A kind of polyamide resin composition and preparation method thereof

A technology of polyamide resin and composition, applied in the field of polymer chemistry, can solve the problems of high cost, decreased thermal and oxygen aging resistance, poor moisture and heat aging resistance, etc., and achieve the effect of excellent long-term thermal and oxygen aging resistance

Active Publication Date: 2019-12-13

KINGFA SCI & TECH CO LTD +2

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the amount of polyol added is large and the cost is high

Moreover, when it is treated under more stringent test conditions (85°C and 90% relative humidity) for 14 days, its thermal oxygen aging resistance will gradually decrease, and when it is extended to 21 days, it is found that its thermal oxygen aging resistance will drop significantly , because of its poor long-term moisture and heat aging resistance under this condition

Therefore, its scope of application is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

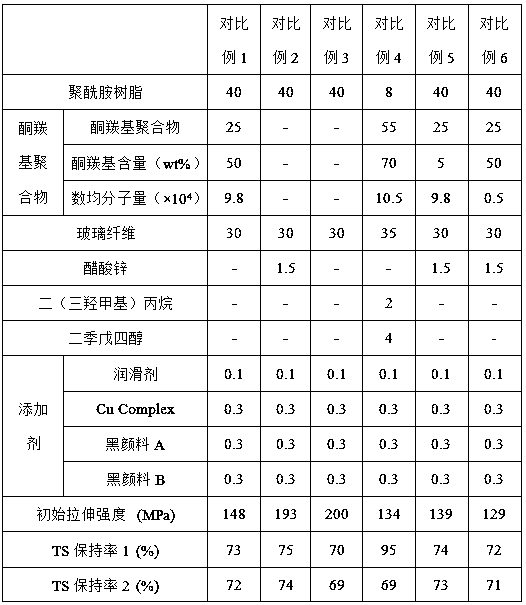

Embodiment 1-21 and comparative example 1-6

[0053] Preparation of polyamide resin composition:

[0054] According to Table 1, the dried polyamide resin, metal salt compound, ketone carbonyl polymer, filler and additives are blended, and then extruded through a twin-screw extruder at a temperature of 220°C-280°C, cooled, and pelletized. A polyamide resin composition was obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed are a polyamide resin composition and a preparation method therefor. The polyamide resin composition comprises the following components in parts by weight: 5-60 parts of a polyamide resin; 0.1-5 parts of a metal salt compound; 0.5-35 parts of a ketone carbonyl polymer. The present invention is selected from a compound containing ketone units having an alternating structure of olefin-derived comonomer repeating units and carbon monoxide-derived repeating units, the ketone carbonyl content of the ketone carbonyl polymer being 15wt%-80wt%, preferably 30wt%-80wt%, the number average molecular weight being greater than or equal to 1×104 and less than or equal to 3×105. The metal element of the metal salt compound is selected from at least one in groups IA-IIA and groups IB-IIB, and the anions paired with the metal ions are selected from at least one of halogen ions and acetate ions. The polyamide resin composition has advantages such as excellent long-term thermo-oxidative aging resistance, excellent long-term hydro-thermal aging resistance under conditions of 85°C and 90% relative humidity, and low costs.

Description

technical field [0001] The invention relates to the technical field of polymer chemistry, in particular to a polyamide resin composition and a preparation method thereof. Background technique [0002] Due to their excellent mechanical properties, chemical resistance, processability, and heat-oxidative aging resistance, polyamides are often used in the electronics and motor vehicle industries that have strict requirements on the working environment. Among them, the applications around the motor vehicle engine Very common. The demand for high temperature resistance of materials in the field of motor vehicles is becoming more and more obvious. This is based on the fact that the temperature in the surrounding area of the automobile engine is usually higher than 150 ° C, especially for engines with turbocharged air intake, the temperature is even higher than 180 ° C or even High temperature above 200°C. As polyamide compositions are often used at such service temperatures, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L77/06C08L23/08C08L23/14C08K7/14C08K5/098C08K3/16

CPCC08L77/06C08L2201/08C08L23/16C08K7/14C08K5/098C08K3/16

Inventor 罗忠富黄险波叶南飚王大中杨波丁正亚林洁龙

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com