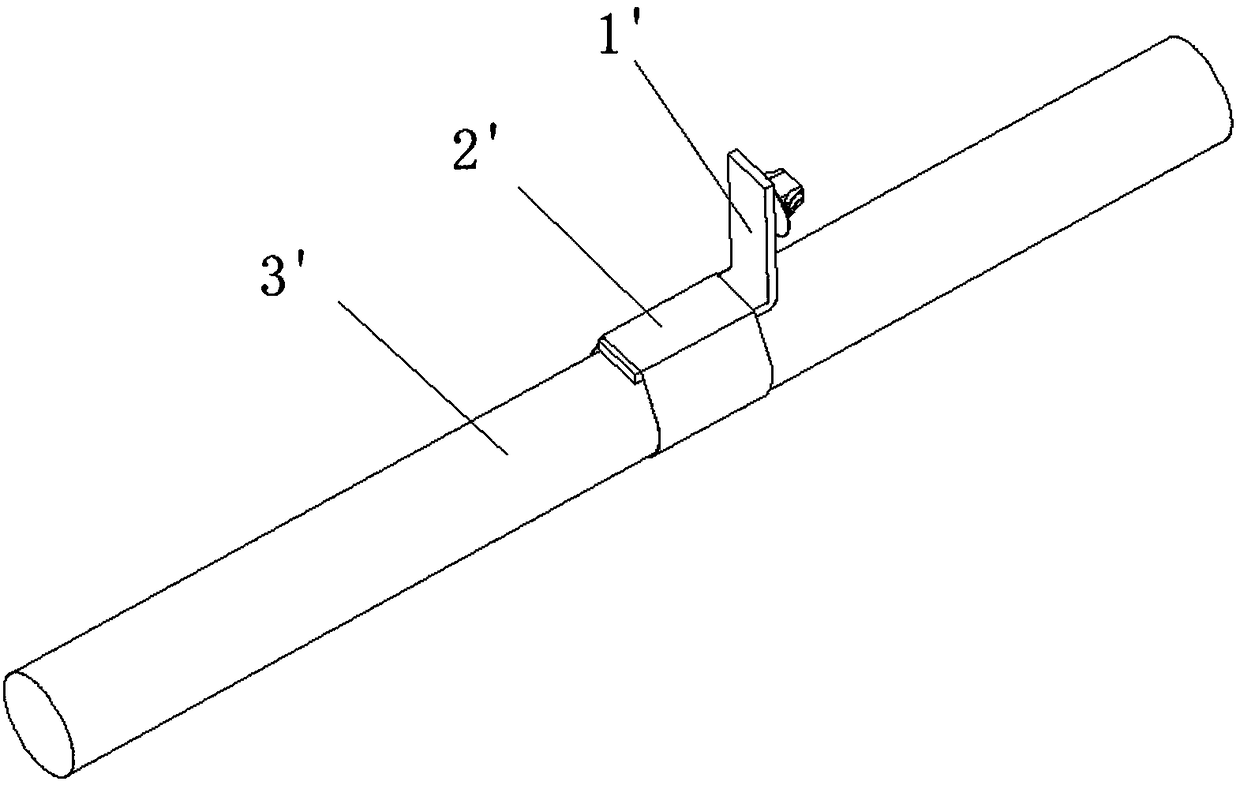

Pipeline route fixing device

A technology for fixing devices and pipelines, which is applied in the field of auto parts, can solve the problems of single fixing method and poor versatility, and achieve the effect of strong versatility and flexible fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, but not to be construed as a limitation of the present invention.

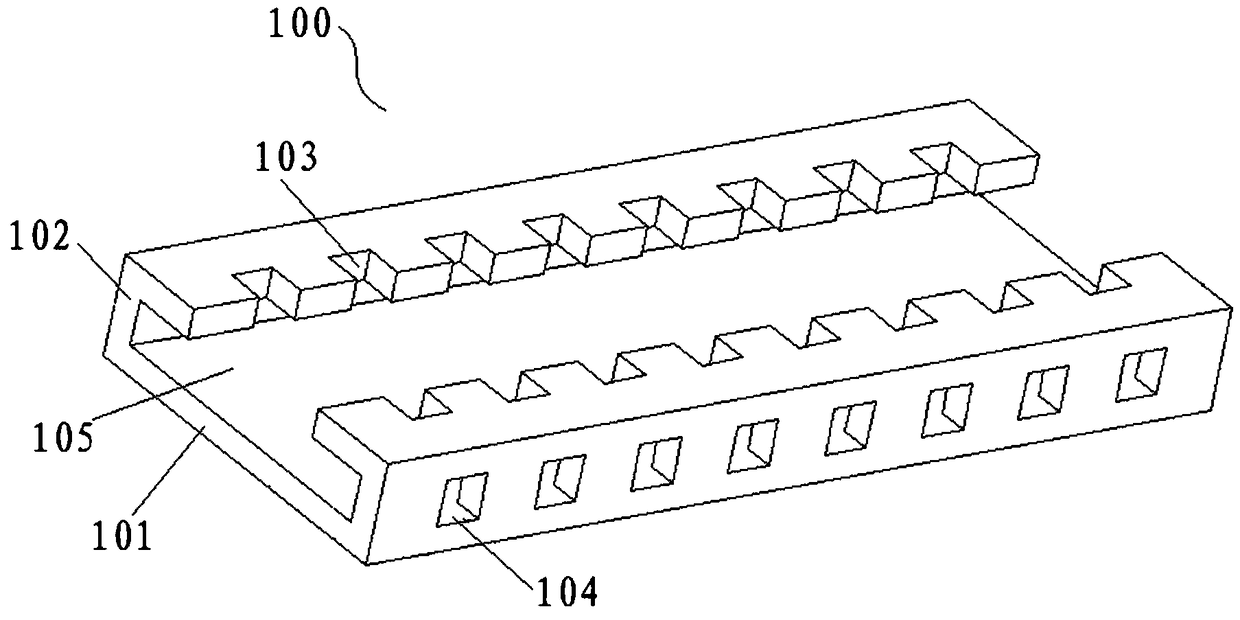

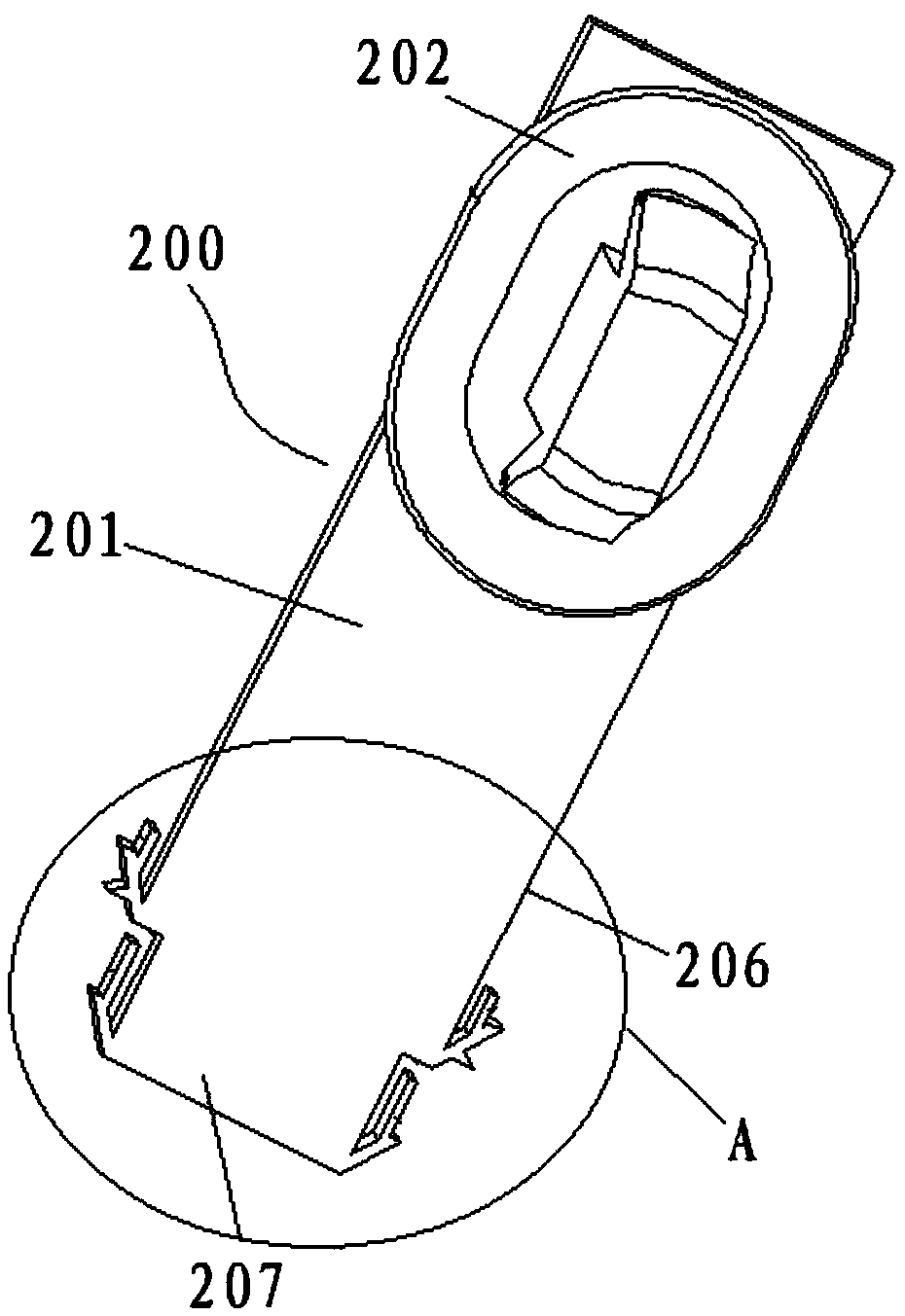

[0029] like Figure 5 As shown, the embodiment of the present invention provides a pipeline line fixing device, including a fixed part 100 and a movable part 200, the movable part 200 is movably fixed on the fixed part 100, wherein:

[0030] refer to figure 2 As shown, the fixing member 100 includes a bottom plate 101 and an L-shaped plate 102. There are two L-shaped plates 102, and the vertical parts of the two L-shaped plates 102 are symmetrically arranged on the bottom plate 101. In the example, the bottom plate 101 and the L-shaped plate 102 are integrally formed, the L-shaped plate 102 is formed on the opposite side walls of the bottom plate 101 , the horizontal portions of the two L-shaped plates 102 extend toward each other, and the L-shaped plate 102 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com