Automatic feeding device for softening of semi-finished glass products

A technology of automatic feeding and semi-finished products, applied in the field of glass semi-finished products softening automatic feeding device, can solve the problems of increasing the volume of the softening furnace, oxidation and deformation of the feeding mechanism, and achieve the effect of facilitating the softening work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

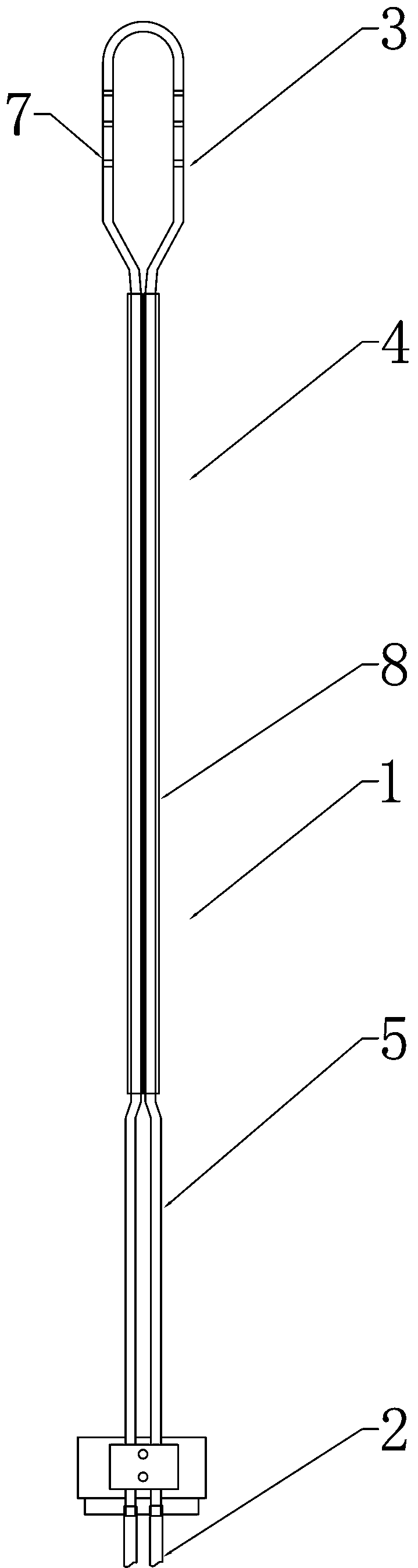

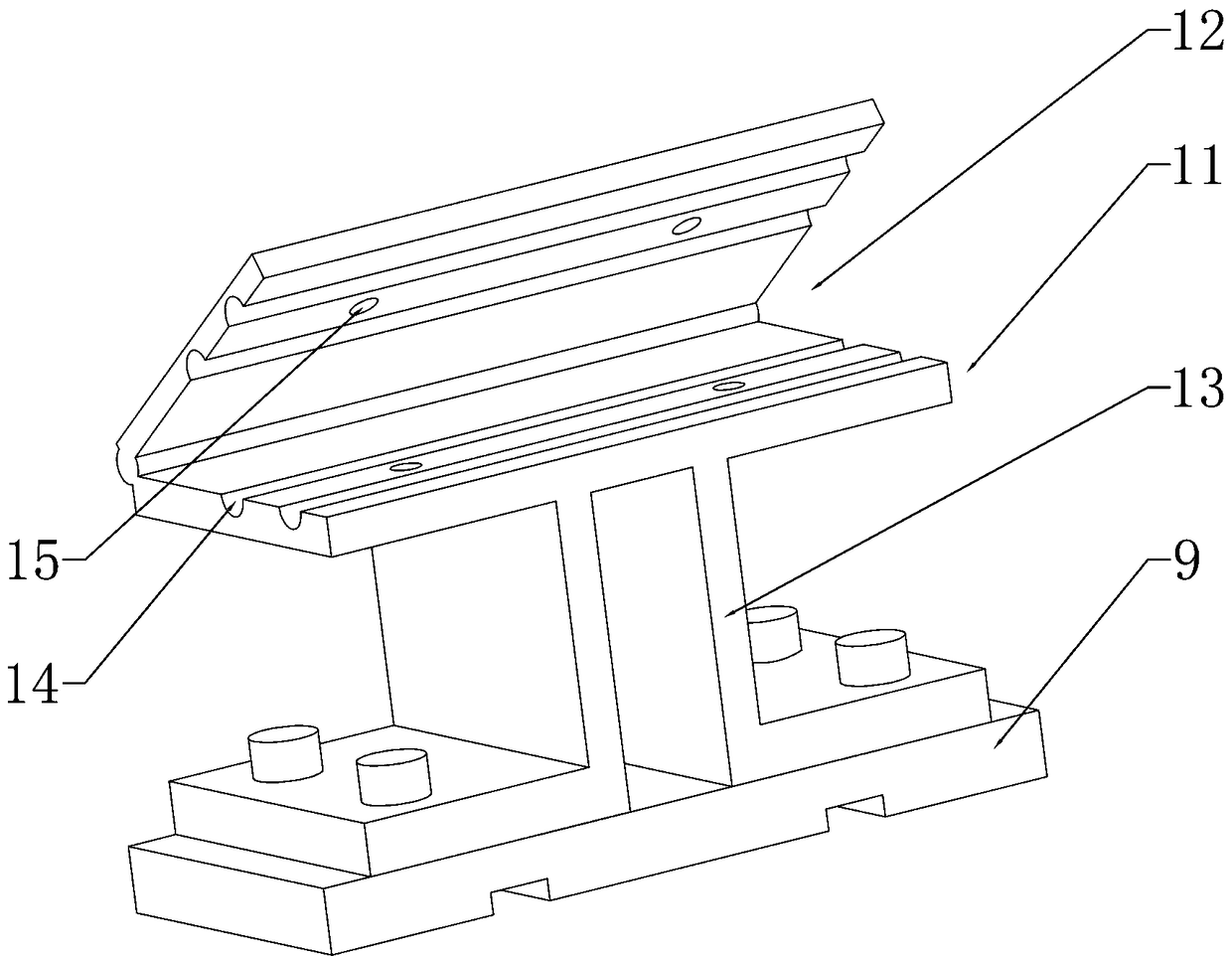

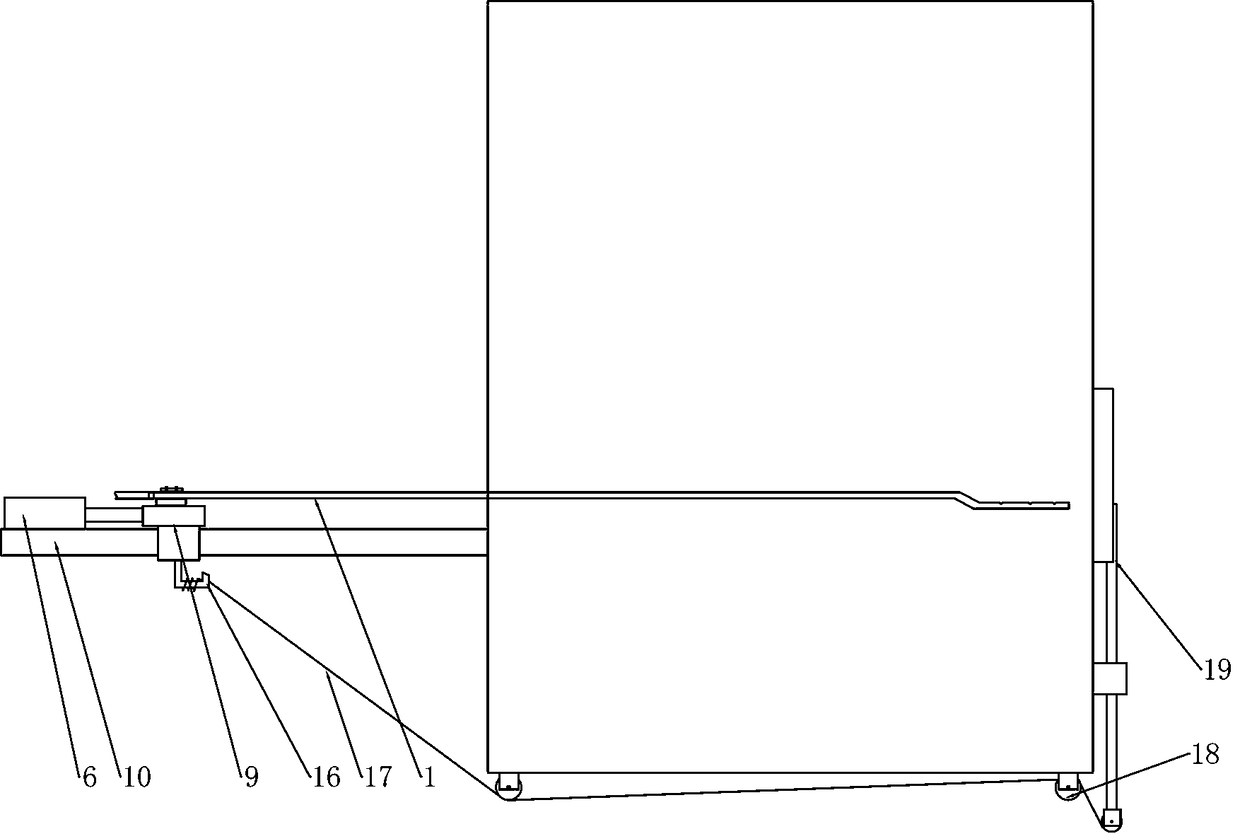

[0016] Such as figure 1 As shown, an automatic feeding device for softening glass semi-finished products includes a feeding rod 1, which is a return rod, and a return cavity is arranged in the return rod, and the end of the cavity communicates with the cooling water pipe 2 to form a cycle together. The cooling pipeline ensures that even in the high-temperature furnace, the temperature of the receiving rod 1 will not rise to a high level, thus avoiding deformation and oxidation of the receiving rod at a high temperature greater than 1000 degrees Celsius for a long time. The material receiving rod 1 includes a front end material receiving part 3, a middle heat-resistant part 4 and a rear end connecting part 5, wherein the front end material receiving part 3 is opened to form a support mouth, and a plurality of limiting grooves are evenly distributed on the support mouth 7. Because the size of the upper end of the glass semi-finished product is large and the size of the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com