A waste resource treatment device

A processing device and recycling technology, applied in the field of waste recycling, can solve problems such as inability to separate straw, insufficient sieving, and pollute the environment, and achieve the effects of high-quality straw crushing, simple structure, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

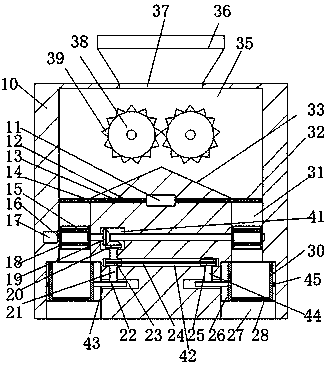

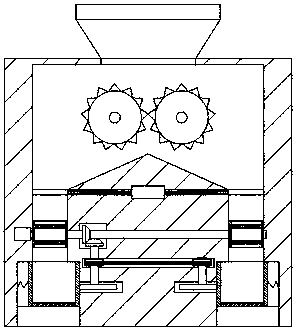

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0016] refer to Figure 1-2 As shown, a waste resource treatment device of the present invention includes a base body 10 and a feed hopper 36 arranged on the top surface of the base body 10. The opening 37 in the inner wall body of the body 10, the bottom of the opening 37 is connected with a crushing chamber 35, and the left and right sides of the bottom of the crushing chamber 35 are respectively connected with a passage chamber 31, and the connection between the crushing chamber 35 and the passage chamber 31 A closing device is provided between them, the bottom of the channel chamber 31 is communicated with a screening chamber 26, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com