Lock and anti-theft door

A lock and lock body technology, applied in the field of smart locks, can solve the problems of lock core intelligence and poor anti-theft performance, and achieve the effects of improving anti-theft performance, reducing costs and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

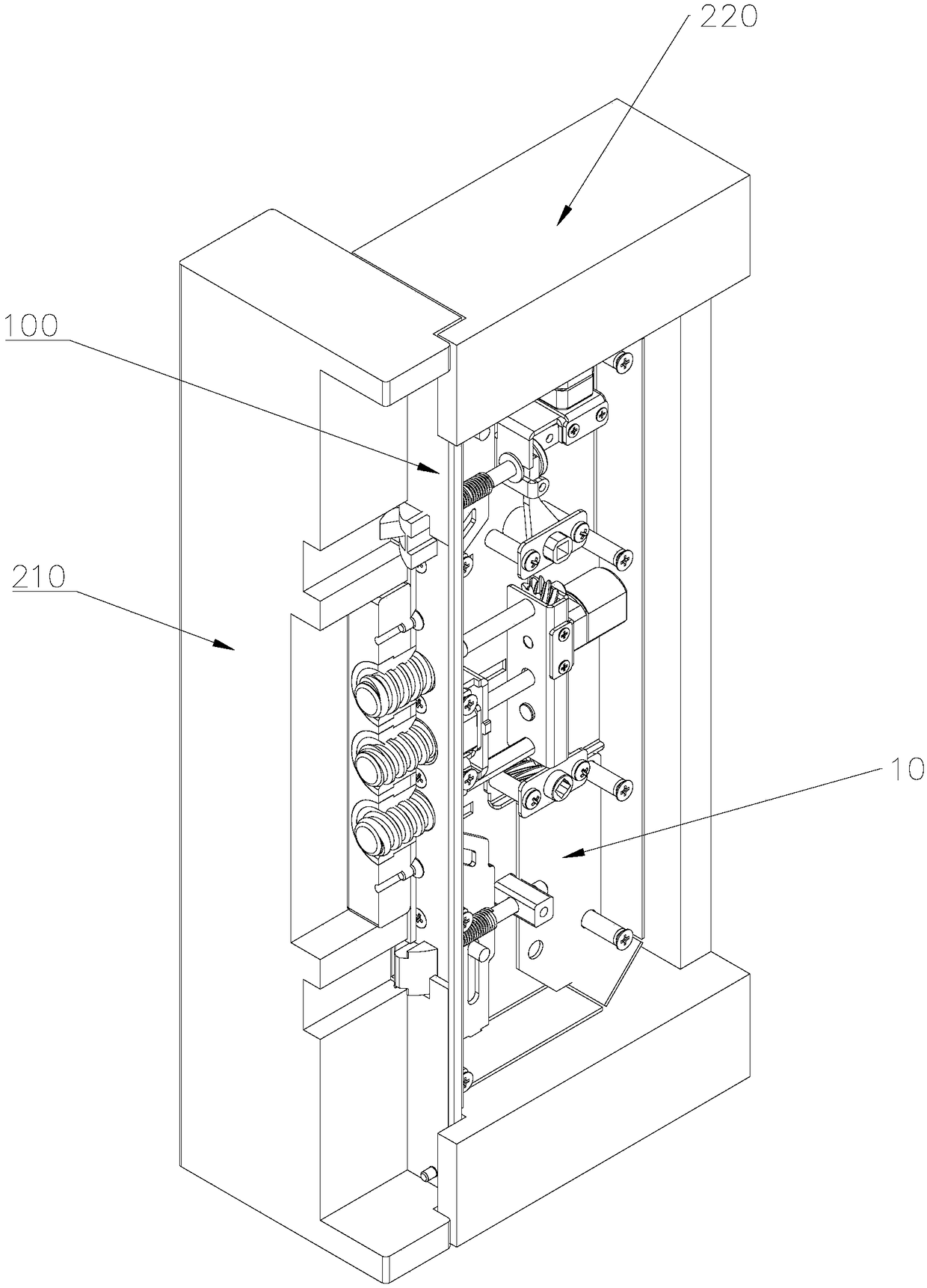

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

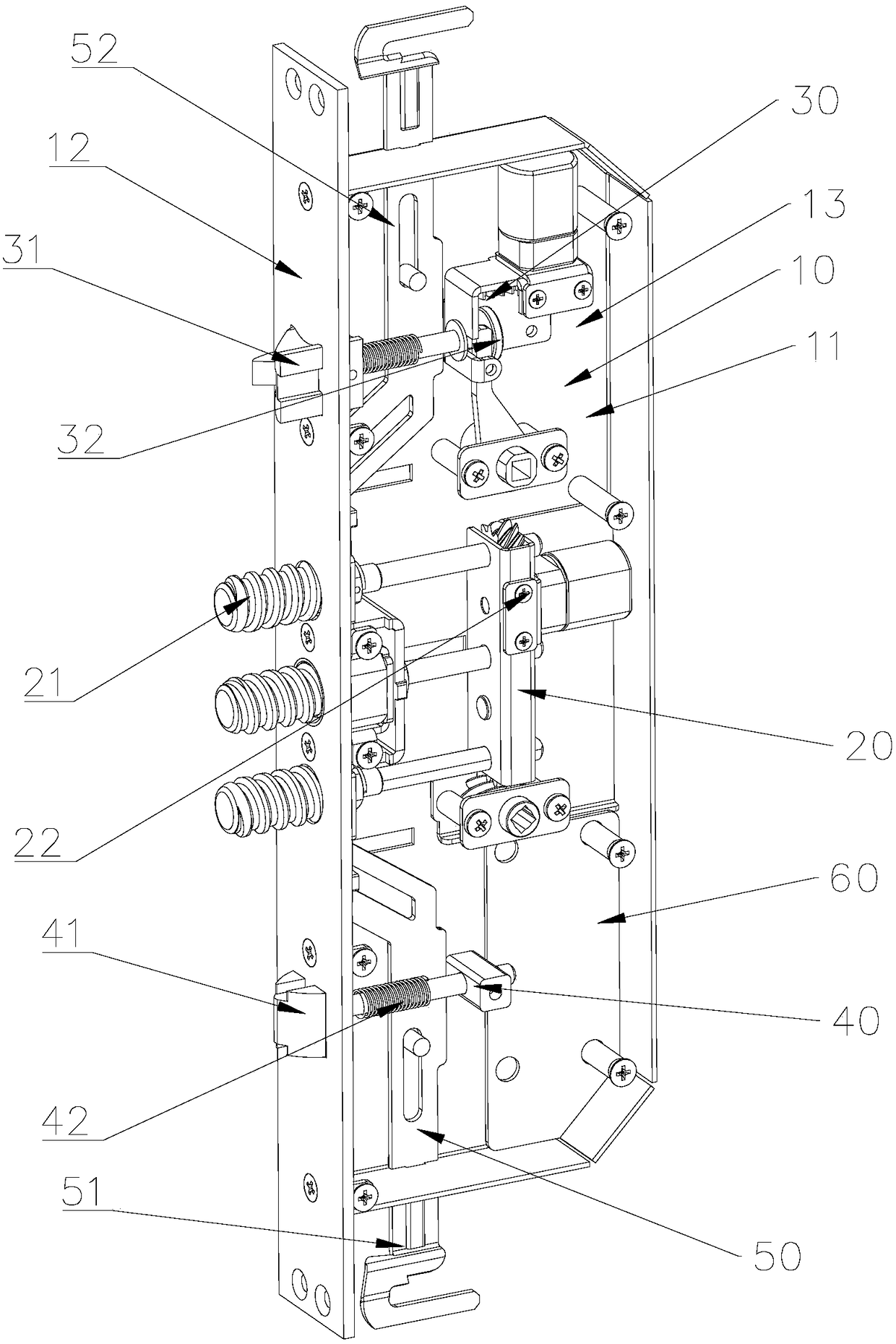

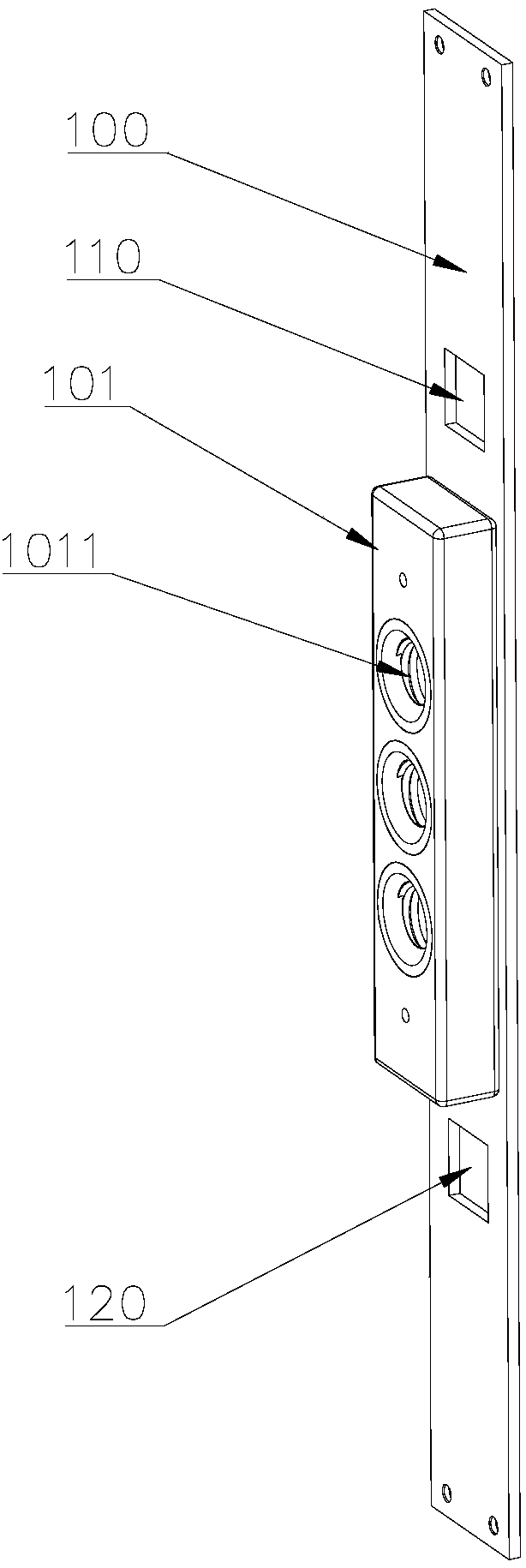

[0029] Such as figure 1 As shown, the present invention provides a preferred embodiment of a lock.

[0030] A lock, the lock includes a lock body 10, and an electric screw mechanism 20 and an electric bolt mechanism 30 arranged on the lock body 10, the electric screw mechanism 20 includes at least one rotating and telescopic penetrating through the lock body 10 The screw rod 21 on the first end surface 12 of the lock body 10, and the first drive assembly 22 that drives the screw rod 21 to rotate and expand. And the second drive assembly 32 that drives the latch tongue 31 to retract.

[0031] Specifically, the lock body 10 includes a housing, and a cavity 11 disposed in the housing. The housing includes a first end face 12 and a second end face 13. on one end surface 12; and, the electric screw rod mechanism 20 and the electric latch ton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com