Connecting rod experimental device for simulating rotor rub-impact faults

A technology for simulating rotors and test devices, applied in the field of test devices and connecting rod test devices for simulating rotor rubbing faults, can solve problems such as reducing reliability and stability, economic losses, and inability to achieve local surface contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

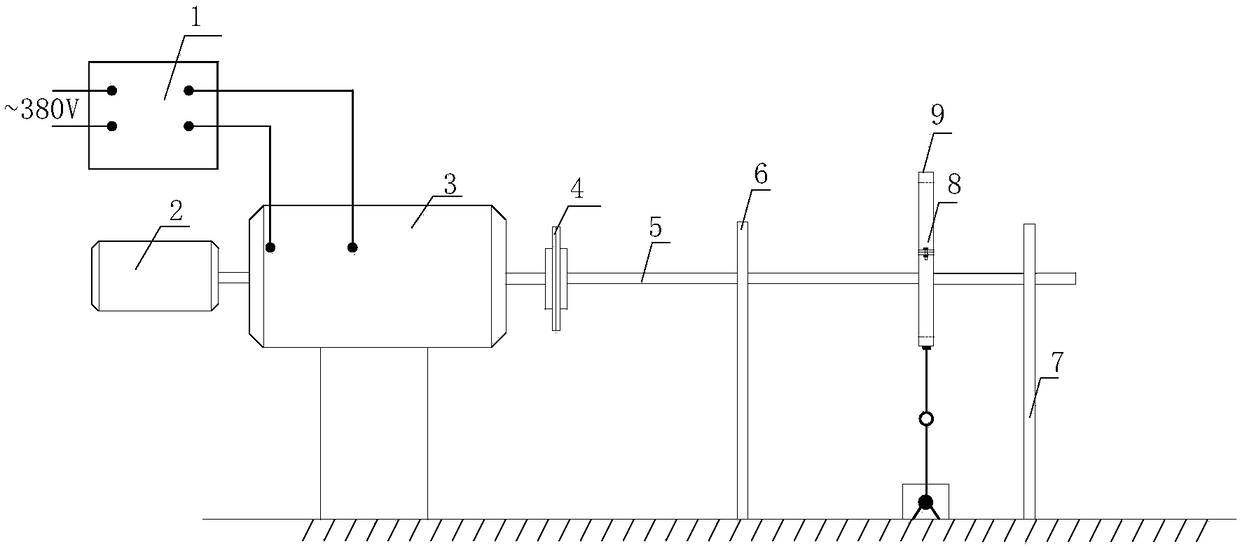

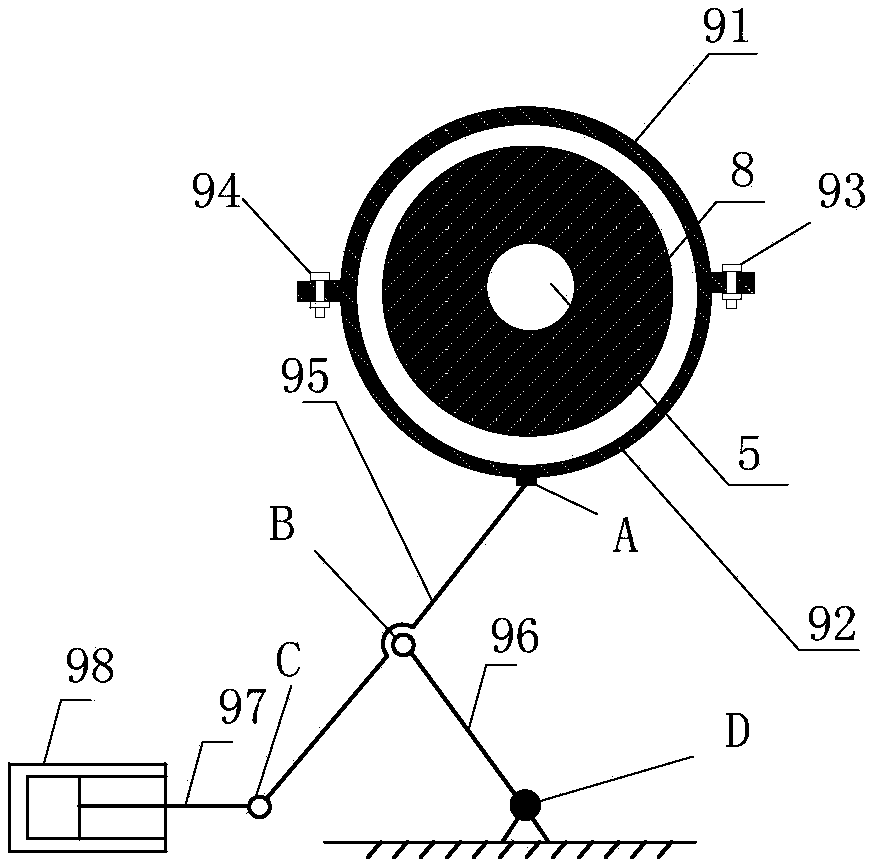

[0015] Such as figure 1 and figure 2 As shown, a connecting rod test device for simulating a rotor friction failure according to the present invention includes a control cabinet 1, a speed measuring motor 2, a DC motor 3, a rotating shaft 5, a first bearing seat 6, a second bearing seat 7, and a turntable 8 And connecting rod rubbing device 9;

[0016] The DC motor 3 and the connecting rod rubbing device 9 are all fixed on the working platform, and the center line of the DC motor 3 and the connecting rod rubbing device 7 are on the same straight line, the speed measuring motor 2 is installed on the DC motor 3, and the DC motor 3 is electrically connected to the control cabinet 1, the output end of the DC motor 3 is connected to one end of the rotating shaft 5, and the other end of the rotating shaft 5 passes through the first bearing seat 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com