Novel hoop

A new type of hoop technology, applied in the direction of connecting components, mechanical equipment, friction-clamped detachable fasteners, etc., can solve the problems of increased cost and unfavorable on-site use, and achieves reduced carrying weight, convenient use, and improved on-site performance. The effect of management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

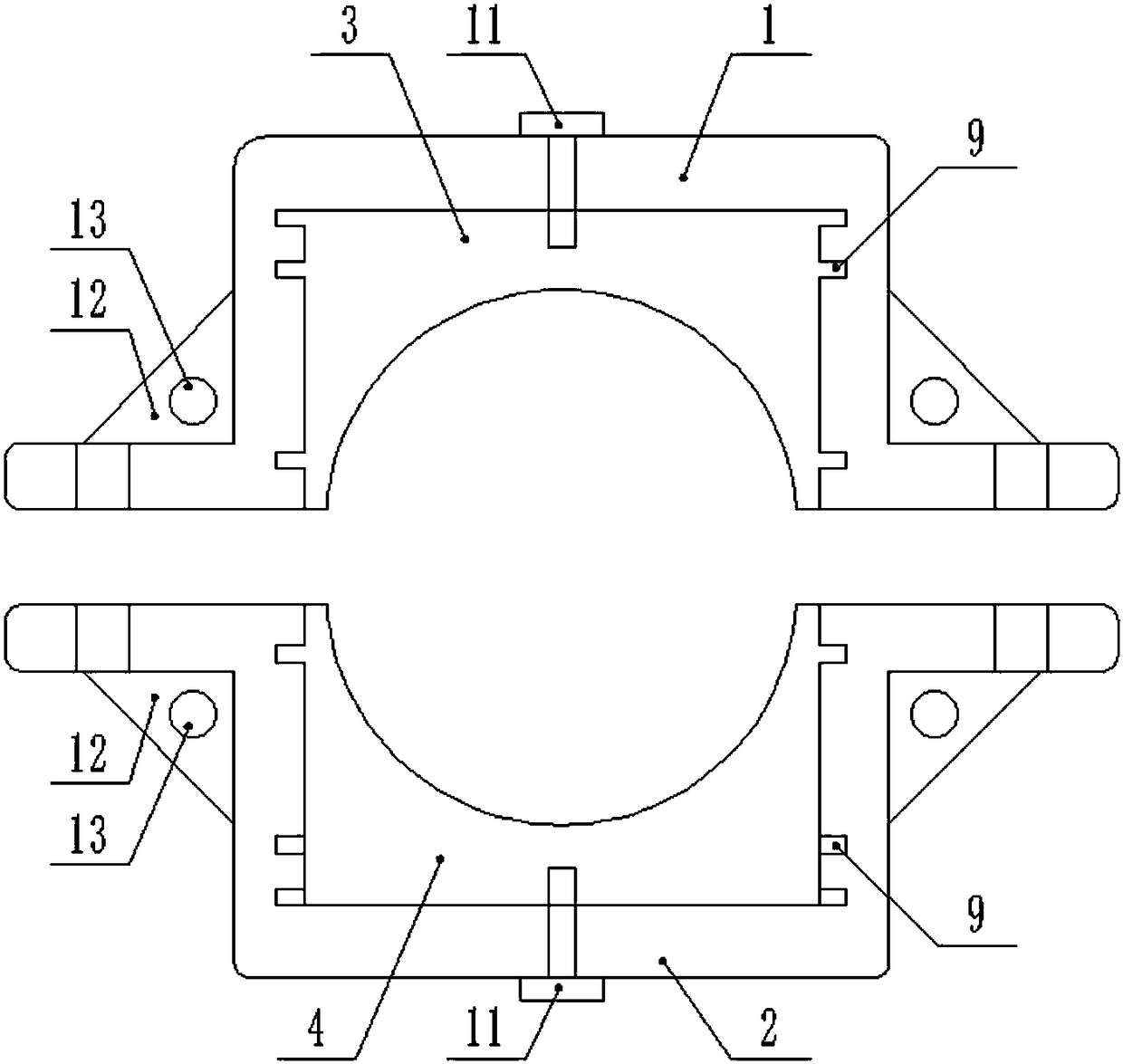

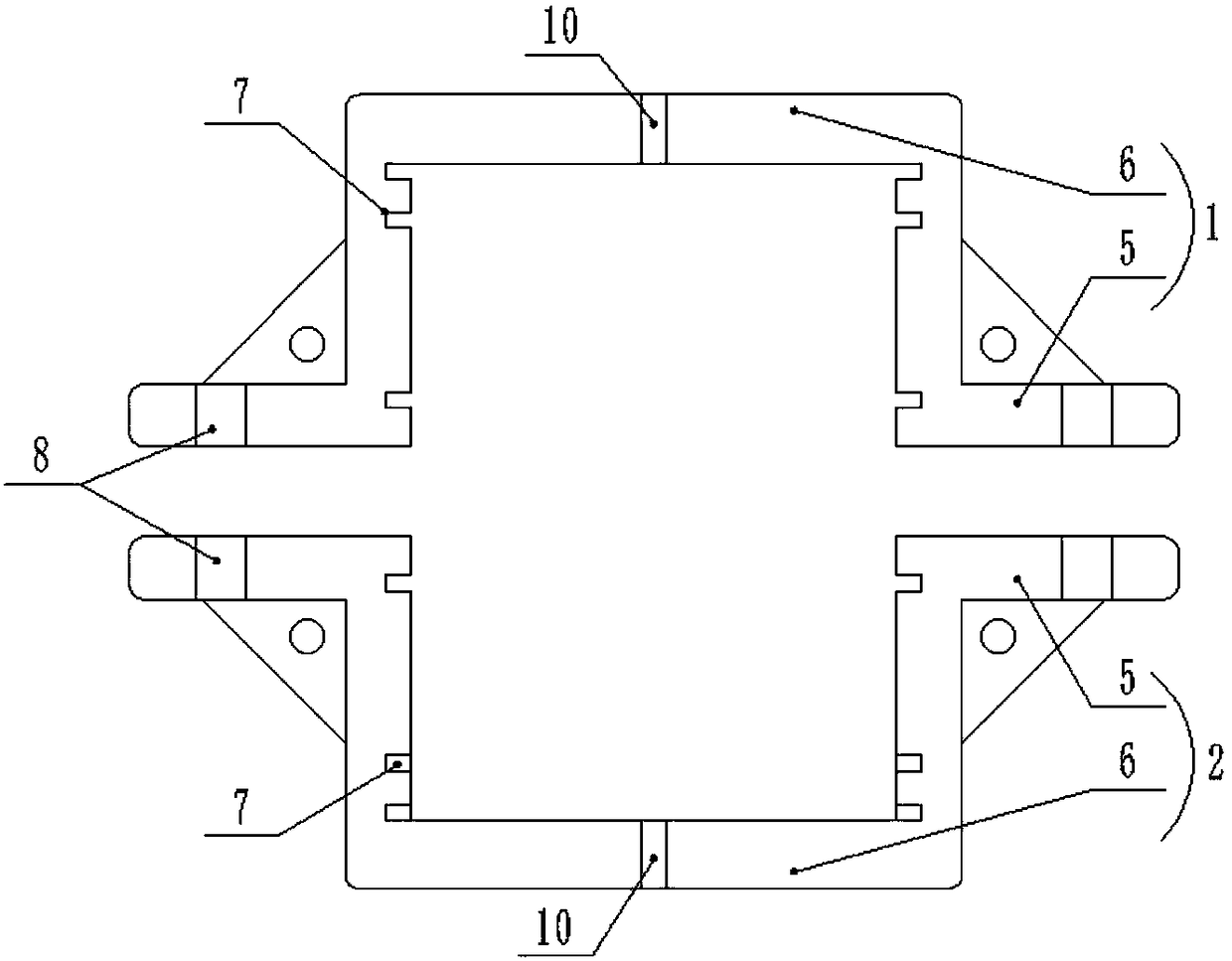

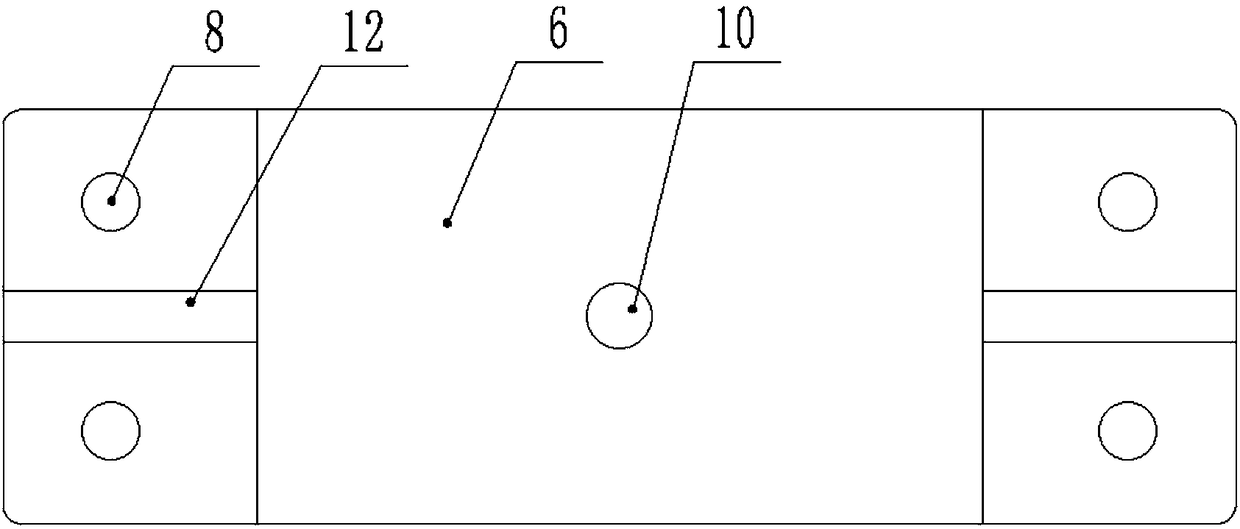

[0030] like Figure 1-2 As shown, a new hoop includes an upper half hoop 1, a lower half hoop 2, an upper half insert 3 and a lower half insert 4, and both the upper half hoop 1 and the lower half hoop 2 include mounting ears 5 and the hoop body 6 with a U-shaped cross section, the mounting ears 5 are symmetrically arranged on both sides of the opening of the hoop body 6; both sides of the inner wall of the hoop body 6 are symmetrically provided with a number of card slots 7; the upper half The mounting ears 5 of the hoop 1 and the lower half hoop 2 are provided with corresponding bolt holes 8, and the upper half hoop 1 and the lower half hoop 2 move through the bolts provided in the corresponding bolt holes 8. Connection; a reinforcing plate 12 is provided between the hoop body 6 and the mounting ear 5 , and a through hole 13 is provided on the reinforcing plate 12 .

[0031] The cross-section of the upper half insert 3 and the lower half insert 4 is arch bridge-shaped, and ...

Embodiment 2

[0040] like Figure 1-3 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the upper half of the hoop 1 The top wall of the hoop body 6 and the bottom wall of the hoop body 6 of the lower half hoop 2 are provided with through threaded holes 10, and the top of the upper half inlay 3 and the bottom of the lower half inlay 4 are provided with The screw holes corresponding to the screw holes 10 are connected by fixing screws 11 between the screw holes 10 and the screw holes. The hoop body 6 of the upper half hoop 1 and the upper half insert 3 and the hoop body 6 of the lower half hoop 2 and the lower half insert 4 can be more stably connected by fixing the screw 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com