A pulping process, prepared slurry and application thereof

A process and pulping technology, applied in the application, preparation of tobacco, tobacco, etc., can solve the problems of poor overall sensory quality, poor aroma quality of tobacco flakes, and large differences in tobacco flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The preparation of embodiment 1 tobacco sheet 1

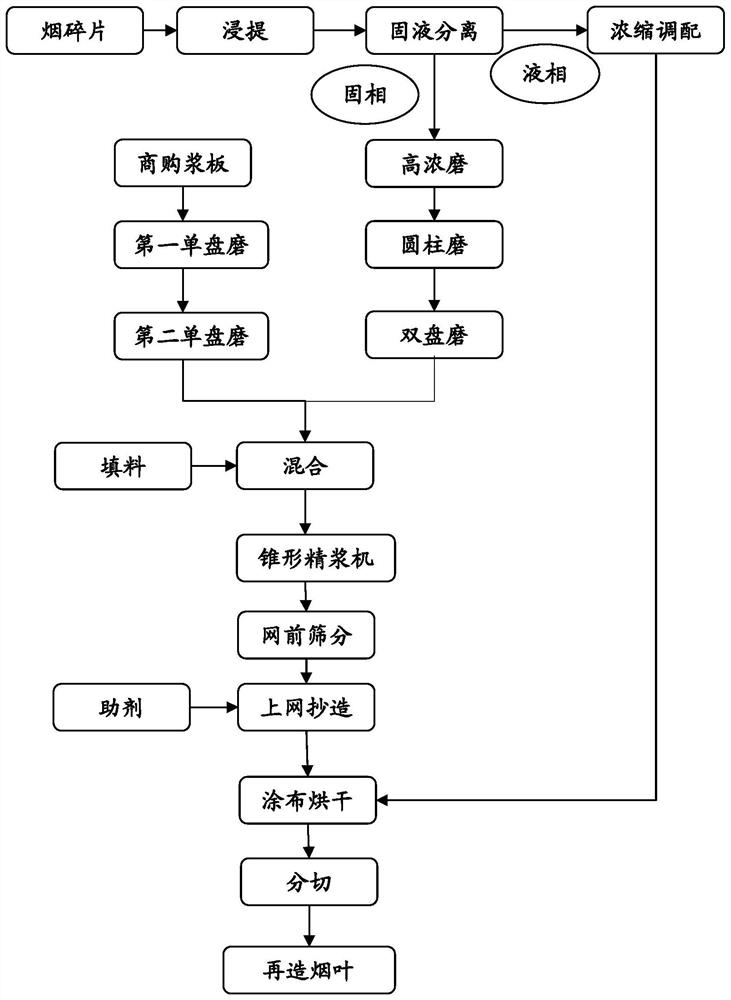

[0129] Preparation process such as figure 1 Shown:

[0130] (1) According to the proportions in Table 1, ten kinds of tobacco fragments were mixed to obtain 1000 g of mixed tobacco fragments. The mixed smoke fragments and 72°C hot water are introduced into the primary extraction tank at a material-to-liquid (weight) ratio of 1:7 for leaching for 30 minutes, and centrifuged to obtain supernatant and residue, wherein the centrifugal speed is 2600r / min, The centrifugation time is about 1 to 2 minutes; the residue is subjected to secondary leaching according to the above method to obtain liquid and sediment, and the obtained liquid is returned to the primary extraction tank to participate in leaching.

[0131] Table 1

[0132] Variety Ratio (%, w / w) Pu-erh flue-cured tobacco fragments 10 Qujing flue-cured tobacco fragments 8 Chuxiong flue-cured tobacco fragments 8 Dali flue-cured tobac...

Embodiment 2

[0139] The preparation of embodiment 2 tobacco sheet 2

[0140] Preparation process such as figure 1 Shown:

[0141] (1) Mix ten kinds of tobacco pieces according to the ratio in Table 2 to obtain 1000 g of mixed tobacco pieces. The mixed smoke fragments and 72°C hot water are introduced into the primary extraction tank at a material-to-liquid (weight) ratio of 1:7 for leaching for 30 minutes, and centrifuged to obtain supernatant and residue, wherein the centrifugal speed is 2600r / min, The centrifugation time is about 1 to 2 minutes; the residue is subjected to secondary leaching according to the above method to obtain liquid and sediment, and the obtained liquid is returned to the primary extraction tank to participate in leaching.

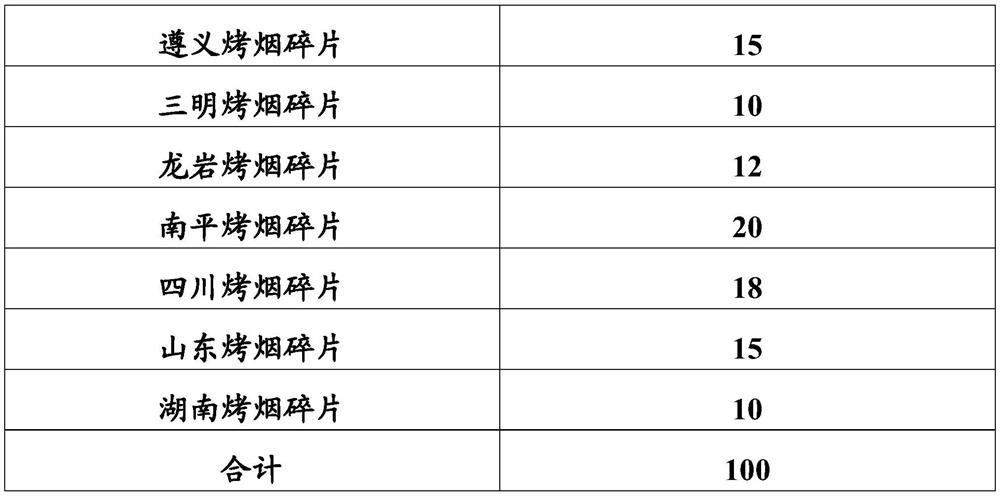

[0142] Table 2

[0143] Variety Ratio (%, w / w) Pu-erh flue-cured tobacco fragments 12 Qujing flue-cured tobacco fragments 10 Chuxiong flue-cured tobacco fragments 10 Dali flue-cured tobacco fragments 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com