High-rise building adopting cast-in-place hollow floors

A hollow floor and cast-in-place technology, which is applied to floors, building components, buildings, etc., can solve problems such as difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the accompanying drawings.

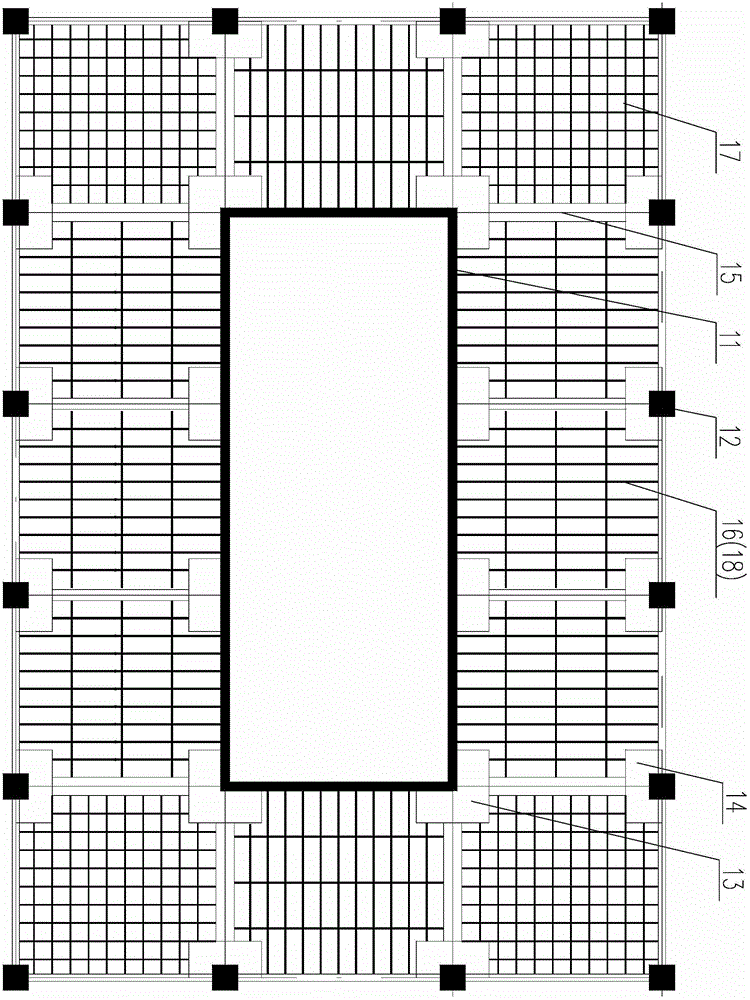

[0023] figure 1 It is the plan view of the high-rise building of the first embodiment of the present invention, the high-rise building of the frame core tube structure is made of the core tube 11 at the central part of the building plane, the outer frame 12 and the floor 18; the hollow floor of the high-rise building with the frame core tube structure The technology must be clear about "one frame and one tube, four points and four sides, eight lines and multiple units, and trough floor"; "one frame" is the outer frame with 12 beams and columns, and the height of the side beams should be larger, preferably 1.2m. The number and cross-sectional area of the columns are determined according to the vertical load; the "one tube" is the core tube 11, and the elevator tube and service workshop are generally concentrated in the core tube; the outer edge of the core tube is surrounded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com