Automatic tail fiber storage device

An automatic storage and pigtail technology, applied in the fiber mechanical structure, light guide, optics, etc., can solve the problems of winding, large occupation area, pigtail extrusion, etc., to achieve the effect of convenient use, simple wiring, and protection of pigtails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

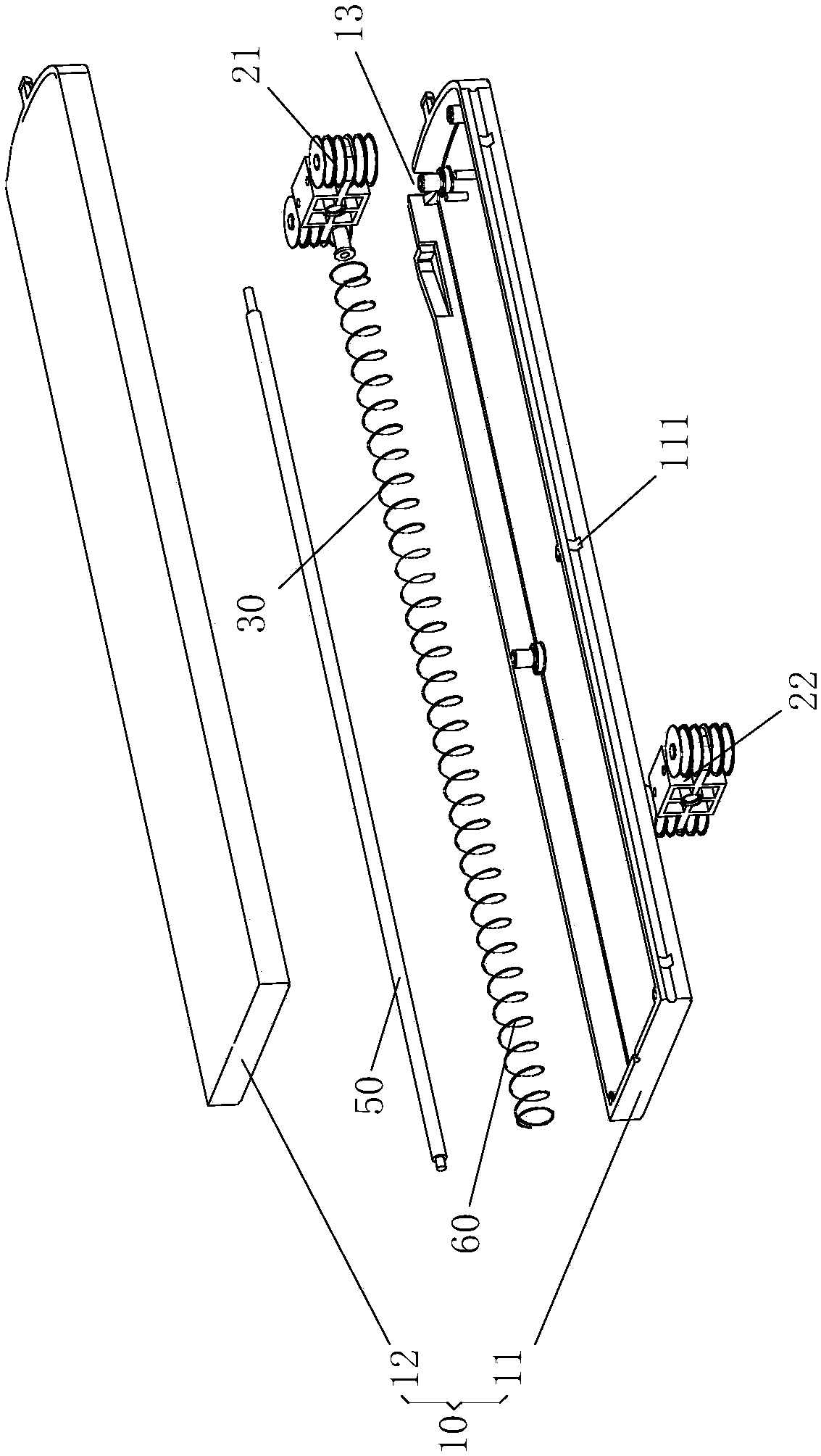

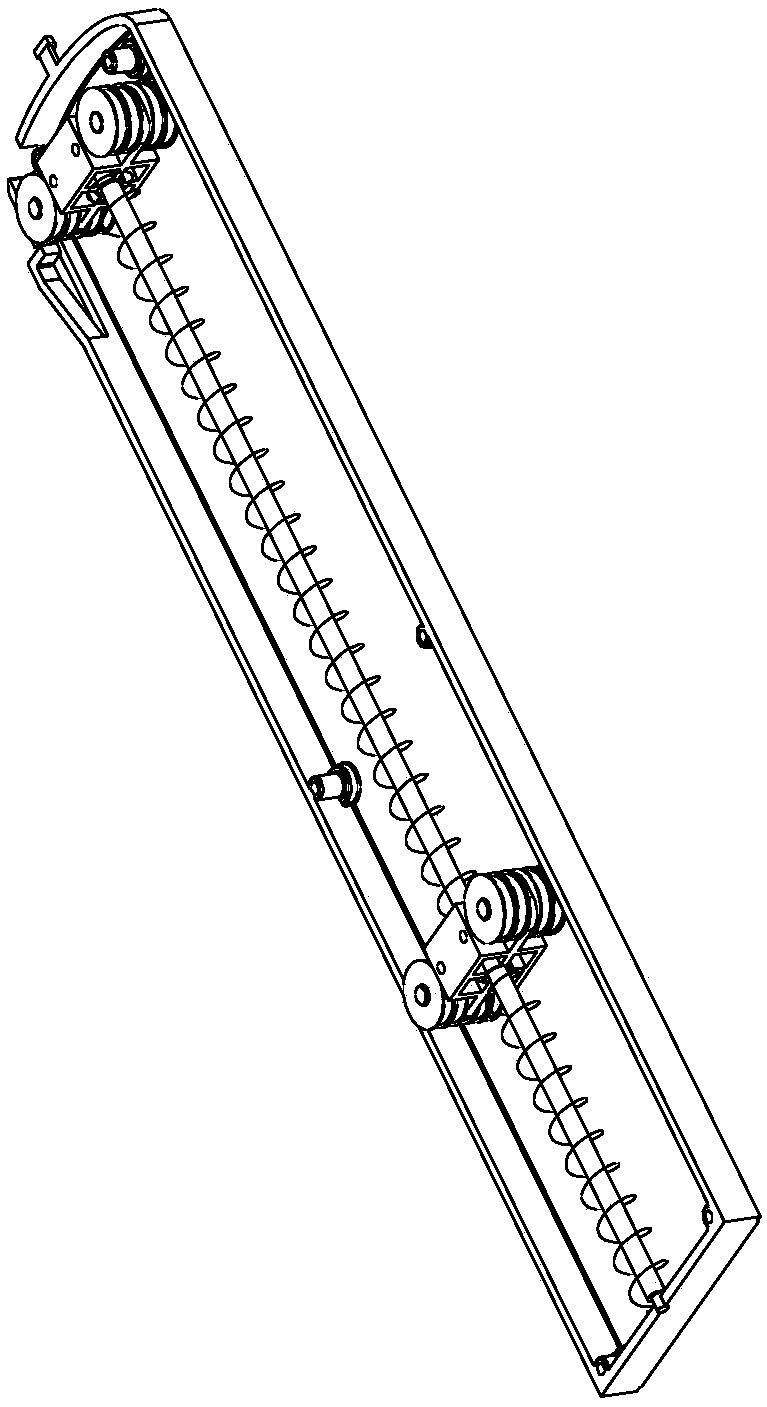

[0035] Examples, see figure 1 , figure 2 and Figure 4 Shown: a pigtail automatic storage device for storing a pigtail 100 having a connector 101, which is usually a standard connector.

[0036] in particular:

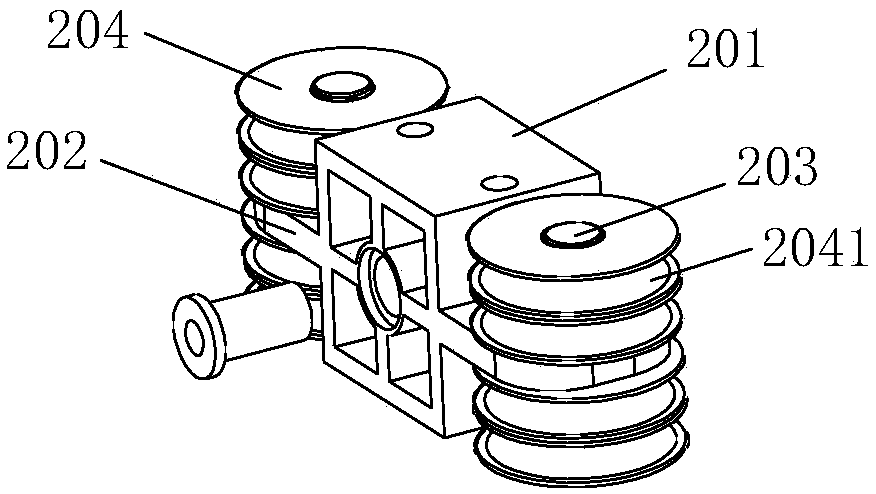

[0037] The pigtail automatic storage device includes: a box body 10, a fixed pulley block 21 and a movable pulley block 22, a first compression spring 30, a clamping device 40 and other components.

[0038] A side of the box body 10 is provided with a fiber inlet hole 13 for the pigtail 100 to pass through.

[0039] The fixed pulley block 21 is fixed on the right part of the inner cavity of the box body 10 , and the movable pulley block 22 is located in the inner cavity of the box body 10 and is positioned on the left side of the fixed pulley block 21 . Generally speaking, the fiber inlet hole 13 is located on the side of the cassette body 10 where the fixed pulley block 21 is located, that is, the right side of the cassette body 10 .

[0040] The first compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com