A Simulation Method of Nuclear Material in Molten Salt Reactor

A simulation method and nuclear material technology, applied in reactors, nuclear engineering, nuclear power generation, etc., can solve problems such as the inability to simulate nuclear materials, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

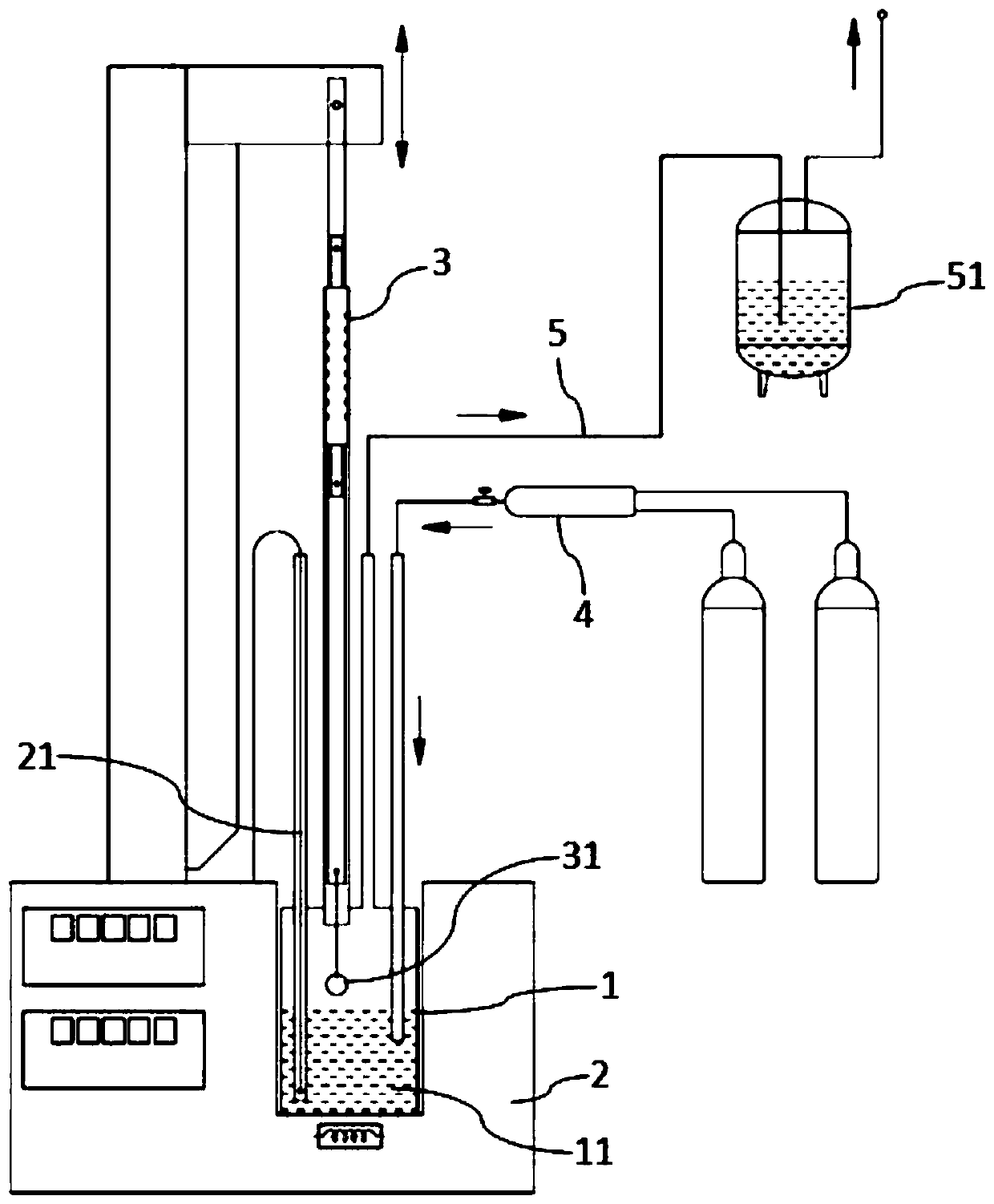

[0018] The method for simulating nuclear materials in a molten salt reactor according to the present invention specifically includes step S1, providing a method such as figure 1 The shown device for simulating nuclear materials in a molten salt reactor includes a tank body 1, a high-temperature furnace 2, a lifting device 3, an air inlet pipeline 4 and an air outlet pipeline 5, wherein the tank body 1 is designed to hold FLiNaK The molten salt 11, the high temperature furnace 2 is arranged under the tank body 1 for heating the molten salt 11 in the tank body 1, and the lifting device 3 is designed to hang the nuclear material sample 31 on the tank body 1 Inside, the air inlet pipeline 4 is designed to communicate with the tank body 1 to introduce gas into the tank body 1 , and the gas outlet pipeline 5 is also designed to communicate with the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com