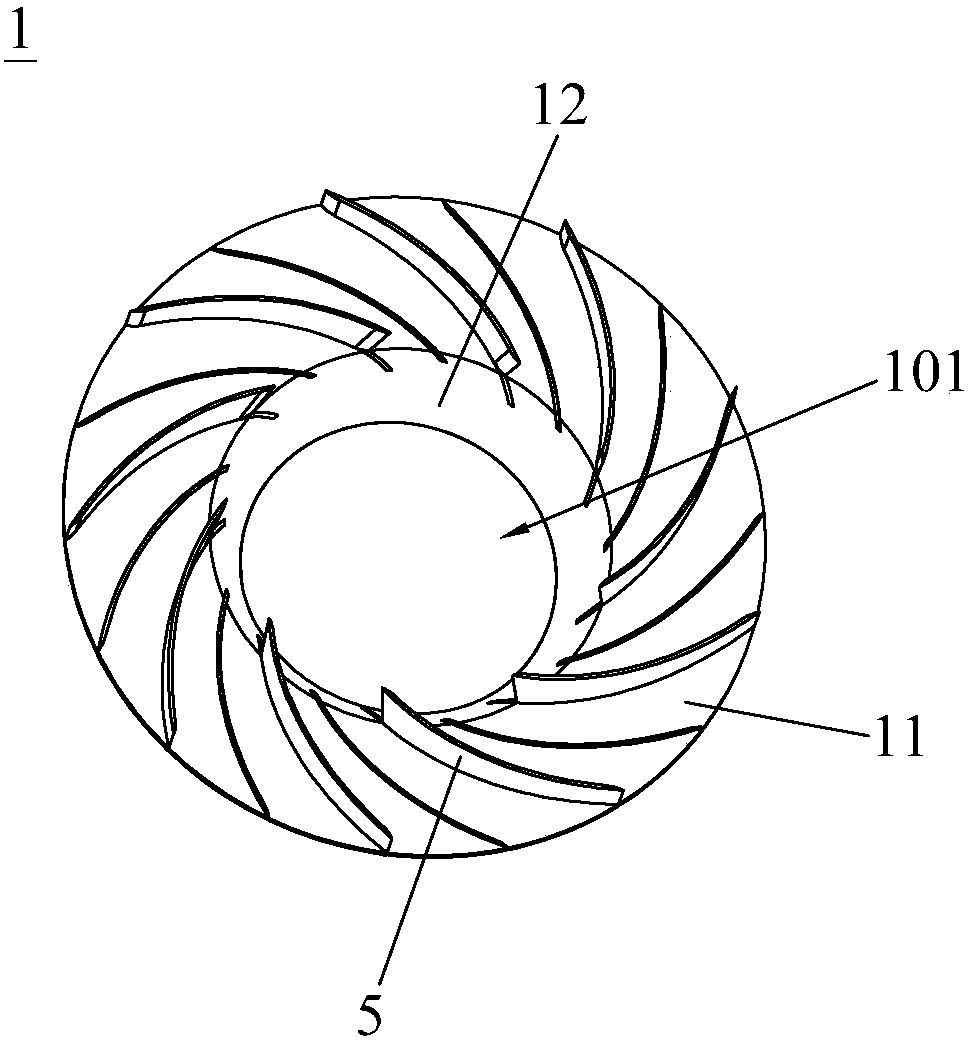

Split forming mixed flow turbine

PendingCN108223442AImprove the air supply effectPrevent leakingPump componentsPumpsMixed flowEngineering

The invention discloses a split forming mixed flow turbine. The turbine comprises an outer flow guide cover and an inner flow guide cover, and a plurality of first blades are arranged around the central axis of any one of the inner wall of the outer flow guide cover and the outer wall of the inner flow guide cover, wherein the inner flow guide cover and the outer flow guide cover are arranged in acooperating mode; a flow guide air channel is formed among the first blades, the outer wall of the inner flow guide cover and the inner wall of the outer flow guide cover; and a plurality of second blades are arranged on the outer wall of the outer flow guide cover and around the central axis. The split forming mixed flow turbine has the advantages of being capable of preventing leakage and effectively improving the air supply performance.

Owner:东莞市卓奇电子科技有限公司

A high-rise building with a cast-in-place hollow floor

InactiveCN103981944BEasy constructionFilled with light weightFloorsReinforced concreteSpatial structure

The invention provides a high-rise building with a cast-in-place hollow floor, which is composed of a core tube, an outer frame, a hollow floor, a steel mesh and an organic cavity; The force wall constitutes a closed space structure; the outer frame is a frame force member composed of beams and columns outside the building plane; the main beam is a reinforced concrete composite beam or a steel beam; the steel mesh and the organic object are interacted by the steel mesh and the organic object; The steel mesh forms the cavity top surface, the cavity bottom surface, and the two side walls of the cavity side of the composite cavity; the organic object contains air cells or polyphenylene blocks; the organic object forms the other two side walls of the composite cavity side of the steel mesh And the support is between the top surface of the cavity and the bottom surface of the cavity to control the height of the combined cavity of the steel mesh. After the combined cavity of the steel mesh and inorganic objects is placed, concrete is poured, vibrated, maintained, and the floor formwork is removed to realize the application of the cast-in-place hollow floor in high-rise buildings.

Owner:王本淼 +2

Instant heating type heater subassembly

The invention discloses an instant heating type heater subassembly which comprises an instant heating type heater and a water outlet end base of the instant heating type heater, wherein the instant heating type heater subassembly is characterized by also comprising a section shell; the instant heating type heater is arranged at the inner side of the section shell; the wall surface of the section shell is stretched to form a rib with a hole; and two ends of the rib with the hole respectively extend to the upper end surface and lower end surface of the section shell, and a bolt passes through the hole of the water outlet end base and is connected with the rib with the hole on the upper end surface of the section shell, so that the water outlet end base is arranged at the upper end surface of the section shell. According to the heater subassembly, the operations of adding a bent turned edge and tapping are not needed because the section shell is integrally stretched and molded once and the rib with the hole is formed during stretching, therefore, the processing procedure is simplified and the processing efficiency is improved. Furthermore, the bolt is screwed from top to bottom, a screwing tool is not limited by the section shell, and the screwing operation is convenient, moreover, the rib with the hole and the section shell are integrally molded once, and the water outlet end base and the section shell can not loosen easily.

Owner:冯海涛

A kind of preparation method of antibacterial baby diaper

ActiveCN112618169BImprove hydrophilicityNot easy to reverse osmosisAbsorbent padsBaby linensMedicineEngineering

The invention relates to the field of sanitary products, and provides a method for preparing antibacterial baby diapers, which solves the defects of poor antibacterial effect and poor air permeability of antibacterial diapers in the prior art, including preparing an antibacterial and breathable composite layer, preparing an absorber, and preparing a liquid-impermeable The antibacterial bottom layer and the preparation step of combining the antibacterial breathable composite layer, the absorber and the liquid-impermeable bottom layer into one.

Owner:GUANGDONG YINYIN CO LTD

A non-impact piezoelectric jet dispensing valve

ActiveCN111632796BAvoid collision wearHigh precisionLiquid surface applicatorsCoatingsEngineeringSolid particle

The invention belongs to the technical field of piezoelectric injection valves, and specifically relates to a non-impact piezoelectric injection dispensing valve, which includes a valve body, a valve seat and a push rod, the valve body is fixedly connected to the valve seat, and a nozzle is installed at the bottom of the valve seat. There is a first liquid storage chamber inside the valve seat, and a piezoelectric drive mechanism is arranged in the valve body. The liquid storage cavity forms a clearance fit, and a first flow channel is arranged inside the ejector rod, and the first liquid storage cavity, the first flow channel and the second liquid storage cavity communicate with each other. Compared with the prior art, the present invention adopts a non-collision method for dispensing, replaces the striker by the ejector pin, avoids the collision and wear of the nozzle and the striker, improves the accuracy and efficiency of dispensing, saves a lot of maintenance costs, and enhances The service life of the device is extended, the injection of glue containing solid particles is realized, the phenomenon of local heating of the device is reduced, and the phenomenon of glue leakage is prevented.

Owner:东莞市集韵自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com