Suture and suture needle assembly

A suture thread and suture needle technology, applied in the field of medical devices, can solve the problems of cumbersome and time-consuming operation, unsatisfactory, long time interval, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

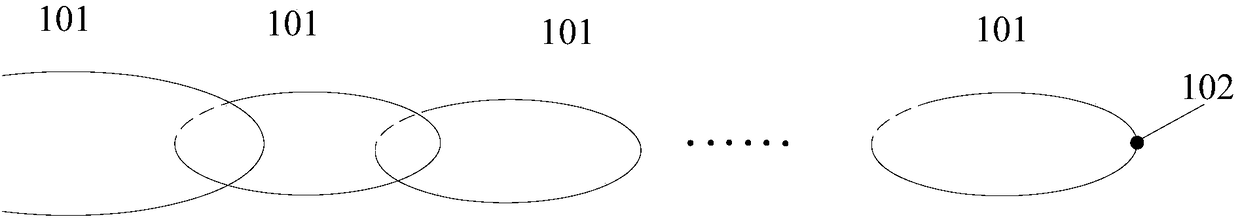

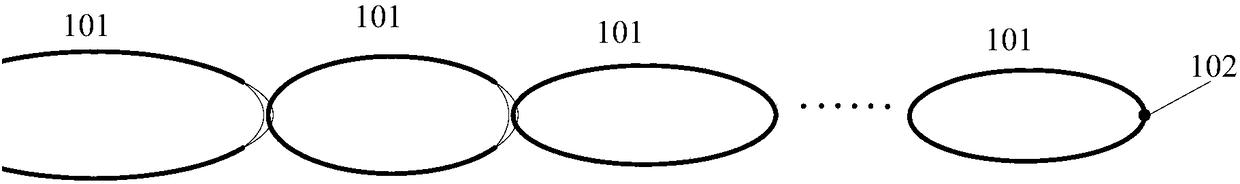

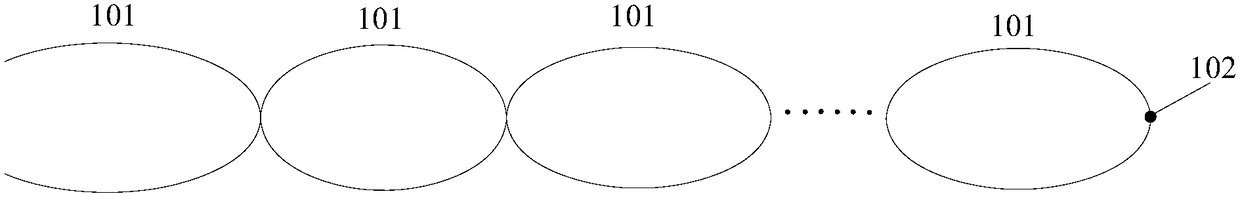

[0023] The embodiment of the present invention provides a suture, please refer to figure 1 , the suture 10 provided by the embodiment of the present invention is used to be connected with a suture needle, and the suture 10 includes: along the direction away from the suture needle (specifically, figure 1 In the direction from left to right) there are at least two suture units 101 connected in sequence, and the suture unit 101 closest to the suture needle (the leftmost suture unit 101) is connected to the suture needle, specifically a suture unit with an opening For circular sutures, the two ends of the opening are connected with suture needles; the remaining suture units 101 are closed circular sutures.

[0024] When suturing with the suture needle assembly provided by the embodiment of the present invention, the first suture can be performed with the circular suture 101 furthest away from the suture needle, and the circular suture 101 can be cut off after the needle operatio...

Embodiment 2

[0043] The embodiment of the present invention also provides a suture needle assembly, including a suture needle and a suture thread. The head end of the suture thread is installed at the tail end of the suture needle, and the suture thread provided in the above-mentioned embodiment 1 of the present invention is used.

[0044] Combine below Figure 7-10 The connection manner of the suture needle 20 and the suture thread 10 will be described in detail. specifically:

[0045] For the first, see Figure 7 , the circular suture 101 closest to the suture needle 20 is a circular suture 101 with an opening, and both ends 1011 of the opening are inserted into the concave needle hole 201 at the tail of the suture needle 20 .

[0046] For the second, see Figure 8 , the circular suture 101 closest to the suture needle 20 passes through the needle hole 202 protruding from the tail end of the suture needle 20 through the connecting thread 103 and is fixed by knotting.

[0047] For the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com