Conveyor-type grilling appliance for cooking or re-thermalizing food

A technology for reheating and food, applied in the field of conveying grills for cooking or reheating food, which can solve the problems of overcooking, unsatisfactory and delicious final food, undercooking of food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

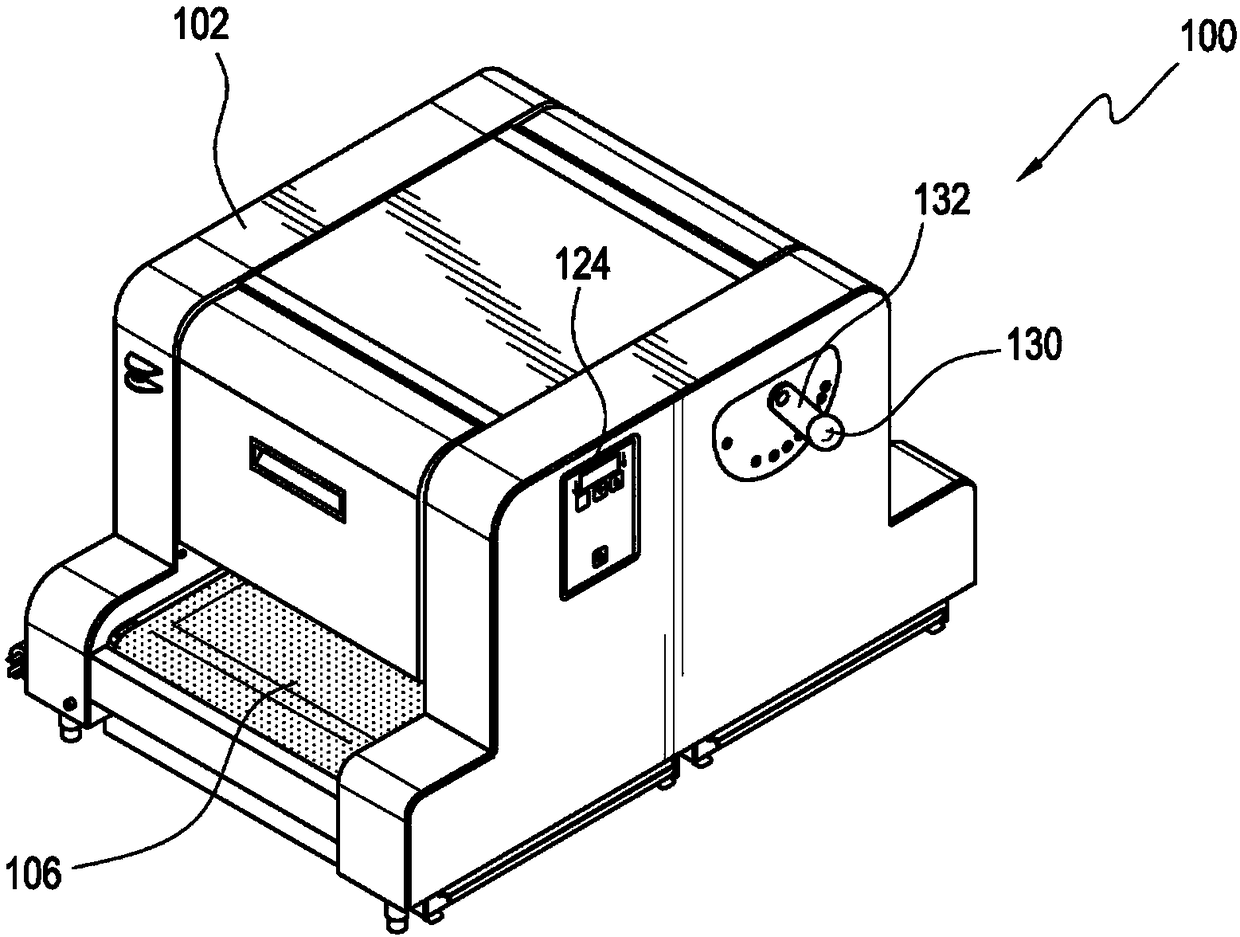

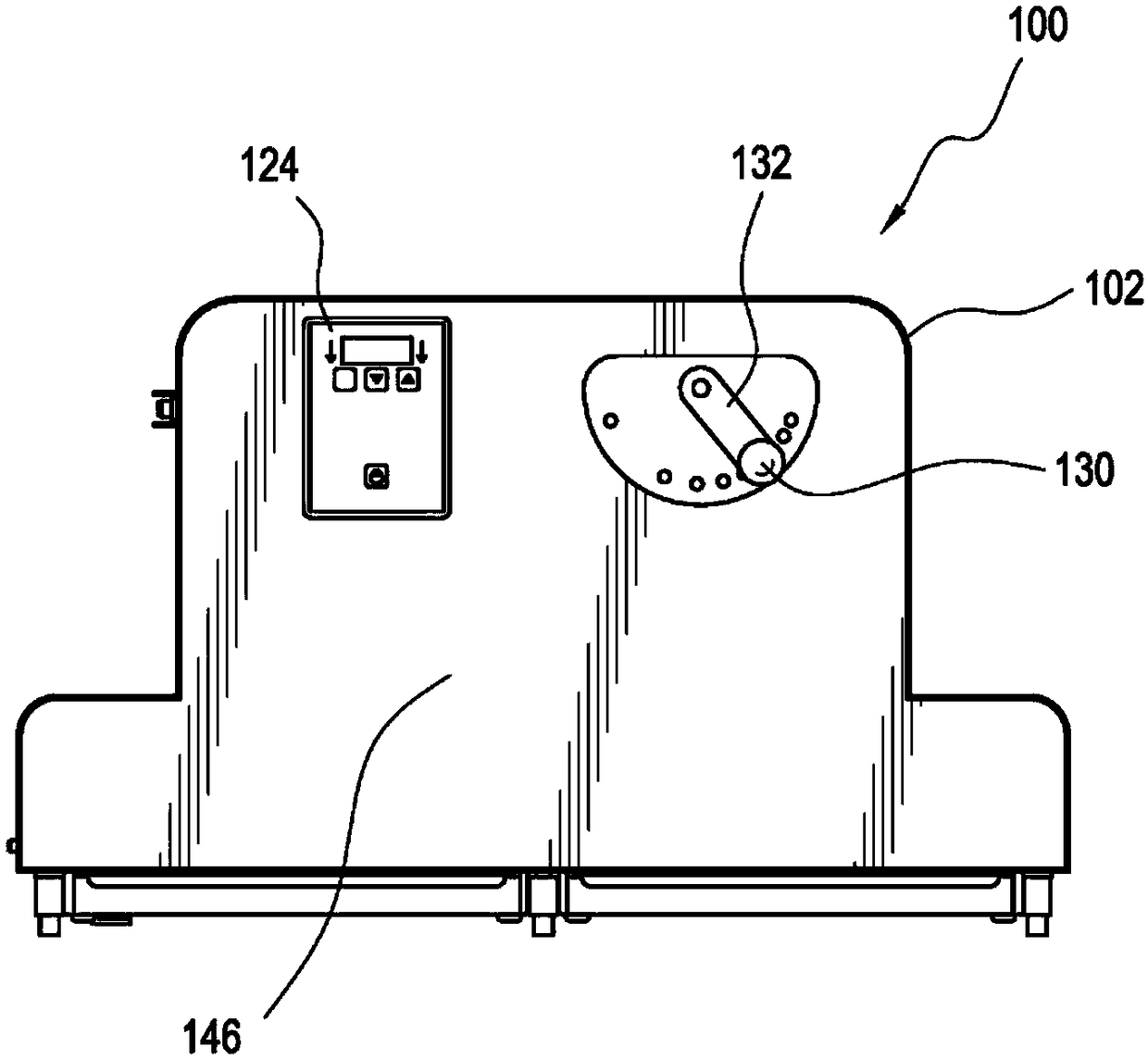

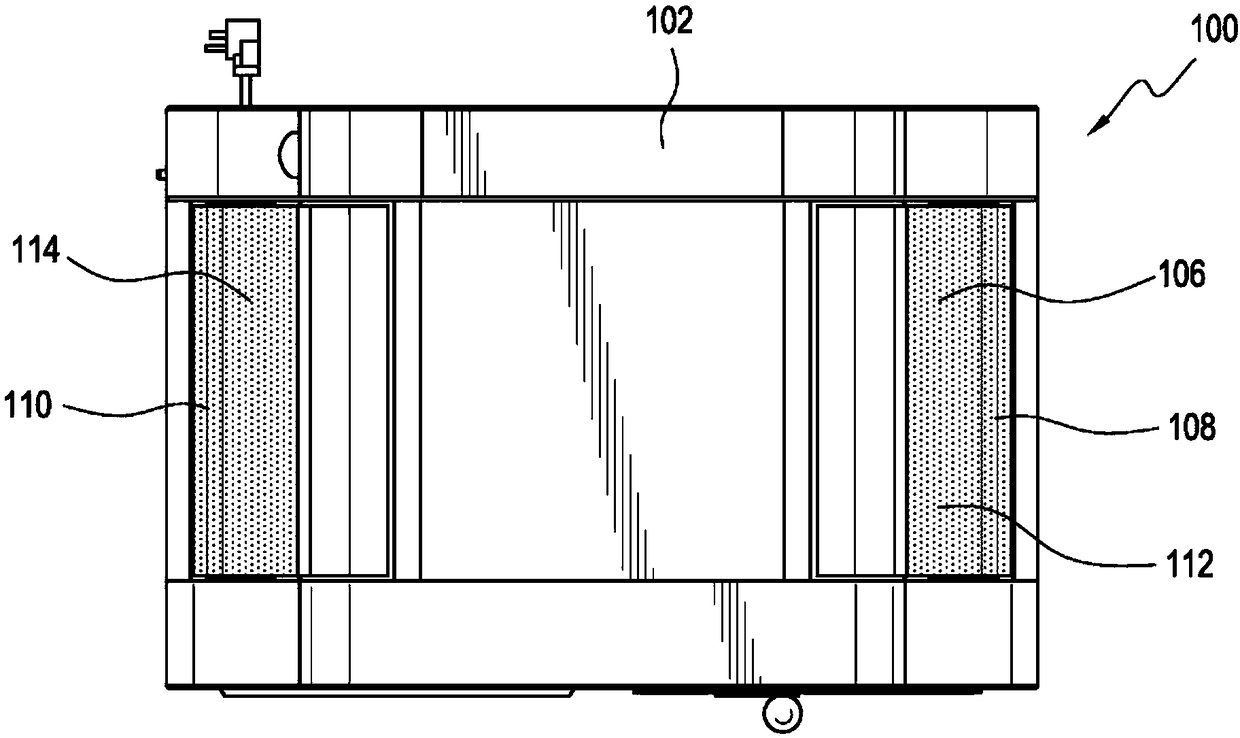

[0025] Referring now to the drawings, and more particularly to the Figure 1-5 , discloses a new and improved conveyor grill for cooking or reheating food and is generally designated by the reference numeral 100. More specifically, it can be seen that the new and improved conveyor grill 100 includes a housing 102 within which a pair of upper and lower conveyor belts 104, 106 are arranged, as can be seen from figure 1 , 3And 4 best realized. The upper and lower conveyor belts 104 , 106 are endless conveyor belts that flow through the housing 102 from the food input or inlet end 108 of the housing 102 to the food output or outlet / discharge end 110 of the housing 102 . The upper conveyor belt 104 is completely enclosed within the housing 102 , while the opposite ends of the lower conveyor belt 106 extend beyond each end of the housing 102 . In this manner, the first moveable platform area 112 of the lower conveyor belt 106 is defined at the food input or entry end 108 of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com