Grading gravel CBR numerical experiment method based on three-dimensional state

A three-dimensional state, numerical test technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the interlocking effect and the distribution characteristics of the gap between the crushed stones cannot be considered, and the internal particles of the graded crushed stone cannot be obtained. Micromechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example demonstrates the specific implementation process of the present invention with limestone crushed stone, the basic physical properties of crushed stone are shown in Table 1, and the micromechanical parameters are shown in Table 2.

[0083] Table 1 Optimum moisture content of graded gravel

[0084] Dry density (g / cm3)

2.31

2.334

2.346

2.338

2.334

Average moisture content (%)

3.78

4.41

4.83

5.37

5.84

[0085] Table 2 Micromechanical parameters

[0086]

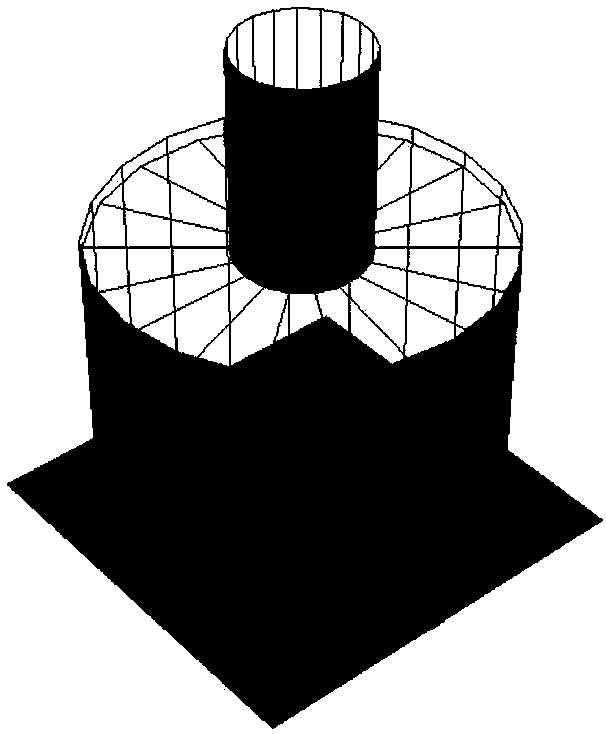

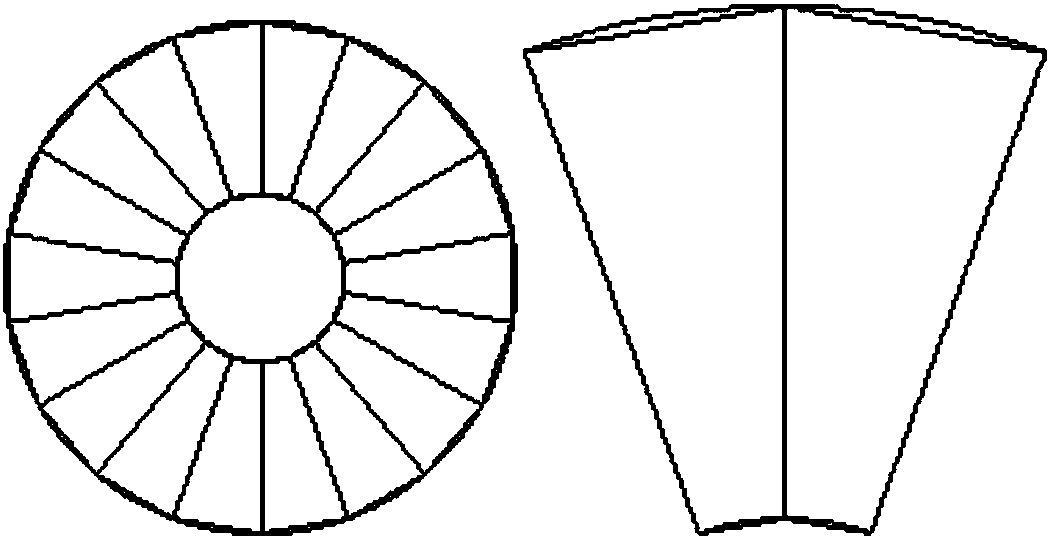

[0087] Step a: Through the WALL command in PFC3D, respectively establish the bottom surface (circular wall) and side wall (column wall) of the test mold, such as figure 1 As shown, gravel particles are generated according to the actual gradation, and physical properties such as gravel density are endowed. According to the test results and fitting curve, the optimal moisture content of graded gravel is 4.85%, and the maximum dry density is 2.346g / cm 3 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com