Detachable heat shielding hearth structure specially used for pyrolytic self-cleaning oven

A furnace structure and heat shielding technology, applied in the field of kitchen ovens, can solve the problems of waste of heat source, reduced pyrolysis effect and high construction cost, and achieve the effect of easy realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

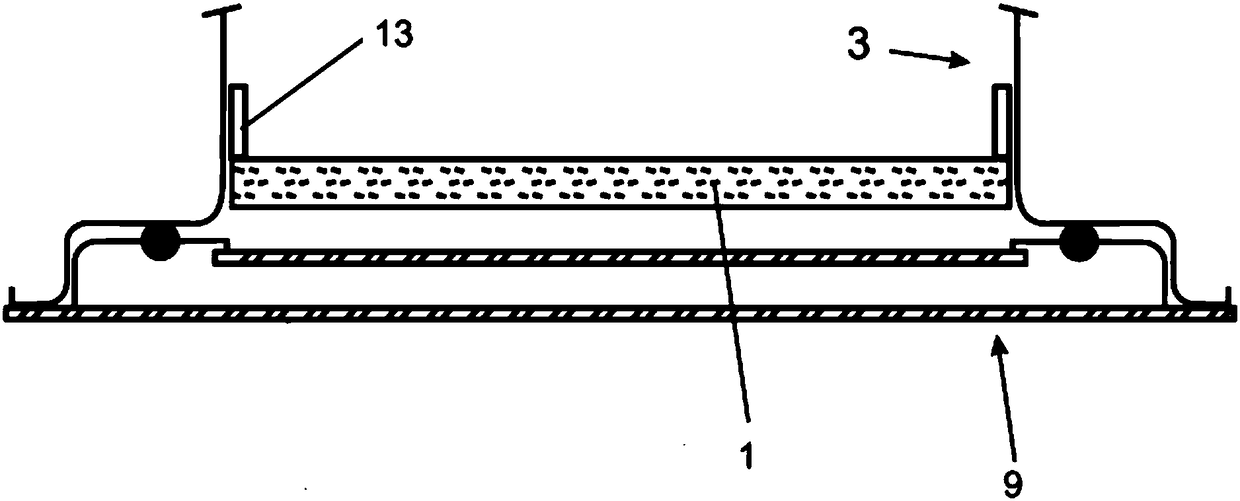

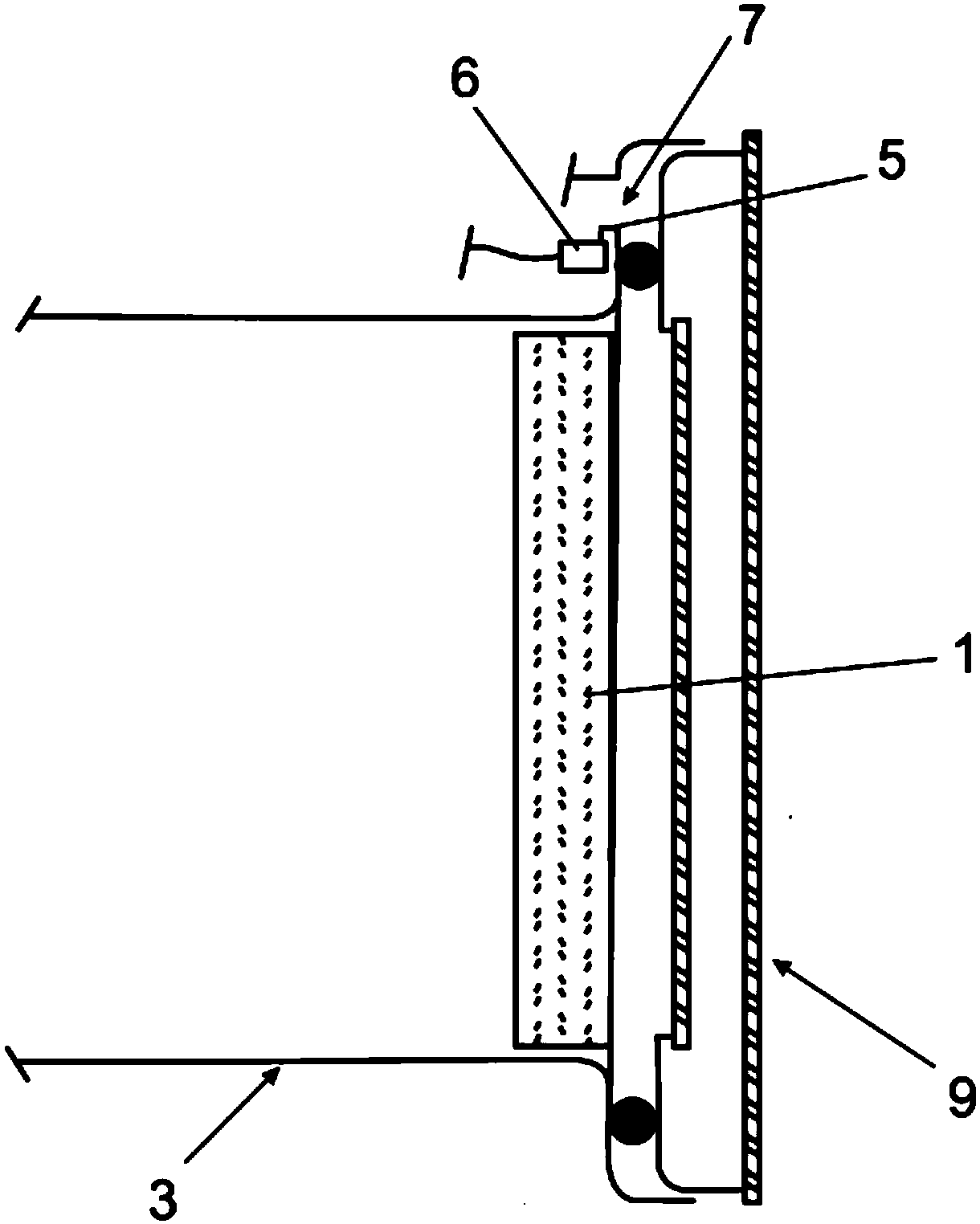

[0021] Such as figure 1 and figure 2 As shown, the special detachable heat shielding furnace structure for pyrolytic self-cleaning oven, one side of the oven is provided with an oven door 9, and the joint between the furnace chamber 3 and the oven door 9 is provided with a detachable heat shield Unit 1, heat insulation unit 1 is in the shape of a plate and completely covers the hearth 3 of the oven.

[0022] The principle of the present invention is that the present invention is based on the fact that a detachable heat insulation unit 1 is arranged between the existing oven hearth 3 and the oven door 9, which can be adjusted according to different usage states of the oven to meet different situations. Overcome the defects of the prior art.

[0023] Such as figure 2 As shown, in some embodiments, the side walls on both sides of the furnace 3 are provided with a number of guide grooves arranged parallel to each other, and each guide groove is perpendicular to the oven door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com