Construction method of basement roof

A technology of basement roof and construction method, which is applied in the direction of floor slab, building material processing, wine cellar, etc., can solve the problems of hindering equipment hoisting, easy to rust, etc., and achieves the effect of stable structure and convenient hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

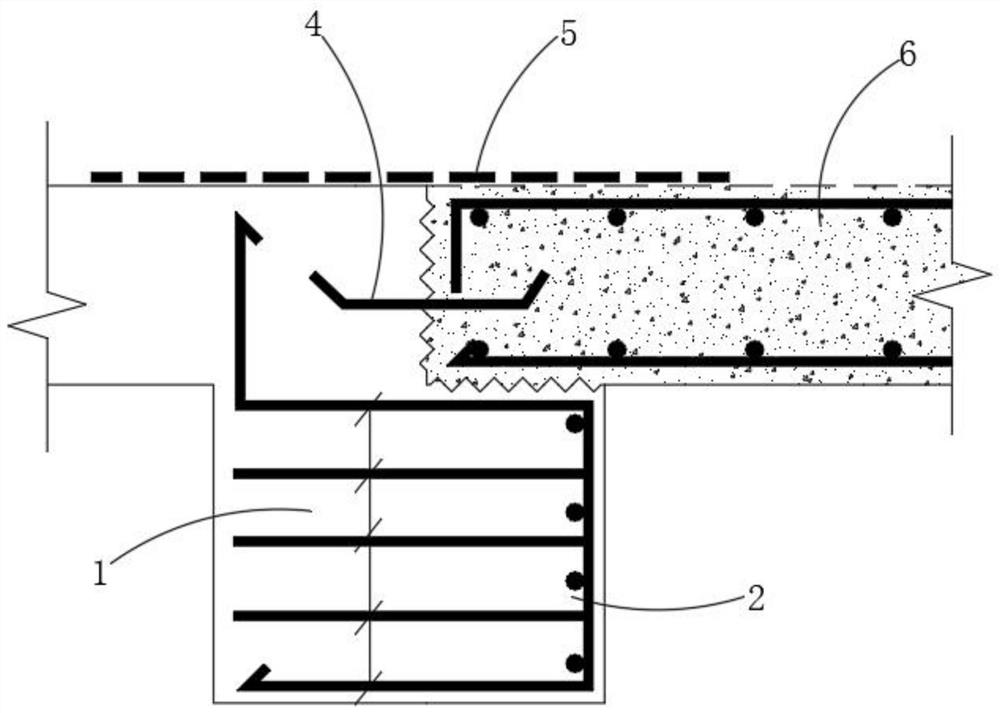

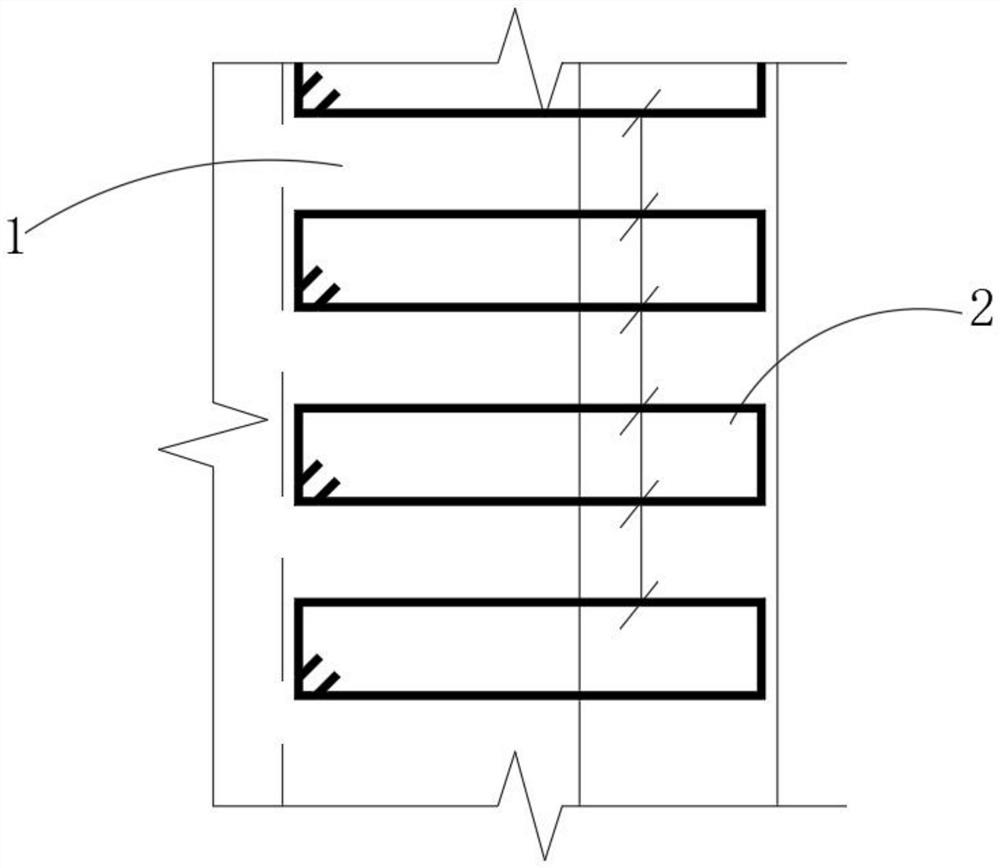

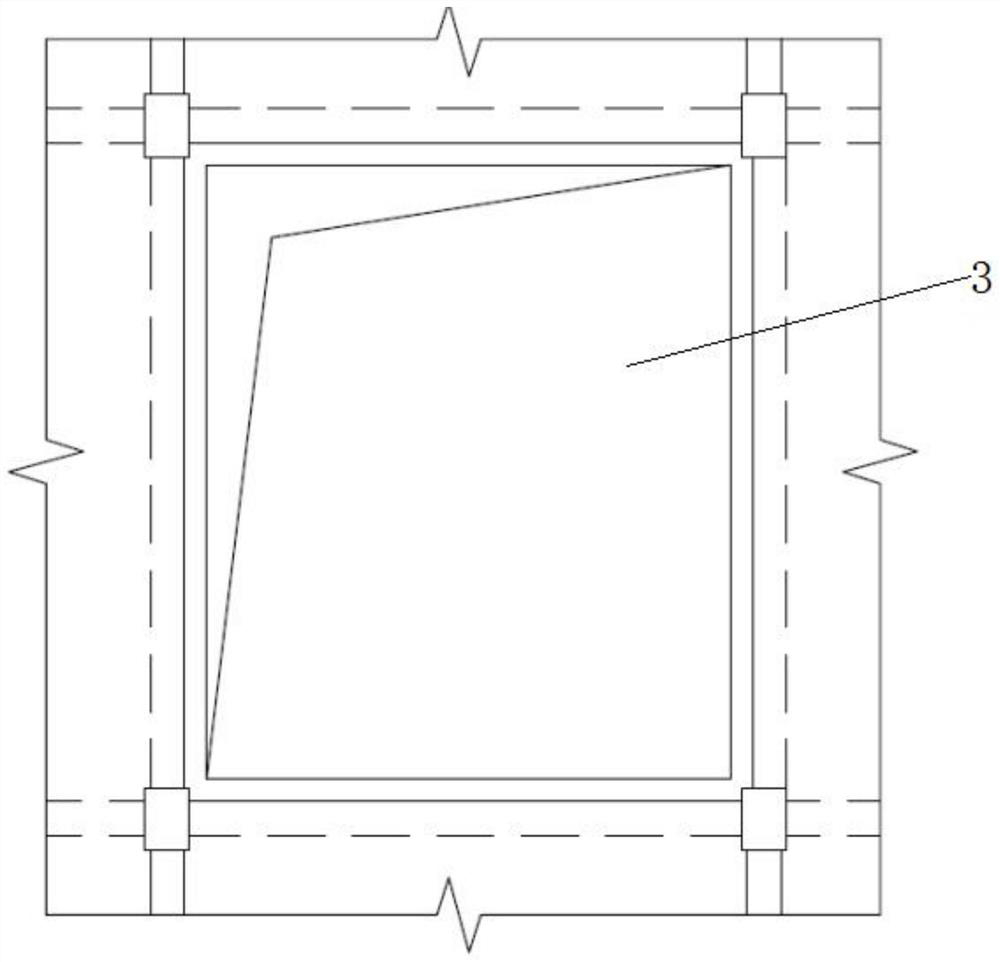

[0023] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a basement roof, including a hole edge beam 1 and a corbel 2, the corbel 2 is connected to the vertical surface of the hole edge beam 1 and the corbel 2 faces away from the hole The side beam 1 extends in the direction, and the corbel 2 encloses a hole forming the hoisting hole 3 , the hole is covered with a cover plate 6 , and the cover plate 6 rests on the corbel 2 . In this embodiment, a circle of corbels 2 protrude from the hole side beam 1 into the hoisting hole 3, and the corbels 2 and the hole side beam 1 are cast-in-situ at the same time, which can ensure the stability of the structure. The cover plate 6 is a post-casting plate, and the hole is blocked after the hoisting hole 3 is used. Specifically, before the construction of the post-casting slab, the contact surface of the new and old concrete should be chiseled first, rinsed with clean water to keep the surface moist,...

Embodiment 2

[0028] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a construction method for a basement roof, comprising the steps of: firstly forming a hoisting hole 3 in a cast-in-place concrete beam-slab structure, and then closing the hoisting hole 3 with a post-casting plate after it is used; In the beam-slab structure, cast-in-place hole beam 1 and corbel 2 at the same time, the corbel 2 protrudes away from the hole side beam 1, and the corbel 2 encloses the hole forming the hoisting hole 3 . In this embodiment, a circle of corbels 2 protrude from the hole side beam 1 into the hoisting hole 3, and the corbels 2 and the hole side beam 1 are cast-in-situ at the same time, which can ensure the stability of the structure. The cover plate 6 is a post-casting plate, and the hole is blocked after the hoisting hole 3 is used. The post-casting plate here is the cover plate 6 .

[0029] As an optimization scheme of the embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com