Adsorption type water-cooling machine

A water chiller and adsorption technology, which is applied in the direction of adsorption machines, refrigerators, refrigeration and liquefaction, etc., can solve the problems of poor refrigeration efficiency, low heat exchange rate, and high cost, so as to speed up the cycle speed, increase the heat exchange rate, The effect of speeding up the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

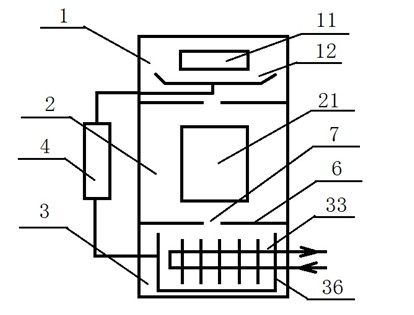

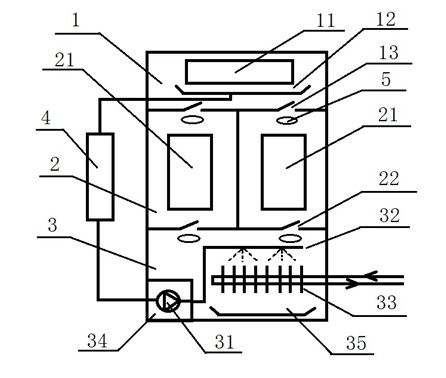

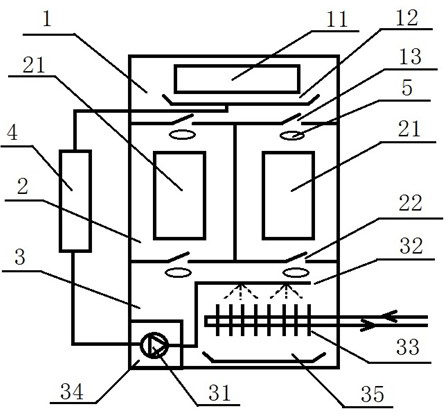

[0020] Such as figure 2 An adsorption chiller is shown, which includes: a condensation chamber 1, an adsorption chamber 2, an evaporation chamber 3, and a liquid reservoir 4; the chambers are separated by a partition 6, and a channel 7 is provided on the partition; The liquid reservoir 4 is connected to the condensation chamber 1 through one end of the pipeline, and the other end is connected to the evaporator 3;

[0021] The condensation chamber 1 is provided with a condenser 11, a condensation chamber water pan 12 and two first airtight flaps 13; the condensation chamber water pan 12 is located directly below the condenser 11 and is used to collect After turning into a liquid refrigerant, the condensation chamber water pan 12 is connected to the liquid reservoir 4 through a pipeline; the first airtight flap 13 is located above the passage between the condensation chamber 1 and the adsorption chamber 2;

[0022] The adsorption chamber 2 is provided with an adsorption bed 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com