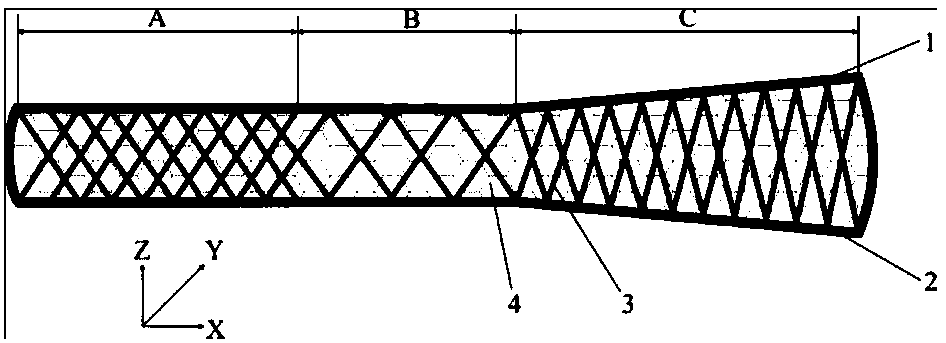

Weft-knitted spacer fabric, preparation method thereof and polyurethane foam composite material containing fabric

A polyurethane foam and spacer fabric technology, applied in weft knitting, chemical instruments and methods, knitting, etc., can solve the problems of separation damage, poor load-bearing performance, limited range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

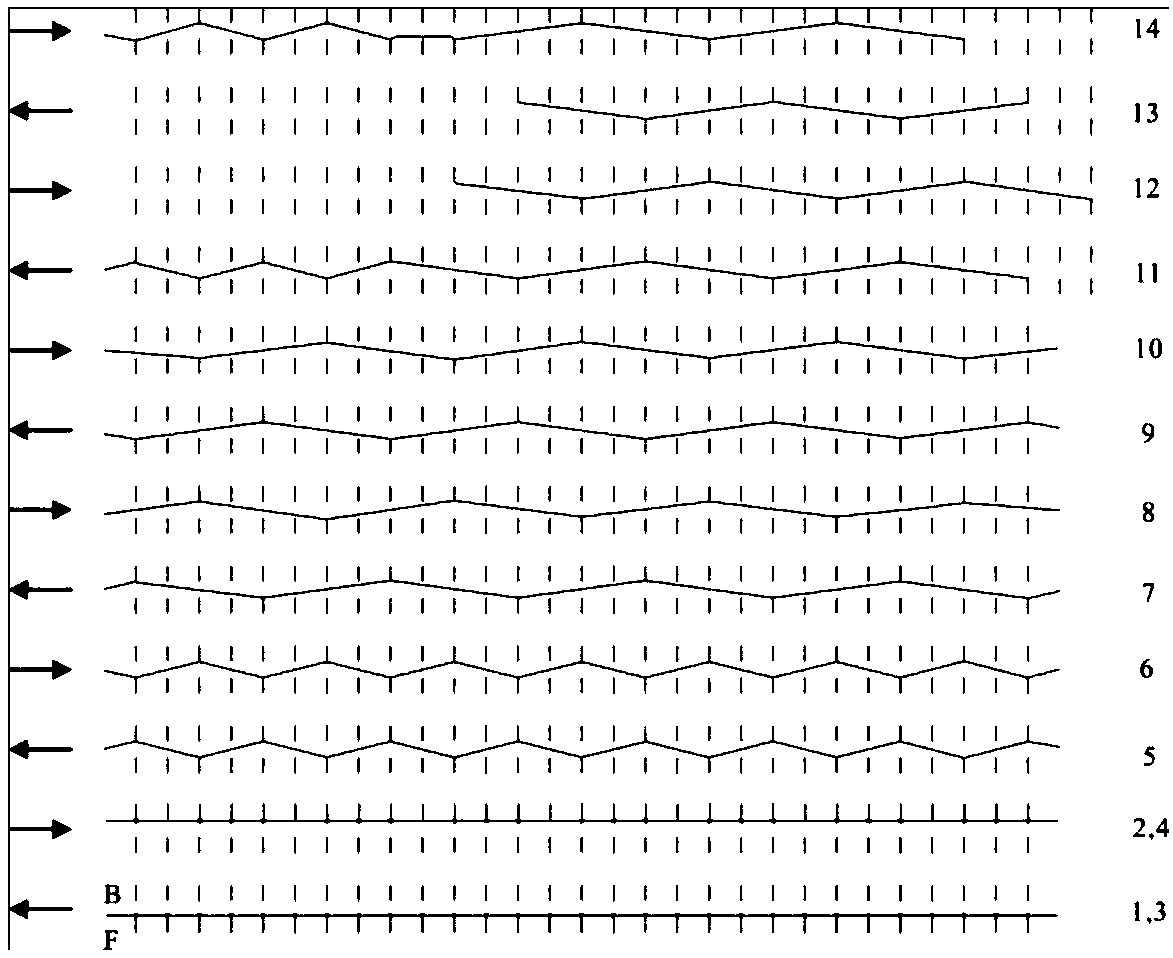

Method used

Image

Examples

Embodiment Construction

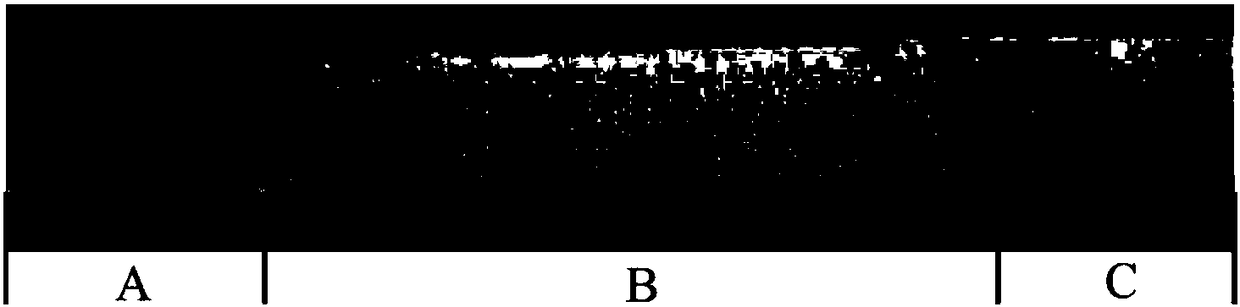

[0095] 1. Measurement method

[0096] During the experiments, the toughness, density, hardness and mechanical properties of the weft-knitted spacer fabric reinforced PU composites were measured.

[0097] The density of the weft-knitted spacer fabric reinforced PU composite was measured from the top layer to the bottom layer by using a DPX300LTE density analyzer. According to the test standard, a sample with a size of 5cm (length) x 5cm (width) x 1cm (thickness) should be prepared, then placed in the chamber and scanned by X-rays. Thus, a density profile is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com