Automatic electric construction robot

A technology of electric power construction and robots, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of staff damage, ground pollution, and reduce the speed of electric power construction, so as to prevent the danger of falling objects, improve the progress, and clean up debris Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

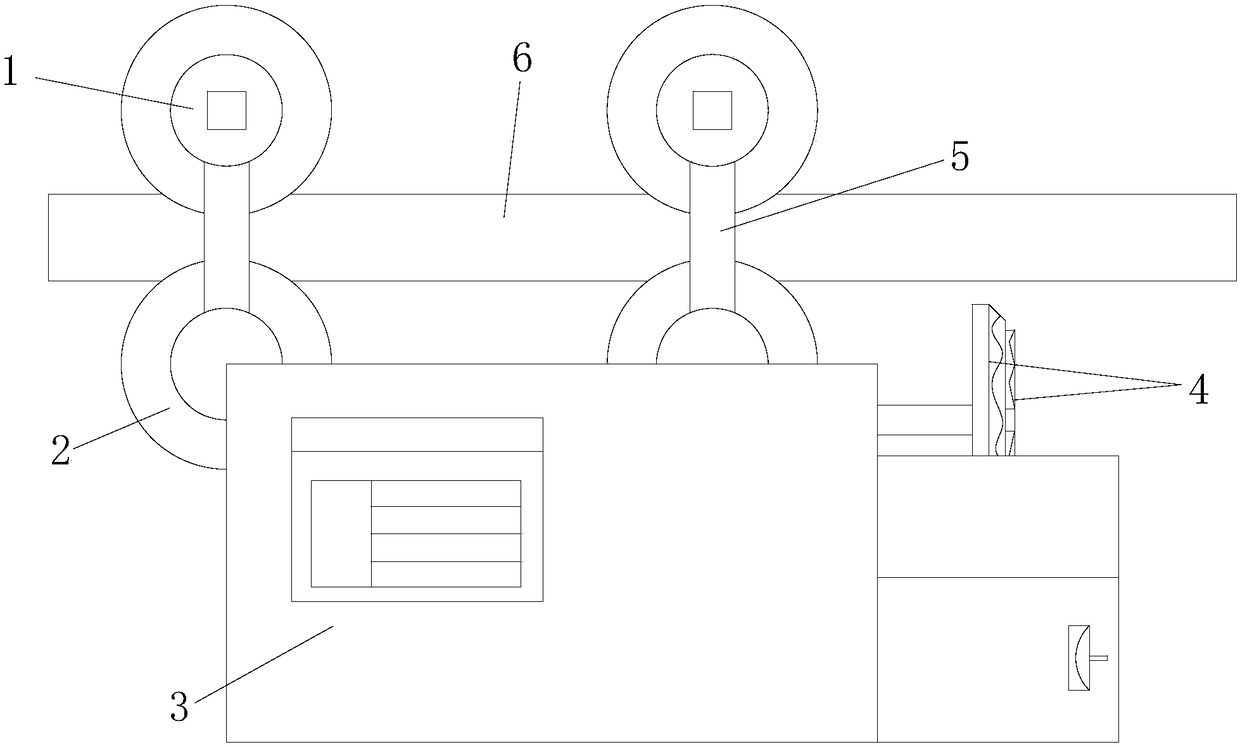

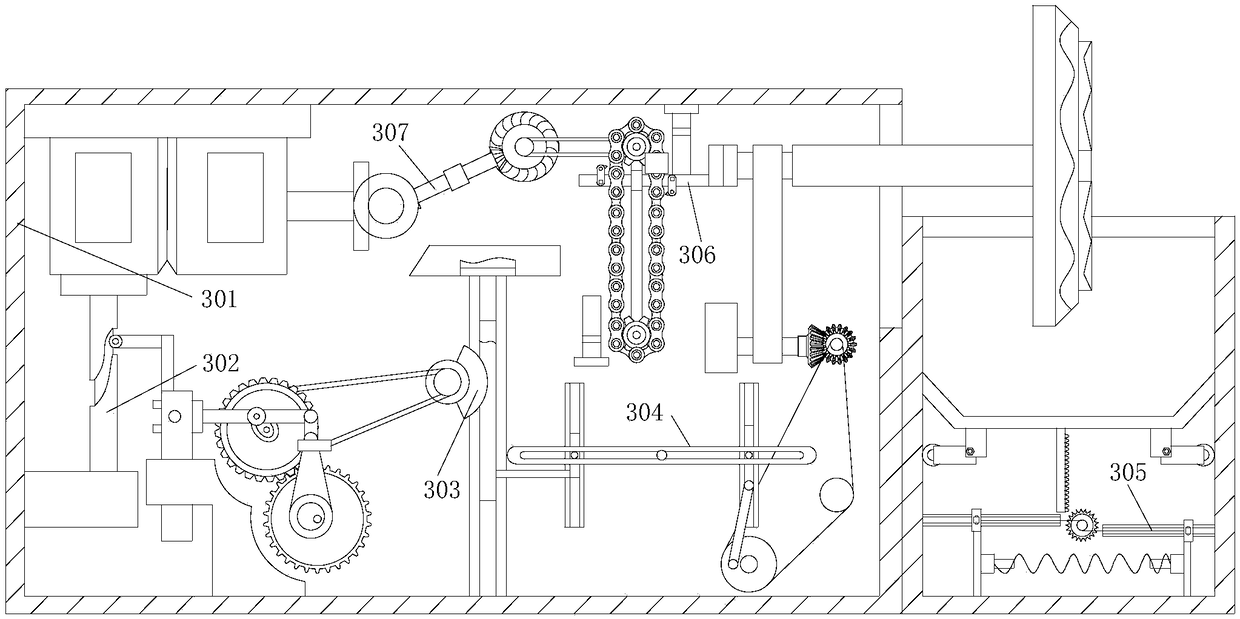

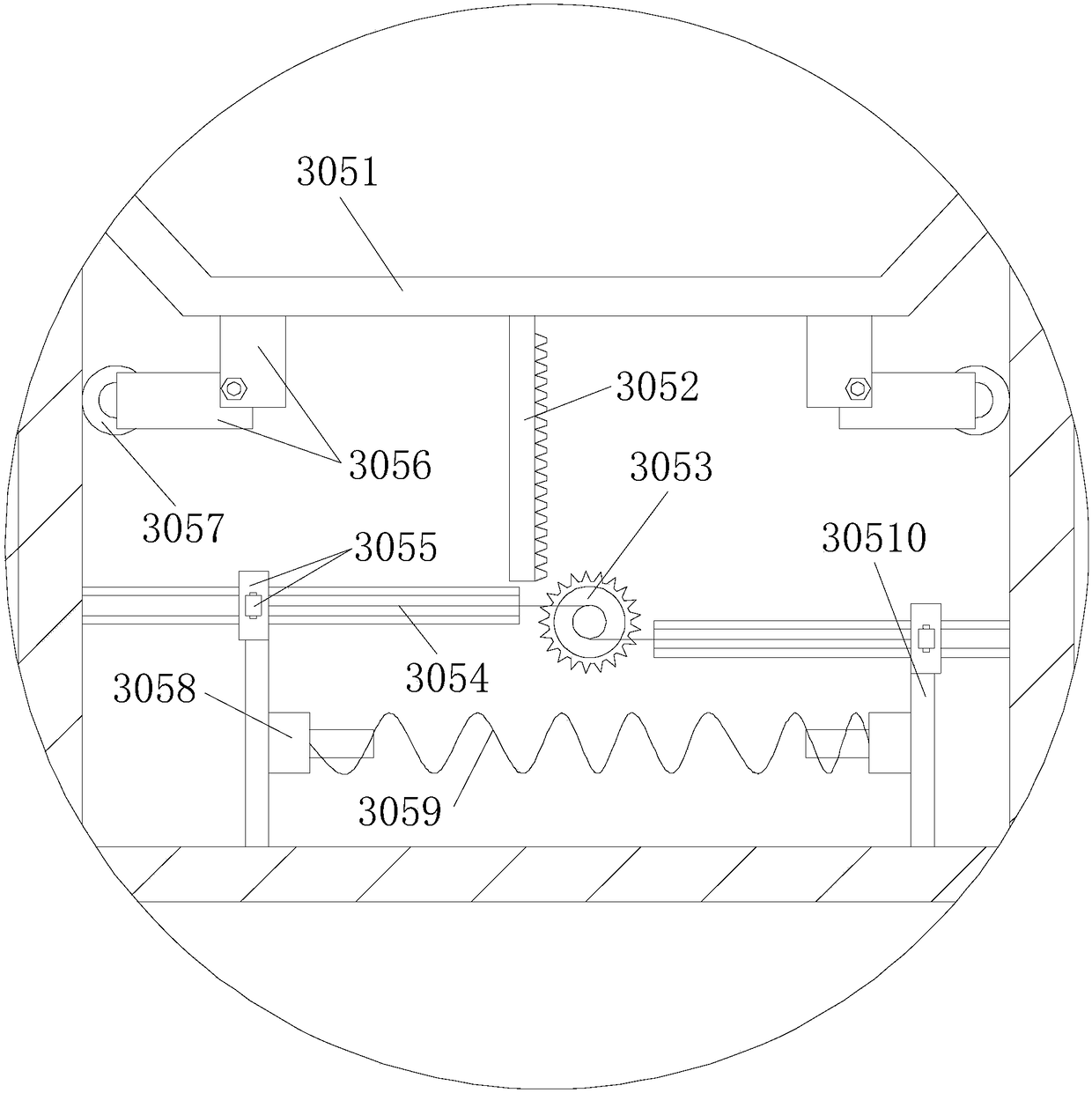

[0026] see Figure 1-Figure 7 , the present invention provides a technical solution for an automated electric construction robot: an automated electric construction robot, the structure of which includes a brake wheel device 1, a matching wire wheel 2, a cleaning device 3, a cleaning cutter head 4, a connecting column 5, and a high-voltage line 6, The brake wheel device 1 is transitionally connected to the matching wire wheel 2 through the connecting column 5, and one end of the connecting column 5 is movably connected to the matching wire wheel 2 in an embedded manner, and the cleaning device 3 is connected to the matching wire wheel 2. The wheels 2 are connected, and the left end of the cleaning cutter head 4 is movably connected to the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com