Initial baking method for tobacco leaves, and tobacco leaves and use thereof

A technology for tobacco leaves and fresh tobacco leaves, which is applied in the fields of application, tobacco, and preparation of tobacco, and can solve problems such as many disputes, inconsistent appearance and quality of tobacco leaves, and inappropriate content of chemical components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

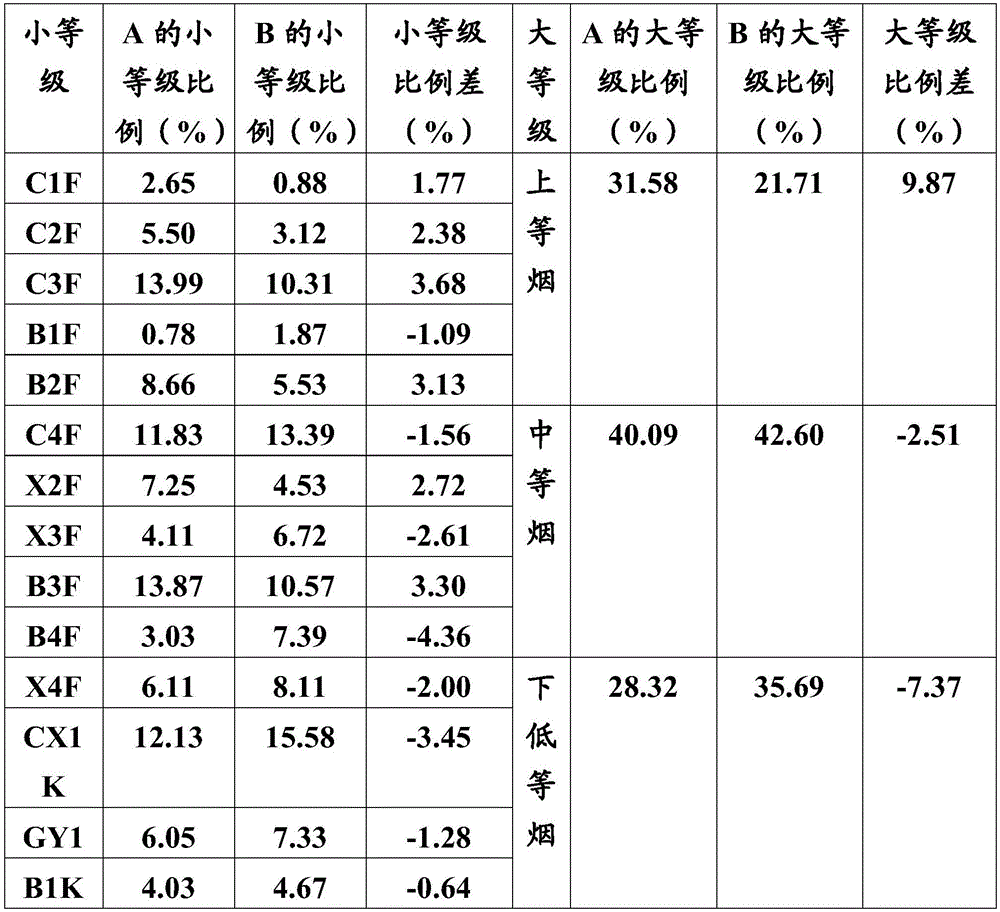

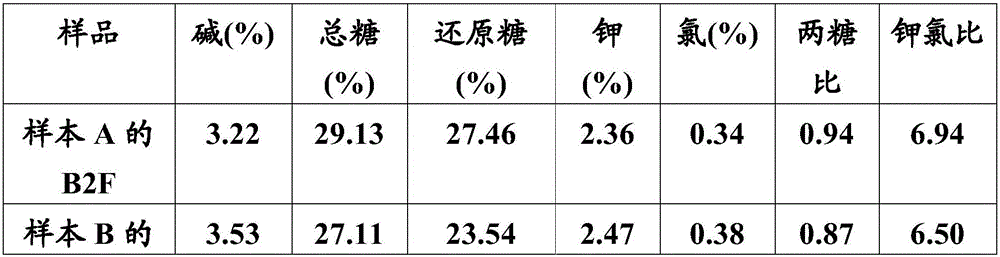

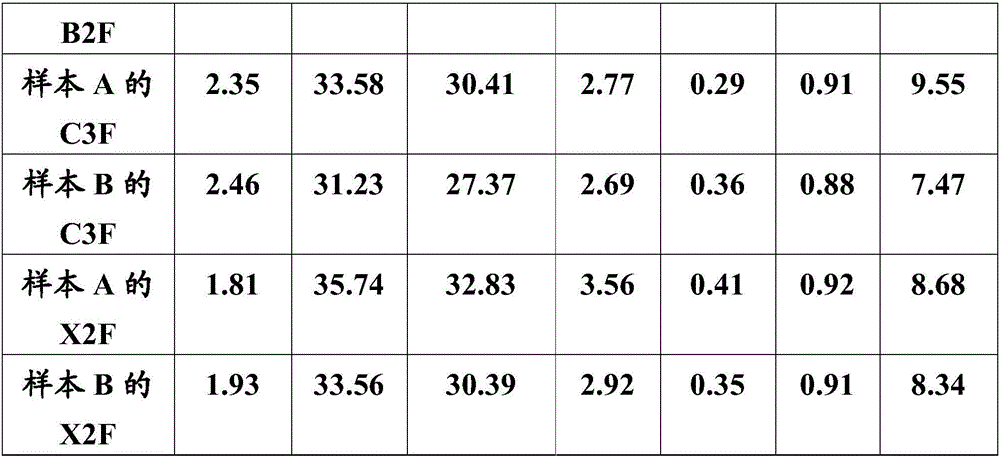

Image

Examples

Embodiment

[0184] Embodiment: the tobacco leaf that obtains according to the first curing method of the present invention

[0185] The fresh tobacco leaves in the upper part, the fresh tobacco leaves in the middle part and the fresh tobacco leaves in the lower part are harvested according to maturity respectively, and the method is as follows:

[0186] 1) For example, 10% of the leaf surface of the upper fresh tobacco leaf has fallen yellow, the main vein and branch veins are completely white, the leaf tip and leaf edge are whitish and roll down, the mesophyll between the first-level branch veins on the leaf surface, and the mesophyll between the second-level branch veins are white. The mesophyll between the mesophyll and the tertiary branch protrudes upward or is depressed downward, and the yellow-white mesophyll accounts for more than 2 / 3 of the total leaf area, so it is harvested as the upper overripe tobacco leaf.

[0187] 2) For example, 90% of the leaf surface of the upper fresh t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com