Method for determining injection start time and injection quantity of fuel

A technology of injection start and fuel injection, applied in fuel injection control, combustion engine, internal combustion piston engine, etc., can solve problems such as complex methods, inaccuracies, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

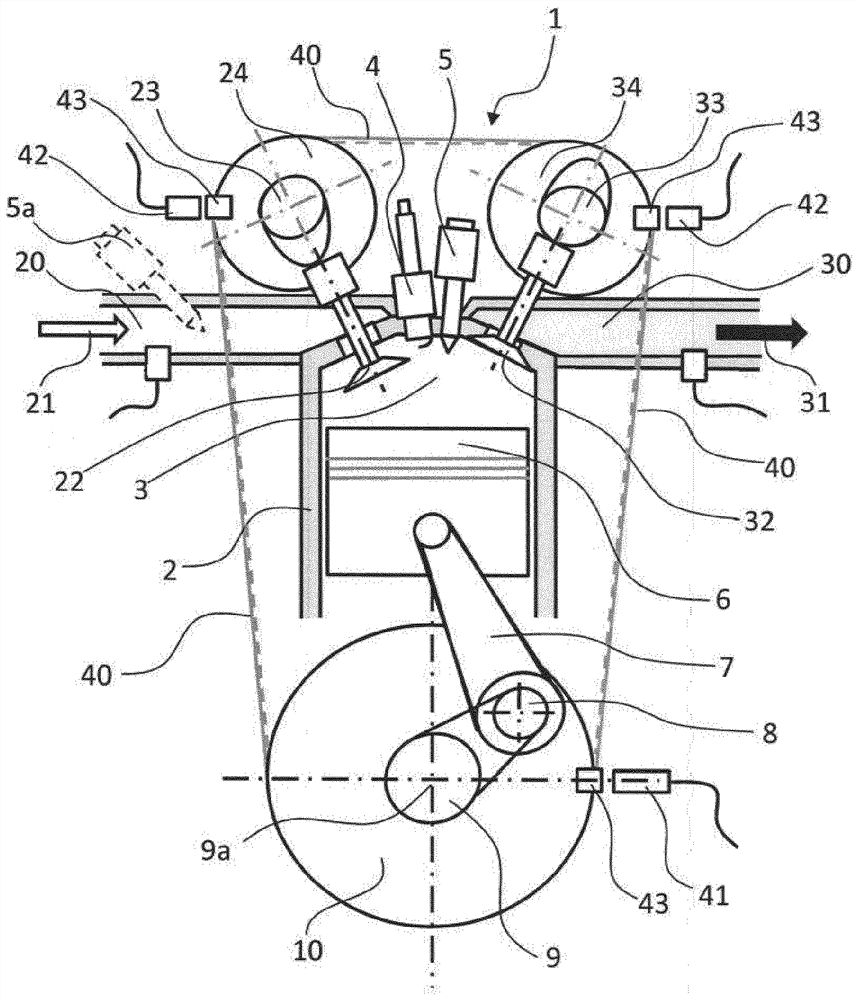

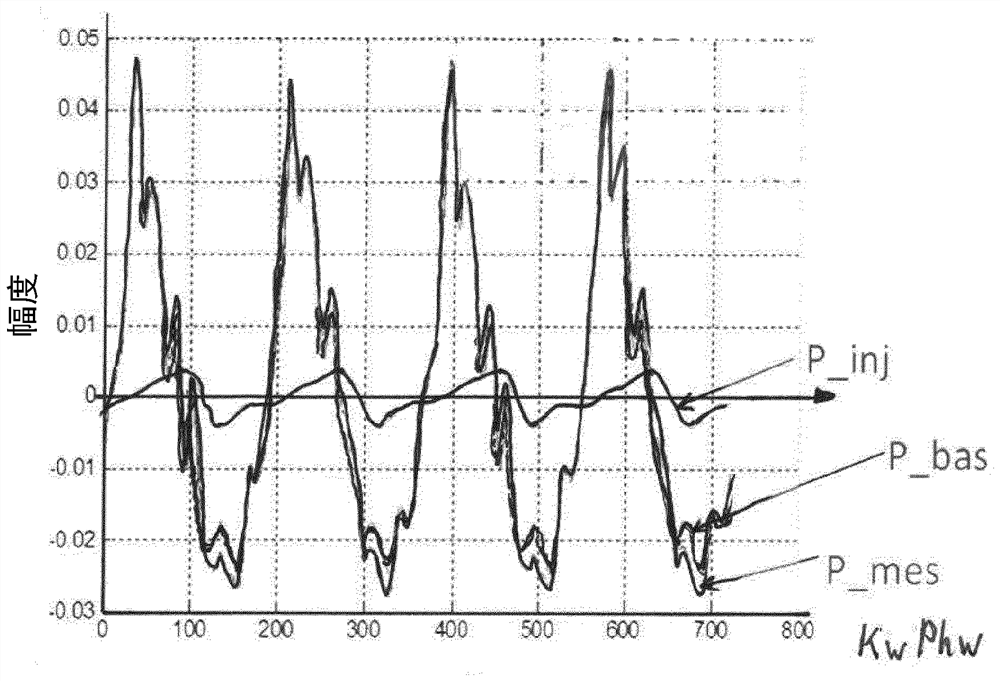

[0029] The invention is based on the insight that, on the assumption of intake-synchronized fuel injection, there is a unique relationship between the distribution of the intake manifold pressure oscillation signal and the injection start time and also the injection quantity of the fuel in the intake tract of an internal combustion engine.

[0030] In the method according to the invention, during normal operation, during intake-synchronized fuel injection, first at defined operating points, the cylinders assignable to the internal combustion engine in the inlet tract of the respective internal combustion engine are measured The dynamic pressure oscillation, and thus generate the corresponding pressure oscillation signal. At the same time, a crankshaft phase angle signal of the internal combustion engine is determined, so to speak, as a reference signal.

[0031] One possible operating point would be eg idle operation at a predetermined rotational speed. Here, intake-synchroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com