Preparation method of anti-oxidation neodymium-iron-boron magnet

A neodymium iron boron, anti-oxidation technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc. Intrinsic coercivity, the effect of avoiding liquid phase shrinkage differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

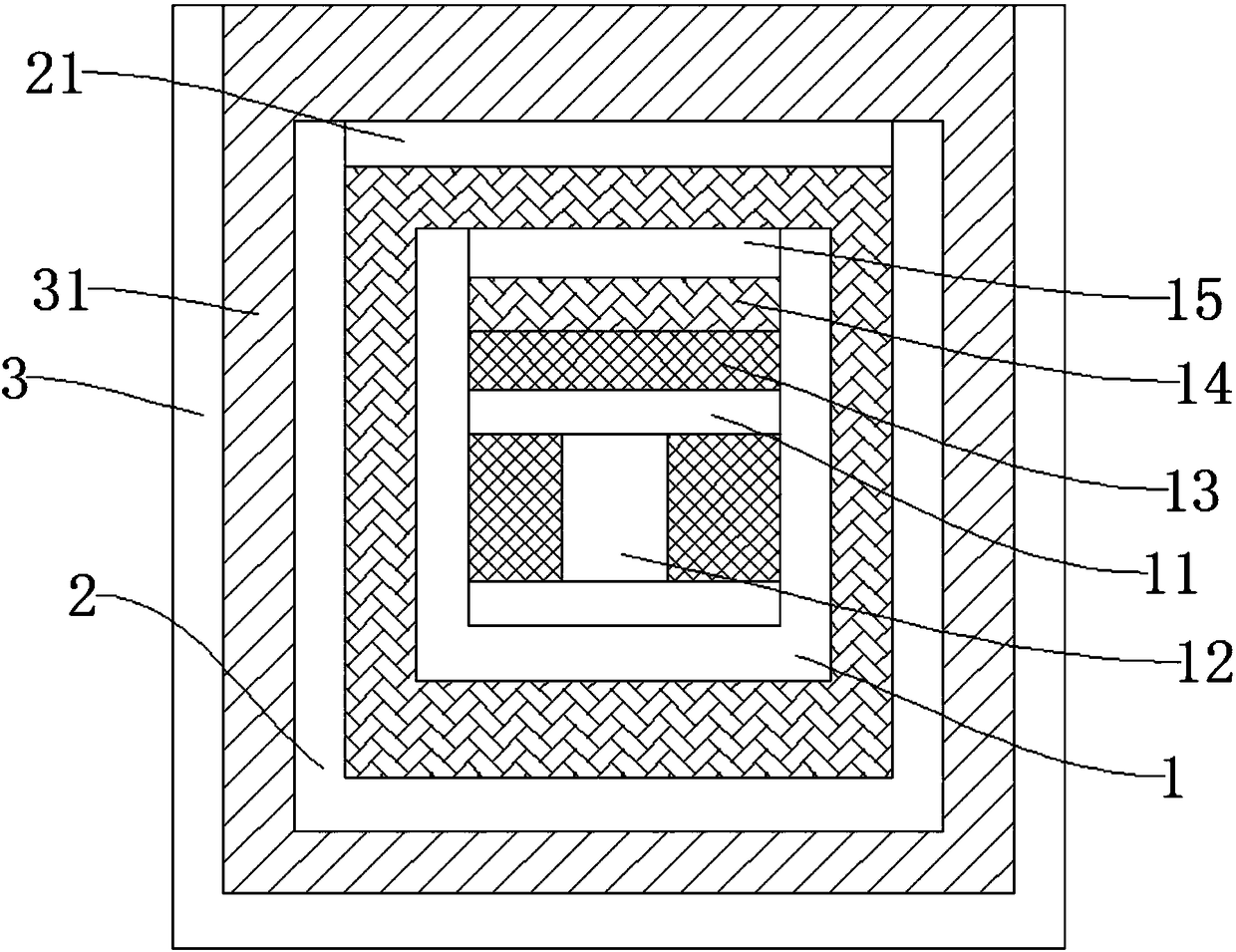

Image

Examples

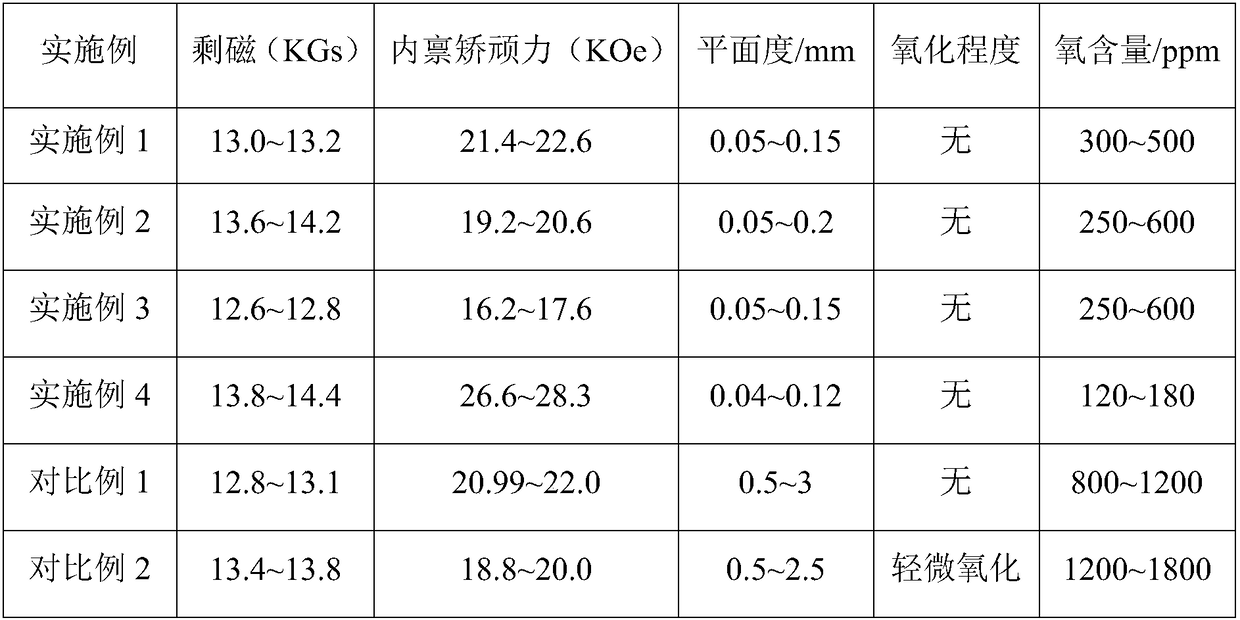

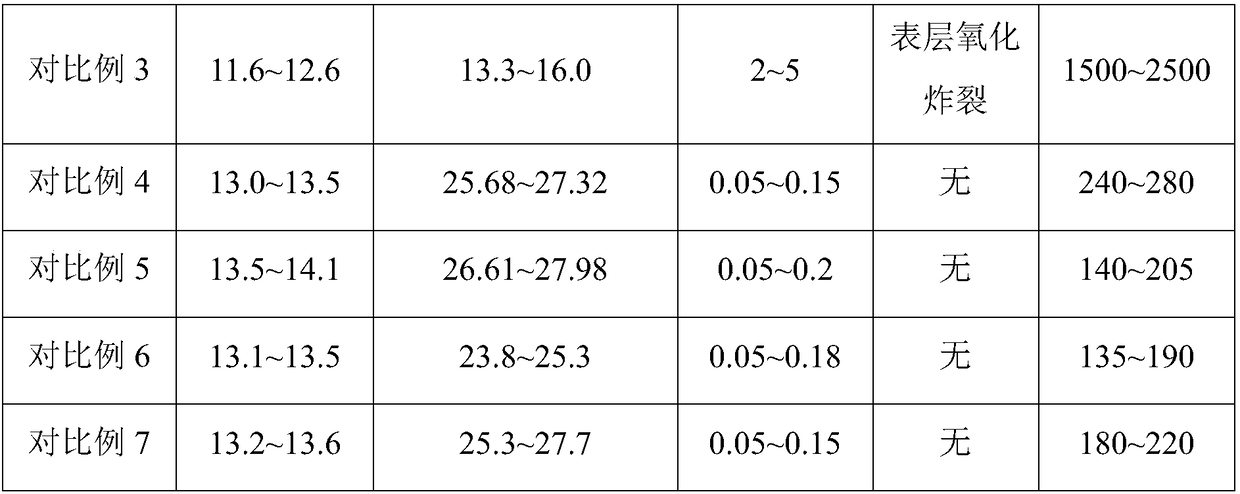

Embodiment 1

[0032] A preparation method of an anti-oxidation NdFeB magnet, comprising the following steps:

[0033] The raw materials are melted in a vacuum melting furnace to obtain NdFeB alloys, and then the NdFeB alloys are placed in a hydrogen breaking furnace and injected with hydrogen to be broken into loose powders of 30-300 μm, and then dehydrogenated at a temperature of 500 ° C for 8 hours Finally, the NdFeB alloy powder is obtained by air mill flow; then the NdFeB alloy powder is mixed with a small amount of antioxidant and pressed in a magnetic orientation machine to a density of 4.6g / cm 3 Obtain the NdFeB magnet green body; place the NdFeB magnet green body in a vacuum sintering furnace, evacuate until the vacuum degree is below 0.3Pa, fill the furnace with argon until the pressure in the furnace is 95KPa, and turn on the fan in the furnace to wash the furnace for 30 minutes; Then evacuate again to below 0.3Pa, sinter at a temperature of 1050°C for 600min, turn off the heater ...

Embodiment 2

[0035] A preparation method of an anti-oxidation NdFeB magnet, comprising the following steps:

[0036] Put the raw materials in a vacuum melting furnace to smelt the NdFeB alloy, then put the NdFeB alloy in a hydrogen breaking furnace and pass in hydrogen gas, break it into a loose powder of 30-300 μm, and then dehydrogenate it at a temperature of 580 ° C for 6 hours Finally, the NdFeB alloy powder is obtained by air mill flow; then the NdFeB alloy powder is mixed with a small amount of antioxidant and pressed in a magnetic orientation machine to a density of 4.6g / cm 3 Obtain the NdFeB magnet green body; place the NdFeB magnet green body in a vacuum sintering furnace, evacuate until the vacuum degree is below 0.3Pa, fill the furnace with argon until the pressure in the furnace is 100KPa, and turn on the fan in the furnace to wash the furnace for 20 minutes; Then evacuate again to below 0.3Pa, sinter at a temperature of 1050°C for 360min, turn off the heater of the sintering f...

Embodiment 3

[0038] A preparation method of an anti-oxidation NdFeB magnet, comprising the following steps:

[0039] Put the raw materials in a vacuum melting furnace to smelt the NdFeB alloy, then put the NdFeB alloy in a hydrogen breaking furnace and pass in hydrogen gas, break it into a loose powder of 30-300 μm, and then dehydrogenate it at a temperature of 520 ° C for 4 hours Finally, the NdFeB alloy powder is obtained by air mill flow; then the NdFeB alloy powder is mixed with a small amount of antioxidant and pressed in a magnetic orientation machine to a density of 4.4g / cm 3 Obtain the NdFeB magnet green body; place the NdFeB magnet green body in a vacuum sintering furnace, evacuate until the vacuum degree is below 0.3Pa, fill the furnace with argon until the pressure in the furnace is 85KPa, and turn on the fan in the furnace to wash the furnace for 15 minutes; Then evacuate again to below 0.3Pa, sinter at a temperature of 1020°C for 180min, turn off the heater of the sintering fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com