Anti-seeping treatment method of wall between windows of high-rise building external wall

A processing method, the technology of the wall between windows, applied in the processing of building materials, construction, building components, etc., can solve the problems of watermark leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

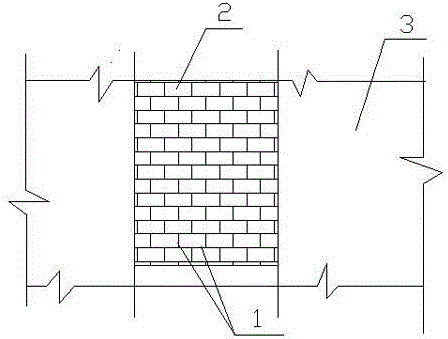

[0012] Such as figure 1 As shown, the present invention provides a kind of anti-leakage treatment method of high-rise building exterior wall window wall, comprises mortar joint 1, window wall 2 and concrete shear wall 3, step 1: material selection, cement brick or fly ash concrete add Air blocks, stick to the strict sampling inspection and test system for cement bricks or fly ash concrete air blocks entering the site, after passing the inspection and re-inspection, they are used for engineering masonry, and are used for cement for exterior walls and window walls 2 Bricks or fly ash concrete aerated blocks should be regular in shape, with edges and corners for masonry here; Step 2: Masonry, masonry mortar is prepared in strict accordance with the mix ratio, when masonry, use full pavement Squeeze masonry, the thickness of the mortar joint 1 is strictly controlled at 10-12mm, the fullness of the mortar must reach more than 90%, and there are 3 vertical joints between the cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com