Solid floor with anti-corrosion and anti-seepage functions

A floor and functional technology, applied in the field of solid floor, can solve the problems of shortened service life, perishable edge of the board, poor overall effect, etc., and achieve the effect of strong practicability and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

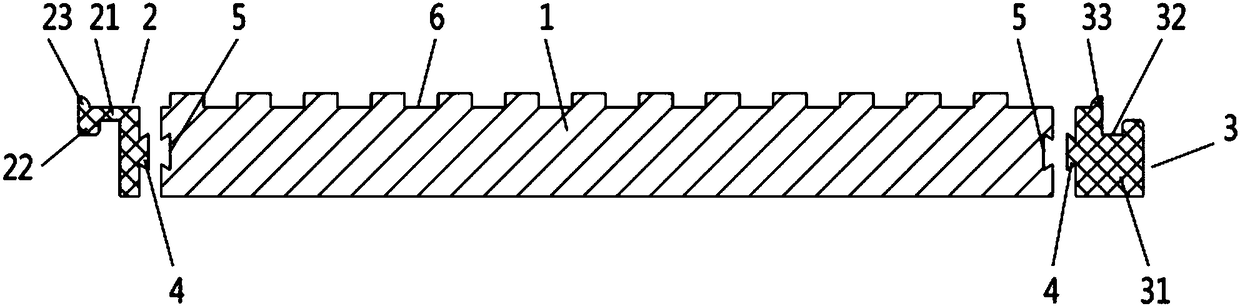

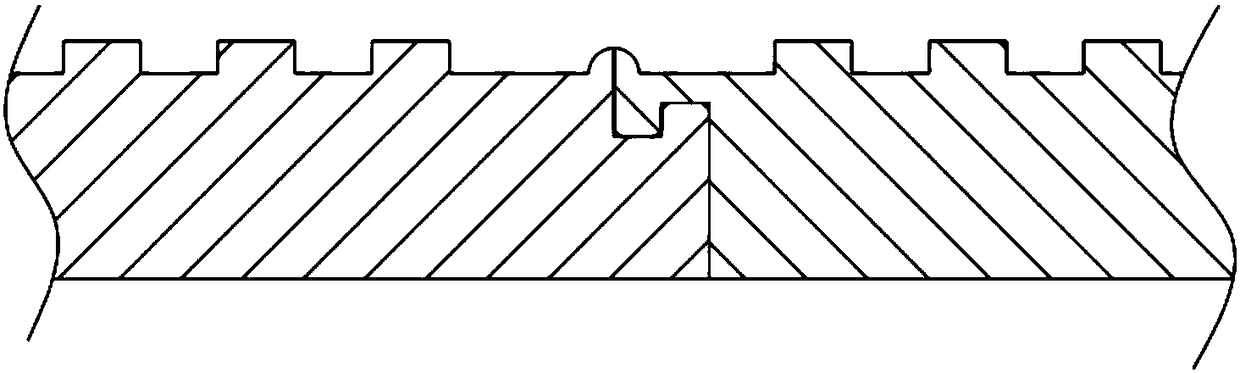

[0014] like figure 1 and figure 2 As shown, the solid floor with anti-corrosion and anti-seepage function involved in this embodiment includes a floor body. The solid wood middle board 1 is composed of the main auxiliary bar 3 on the right side, and the upper position of the side of the sub auxiliary bar 2 has a protrusion one 21 extending laterally, and the protrusion one 21 also has a downward facing protrusion two 22, the main auxiliary bar 2 The lower position of the bar 3 side has a projection three 31 extending laterally, and a groove 32 with a notch upwards is also arranged on the projection three 31, and the groove 32 is adapted to the two projections 22; The upper surface of the auxiliary strip 2 has a quarter round bump 1 23, and the quarter round bump 1 23 is located on the back side of the protrusion 2 22, and the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com