Monitoring method of mold cooling pipeline

A technology for cooling pipes and mold cooling, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as complex cooling systems, increased processing, and poor cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A monitoring method for a mold cooling pipeline, the principle of which is:

[0024] S1, pass a cooling liquid of a specific pressure to the inlet of the cooling pipe of the mold to be monitored;

[0025] S2, obtain the detected flow value of the cooling liquid at the outlet of the cooling pipe of the mold to be monitored within a specified time;

[0026] S3, repeat the above-mentioned steps S1 and S2 at least once to obtain several detected flow values, and average each detected flow value as the monitored flow value;

[0027] S4, by comparing the monitored flow rate value and the standard flow rate value, it is judged whether the cooling pipe of the mold to be monitored is qualified.

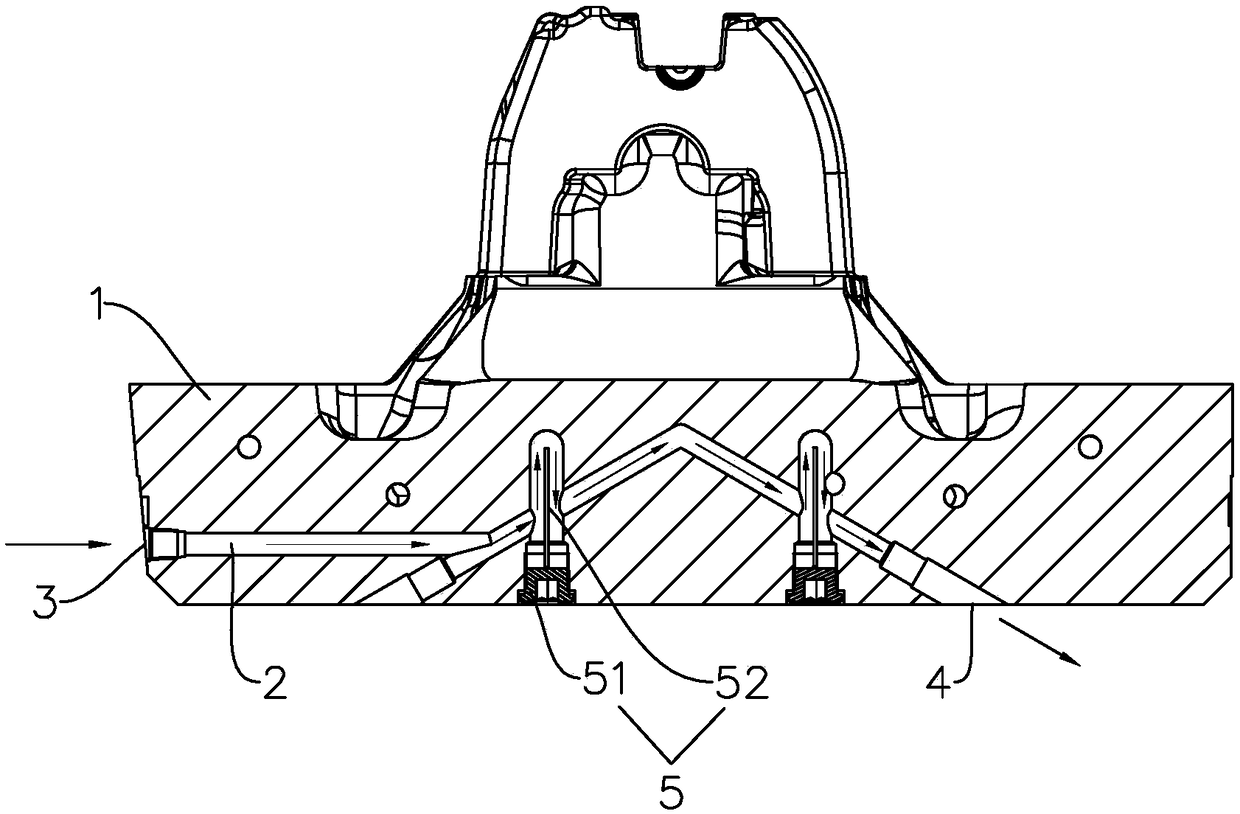

[0028] In an embodiment, refer to figure 1 , shows a lower mold 1, which is arranged with a cooling pipe 2. The cooling pipe 2 is composed of a plurality of cooling water holes arranged in the lower mold 1. Similarly, the diameter of each cold water hole is selected according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com