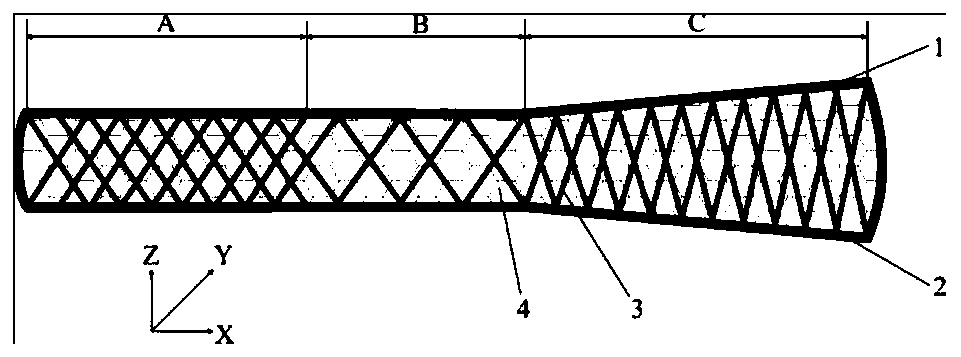

A kind of weft-knitted spacer fabric and its preparation method, and polyurethane foam composite material comprising the fabric

A technology of spacer fabrics and composite materials, applied in the directions of weft knitting, chemical instruments and methods, knitting, etc., can solve the problems of limited range, separation damage, poor bearing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

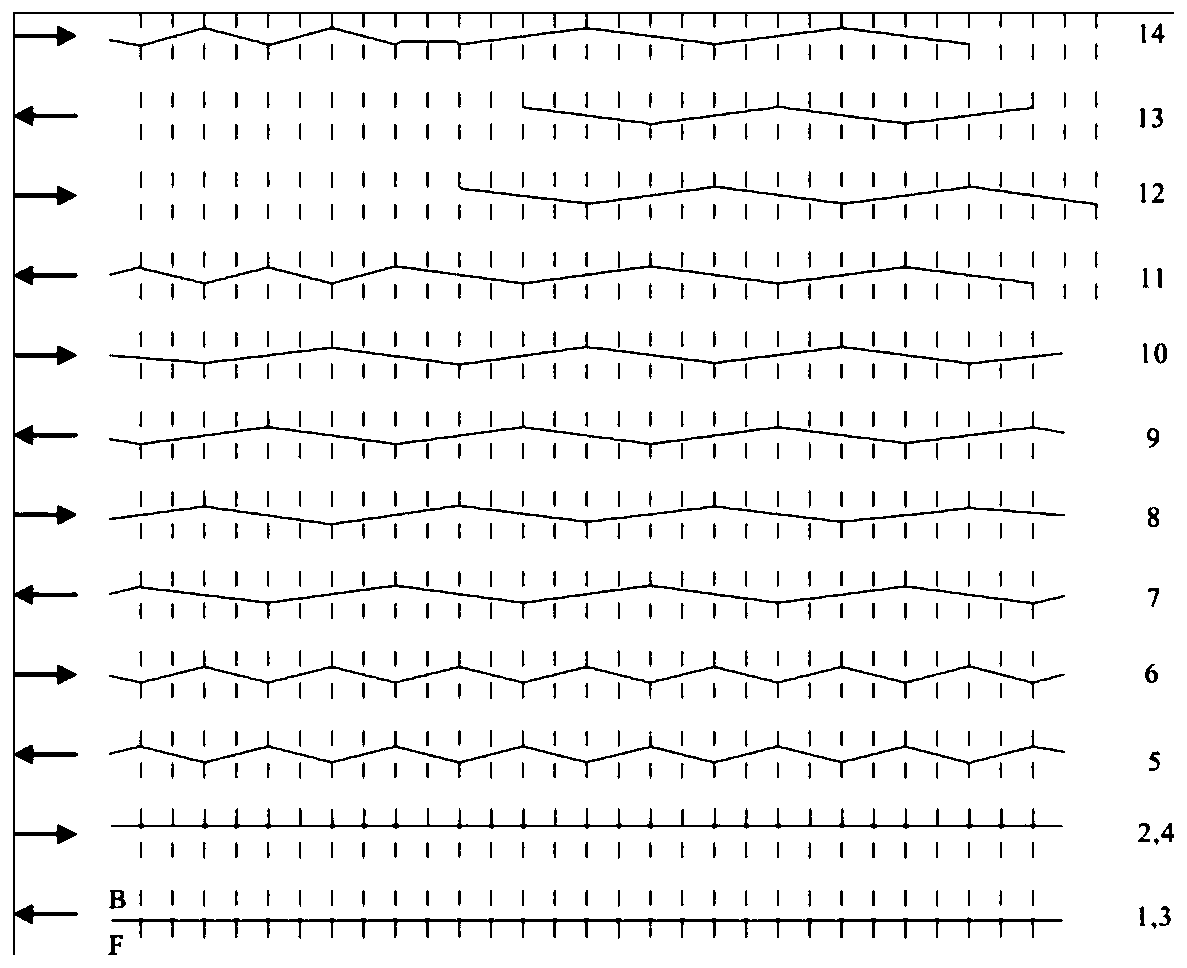

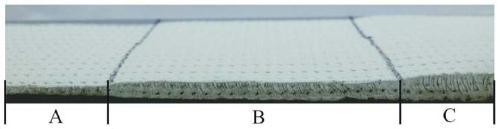

Method used

Image

Examples

Embodiment Construction

[0095] 1. Measurement method

[0096] During the experiments, the toughness, density, hardness and mechanical properties of the weft-knitted spacer fabric reinforced PU composites were measured.

[0097] The density of the weft-knitted spacer fabric reinforced PU composite was measured from the top layer to the bottom layer by using a DPX300LTE density analyzer. According to the test standard, a sample with a size of 5cm (length) x 5cm (width) x 1cm (thickness) should be prepared, then placed in the chamber and scanned by X-rays. Thus, a density profile is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com