A missile center of mass adjustment device and adjustment method

An adjustment device and quality technology, which is applied to the adjustment of the mass center of missiles and the field of missile mass center of mass adjustment devices, can solve the problems of difficult lead block removal, difficulty, and complex configuration, and achieve flexible and diverse fixed methods, processing and manufacturing Convenience and excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

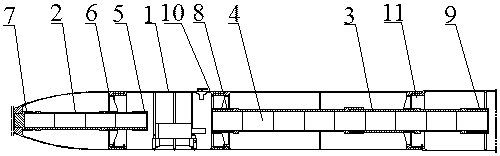

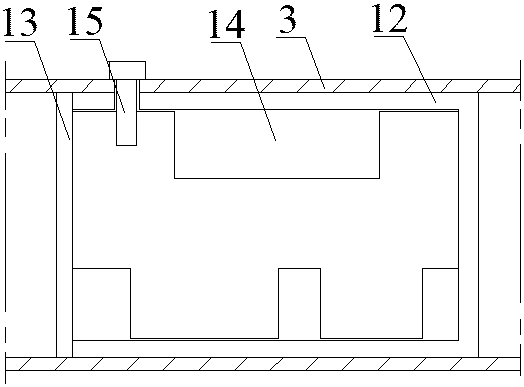

[0023] Such as figure 1 The missile center of mass adjustment device shown includes a front-end weight tube 2 and a rear-end weight tube 3 located in the missile cabin 1, and several counterweights 4 arranged in the front-end weight tube 2 or the rear-end weight tube 3 , the first front end cap 7 and the first rear end cap 5 that are detachably connected to the two ends of the front weight tube 2 respectively, the second front end cap 8 and the second front end cap 8 that are detachably connected to the two ends of the rear weight tube 3 respectively Two rear end caps 9, the front end counterweight pipe 2 is fixed in the cabin section one by the first front end cap 7 embedded in the cabin section one and the first flange plate 6 connected with the cabin section one, and the rear end counterweight tube 3 passes through the first flange plate 6 connected with the cabin sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com