Gearbox rear cover bearing high-precision assembling equipment

A technology for assembling equipment and gearboxes, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor willfulness, simple and rough installation of sealing rings, easy to gnaw edges, etc., to achieve a small footprint, The effect of a compact system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

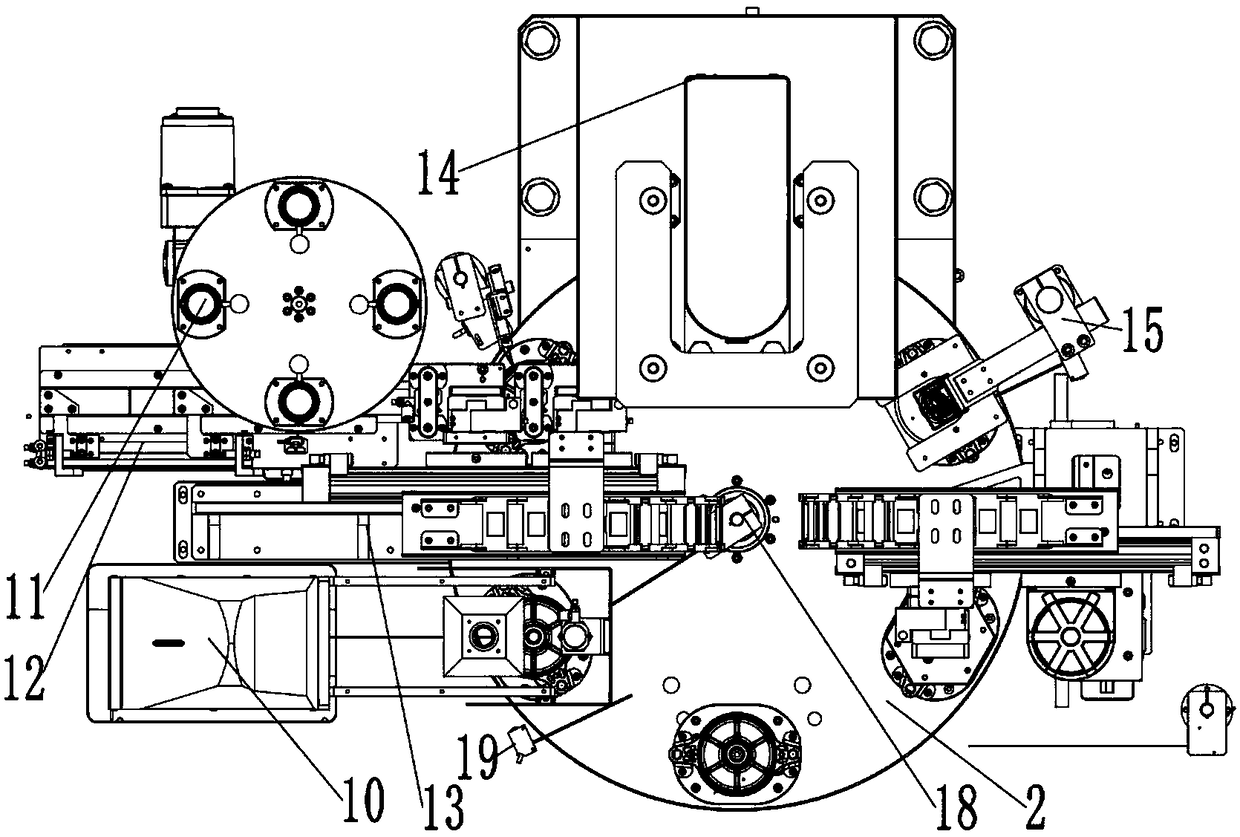

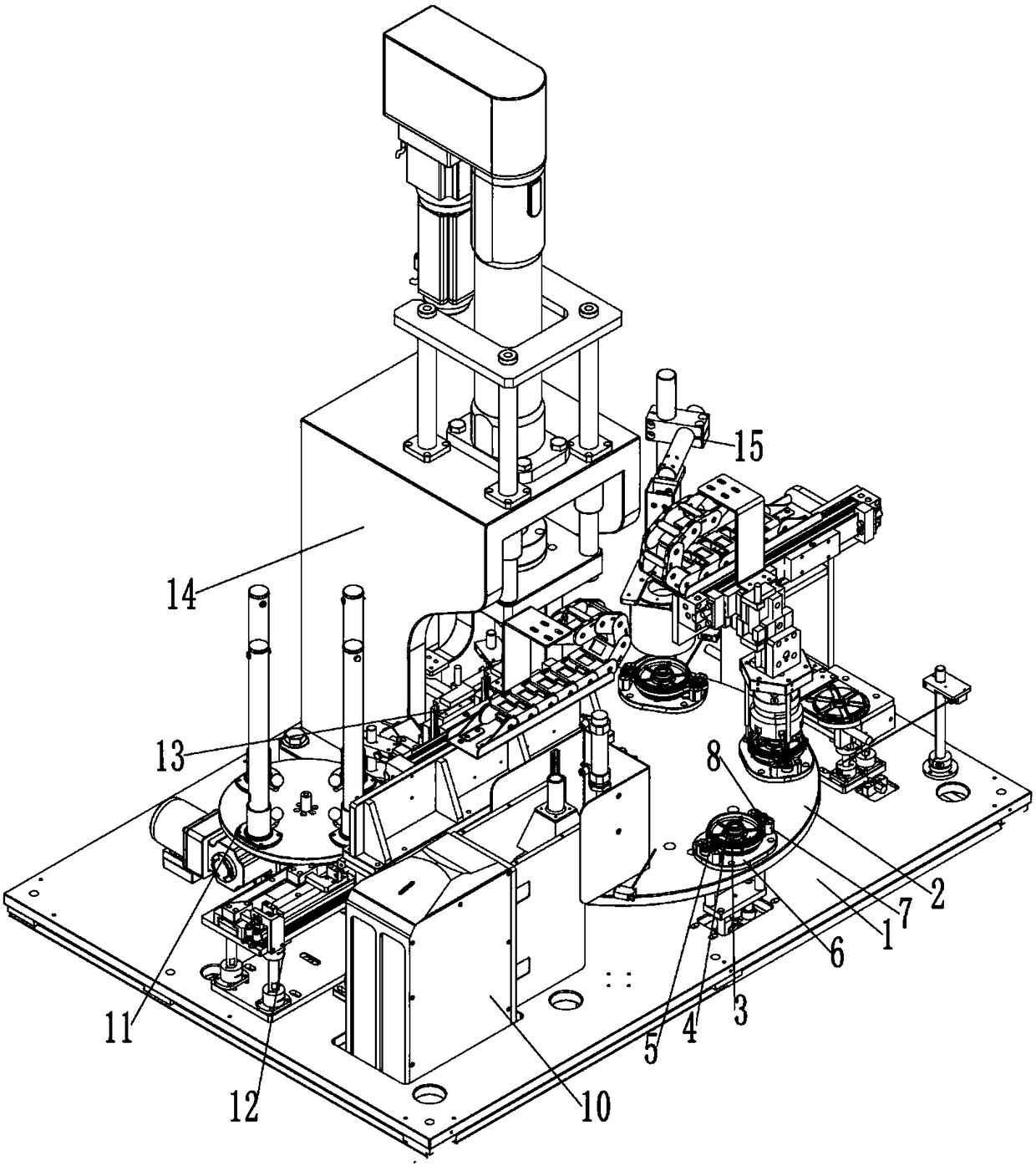

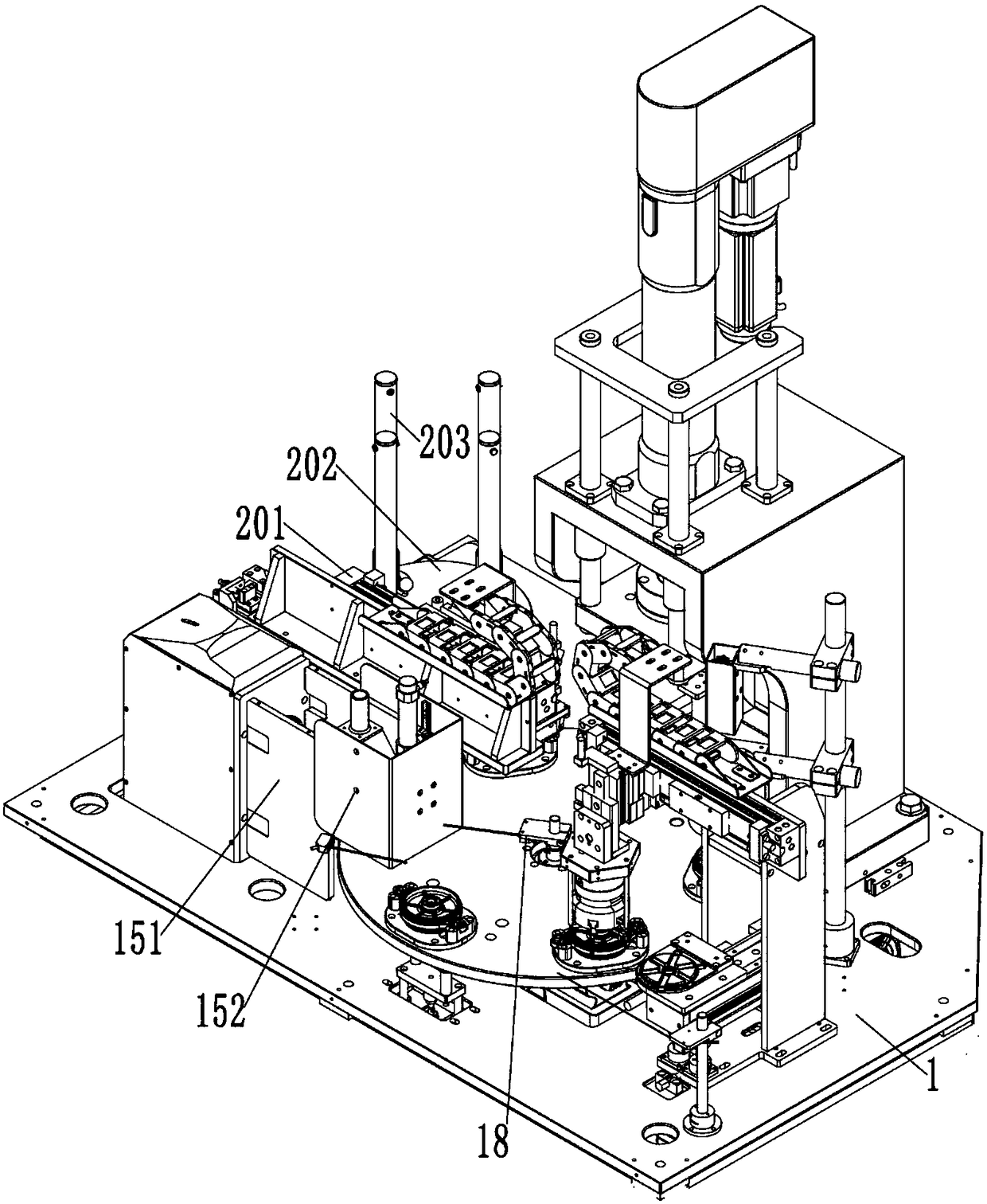

[0041] Such as Figure 1-10 As shown, the transmission back cover bearing high-precision assembly equipment of this embodiment includes a base 1, a rotary station device 2 arranged on the base 1, a protective cover on the base 1, and is arranged on the base 1 and is connected to the base 1. The gearbox rear cover assembly center corresponding to the rotary station device 2;

[0042] The rotary station device 2 includes a station driving motor 102 arranged on the base 1, a station rotating disk 101 which is connected to the station driving motor 102 and rotates on the base 1, and is distributed on the station rotating disk 101 according to the process. The rotary station, the tire part 6 that is arranged at each rotary station and is used to fix the lower end surface of the gearbox cover 3, the U-shaped clamps 7 that are arranged on the symmetrical sides of the upper end surface of the tire part 6, and the setting The V-shaped positioning groove 8 on the U-shaped card seat 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com