Drum for building and shaping a tyre carcass

A kind of carcass and tire technology, applied in the field of tire manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, a tire in a cylindrical state before forming will be referred to as a carcass, and a tire that has been formed but not cured will be referred to as a green tire. The green tire is thus the result of a shaped and shaped carcass provided with a crown shape.

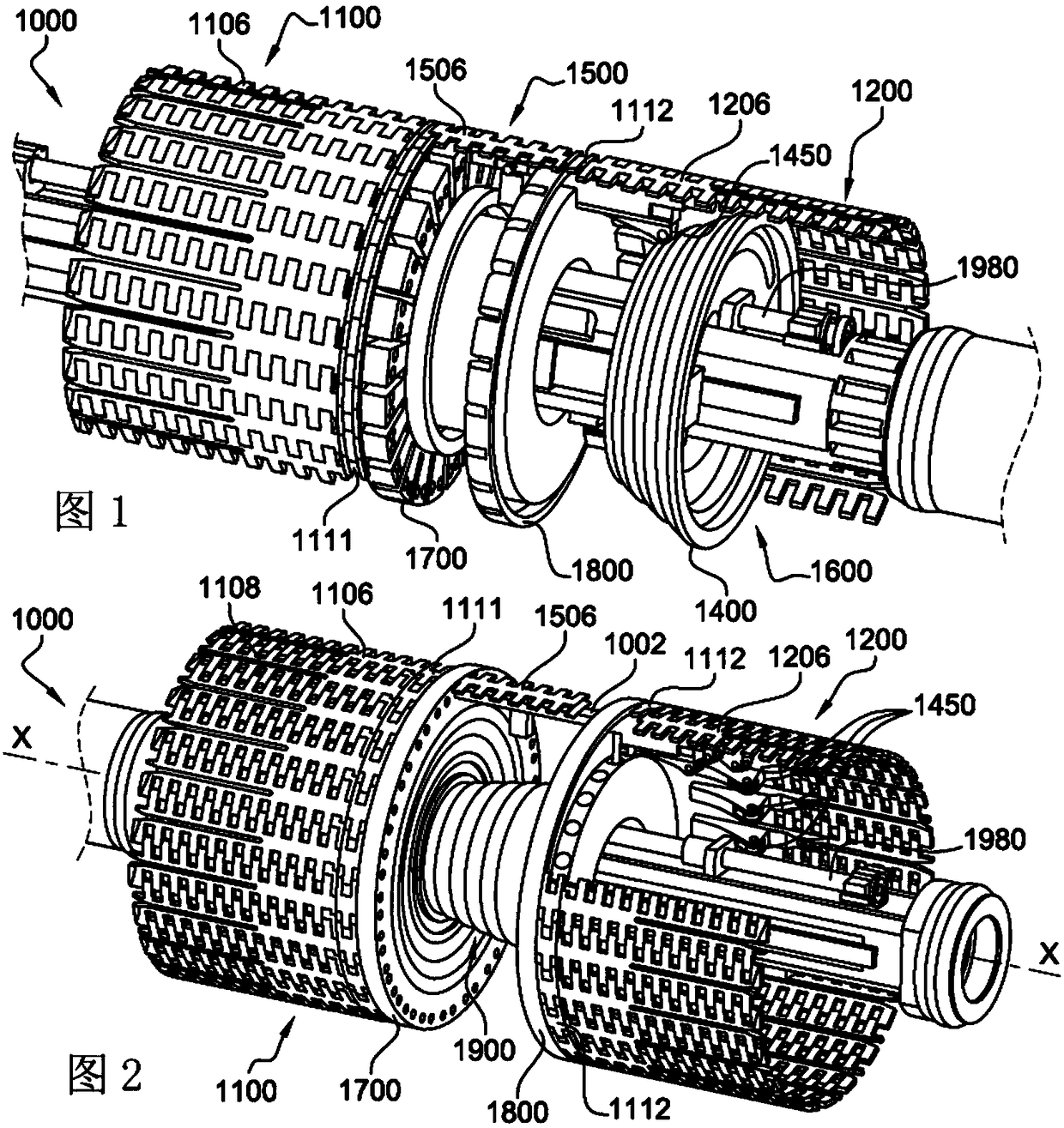

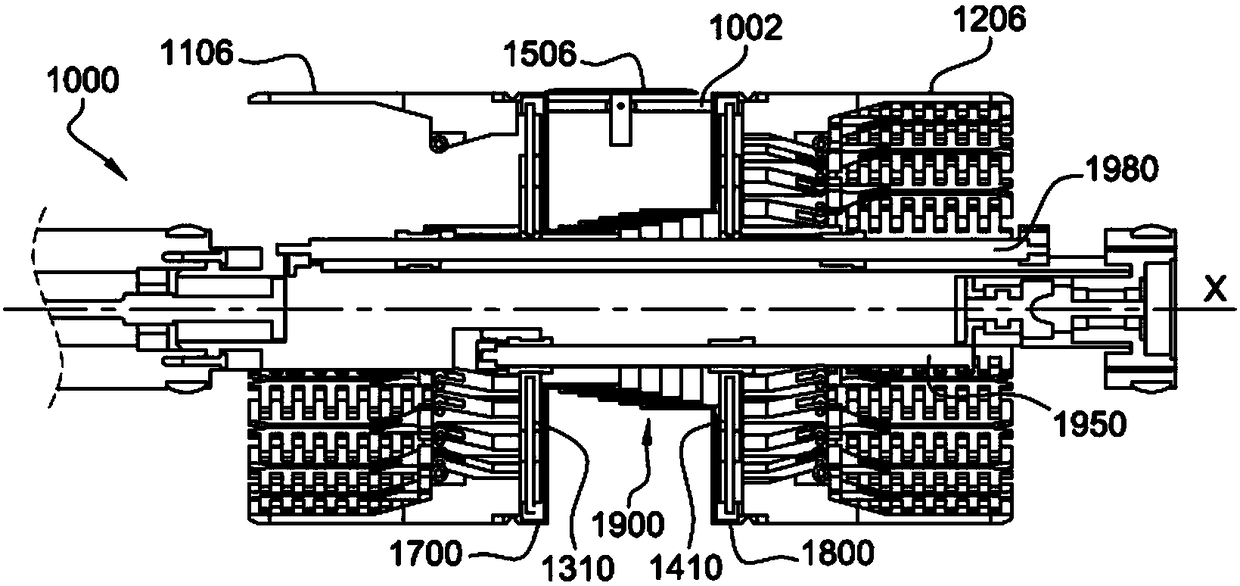

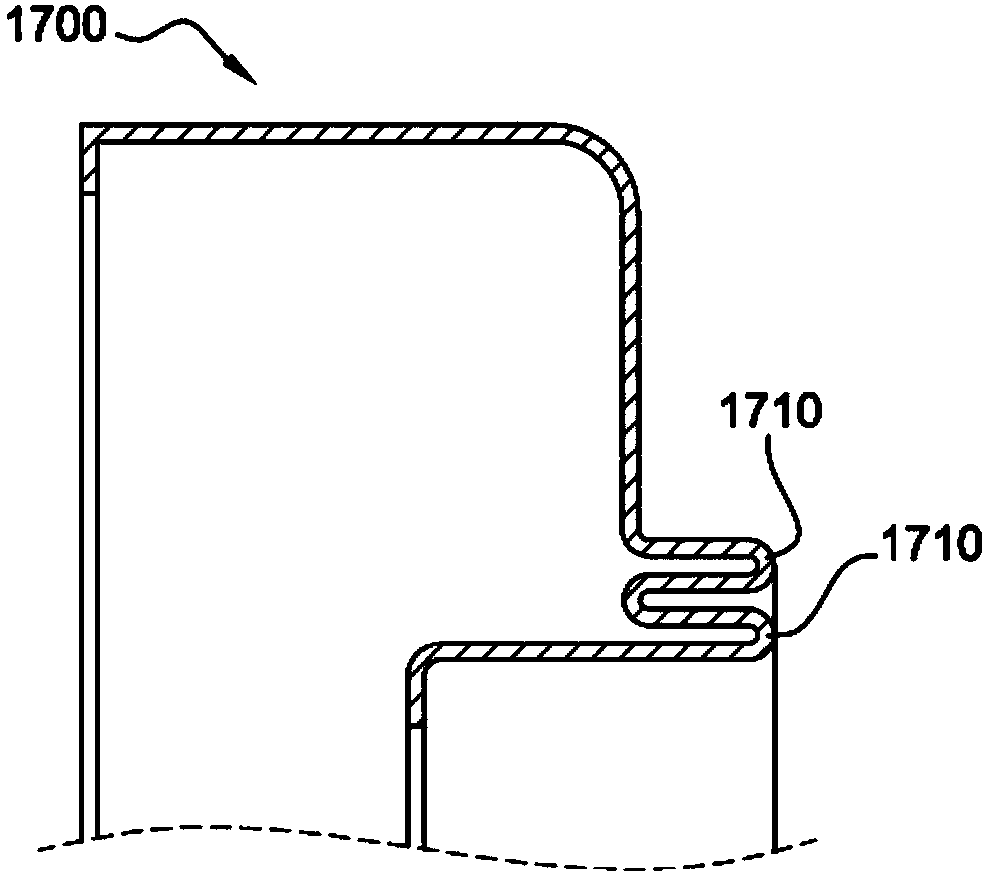

[0036] Figure 1 to Figure 3 A drum 1000 for shaping and shaping a tire carcass according to the invention is shown. It comprises a first kit 1100 of end segments including in particular a segment 1106 and a second kit 1200 including a segment 1200 . refer to figure 2 and image 3 , these segment sets 1100 and 1200 form the end portions of the surface for shaping a tire carcass of overall cylindrical shape having the main axis X of rotation. Each end segment of the first sleeve 1100 is mounted with the ability to move in radial direction relative to the axis X on a first axially movable support 1310 common to the segments of the first sleeve 1100 . image 3 The support 1310 seen in has an overall c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com