Chassis device for motor vehicle

A technology for motor vehicles and chassis, which is applied to vehicle components, transportation and packaging, and substructures, etc. It can solve problems such as limiting the deformation freedom of longitudinal members, and achieve the effect of improving deformation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In the different drawings, the same parts are always given the same reference numbers, which is why they are usually only described once.

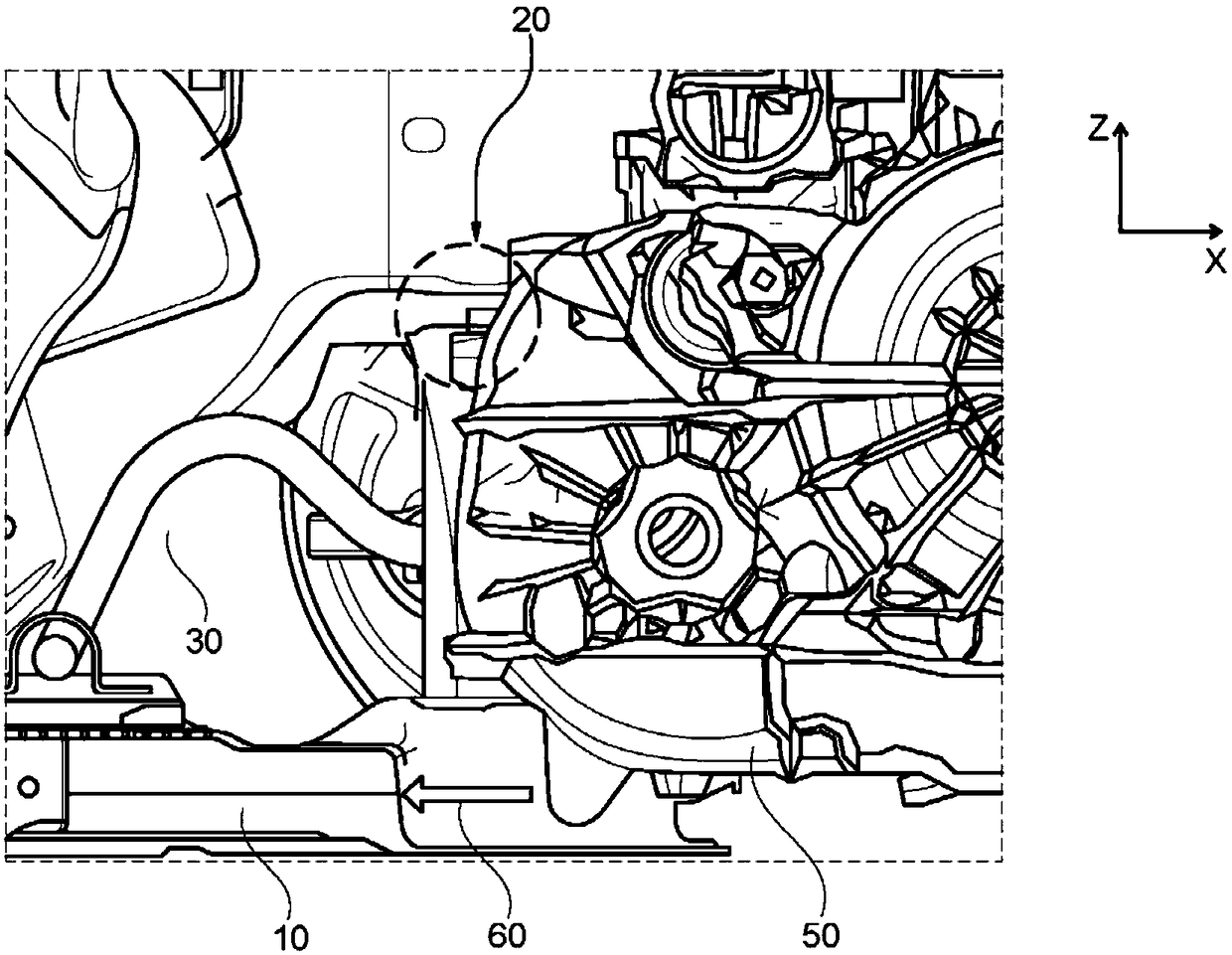

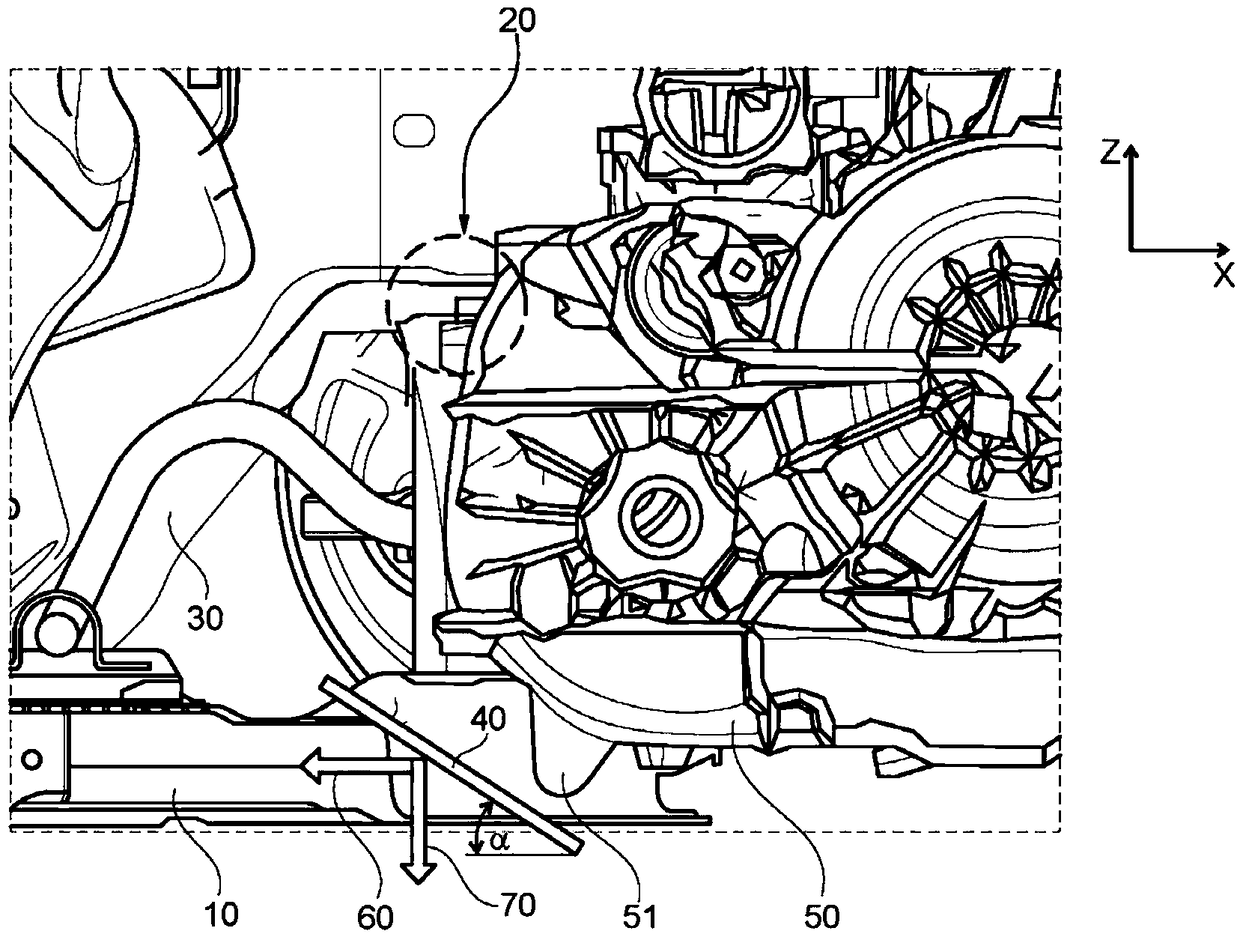

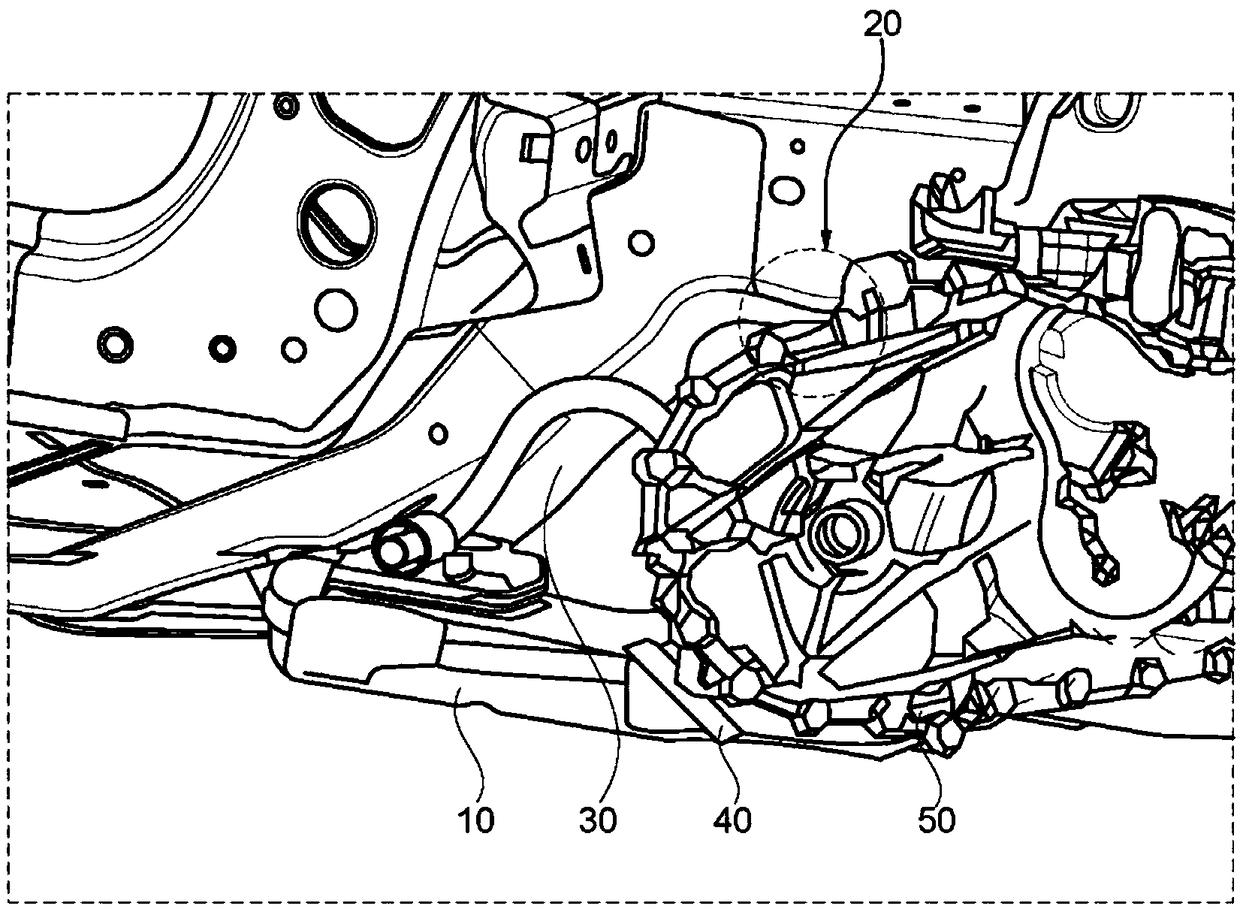

[0031] Such as figure 1 The chassis arrangement shown is preferably located in the front region of the vehicle, not shown, wherein the front of the vehicle is located in the figure 1 on the right side of the . The X-direction extends in the longitudinal direction of the vehicle, while the Z-direction extends vertically through the vehicle. The chassis arrangement has a subframe 11 fastened to the vehicle component. This component is the longitudinal member 30 of the vehicle. The subframe 11 is connected to the longitudinal member 30 via at least one fastening point, not shown in detail. The area of the fastening point is in the figure 1 The circle indicated by the dashed line and the reference numeral 20 in . The subframe 11 is located below this fastening point 20 . Preferably, a plurality of such fastening points are provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap