Mask manufacturing process and mask

A production process and mask technology, applied in the field of medical masks, can solve problems such as loss and failure of medical masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

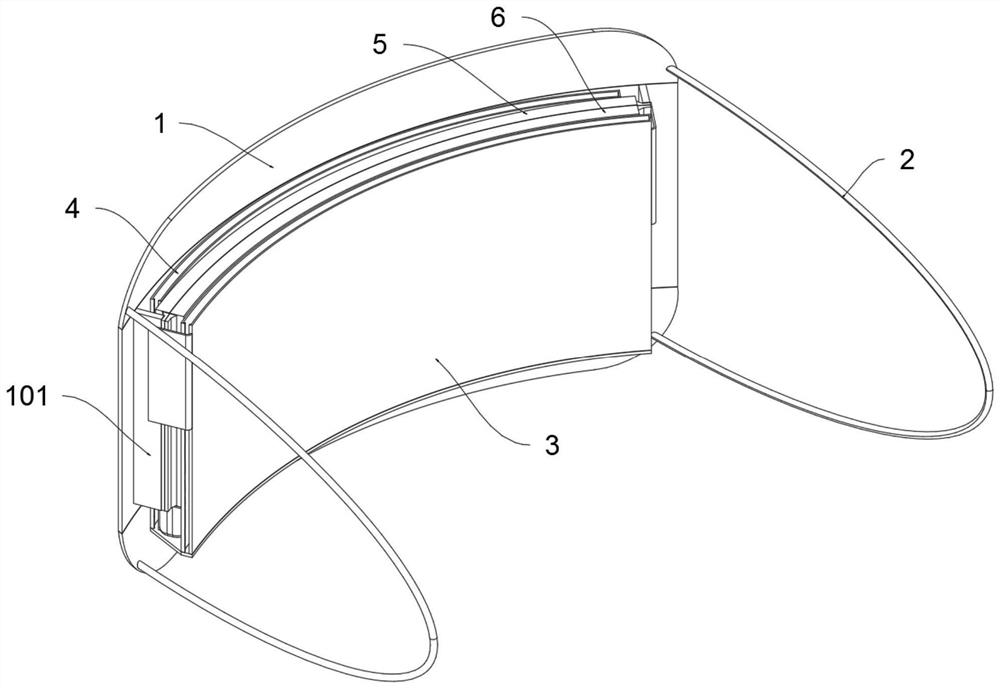

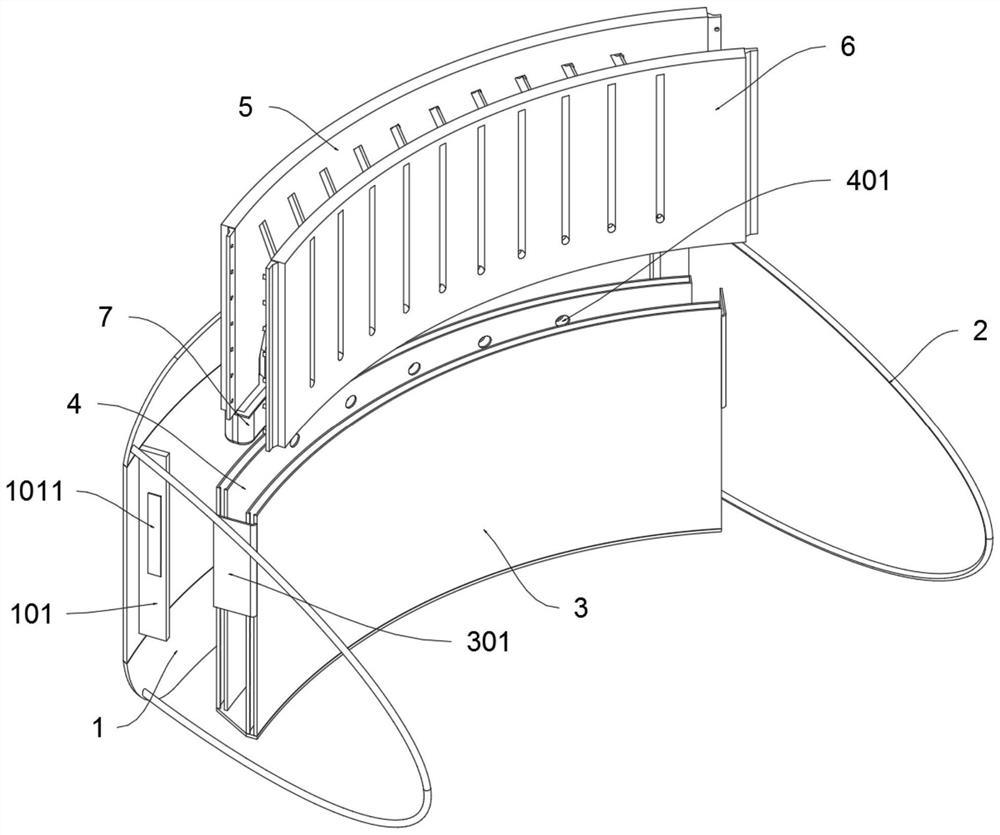

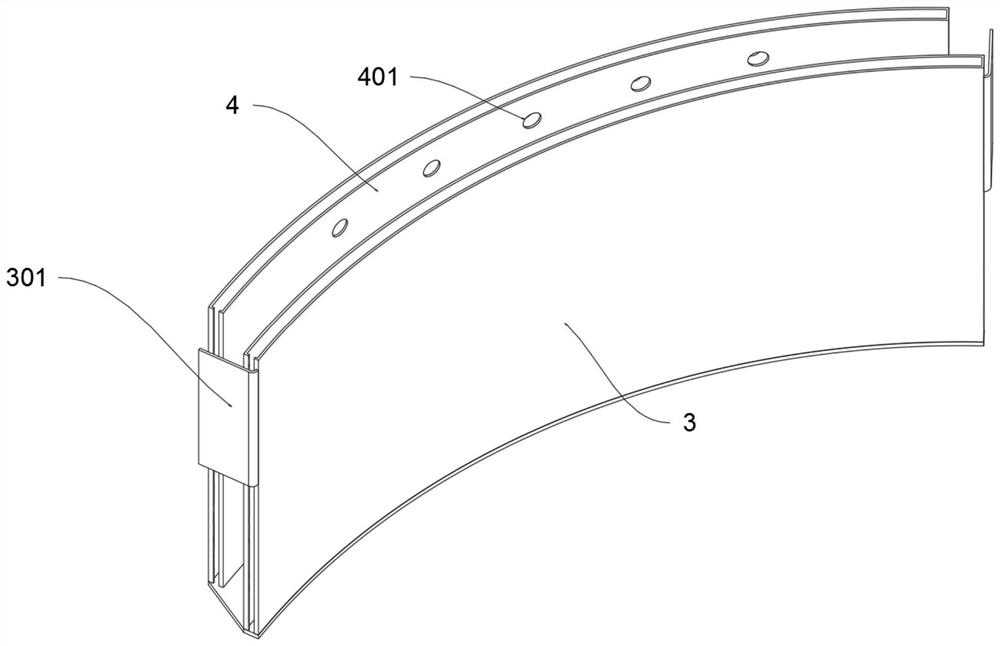

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a mask manufacturing process and a mask, comprising a mask cover body 1, an outer cotton cloth bearing layer 4, an outer moisture-absorbing plate 5, and a water storage box 7; the inner surface of the mask cover body 1 is connected to the inner cotton cloth bearing layer 3 by Velcro And the both sides of mouth mask cover body 1 are fixedly connected with mouth mask fixing rope 2; The bottom of outer cotton cloth bearing layer 4 is fixedly connected with the bottom of inner cotton cloth bearing layer 3, and outer cotton cloth bearing layer 4 is positioned at the outside of inner cotton cloth bearing layer 3; Outer moisture-absorbing plate 5 The two sides of the inner moisture-absorbing board 6 are connected by buckles, and the outer moisture-absorbing board 5 and the inner moisture-absorbing board 6 are between the outer cotton cloth bearing layer 4 and the inner cotton cloth bearing layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com