Manufacturing method of steel mesh member used for forming holes of hollow floor slab

The technology of a hollow floor and a manufacturing method can be applied to building components, floor slabs, building structures, etc., and can solve the problems of increasing cost, inability of polystyrene blocks, and taking up loading space for polystyrene blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described below in conjunction with the accompanying drawings.

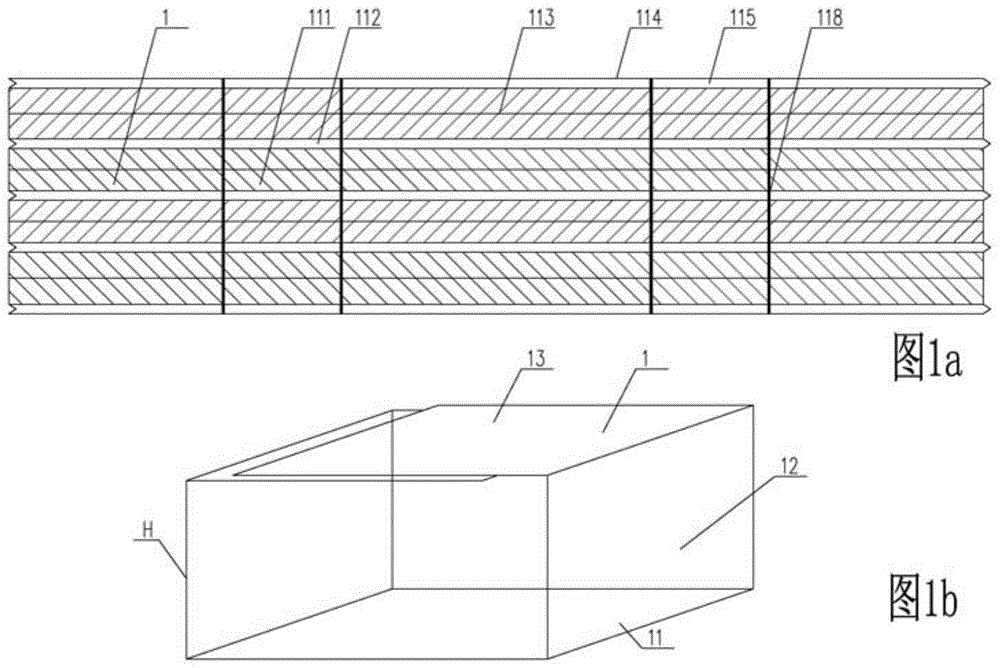

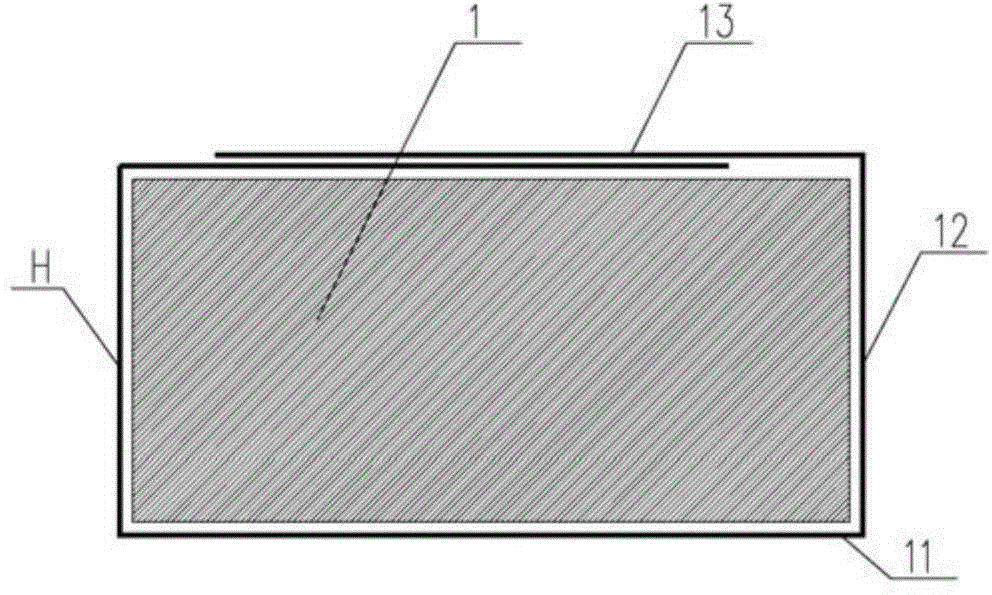

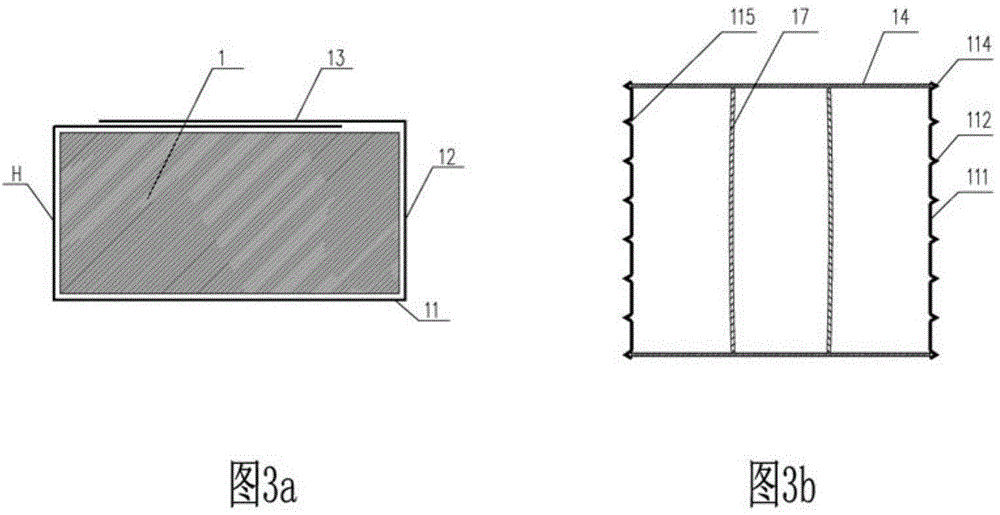

[0028] figure 1 Structural diagram of the cavity component steel mesh formed by the steel mesh and the thin plate in the first embodiment of the present invention, such as figure 1 As shown, the steel mesh of the cavity member 1 formed by the steel mesh and the thin plate includes a mesh plate 111, a reinforcing rib 112, a connecting plate 113 and an edge reinforcing rib 114, and the mesh plate and the reinforcing rib are the same as the connecting plate and the edge reinforcing rib The thin steel plate is made by punching and stretching with a special machine; the steel mesh reinforcement ribs are pressed in the vertical direction to have bending marks at the bending places that need to be quantitatively bent during combination; the bottom surface 11 of the cavity member made of the steel mesh is determined by the bending marks, Cavity member side walls 12 and cavity member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com