Drive unit for adjusting vehicle components with magnetic brake

A technology of vehicle components and driving equipment, which is applied in the direction of switches with braking devices, vehicle components, wing leaf components, etc., which can solve the structural space consumption requirements of braking devices, be easily affected by temperature, and brake devices are easy to wear, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

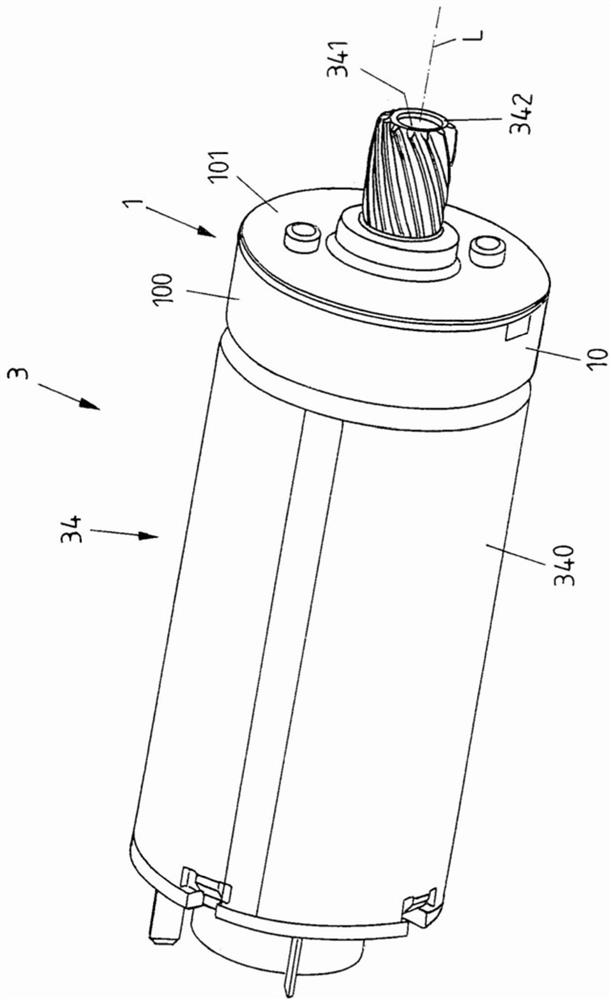

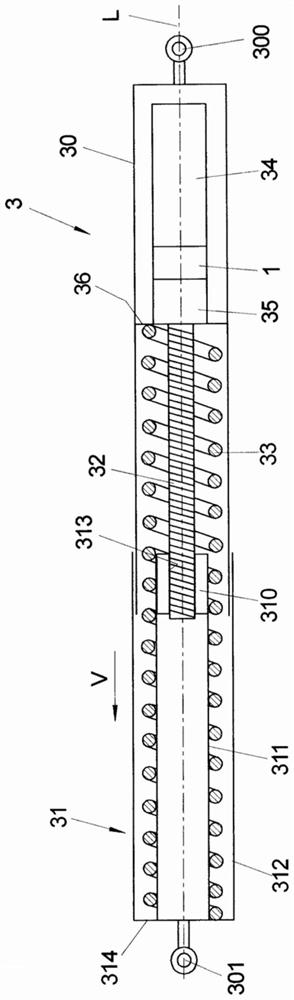

[0052] figure 1 The drive device 3 is shown in perspective, which has an electric drive 34 and a permanent magnet brake 1 . Electric drive 34 is designed as an electric motor and has, in housing 340 , a stator that is fixed relative to housing 340 and a rotor that is rotatable relative to the stator. The rotor is rotatable about a longitudinal axis L and drives a driven shaft 341 on which is arranged a transmission 35 arranged downstream (cf. Figure 3A with 3B ) of the pinion element 342 to adjust the vehicle components.

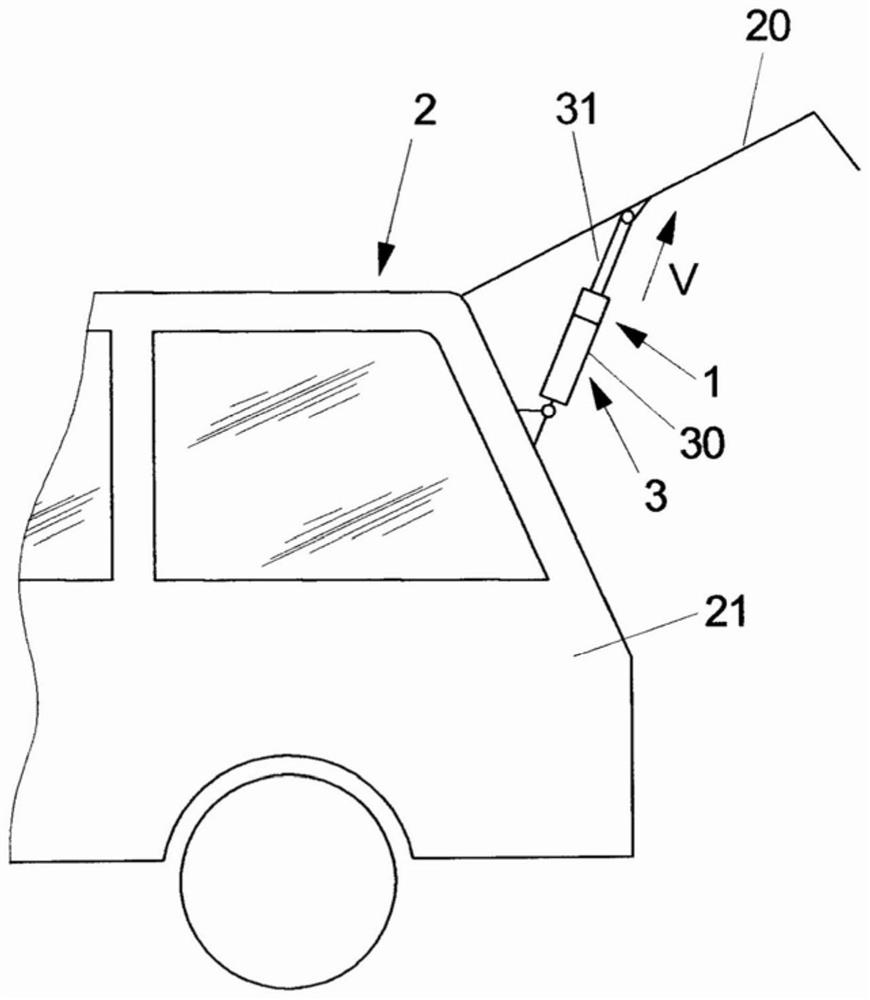

[0053] as from figure 2 As can be seen in FIG. 2 , a drive device 3 of this type is used, for example, to adjust a rear lid 20 of a vehicle 2 . Drive unit 3 acts in a known manner between rear lid 20 and body 21 of vehicle 2 .

[0054] In principle, however, a drive device 3 of the type described here can also be used to adjust completely different types of vehicle components.

[0055] The drive device 3 can be designed, for example, as a screw drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com