Pipe bending device

A technology of a pipe bending device and a column is applied in the field of pipe bending devices, which can solve the problems of reduced processing efficiency, and achieve the effects of improving efficiency, fast transfer speed, and saving labor and labor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

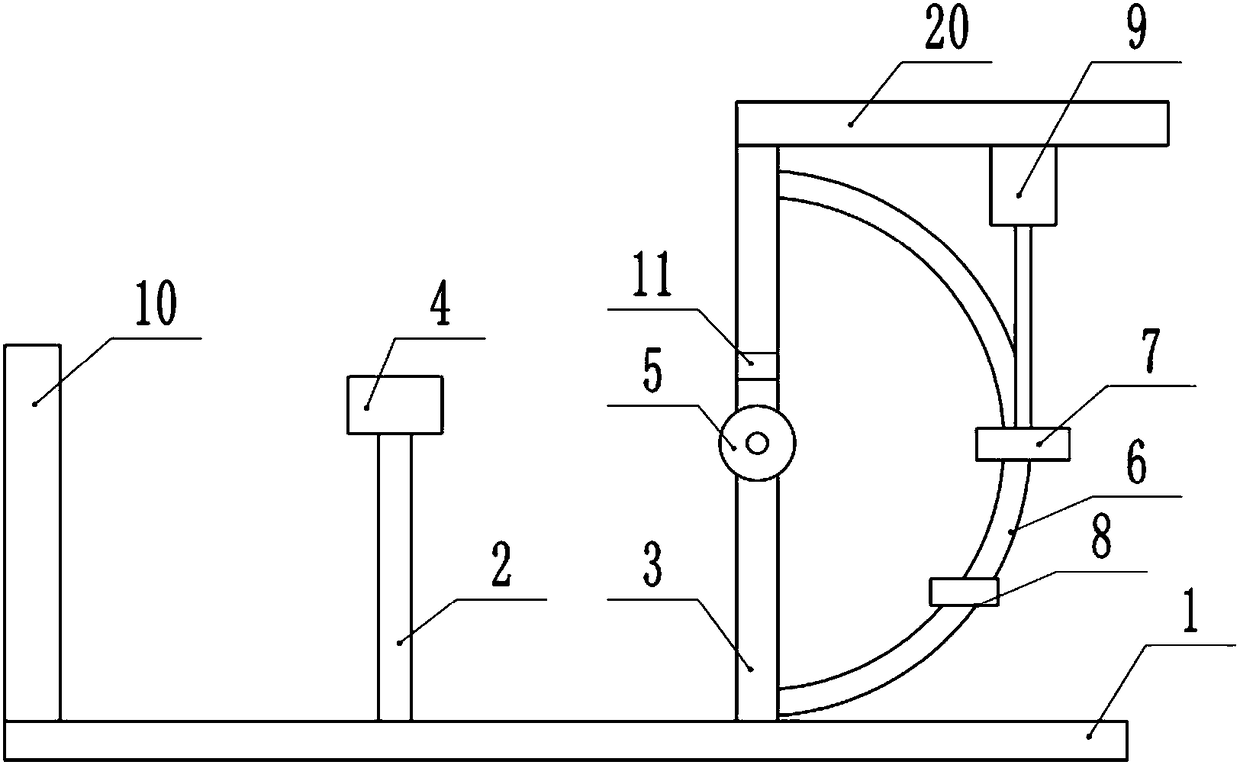

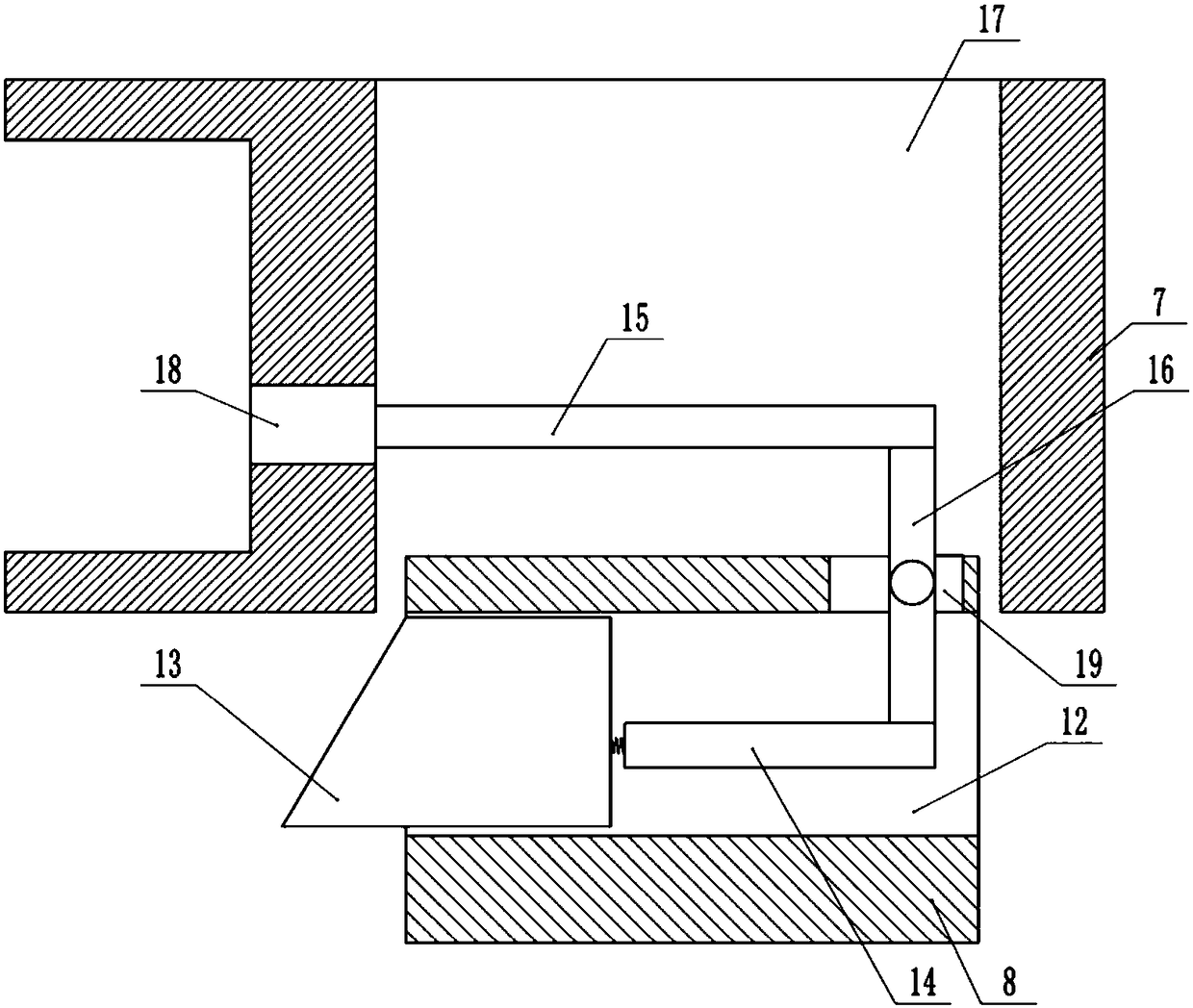

[0025] like figure 1 As shown, a pipe bending device includes a base 1, a slide rail is installed on the base 1, a push plate 10 with rollers is installed in the slide rail, and the push plate 10 slides in the slide rail through the rollers and can maintain a vertical state; The middle part of the base 1 is equipped with a support column 2 through bolts, and the upper end of the support column 2 is equipped with a jacket 4 through bolts, and a horizontal transverse groove is opened on the jacket 4; The middle part is equipped with a supporting roller 5, the lower end surface of the transverse groove is on the same horizontal line as the upper end surface of the supporting roller 5, and the middle part of the supporting roller 5 is provided with an annular groove, and an air bag is installed on the inner wall of the groove; the column 3 is also welded There is a scale ring 6, the scale is printed on the dial plate, and a scale groove is provided on the dial plate, and a positio...

Embodiment 2

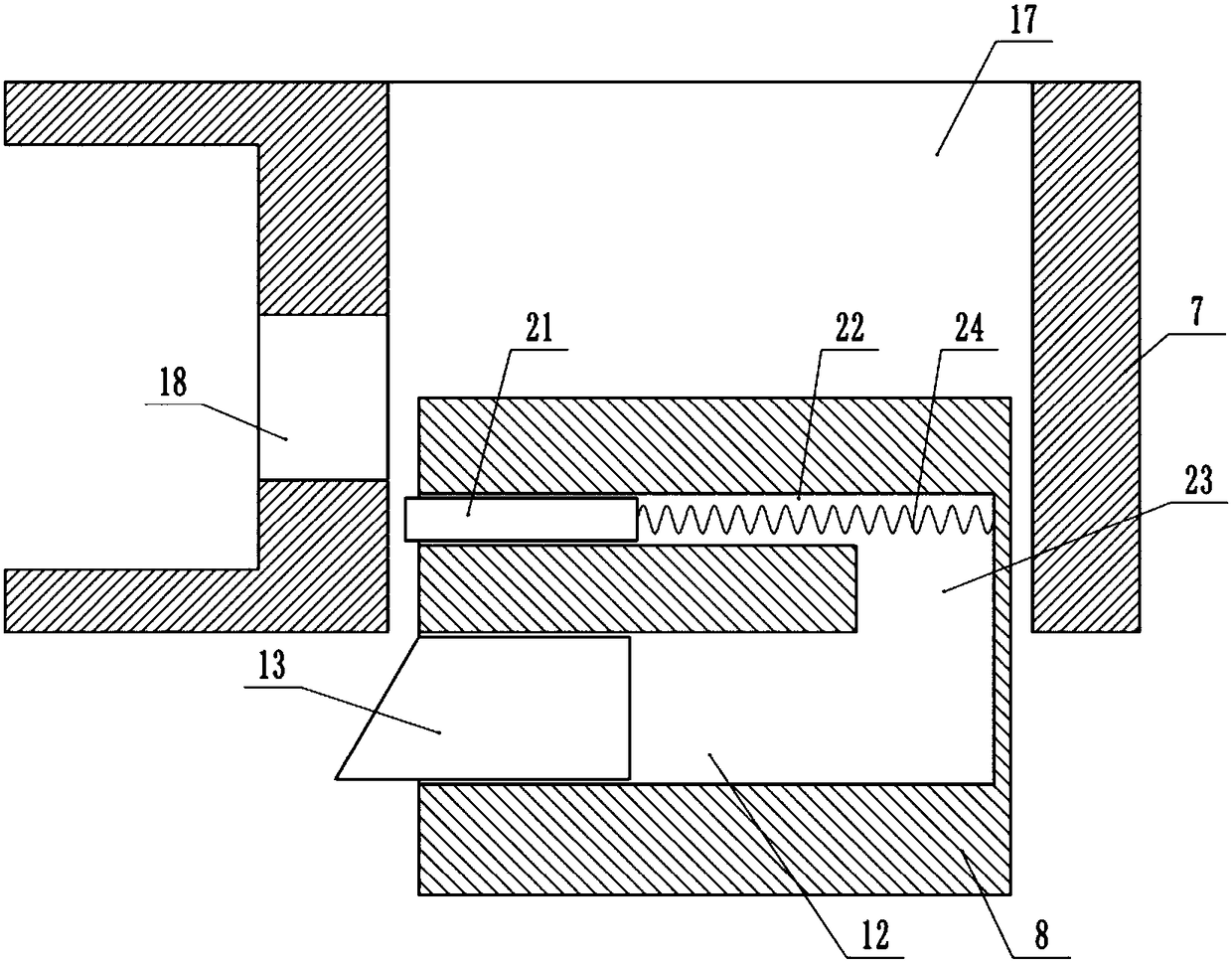

[0028] like image 3As shown, the difference from the bending device in Embodiment 1 is that the push mechanism includes a top block 21 and a horizontal sliding hole 22, the top block 21 slides and is sealed in the sliding hole 22, and the sliding hole 22 is located at the positioning block 8 Above, there is a channel 23 connected between the sliding hole 22 and the cavity structure 12, and a second spring 24 is connected between the inner wall of the channel 23 and the top block 21; When it is flush with the left end face of the positioning block 8, the telescopic block 13 abuts against the limit part; when the ferrule 7 pushes the telescopic block 13 to move into the cavity structure 12, the telescopic block 13 pushes the air in the cavity structure 12 to move, Air movement pushes the top block 21 through the through hole 18 to push the steel pipe away from the ferrule 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com