Device for carrying light composite wallboards

A technology of composite wall panels and handling equipment, which is applied in the direction of transportation and packaging, multi-axis trolleys, trolleys, etc., which can solve the problems of wall panels sliding back and forth, slipping, and uneven moving speed of transport panels, so as to improve stability and improve use convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

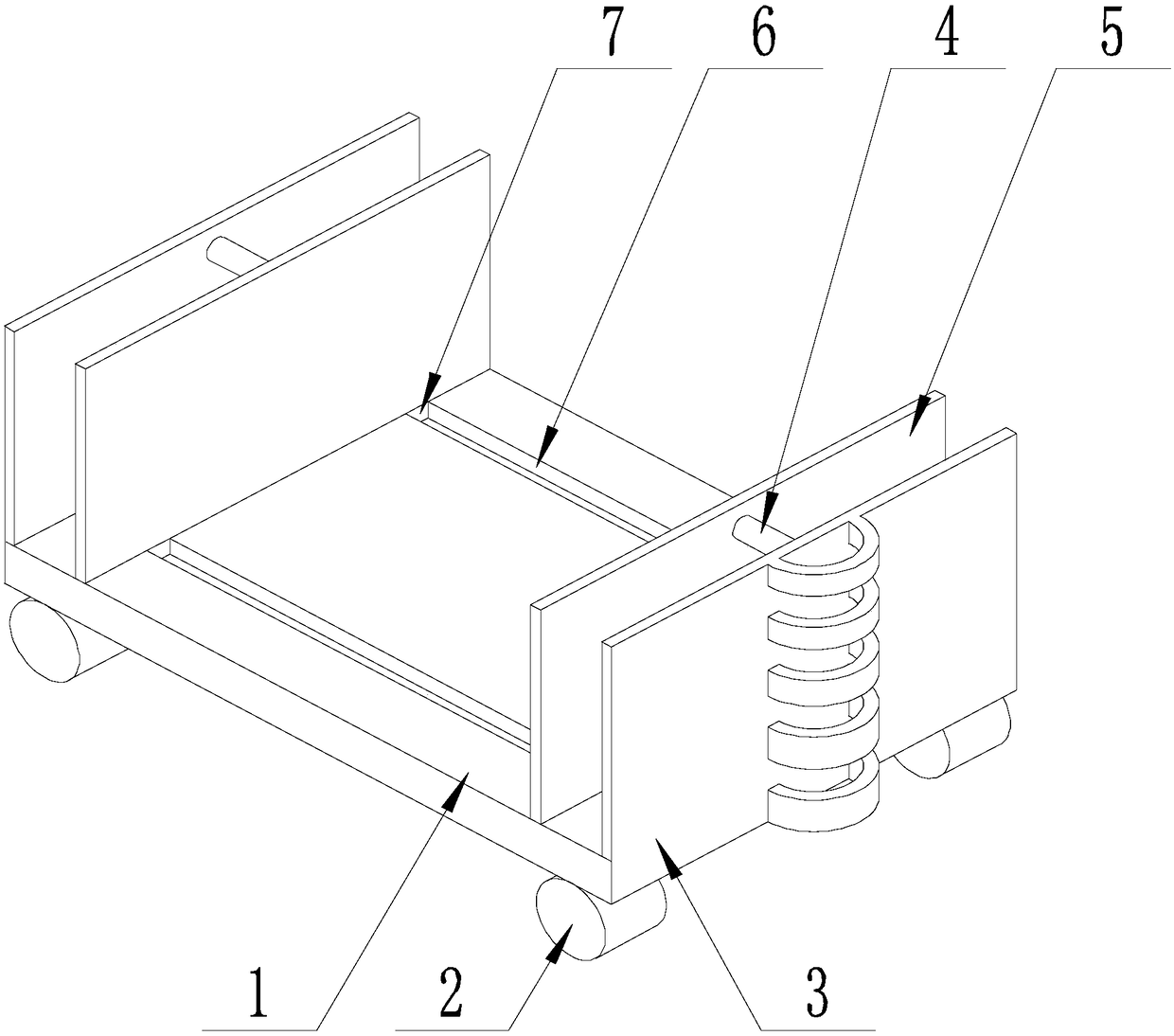

[0032] Such as figure 1 As shown, the handling equipment for lightweight composite wallboards of the present invention includes sequentially connected rollers 2 and transportation boards 1, on the upper surface of the transportation board 1, one end close to the advancing direction of the rollers 2 and one end away from the advancing direction of the rollers 2 Limiting plates 3 are all arranged, and the limiting plates 3 are perpendicular to the advancing direction of the rollers 2, and several shock absorbing springs 4 are arranged on the opposite surfaces of the limiting plates 3, and the telescopic direction of the shock absorbing springs 4 Parallel to the advancing direction of the roller 2, and on the shock absorbing spring 4, a moving plate 5 is provided at one end away from the corresponding limit plate 3, and the shock absorbing spring 4 is compressed so that the limit plate 3 can be moved along the upper surface of the transport plate 1. move.

[0033] Preferably, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com