Combined frame of steel meshed body and organic object for pore forming of cast-in-place hollow floor

A technology of steel mesh body and hollow floor, which is applied in the direction of floors, building structures, building components, etc., and can solve problems such as product damage, cumbersome construction, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the accompanying drawings.

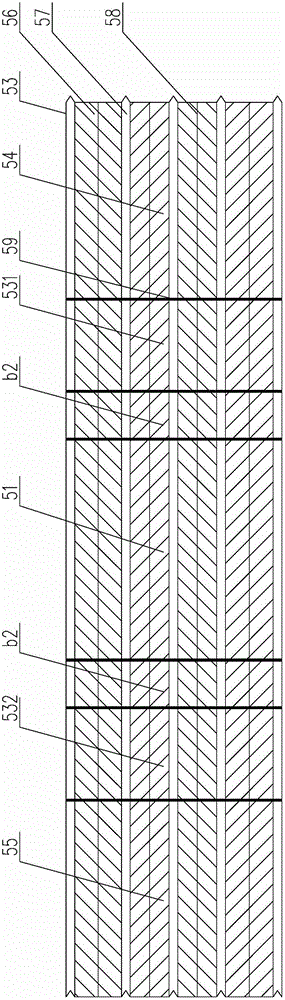

[0023] figure 1 It is a plan view of the steel mesh body in the first embodiment of the present invention, as figure 1 As shown, the steel mesh body includes mesh plate 56, reinforcing rib 57 and connecting plate 58, and mesh plate 56, reinforcing rib 57, connecting plate 58 and edge rib 52 form an interactive integral structure; steel mesh body strengthens The rib 57 is pressed in the vertical direction with multiple rows of bending lines 59, and generally there are four to six bending lines in each block.

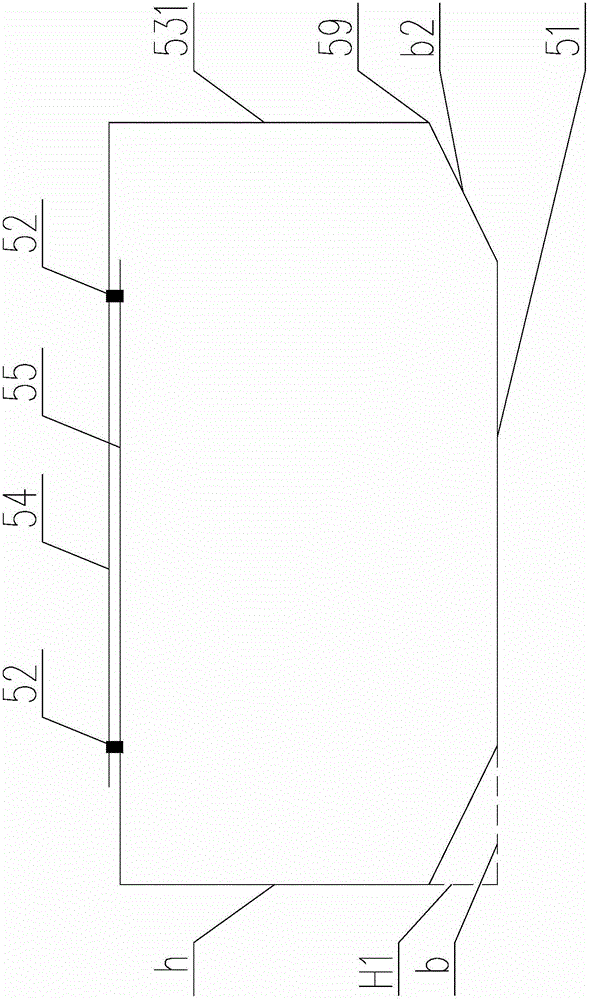

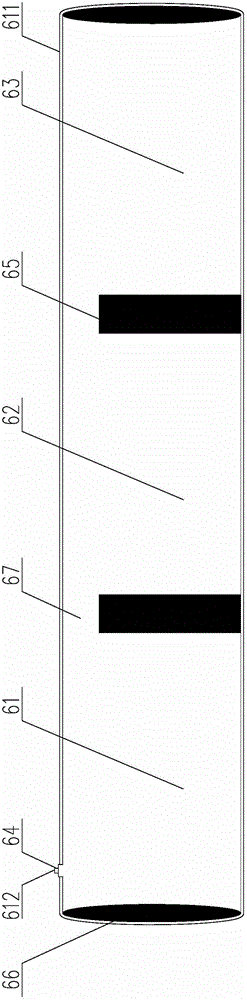

[0024] Such as figure 2 as shown, figure 2 It is a folded view of the frame of the steel mesh body in the second embodiment of the present invention, as shown in figure 2 As shown, the steel mesh body is made into the frame bottom surface 51, and the hypotenuse b 2 , The frame side side walls 531 and side walls 532, the frame top surface 54 and the frame top surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com