Melting point fractionation product of palm oil and oil composition containing same

A technology of palm oil and palm stearin, which is applied in the field of oil composition and food, can solve the problems of poor taste, long crystallization process time, high cost of diacylglycerol, etc., and achieve the prevention of cracking and core material leakage, and the best application performance Effects on sex and mouthfeel, crispness and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Preparation method of melting point product in palm oil fractionation

[0105] The invention provides a method for preparing a melting point product in palm oil fractionation, which is characterized in that it has the following steps: (1) fractionate palm oil as a raw material to obtain a palm stearin mixture; (2) extract the palm stearin mixture obtained in step (1) The stearin mixture is fractionated to obtain the melting point product in the fractionation of palm oil.

[0106] In a preferred embodiment of the present invention, the step (1) includes a (1-1) heating step. Heating to 50-80°C in the (1-1) heating step, preferably heating to 55-70°C in the (1-1) heating step. In a specific embodiment of the present invention, the (1-1) heating step is heated to 60°C.

[0107] In the (1-1) heating step, the constant temperature is performed for 1 to 120 minutes after the heating, and preferably in the (1-1) heating step, the constant temperature is performed for 30 to 9...

Embodiment 1

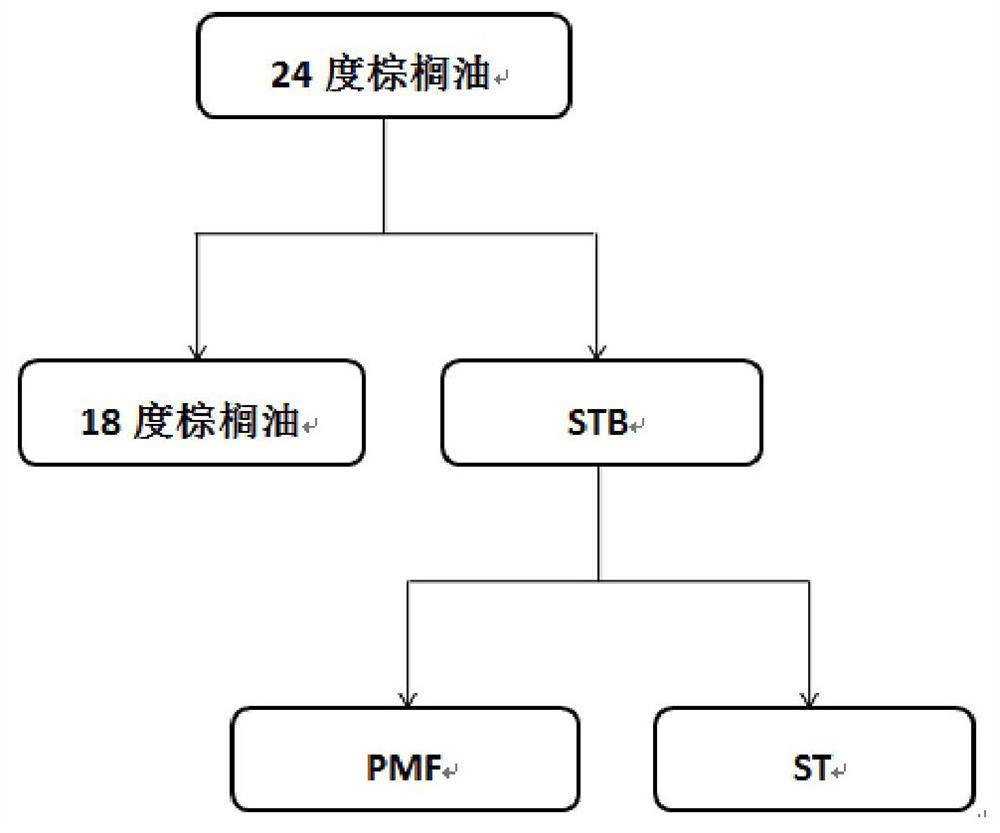

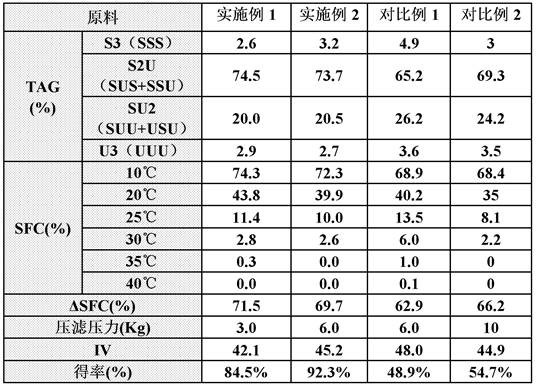

[0178] Using palm oil at 24°C as raw material, PMF with a steeper solid-fat curve and more stable quality was obtained through the following two-step fractionation (crystallization).

[0179]The first step of fractionation: use palm oil (10kg) at 24°C as the raw material to produce STB, and carry out cooling crystallization according to the crystallization steps shown in Table 1.

[0180] The operation steps of the first step of fractionation are shown in Table 1. The specific operation steps are as follows: put 10kg of 24-degree palm oil into the crystallization tank of the dry fractionation test equipment, first heat the water temperature to 60°C, and keep it warm for 60min , Turn on the stirrer and stir at a speed of 40 rpm to completely melt the raw material oil and eliminate crystallization memory. In the second step, the water temperature is uniformly cooled from 60°C to 30°C within 60 minutes, and the stirring speed is 40 rpm. In the third step, the water temperature i...

Embodiment 2

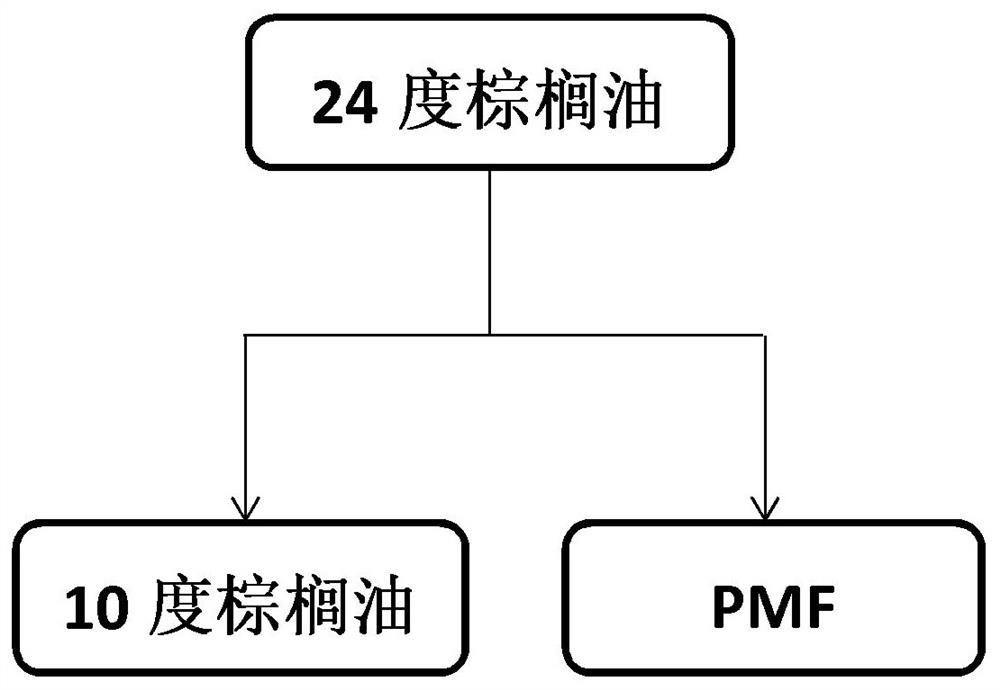

[0188] Using the by-product STB (5kg) of palm oil fractionated at 18°C in the factory as the raw material, carry out cooling crystallization according to the crystallization steps 1 to 3 shown in Table 2, and carry out cooling crystallization with reference to the operation method of Example 1. After the crystallization is completed, the crystallized The slurry was filtered with a filter press pressure of 6kg. The properties of the product obtained by fractionation were shown in Table 5. PMF with an S2U content of 73.7% and a ΔSFC of 69.7% could be obtained, and the fractionation yield reached 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com