Key structure and its lifting mechanism

A lifting mechanism and button technology, applied in the direction of contact operating mechanism, electrical components, electric switches, etc., can solve the problems of poor combination accuracy of components, affecting the user's pressing feel, and poor actuation accuracy, etc., to achieve the best pressing feel and stability The effect of easy maintenance of degree, best combination accuracy and actuation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

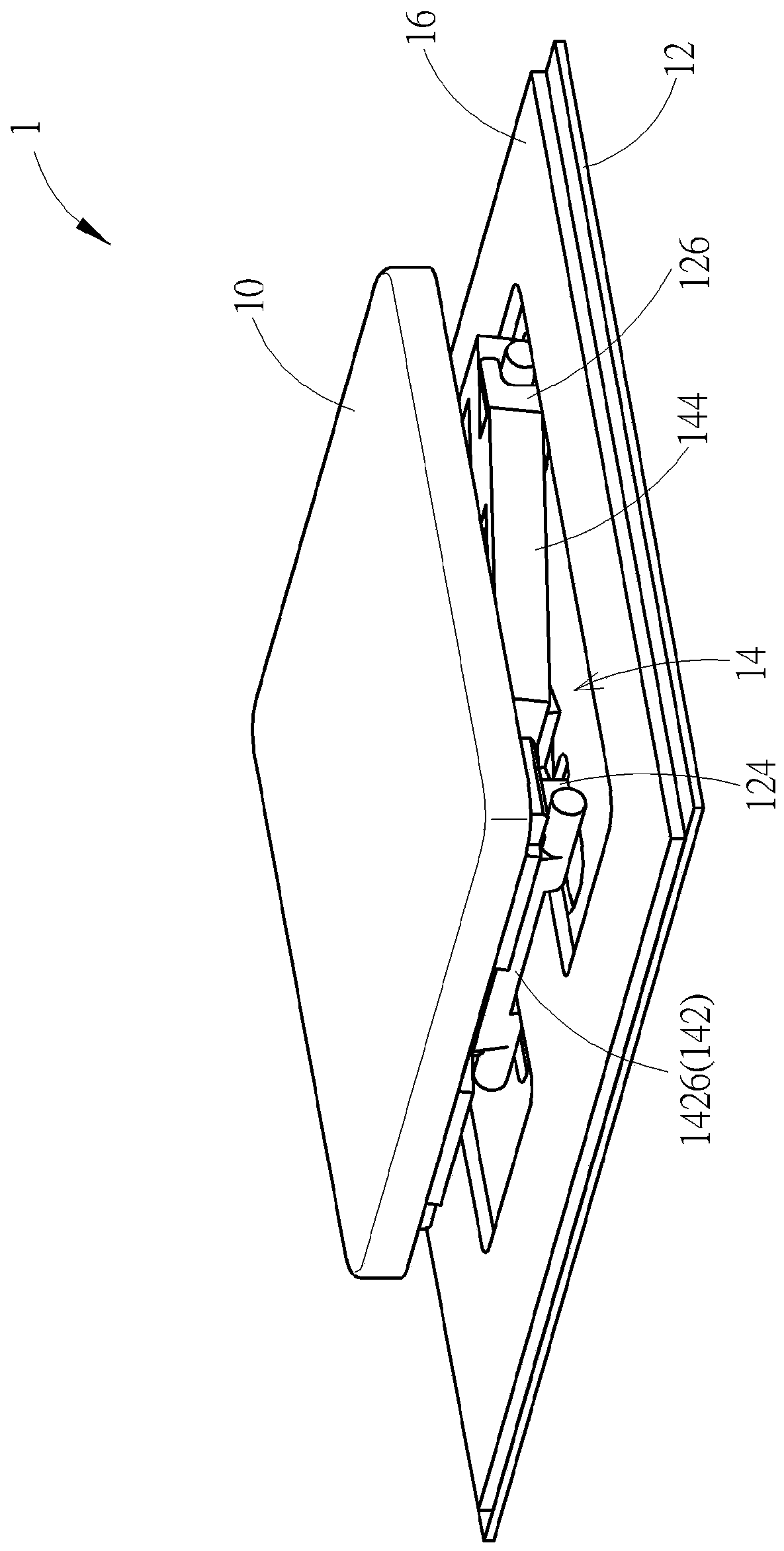

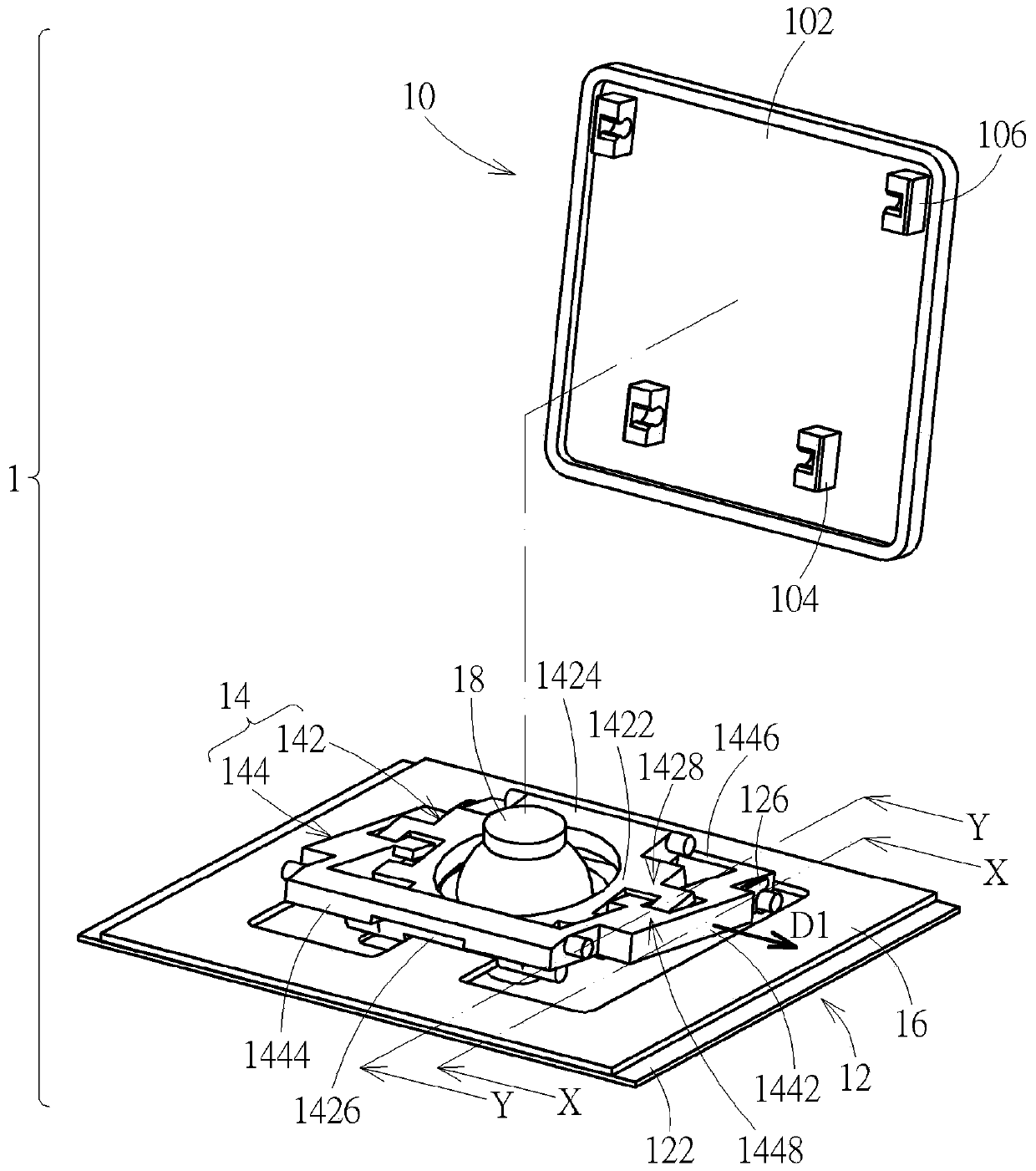

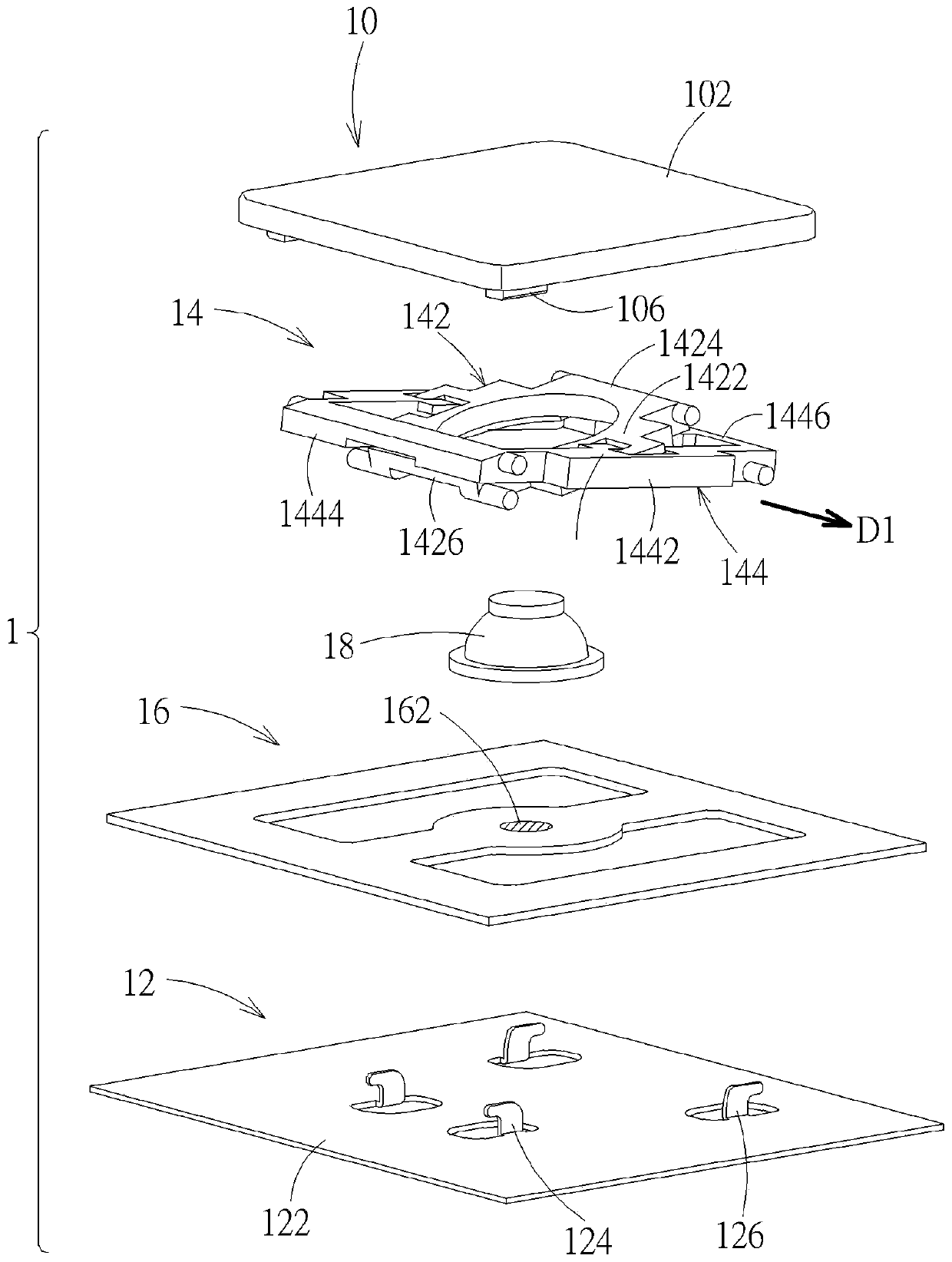

[0032] see Figure 1 to Figure 5 , figure 1 is a schematic diagram of a button structure according to an embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the partial explosion of the middle button structure, image 3 for figure 1 Exploded diagram of the button structure in the middle, Figure 4 for image 3 Exploded diagram of the lifting mechanism of the middle button structure, Figure 5 for Figure 4 A schematic diagram of the second bracket of the middle lifting mechanism at another perspective. The key structure 1 according to an embodiment of the present invention includes a key cap 10 , a base 12 and a lifting mechanism 14 . The base 12 is disposed below the keycap 10 , and the lifting mechanism 14 is connected between the keycap 10 and the base 12 , so that the keycap 10 can move up and down relative to the base 12 via the lifting mechanism 14 . The button structure 1 also includes a thin film circuit board 16 and an elastic rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com