Patents

Literature

37results about How to "Buffering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

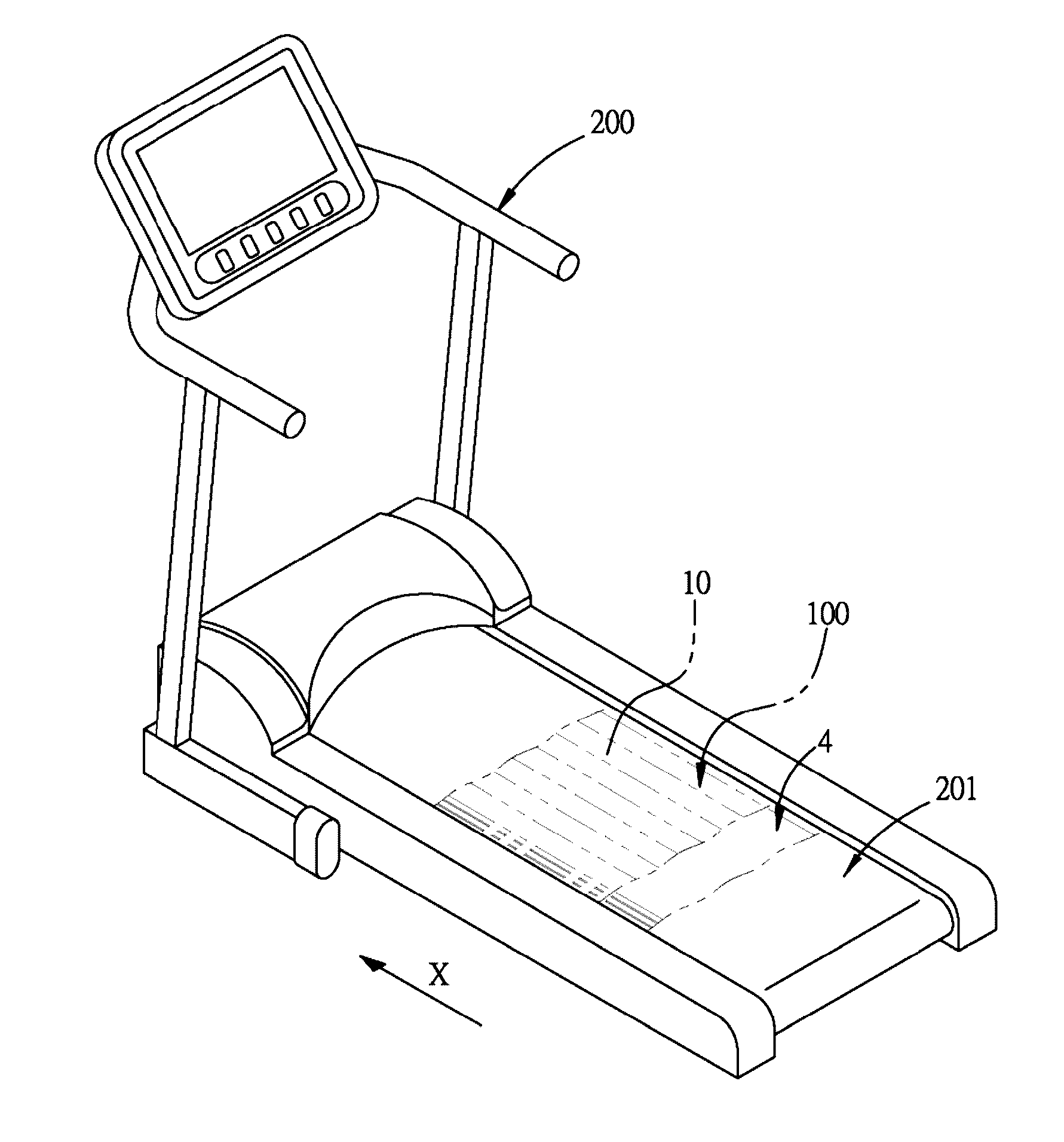

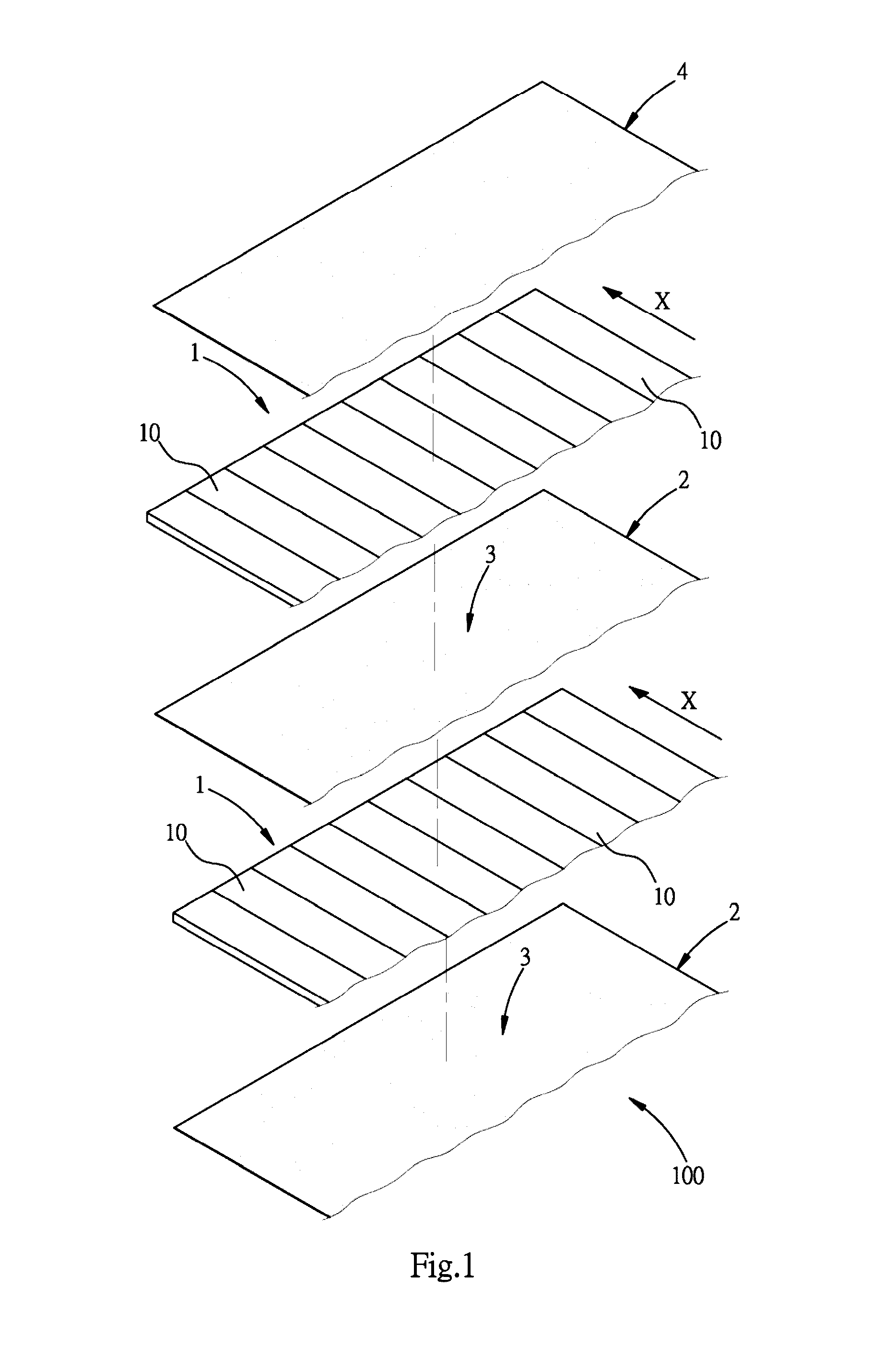

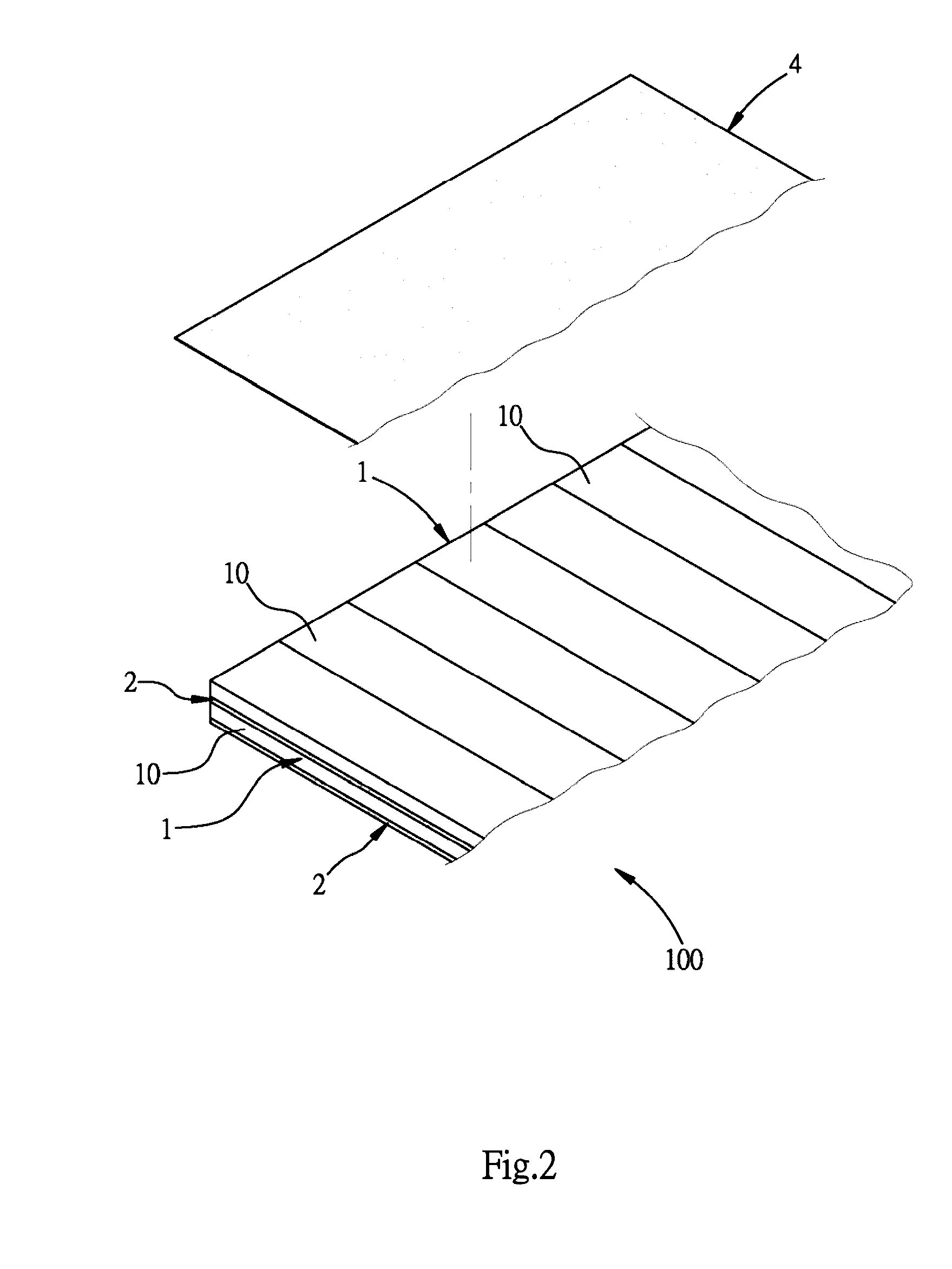

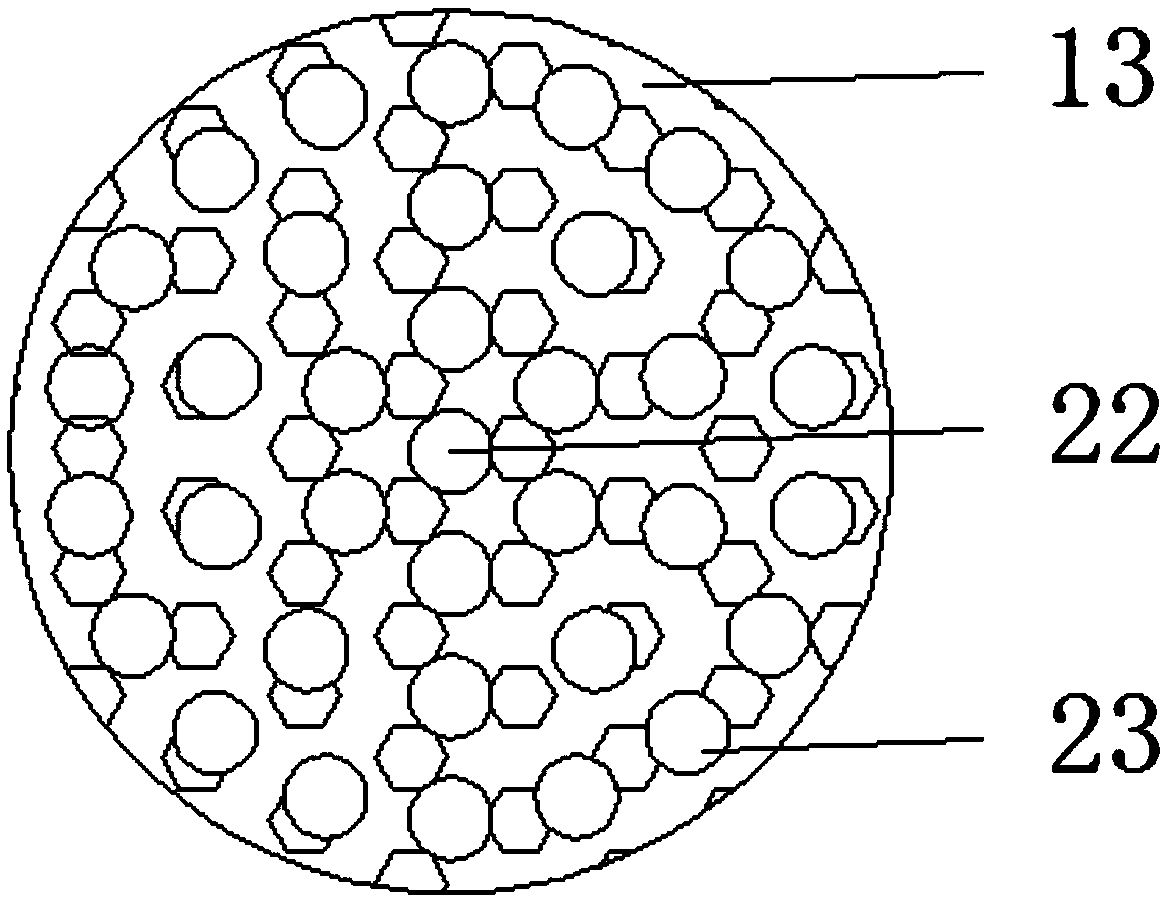

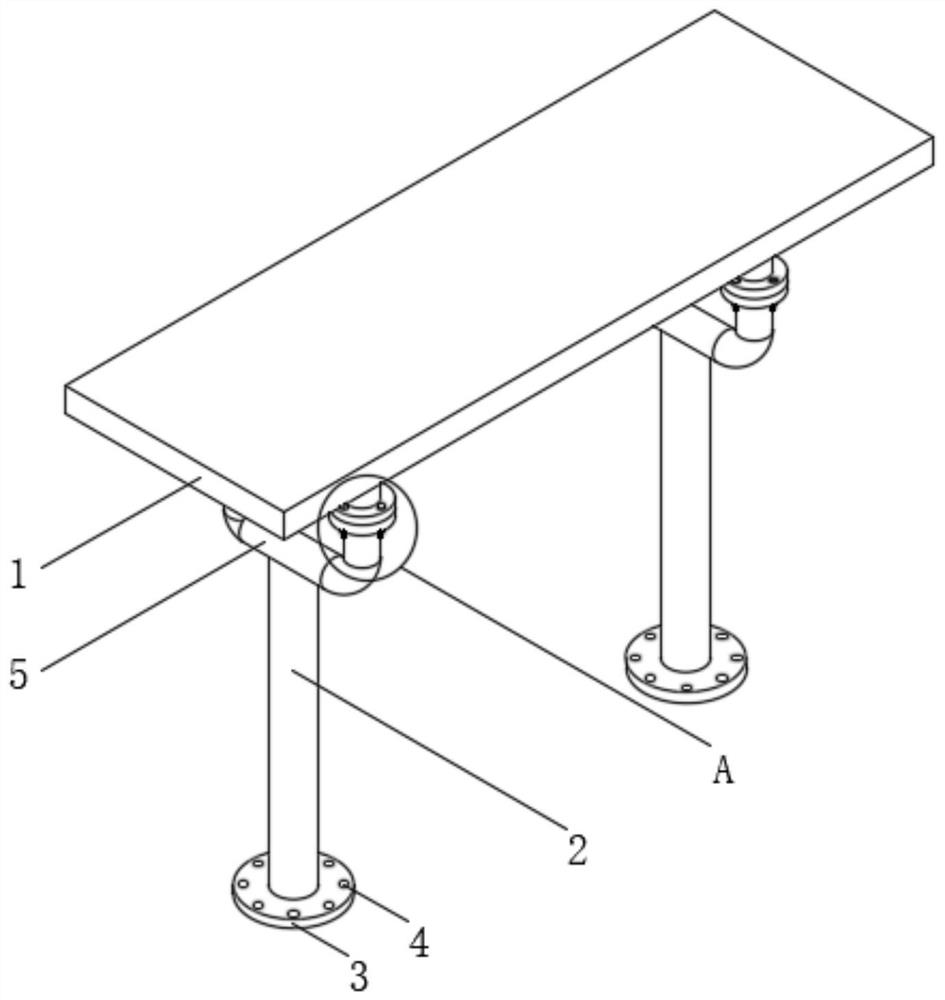

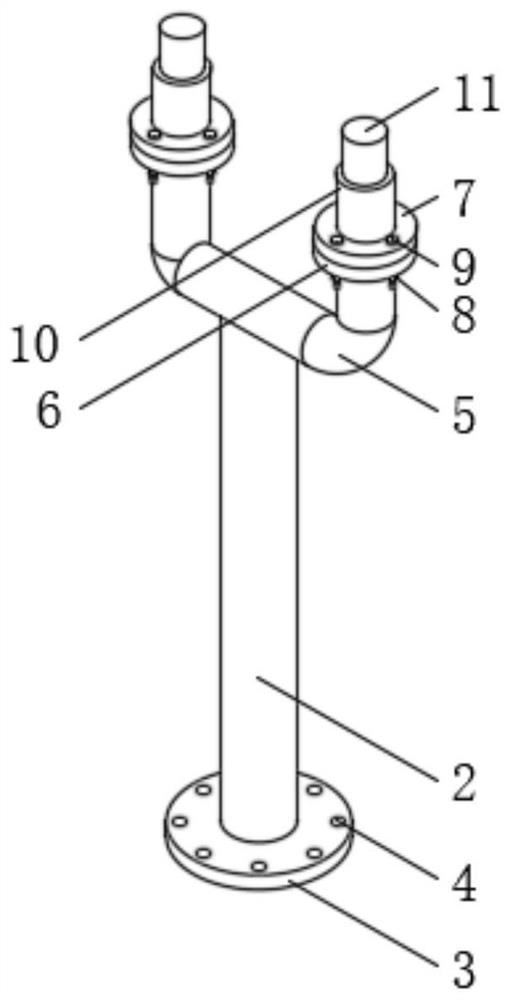

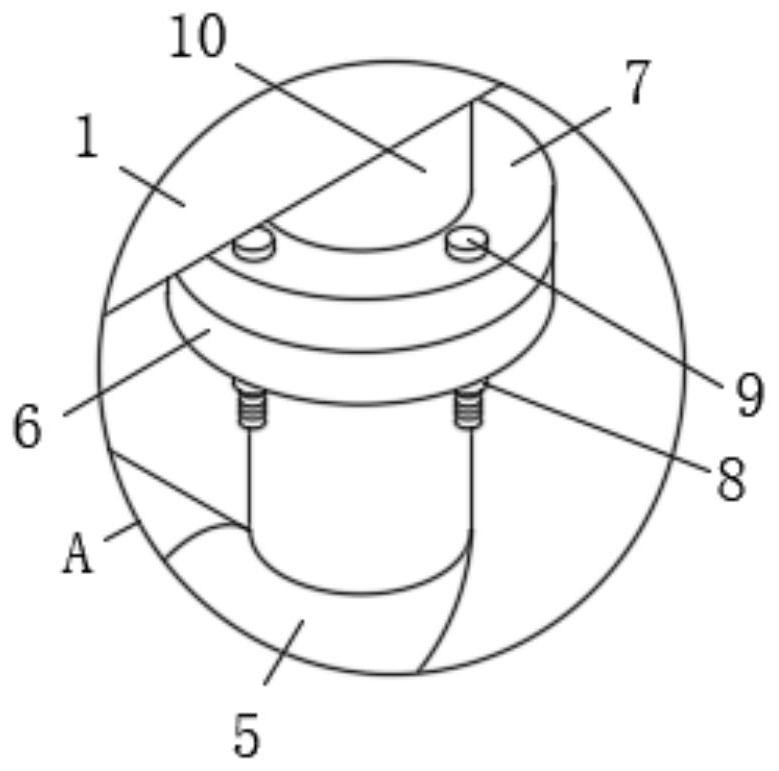

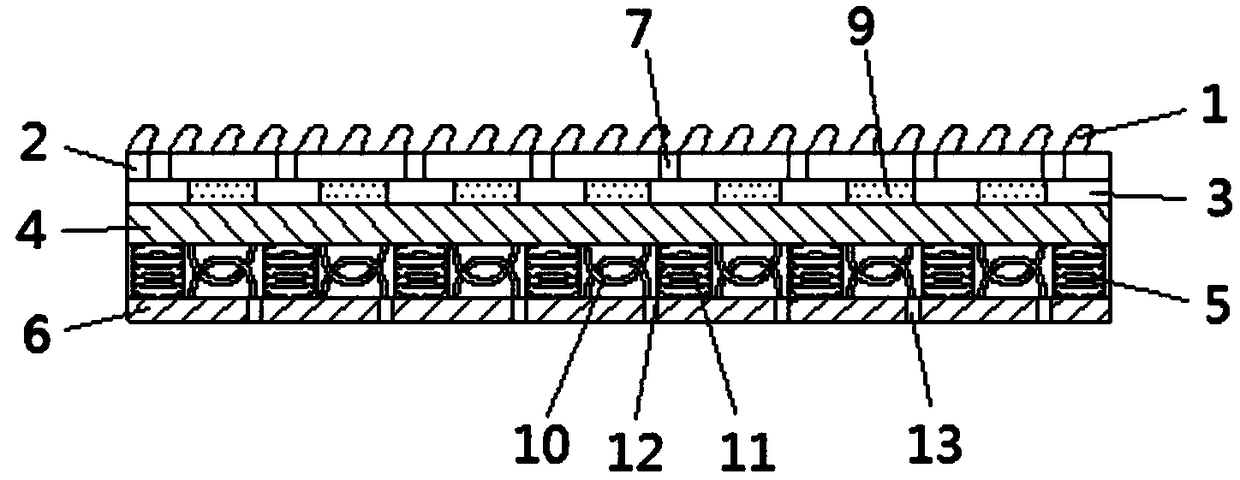

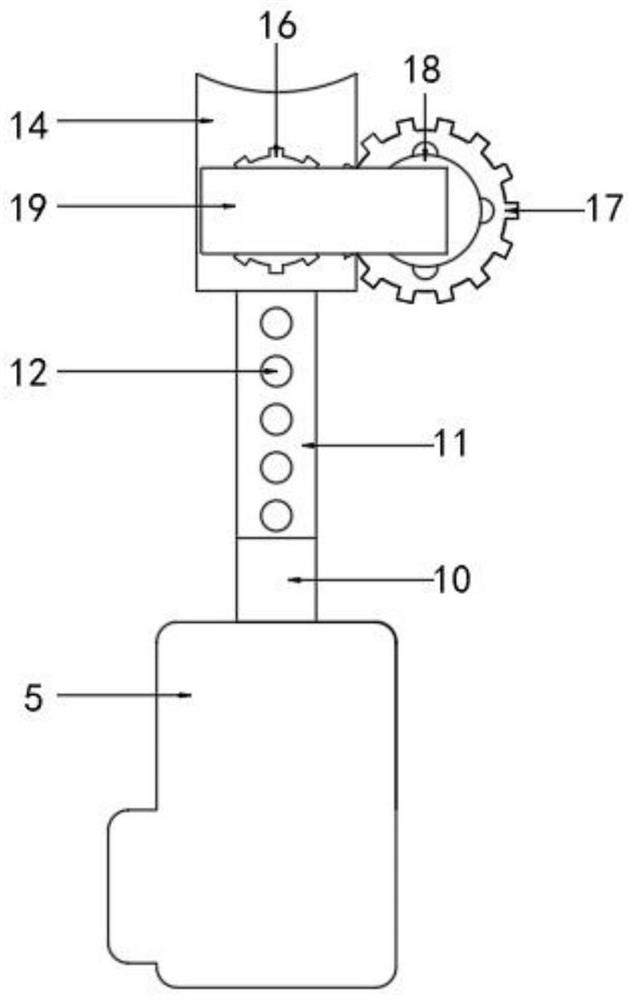

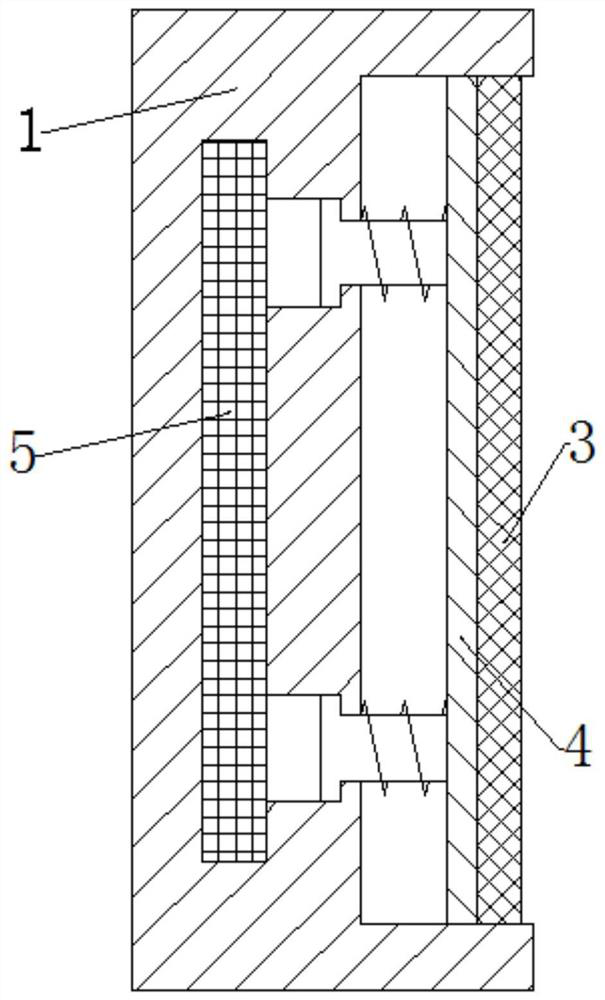

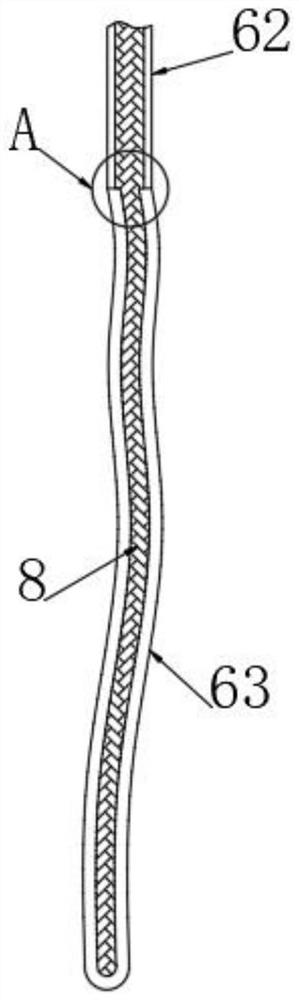

Buffer board structure of a treadmill

ActiveUS9573017B2Improve buffering effectBuffering effectTransportation and packagingSynthetic resin layered productsEngineeringBoard structure

Owner:CHANG SC

Use of low molecular weight amino alcohols in ophthalmic compositions

The use of low molecular weight amino alcohols in ophthalmic compositions is described. These compounds have been found to enhance the efficacy of anti-microbial preservatives.

Owner:ALCON RES LTD

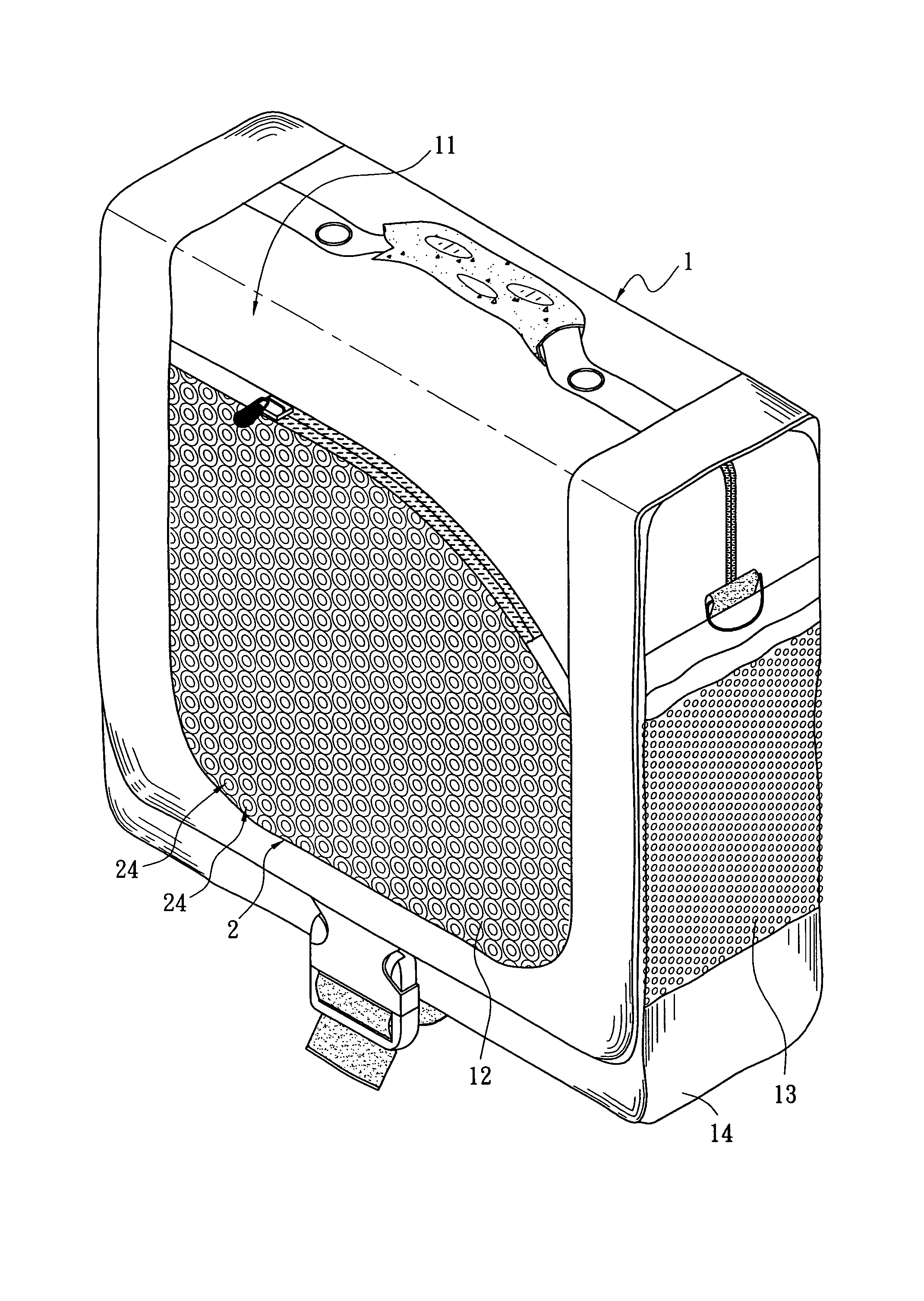

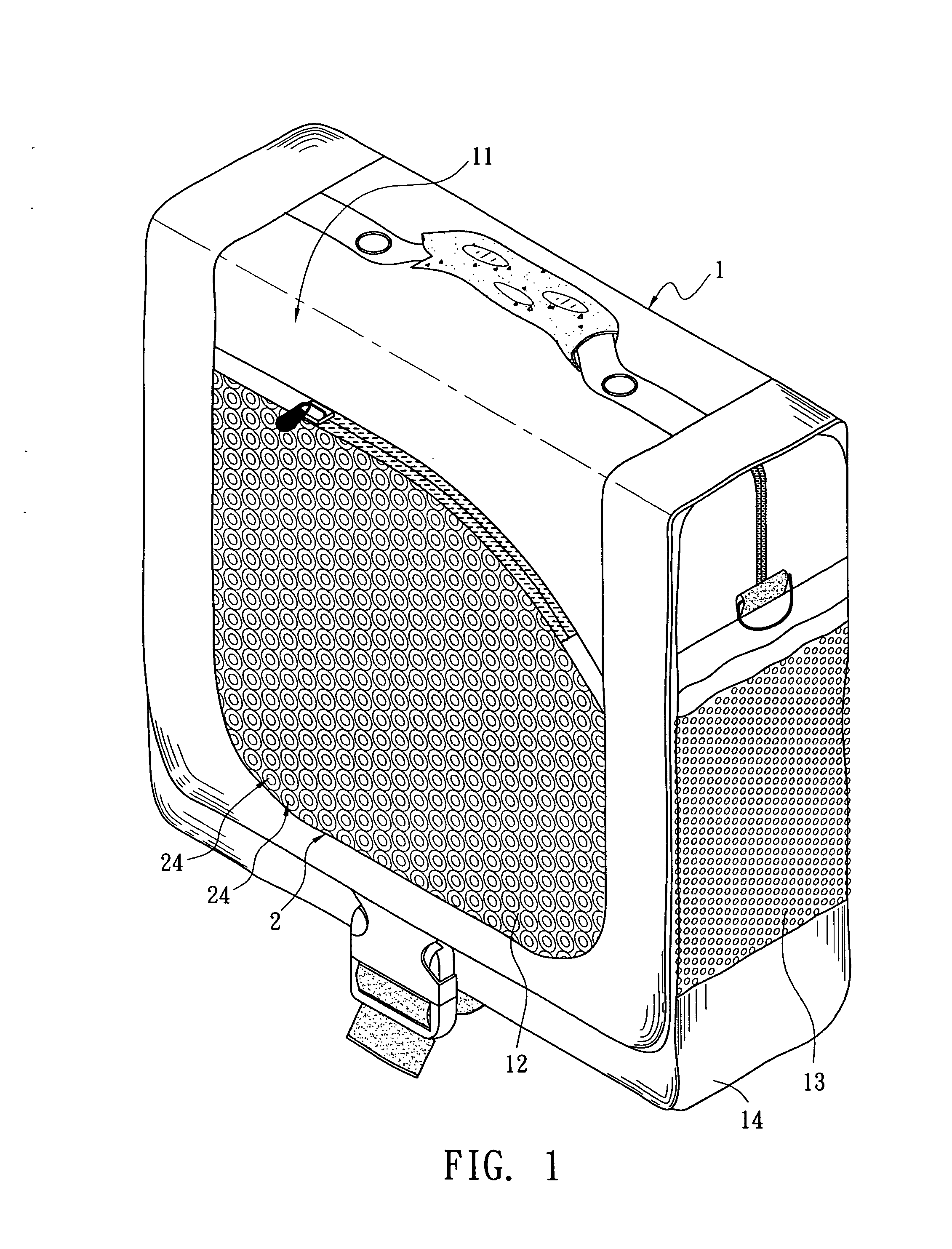

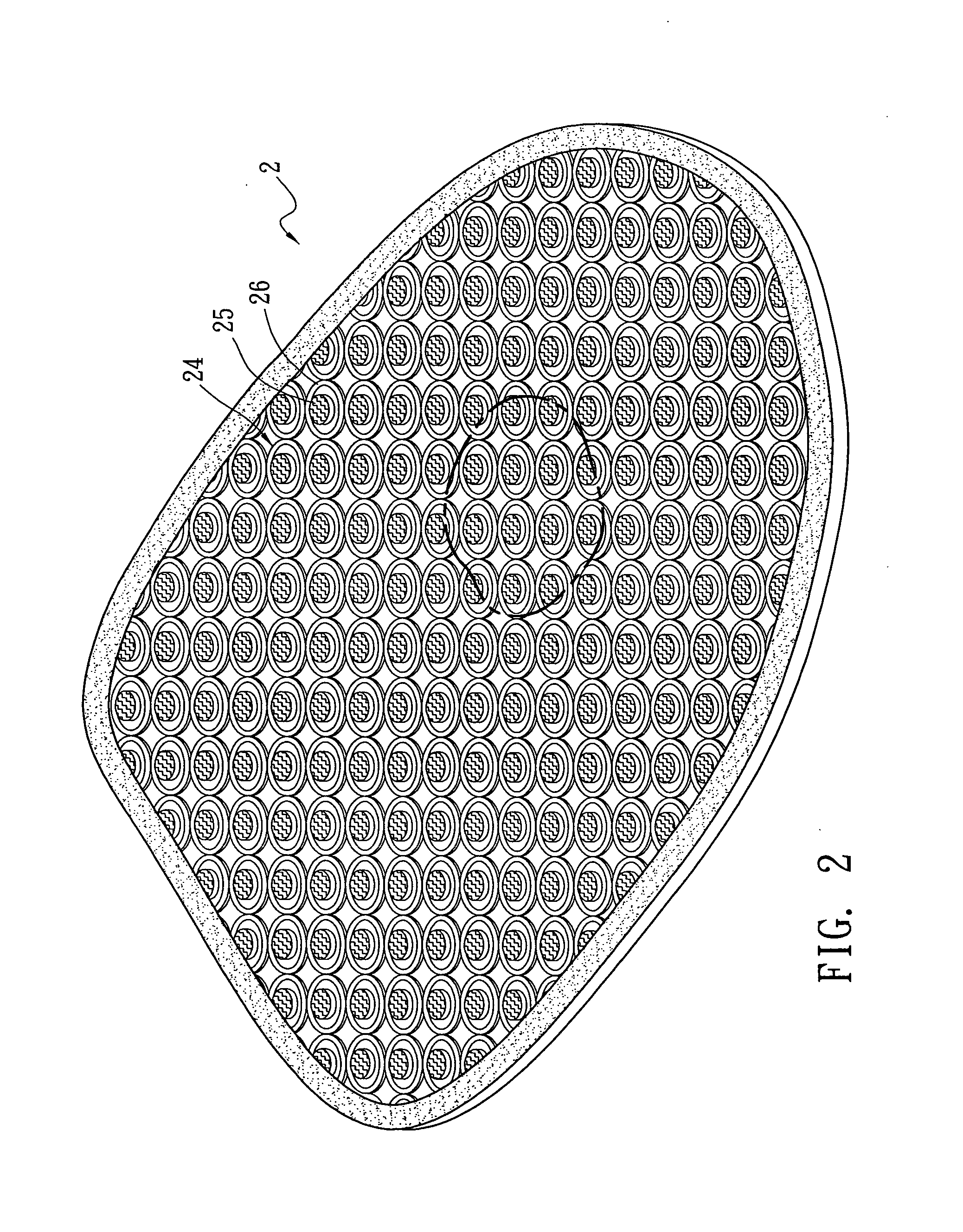

Computer bag

InactiveUS20070237487A1Buffering effectReduce thicknessDigital data processing detailsHandbagsInter layerSurface layer

A computer bag includes a layer of soft buffering piece disposed on inner / outer surface of the bag. The soft buffering piece consists of a surface layer, a middle layer and a bottom layer. The soft buffering piece includes a surface layer made from elastic textile such as Lycra, a middle layer made from waterproofing soft rubber such as styrene-butadiene rubber (SBR) and a bottom layer made from clothes such as jersey cloth. Then the three layers are hot pressing into an integrated piece with certain thickness. And a plurality of projecting units having projecting bars and projecting rings surrounding thereof are disposed evenly on surface of surface layer so as to form a buffering layer. Thus the computer bag has better buffering effect for protecting things therein.

Owner:CASE PAX INT

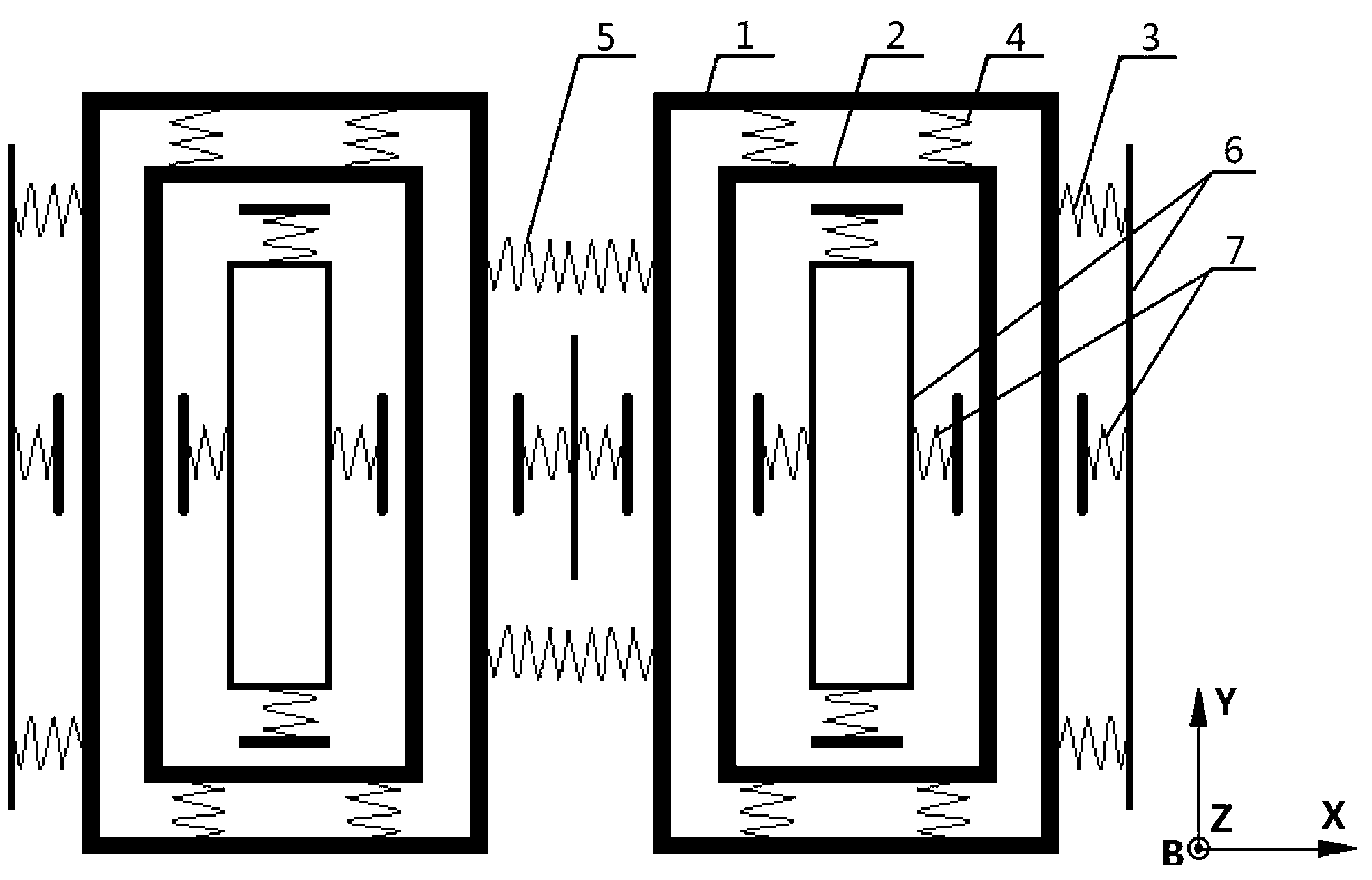

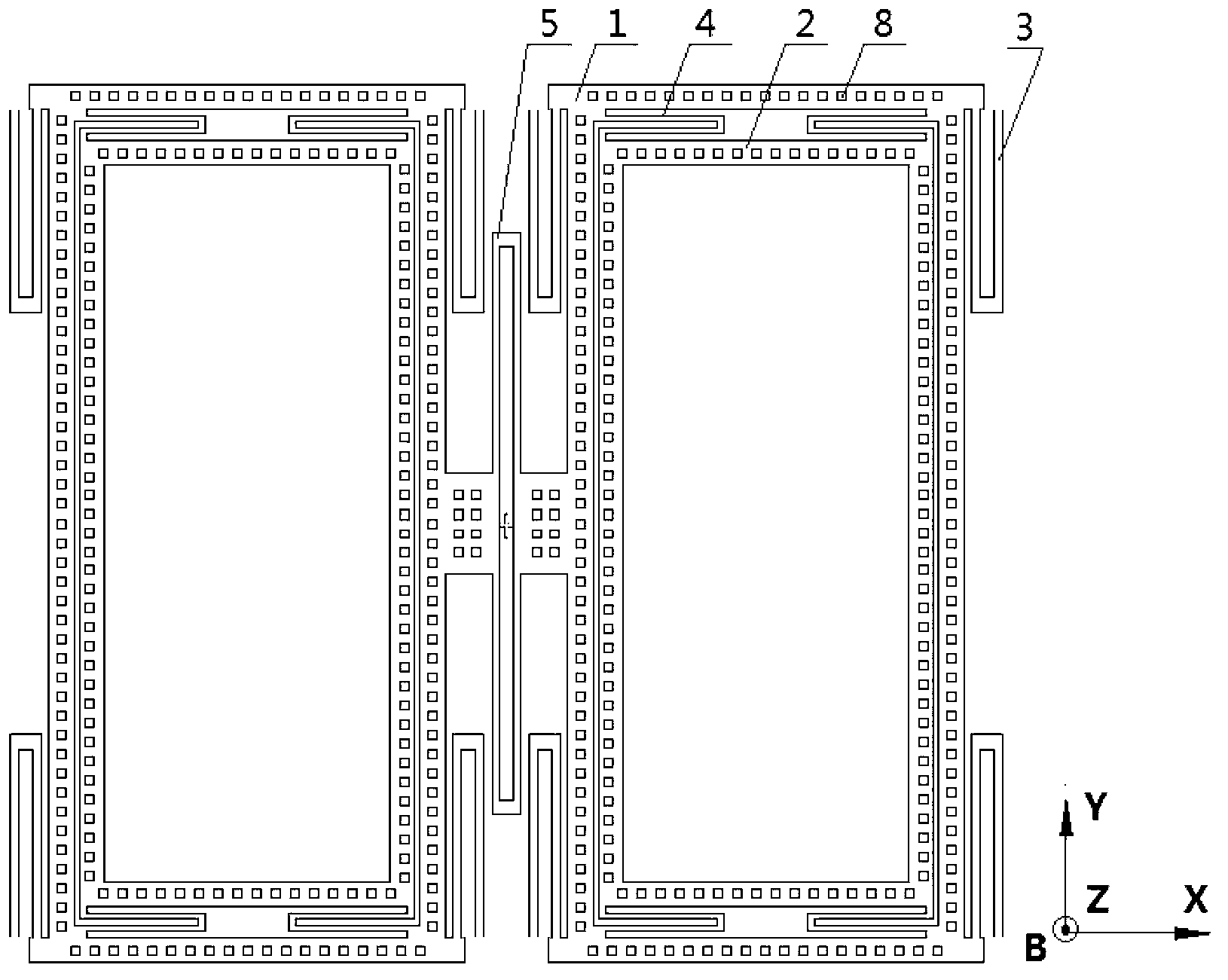

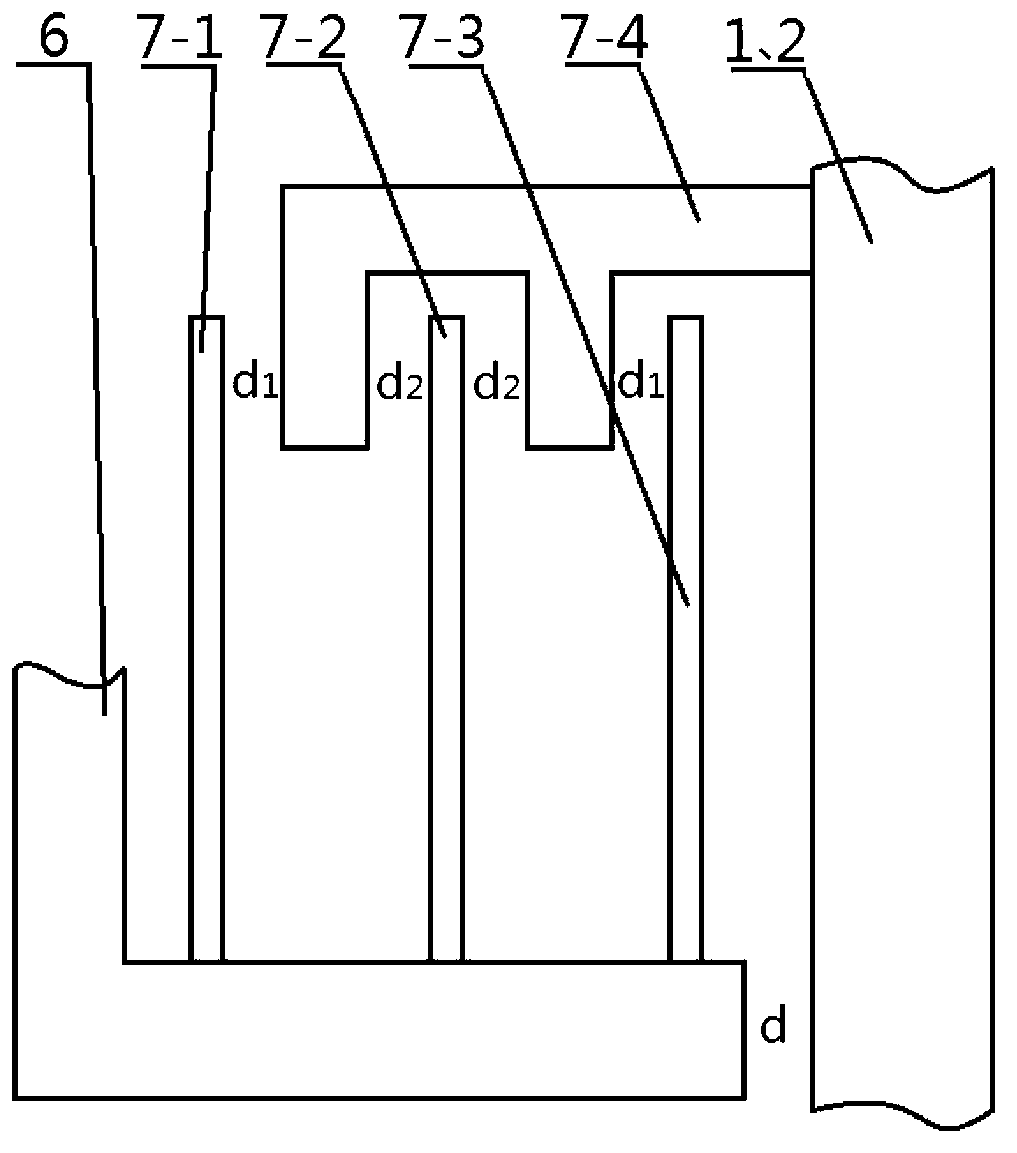

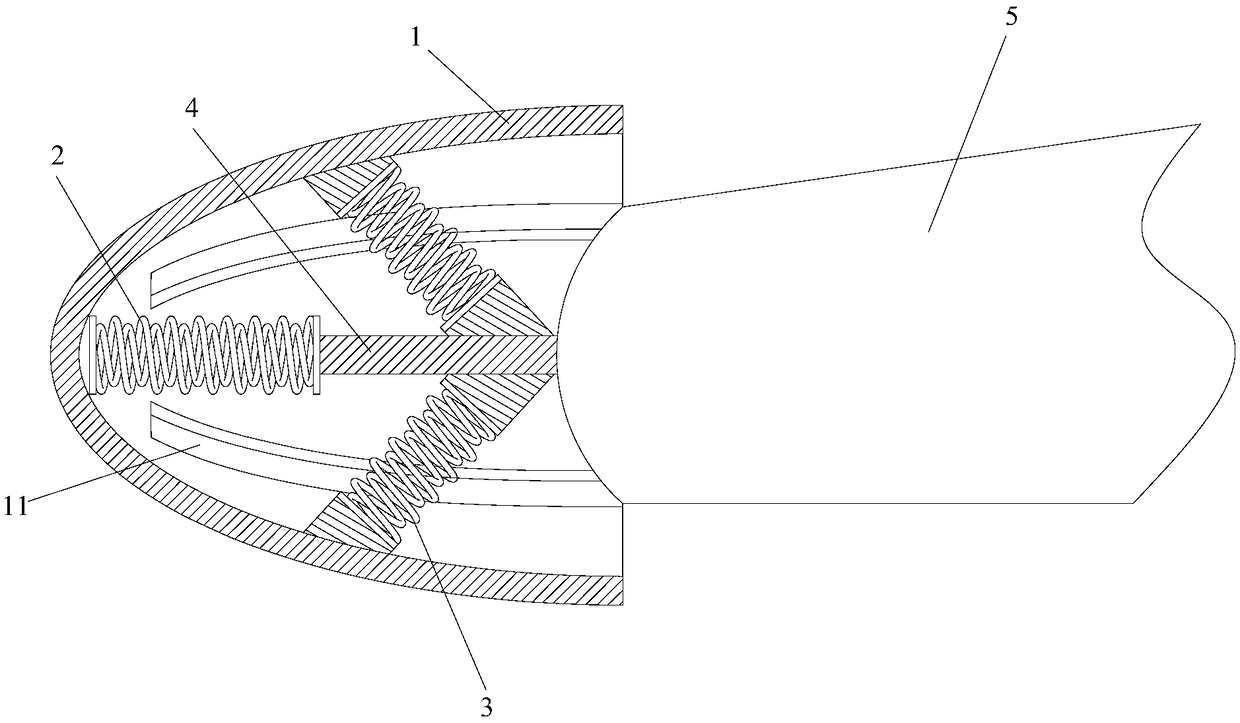

Tuning fork type micromechanical gyroscope capable of resisting high-strength impact

InactiveCN103292798ASimple structureAvoid structural damageSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesTuning forkGyroscope

The invention discloses a tuning fork type micromechanical gyroscope capable of resisting a high-strength impact. The tuning fork type micromechanical gyroscope comprises two single-frame type structures in a bilateral symmetry manner, wherein the two single-frame type structures are connected through an intermediate coupling beam; each single-frame type structure comprises a driving mass frame, a detection mass frame which is arranged in the driving mass frame, a detection elastic beam structure, a driving elastic beam structure, and elastic limiting structures which are paired in the single direction of the horizontal and vertical directions; the detection elastic beam structure is connected with the driving mass frame and the detection mass frame; the driving mass frame is connected with an anchor point through the driving elastic beam structure; each elastic limiting structure comprises elastic limiting comb teeth which are connected to the anchor point, and a limiting stop block which is connected to the driving mass frame or the detection mass frame. By respectively designing the elastic limiting structures in the horizontal and vertical directions, when a main body structure is subjected to the high-strength impact, the elastic limiting structures limit the displacement of the main body structure in the horizontal and vertical directions, and structural damage caused after an elastic beam exceeds an elastic deformation limit during the displacement of the main body structure is avoided.

Owner:TONGJI UNIV

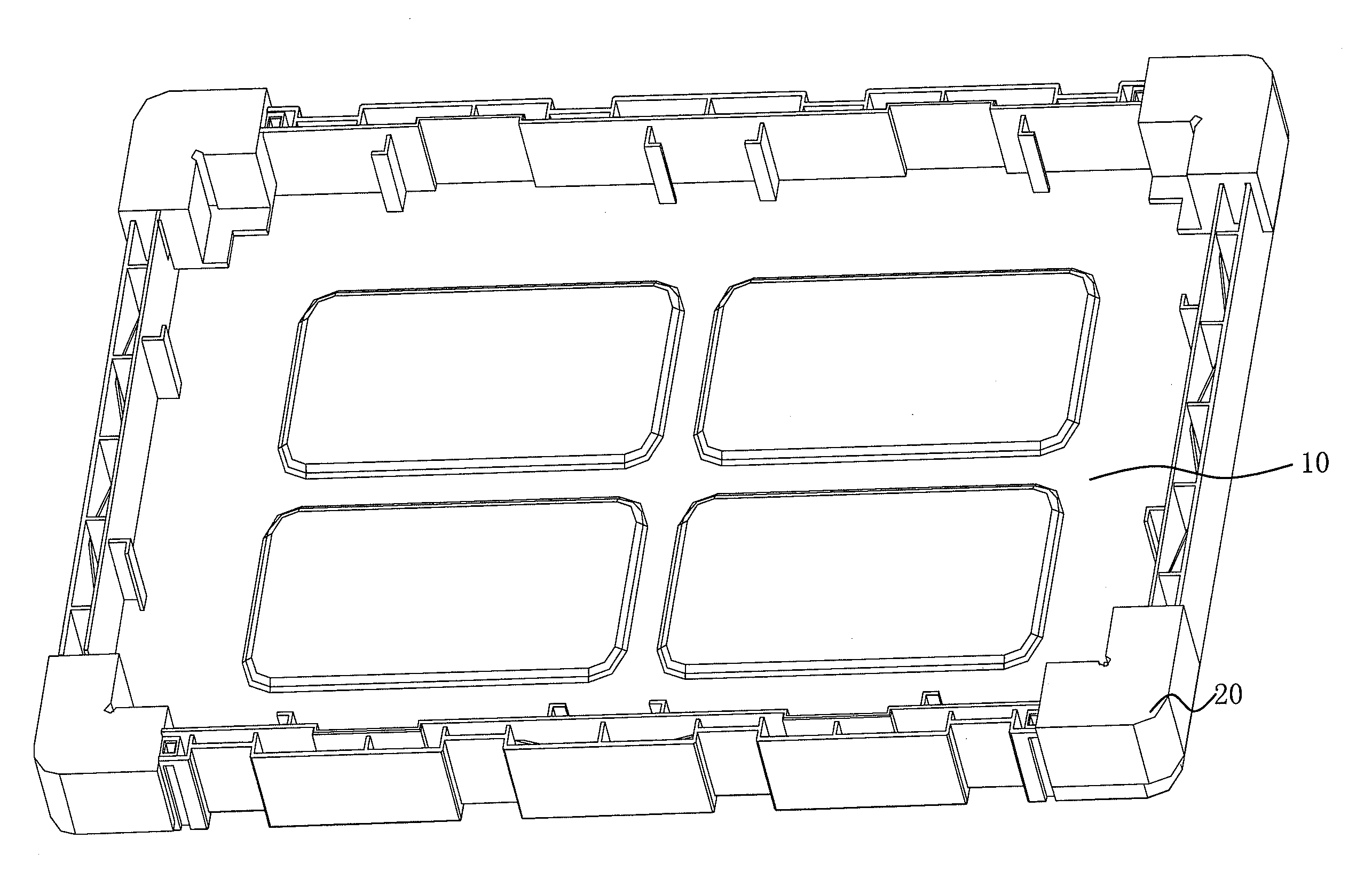

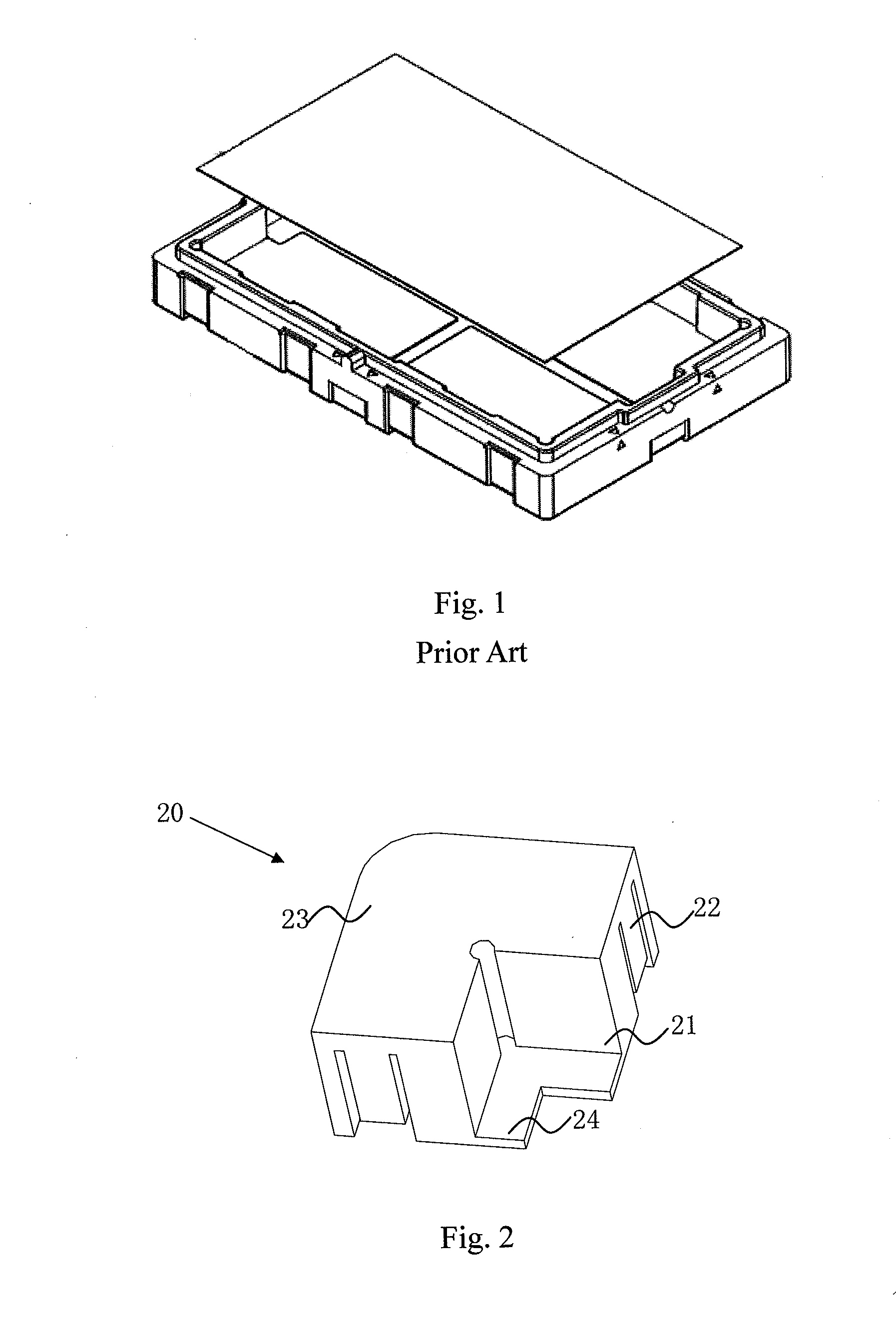

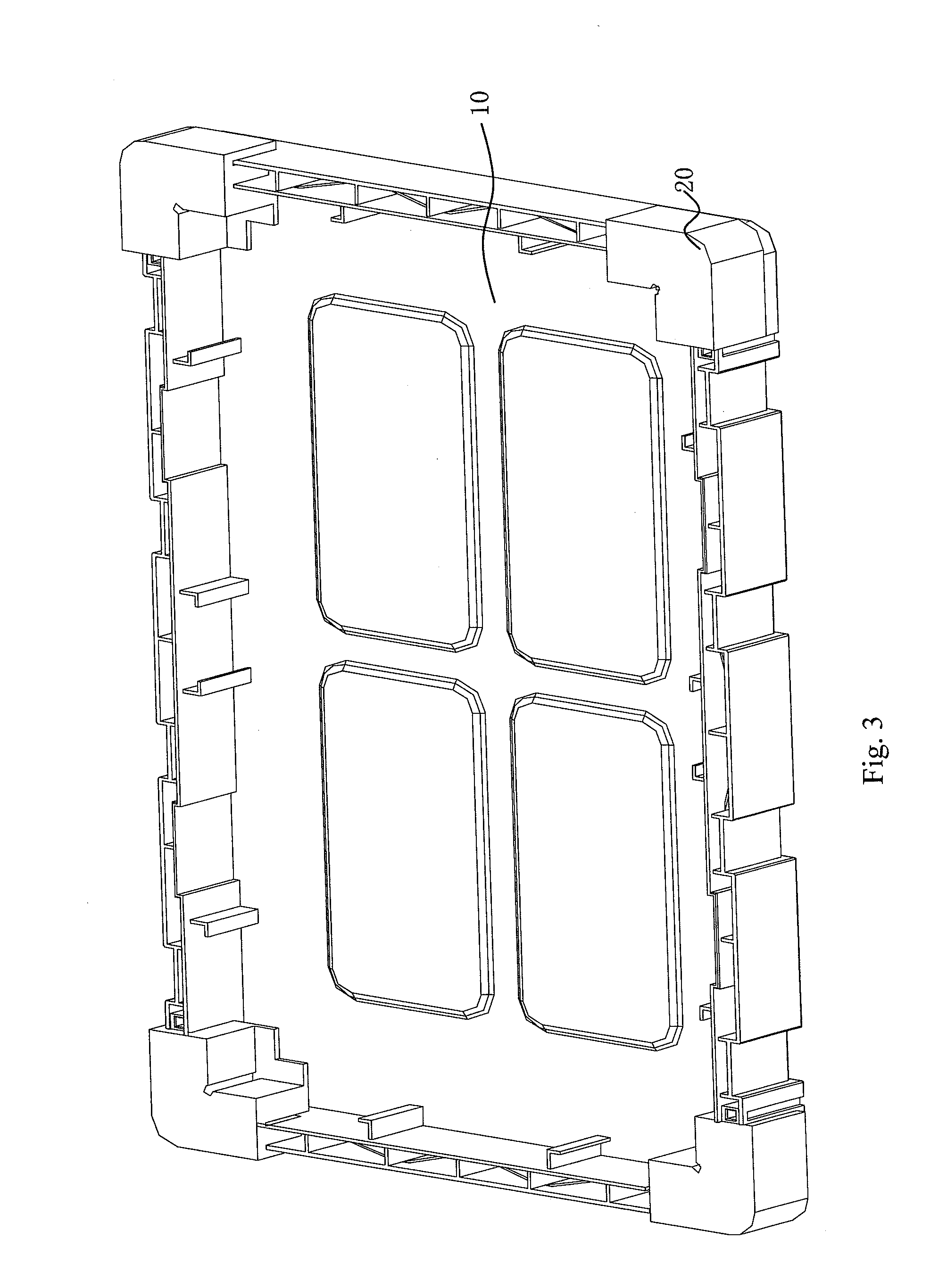

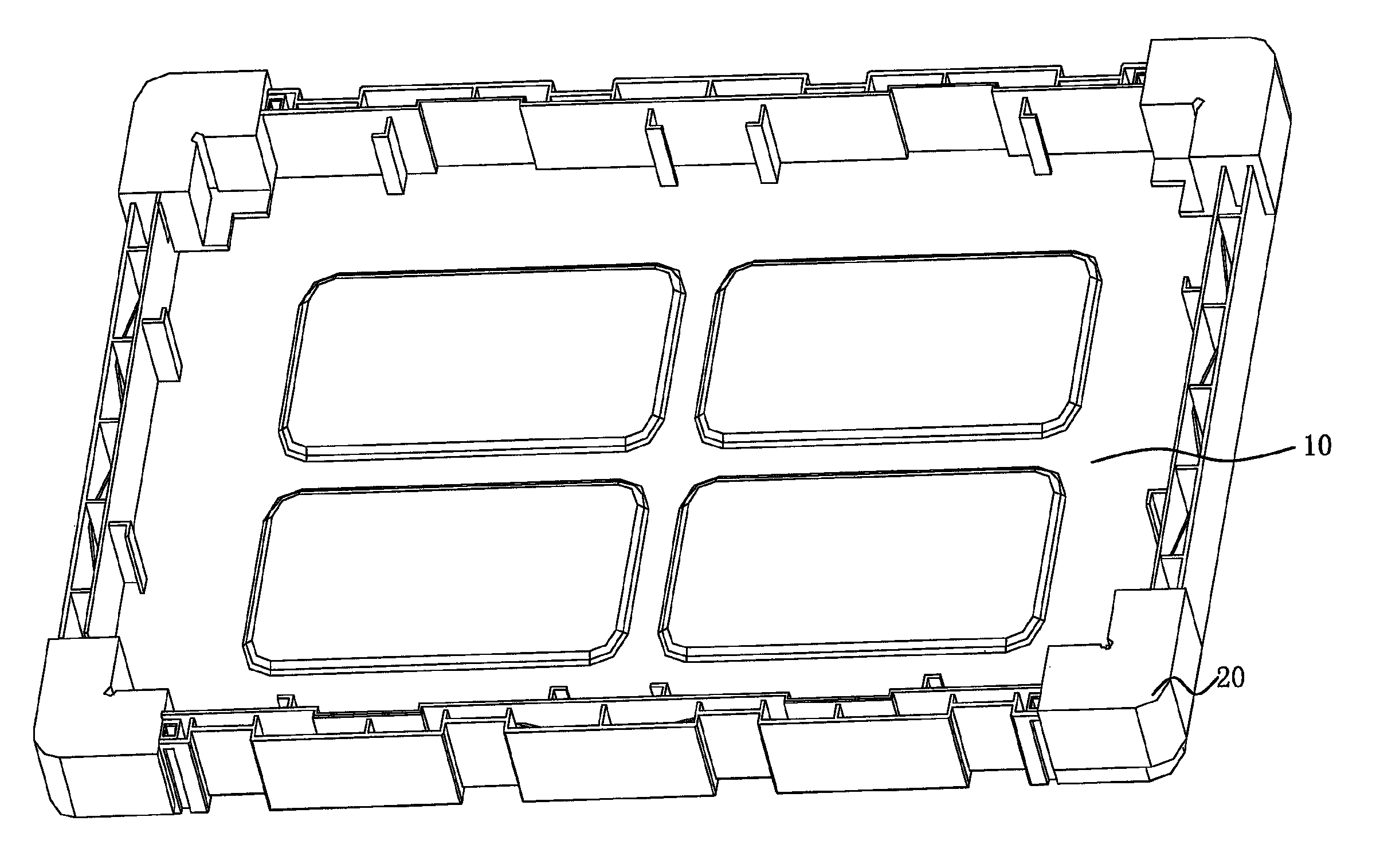

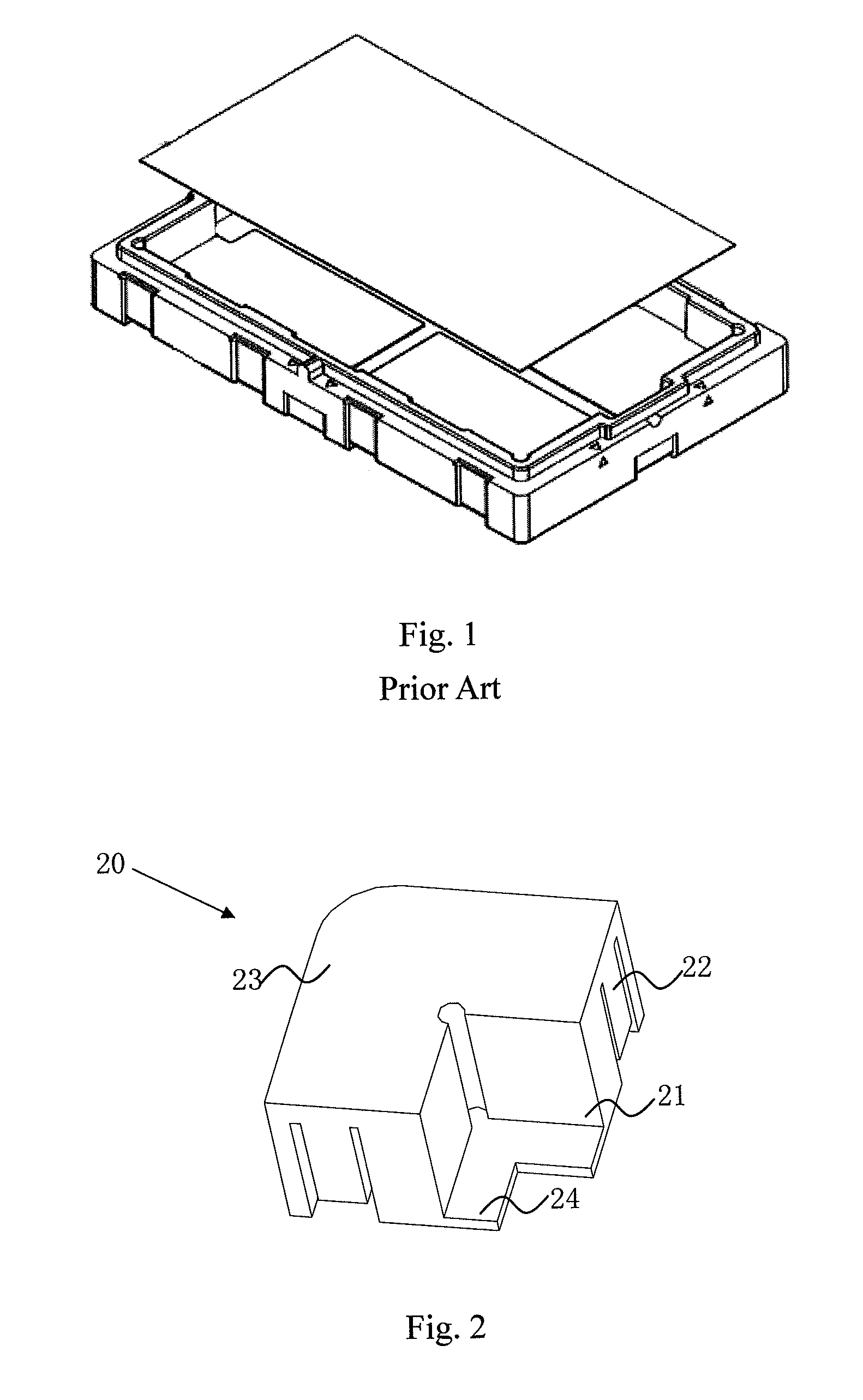

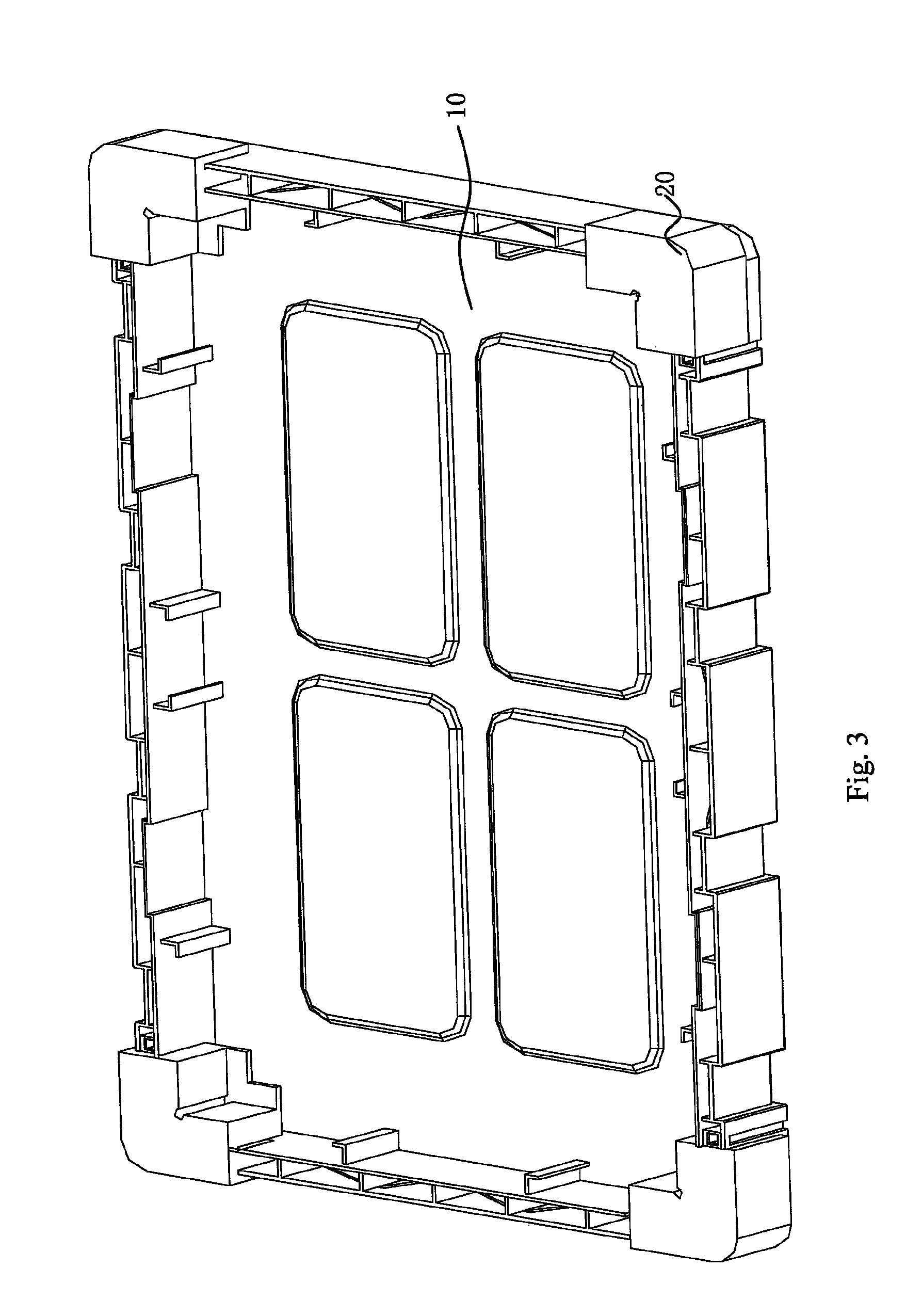

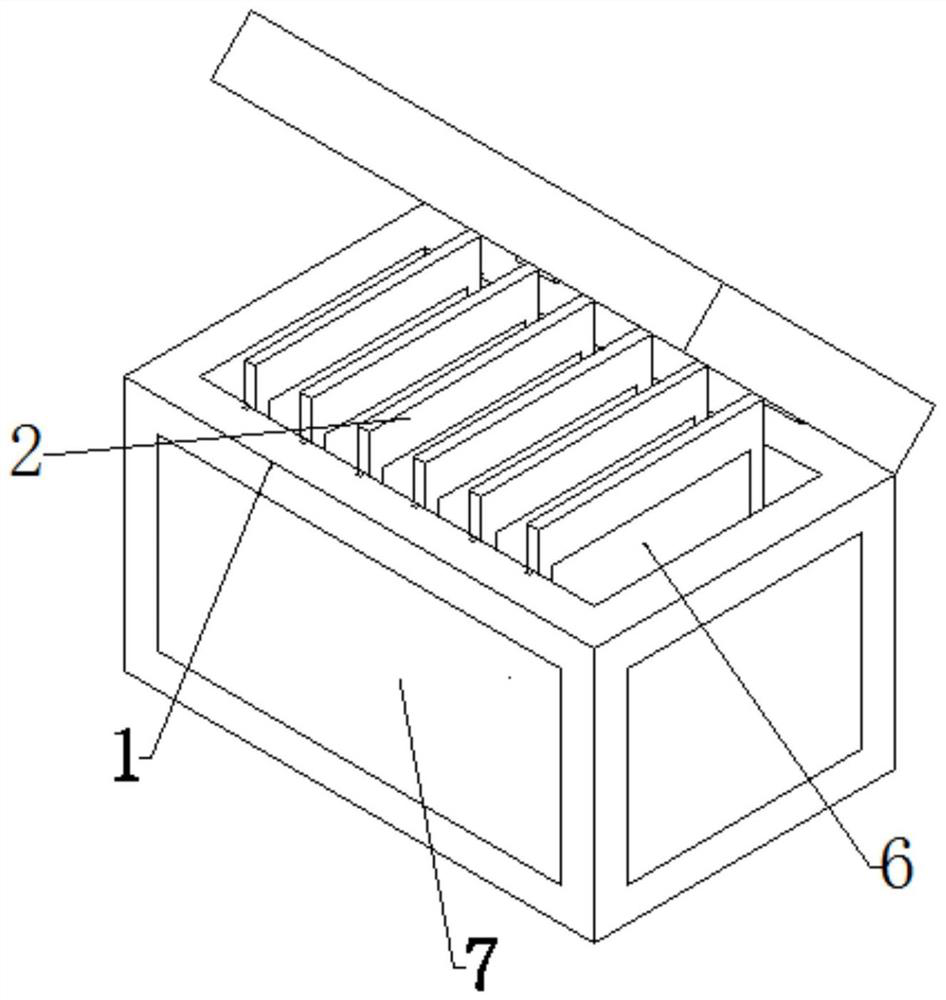

Buffering stop structure and corresponding packing case

ActiveUS20130293803A1Reduce manufacturing costManufacture costNon-linear opticsLiquid-crystal displayEngineering

The present invention relates to a buffering stop structure and a corresponding packing case. The buffering stop structure is disposed at a connecting corner between adjoining side surfaces of a corresponding case main body. The case main body is used to load a liquid crystal display (LCD) panel. The buffering stop structure comprises a fixing portion, a connecting portion and a case buffering portion. The manufacture cost of the buffering stop structure and the corresponding packing case of the present invention is lower, and the buffering effect thereof is better, so as to solve the problems of the packing case of existing technology that has higher manufacture cost and may cause environment pollution.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

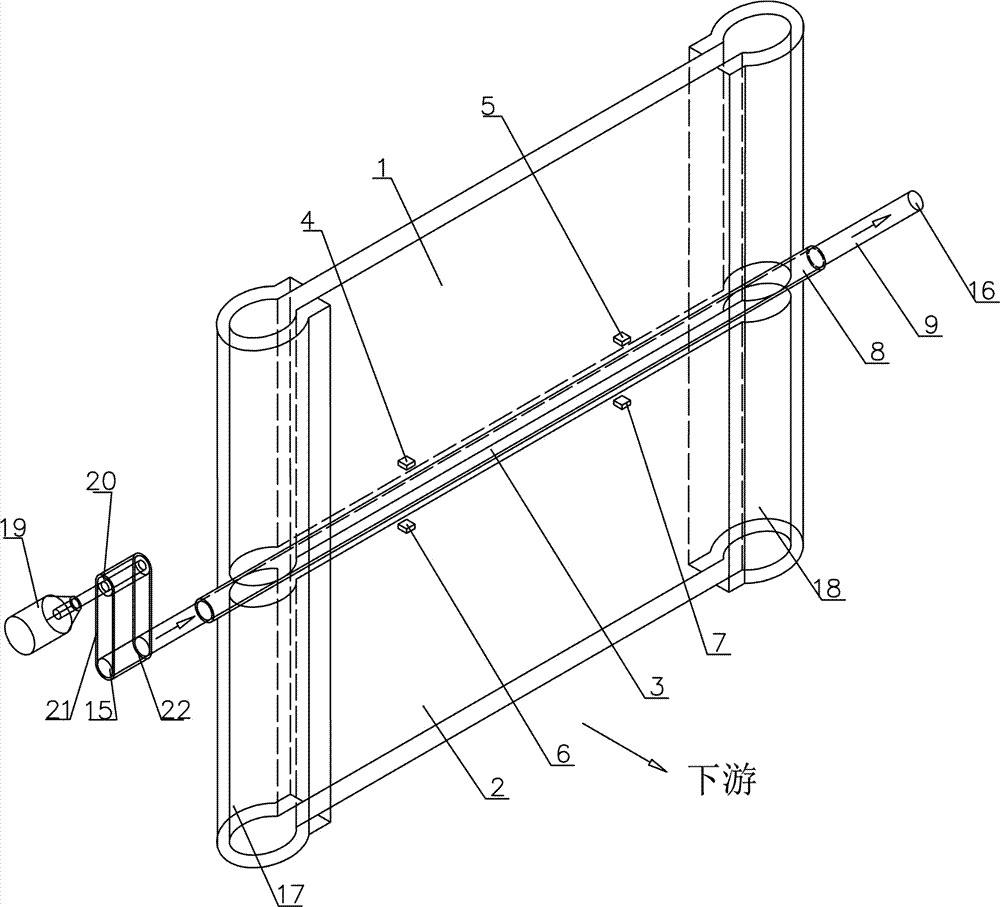

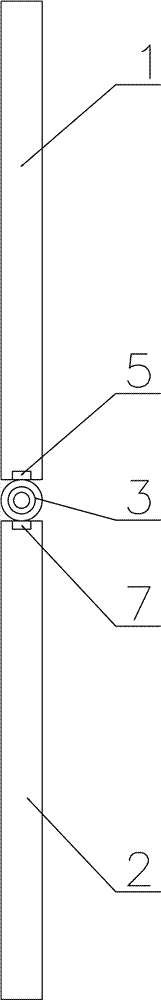

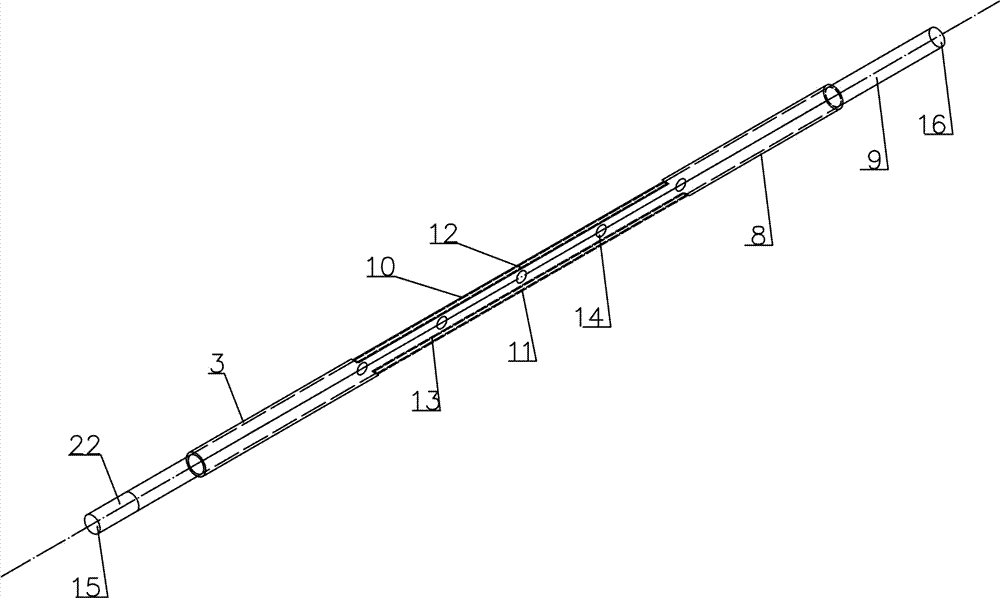

Inflatable type hydropower station ecological tail gate and operation method

The invention relates to an inflatable type hydropower station ecological tail gate and an operation method. The inflatable type hydropower station ecological tail gate is mainly composed of gate blades in longitudinal symmetry and double layers of casing pipes capable of rotating relatively. The gate blades comprise rubber gate boards and supporting steel sheets; by inflating or deflating the interiors of the gate blades, the gate blades extend or contract in the vertical direction along a gate groove, and the gate is opened or closed. The double layers of casing pipes comprise the outer pipe and the inner pipe, the outer pipe is provided with an outer pipe vent groove and a downstream vent hole, an inner pipe vent groove is formed in the inner pipe, a motor drives the inner pipe to rotate to change the air flow direction, and the gate functions are switched. The inflatable type hydropower station ecological tail gate has the advantages of being simple in structure, flexible to operate, short in starting and closing time and low in manufacturing cost, and the ecological optimization function of changing the downstream water quality is achieved while the function of the hydropower station ecological tail gate is achieved.

Owner:CHINA THREE GORGES UNIV

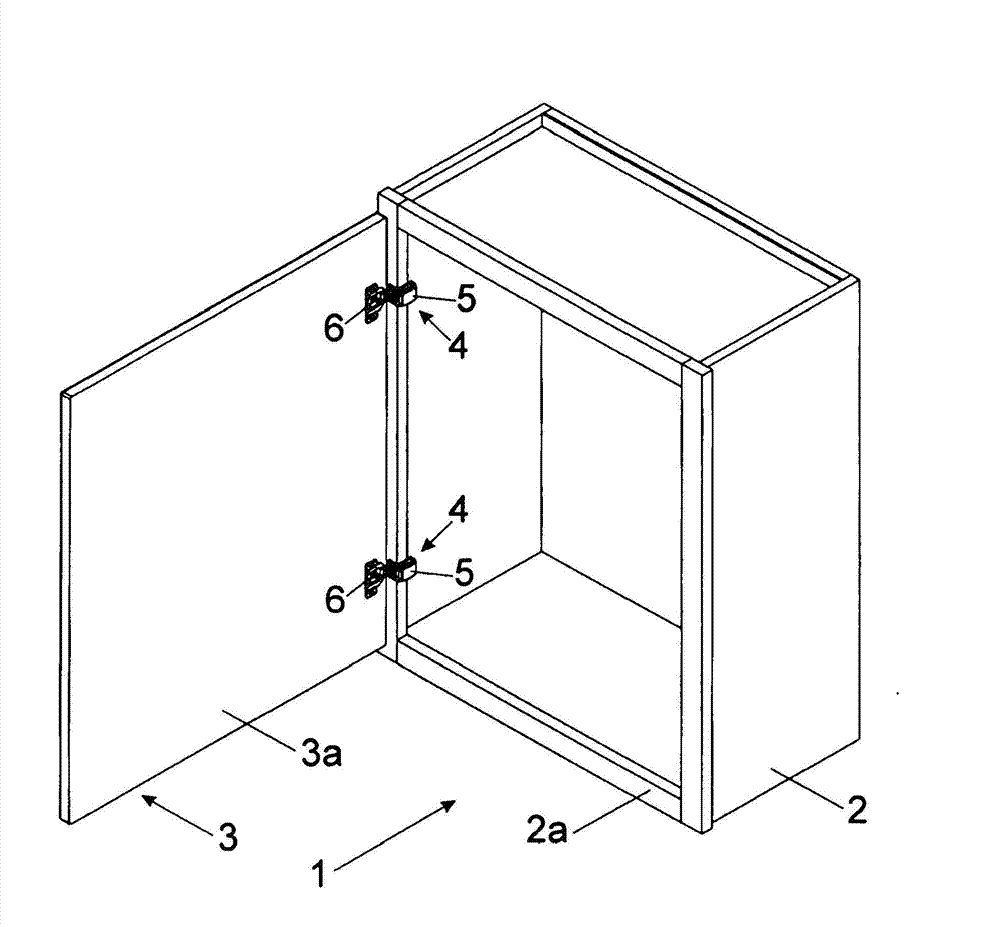

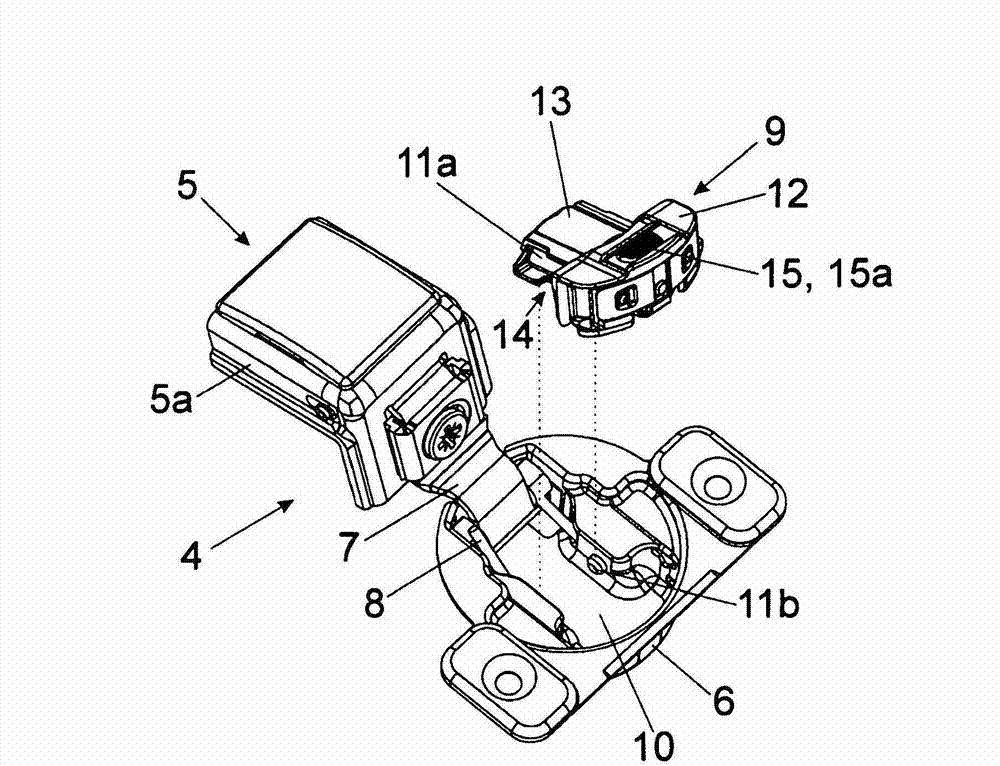

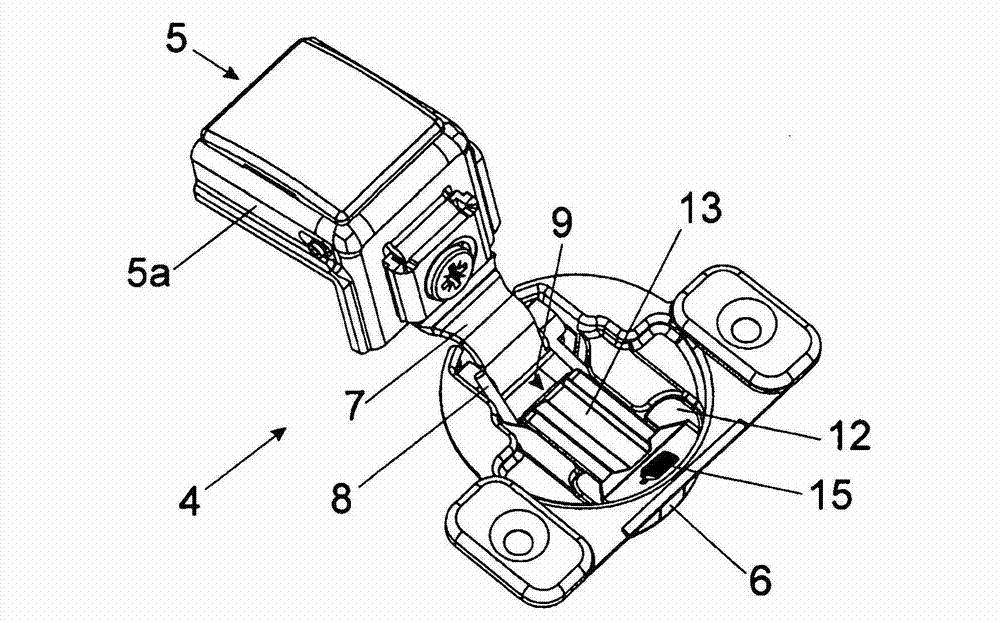

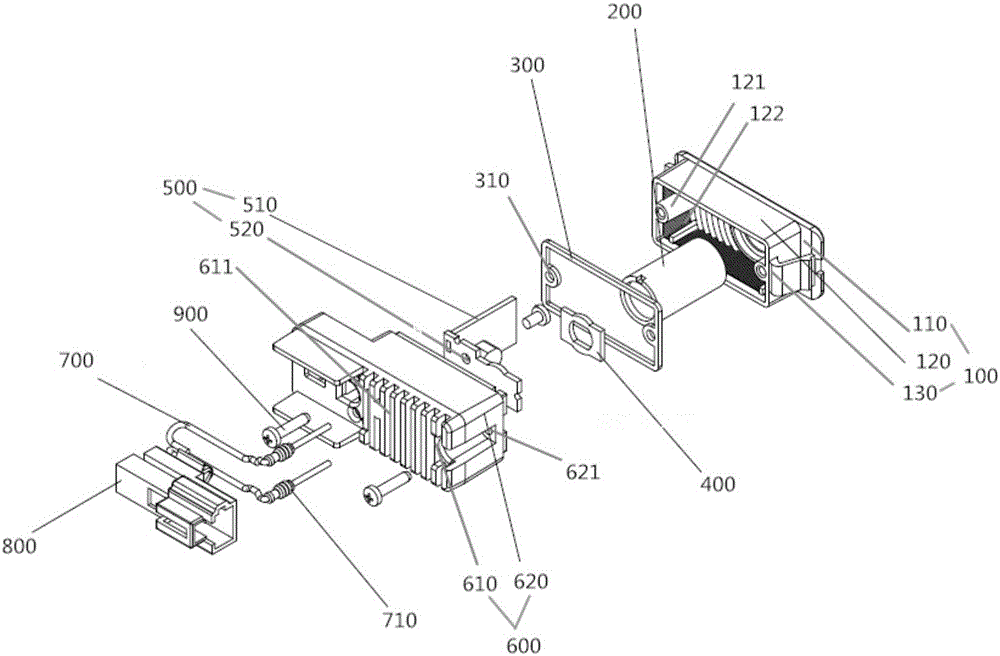

Damping device for furniture parts

ActiveCN103025987ASave spaceBuffering effectBuilding braking devicesWing accessoriesEngineeringRelative motion

The invention relates to a damping device (9) for damping a motion of a movably mounted furniture part (3) or of a movably mounted furniture fitting component of a furniture fitting, comprising a piston (22) arranged in a fluid chamber (21), wherein a damping effect is caused by a relative motion between the fluid chamber (21) and the piston (22) and wherein the piston (22) assumes a pressed-in end position relative to the fluid chamber (21) at the end of the damping stroke and wherein the damping device (9) has a locking device (15), which has a locking element (15a) that can be operated manually or by means of a tool, in order to deactivate the damping effect, wherein the relative position between the fluid chamber (21) and the piston (22) can be releasably locked in the pressed-in end position by the locking element (15a) of the locking device (15).

Owner:JULIUS BLUM GMBH

Use of low molecular weight amino alcohols in ophthalmic compositions

InactiveUS6949218B2High activityEnhanced anti-microbial activitySenses disorderInorganic boron active ingredientsAlcoholPreservative

The use of low molecular weight amino alcohols in ophthalmic compositions is described. These compounds have been found to enhance the efficacy of anti-microbial preservatives.

Owner:ALCON RES LTD

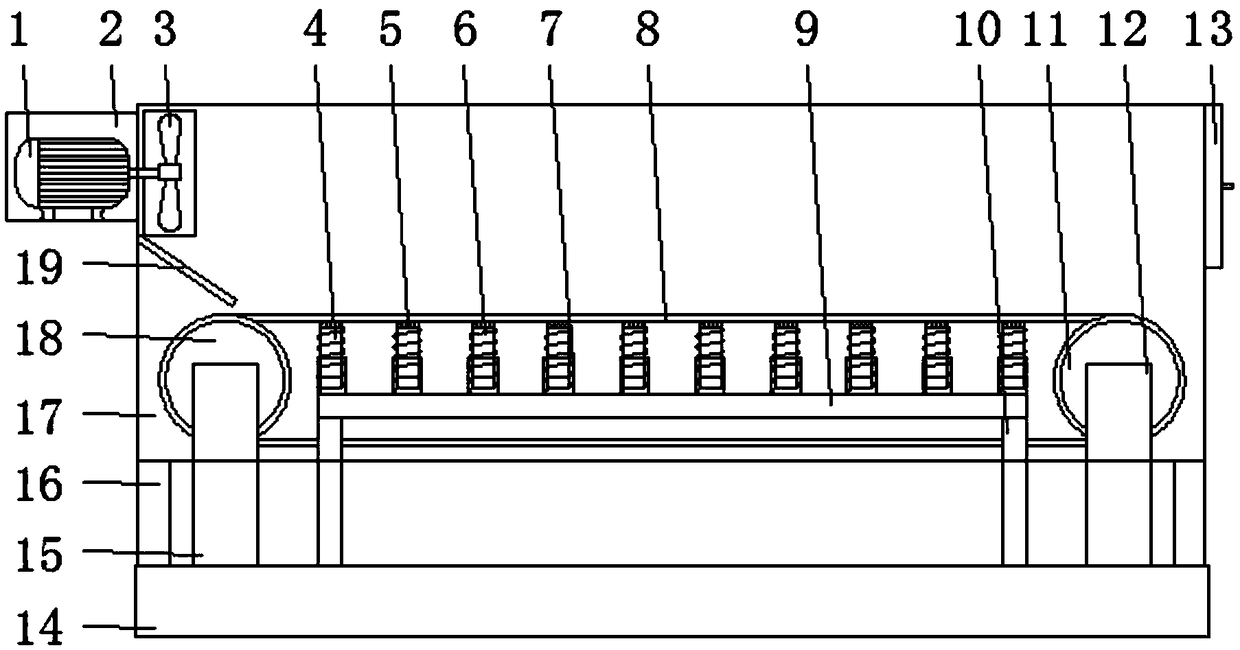

Dustproof conveying device for electric appliance

InactiveCN108750544AEasy to useRealize the buffering effectConveyorsCleaning using gasesElectric machineryArchitectural engineering

Owner:王娟娟

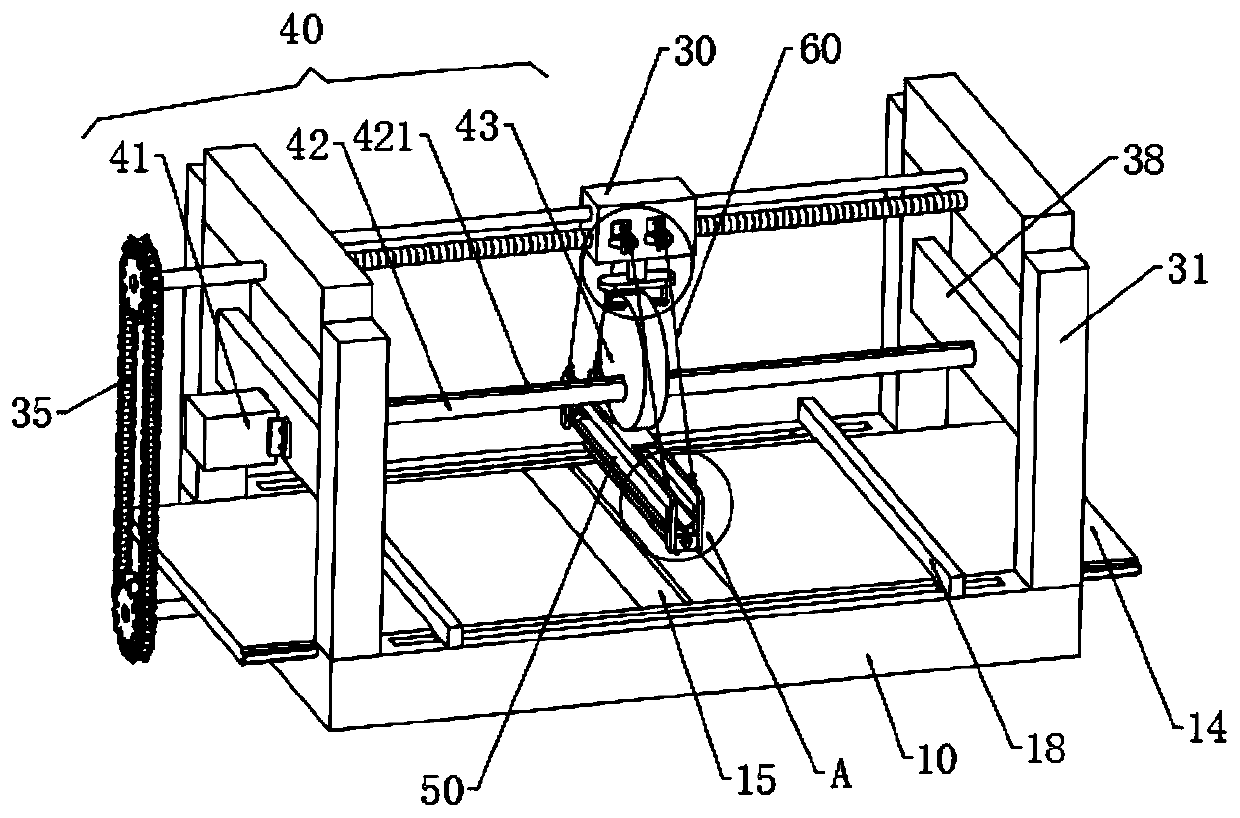

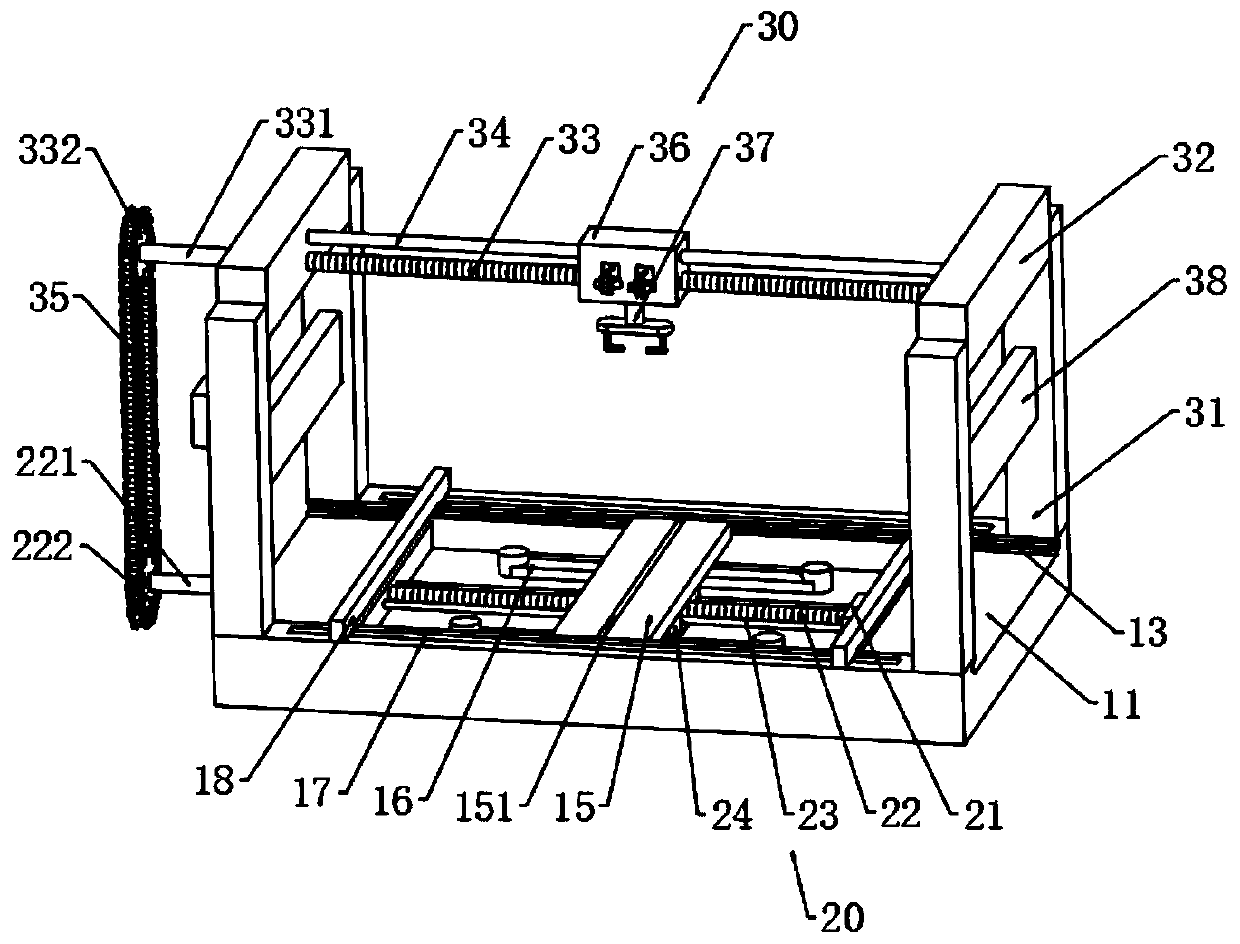

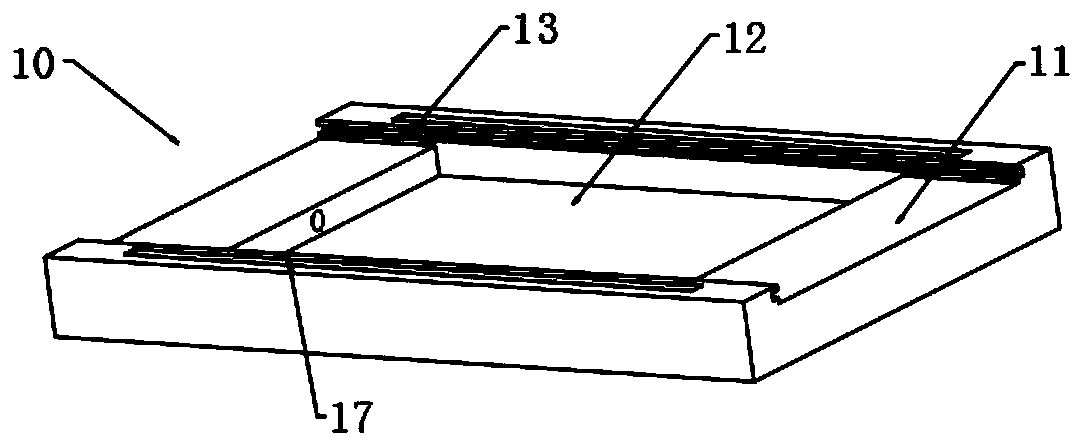

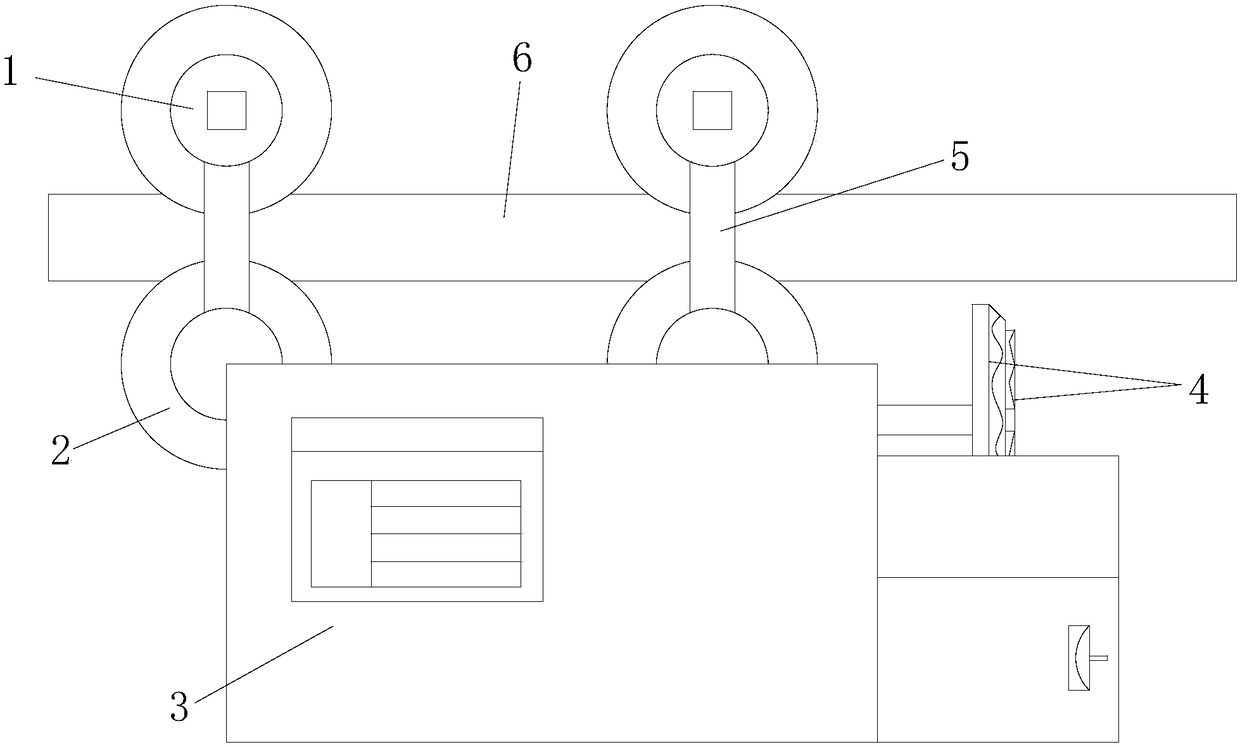

Indentation folding processing method for paper box made of corrugated boards

InactiveCN111391404ASimplifies the replacement and fixation processImprove work efficiencyBox making operationsPaper-makingElectric machineryCorrugated fiberboard

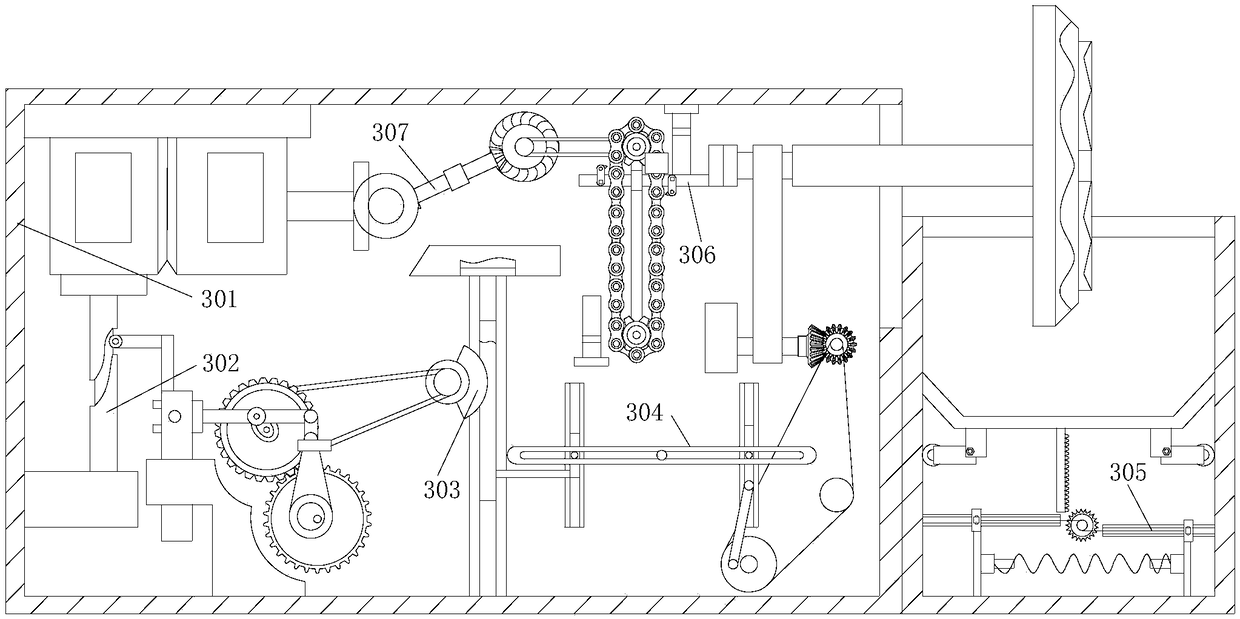

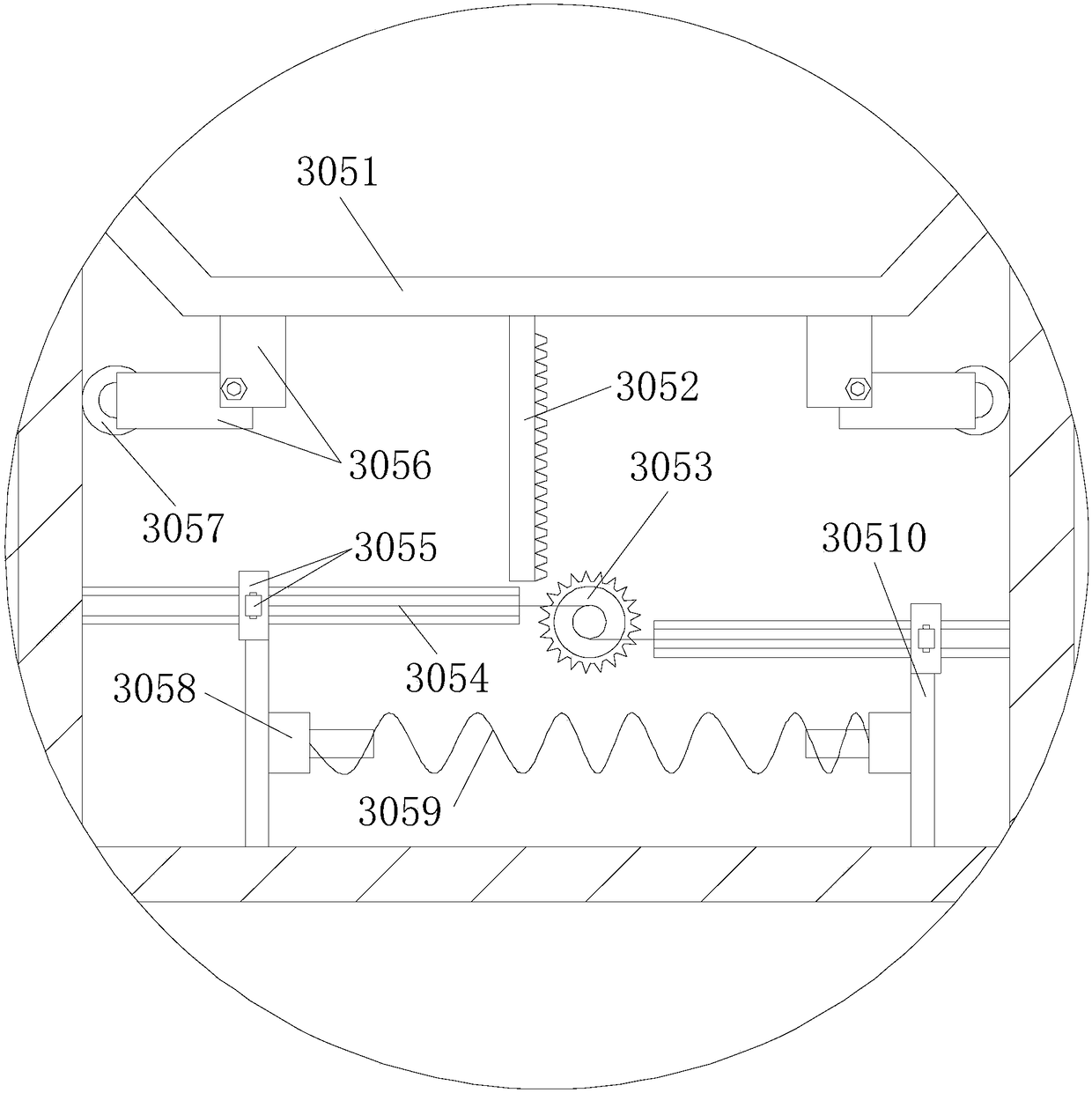

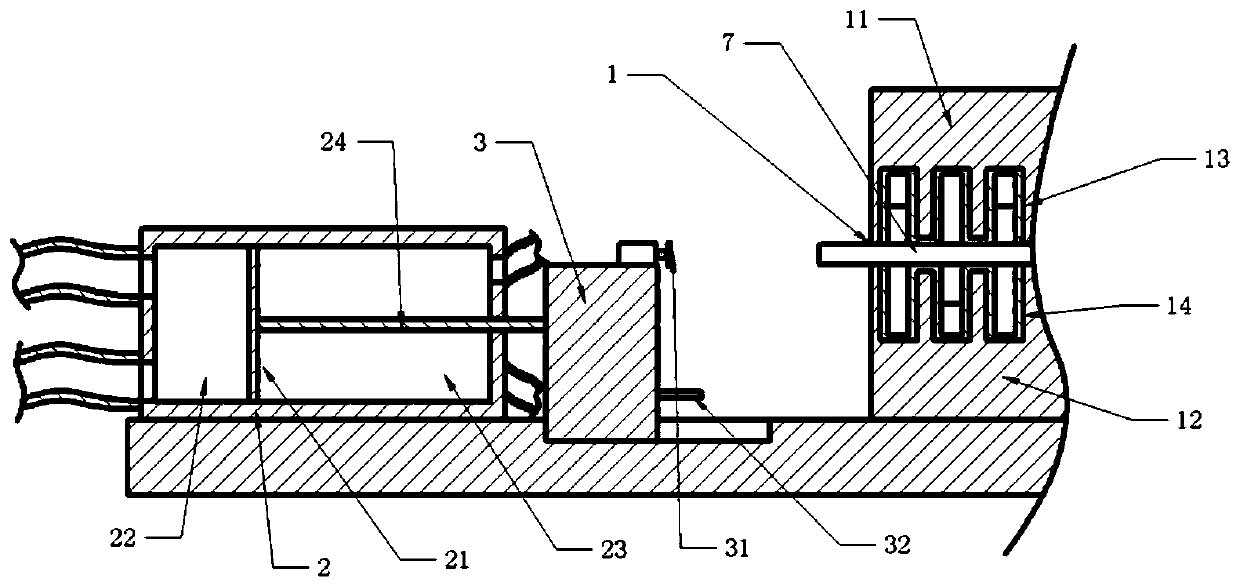

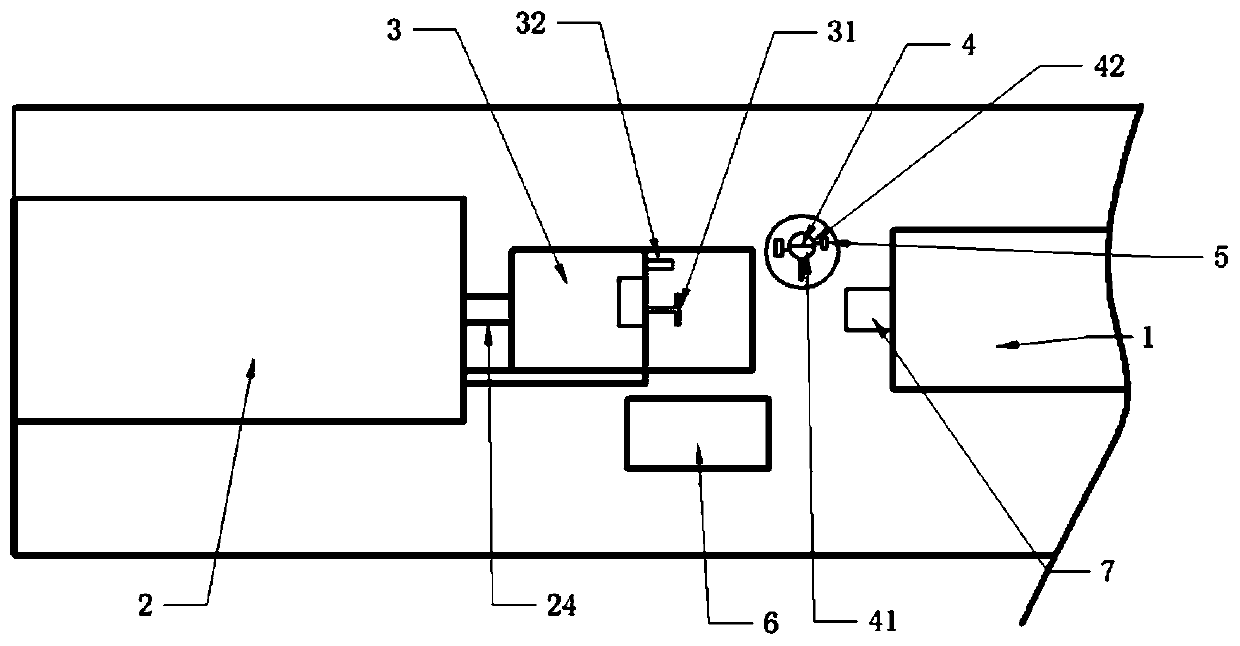

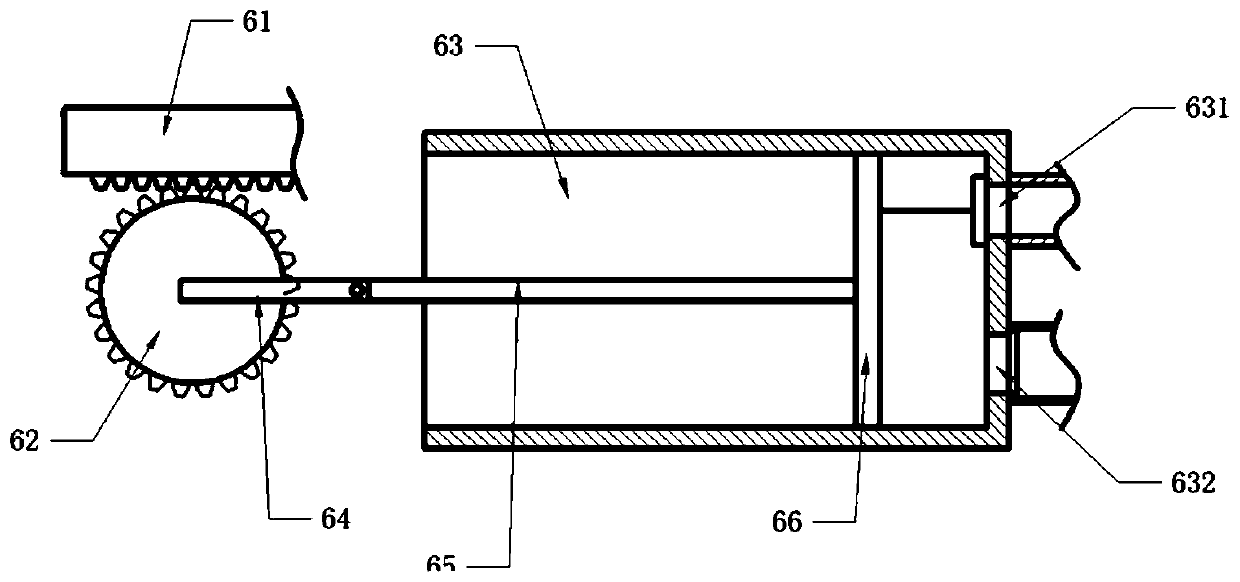

The invention relates to an indentation folding processing method for a paper box made of corrugated boards. The indentation folding processing method adopts a following indentation device. The indentation device comprises a bearing mechanism, an indentation mechanism arranged above the bearing mechanism and a cam mechanism arranged above the indentation mechanism, wherein a dial mechanism connected with the indentation mechanism is arranged above the cam mechanism, and a moving plate drive mechanism is arranged in the bearing device. By cooperation of two lead screws, chain wheels and a chain, a stepper motor drive the two lead screws to rotate synchronously, so that two moving seats drive the indentation mechanism and a moving plate to move synchronously respectively, not only can spacing between indentations be adjusted, but also a semi-circular groove can be used for producing a buffer effect on a cutting tool; a round pipe is sleeved with the cutting tool provided with three cutting heads, the corresponding cutting tool can be replaced by rotation, a locking block is used for limiting rotation of a round rod, so that the cutting tool is fixed, and replacing and fixing processes of the cutting tool are simplified.

Owner:李佳佳

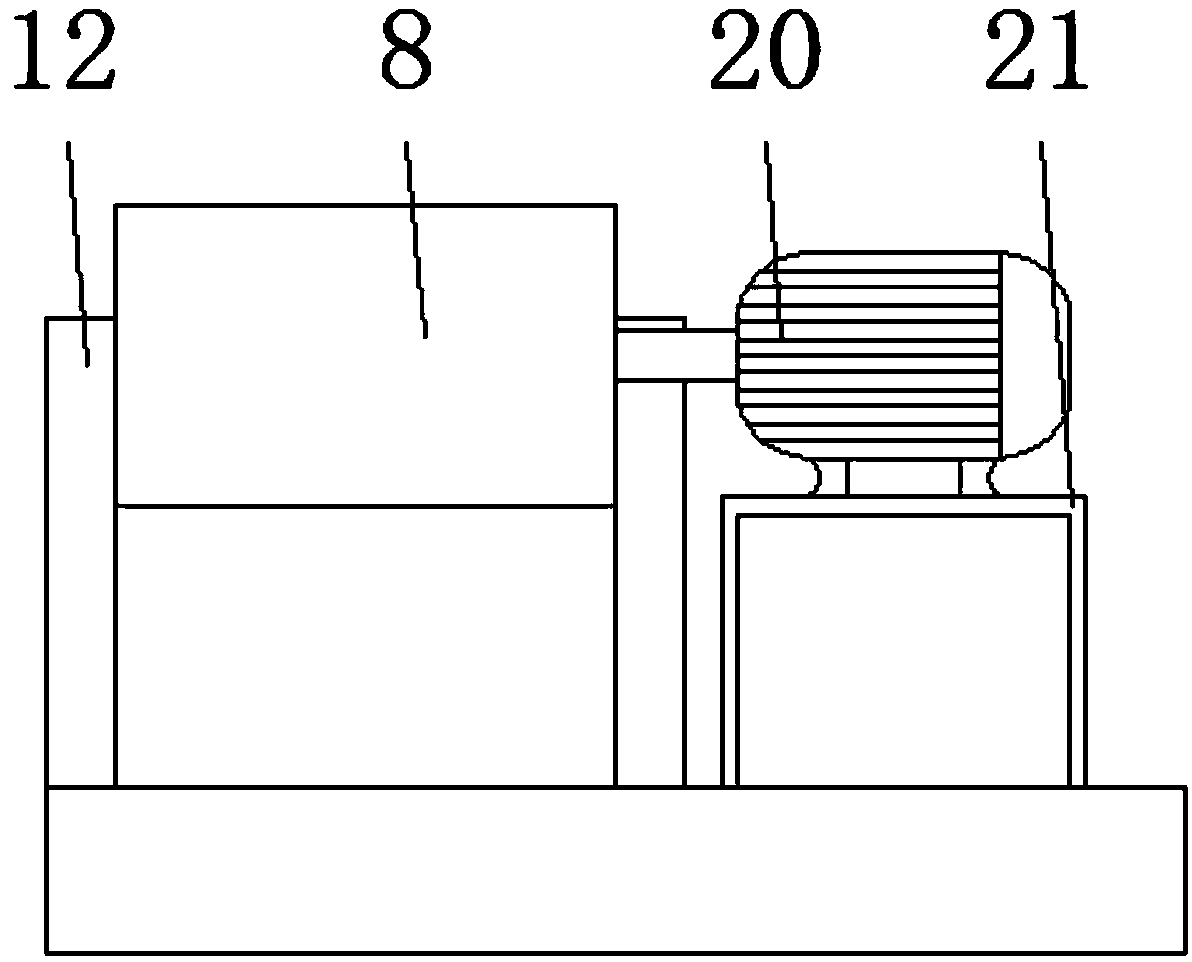

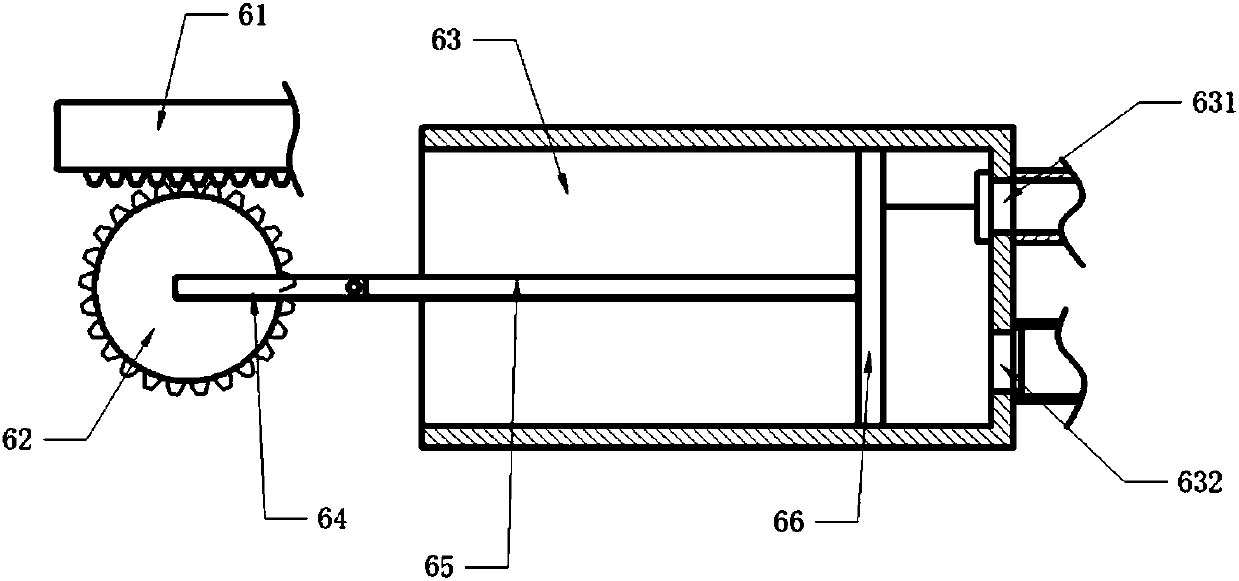

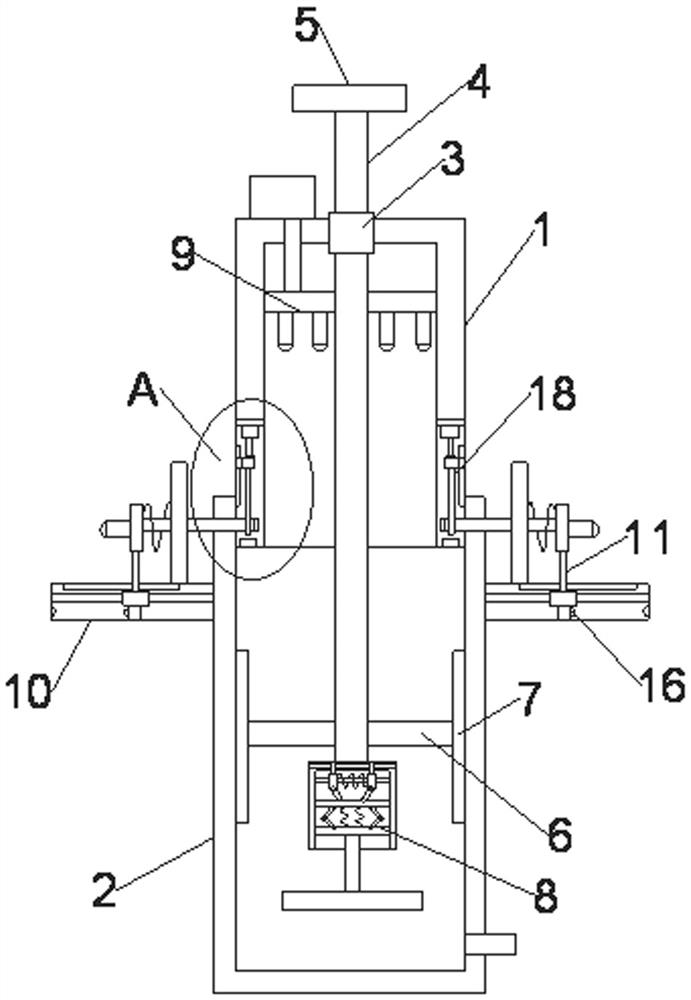

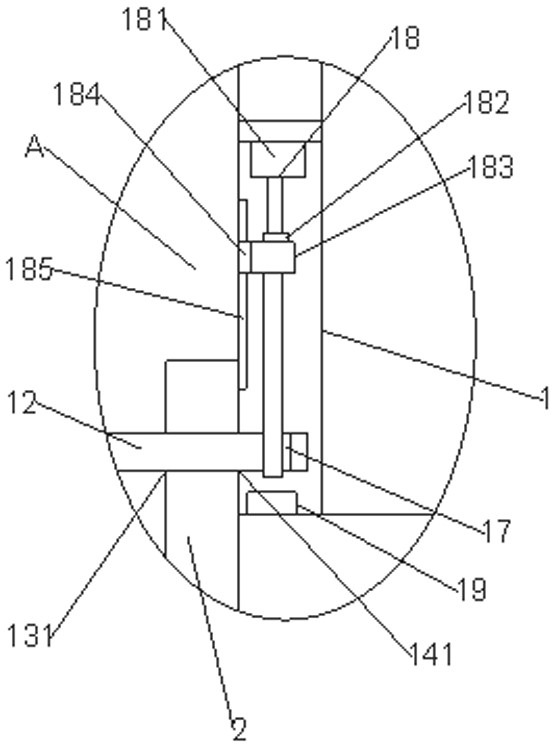

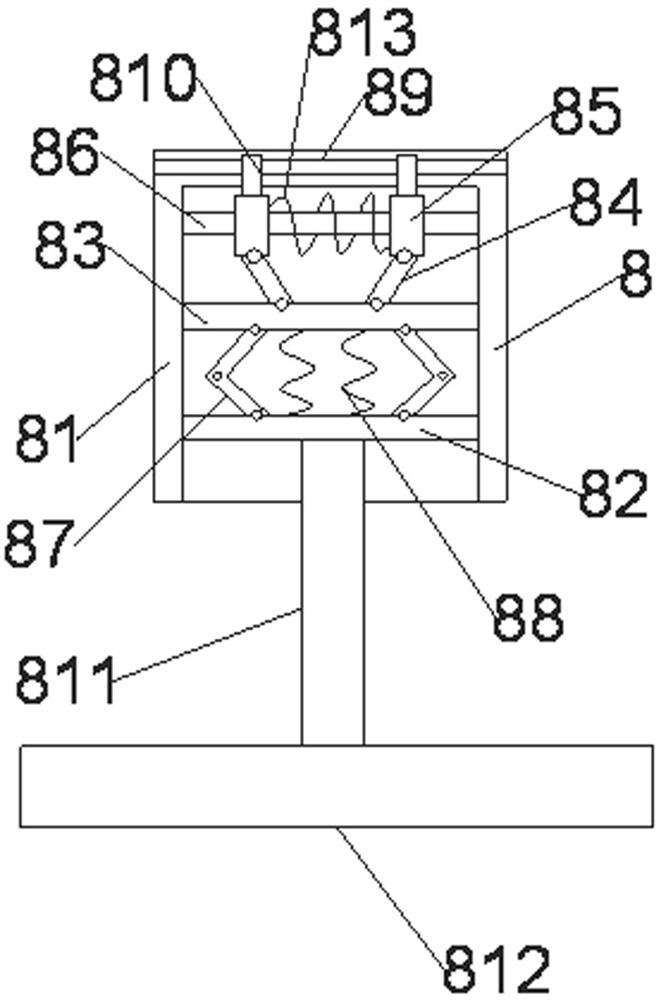

Motorcycle part machining equipment

ActiveCN108015645AImprove machining accuracyAvoid damage to the camshaftGrinding drivesBelt grinding machinesEngineeringElectromagnet

The invention belongs to the technical field of mechanical element machining devices, and discloses motorcycle part machining equipment. The motorcycle part machining equipment comprises a machine frame, a fixing mechanism and a grinding mechanism, wherein the fixing mechanism comprises an upper supporting block and a lower supporting block; mounting grooves are formed in the upper supporting block and the lower supporting block, and air bags are arranged in the mounting grooves; the grinding mechanism comprises a driving part and a grinding part, the driving part comprises an air tank, a partition plate is arranged in the air tank, and the air tank is divided into an air inlet cavity and an air exhaust cavity through the partition plate; a push rod is arranged on the side, close to the air exhaust cavity, of the partition plate; the grinding mechanism comprises a mounting table, and a grinding head and a motor are arranged on the mounting table; a supporting rod and a magnet layer arearranged on the mounting table; and the machine frame is further provided with an emergency stop mechanism, the emergency stop mechanism comprises a power supply, a conductive disc and an electromagnet, and the conductive disc is rotationally connected with the machine frame. The motorcycle part machining equipment solves the problem of high machining cost due to low machining efficiency caused by the facts that two devices are needed when a camshaft is ground and debugging between the two devices needs a long period of time cost in the prior art.

Owner:宁波江北珂达汽车技术有限公司

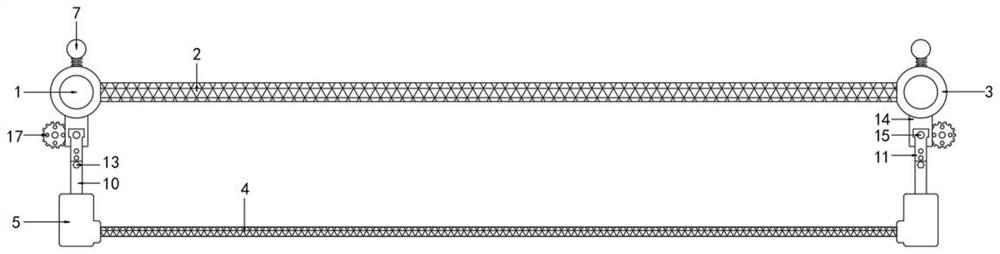

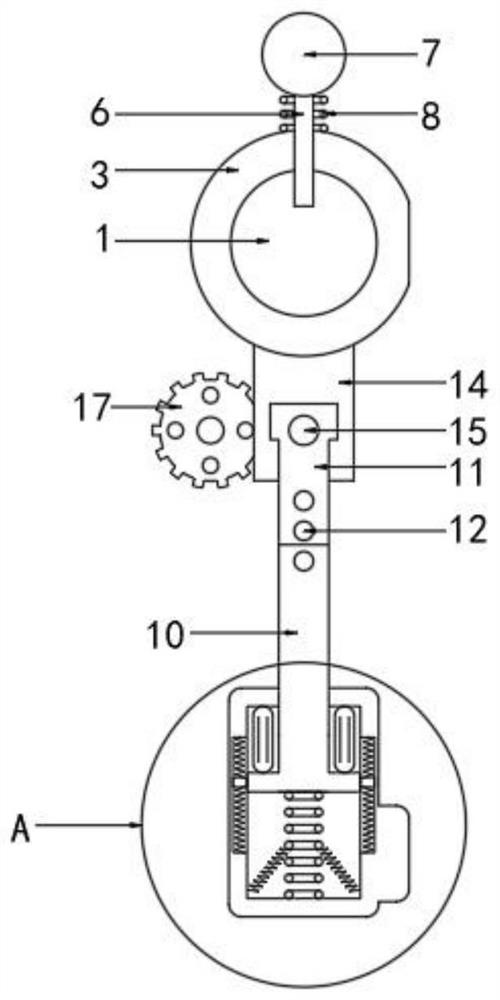

Automatic electric construction robot

InactiveCN108512117AProtection against the danger of falling objectsGood for cleaning up debrisApparatus for overhead lines/cablesEngineeringAutonomation

The invention discloses an automatic electric construction robot. The automatic electric construction robot comprises a brake wheel device, a matching wire wheel, a cleaning device, a clearing cutterhead, a connecting column and a high-voltage wire, wherein the brake wheel device is transitively connected with the matching wire wheel through the connecting column; and one end of the connecting column is movably connected to the matching wire wheel in an embedded way. According to the automatic electric construction robot disclosed by the invention, the transmission of a rotating mechanism anda swing mechanism is driven through the control of a motor braking device, and acts on a cleaning revolving shaft, so that the cleaning cutter head starts to rotationally clean sundries. In the existence of a buffer mechanism, the influence of the gravity of produced sundries on the robot can be reduced, and the sundries can be placed on the robot to prevent the danger of high falling objects. Through the driving action of the transmission mechanism on a lifting mechanism, the height can be adjusted; multi-directional cleaning of the sundries is realized; the sundries can be cleaned better; damage to a high-voltage line is avoided; and the progress of power construction is accelerated.

Owner:张秋达

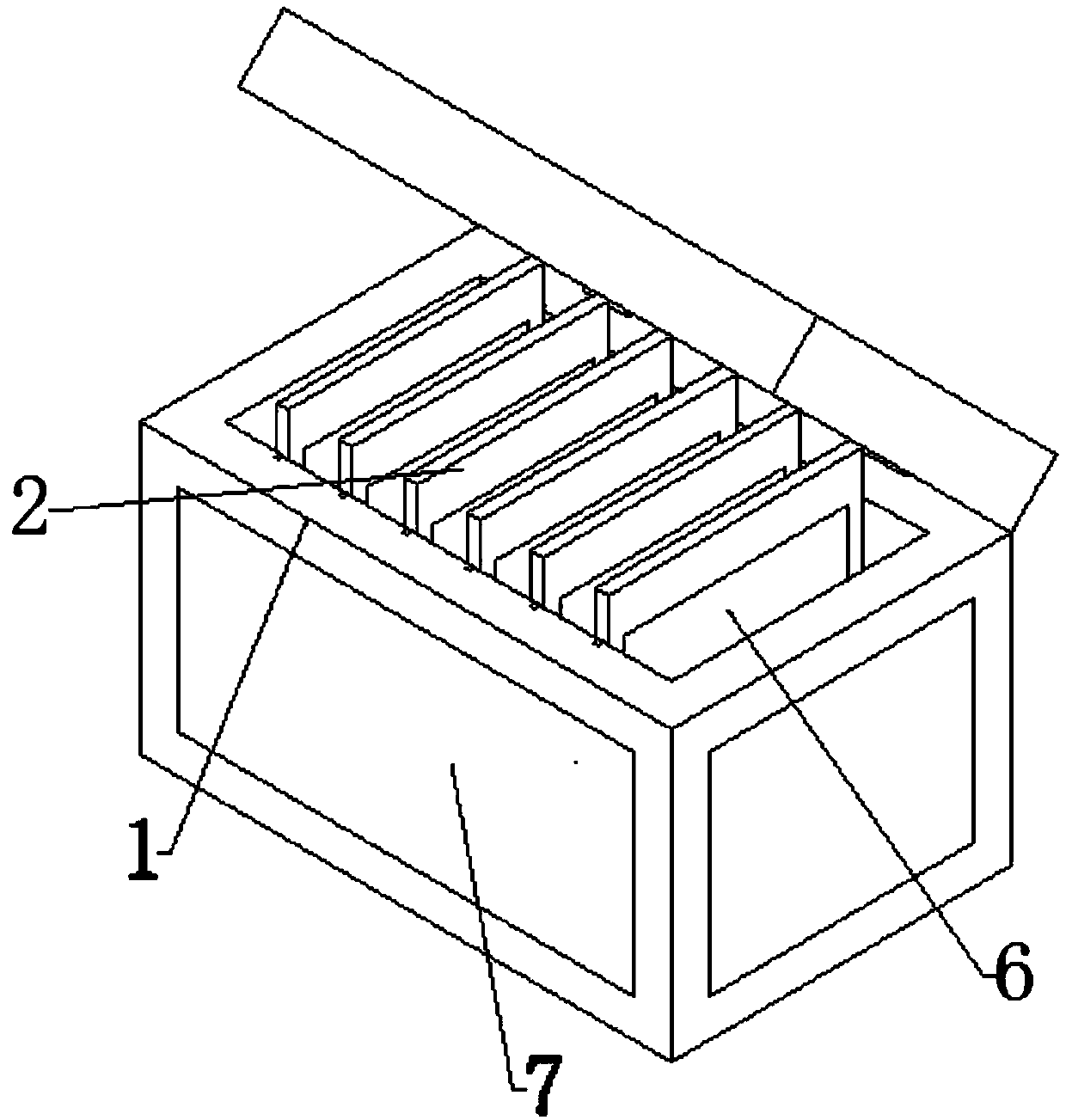

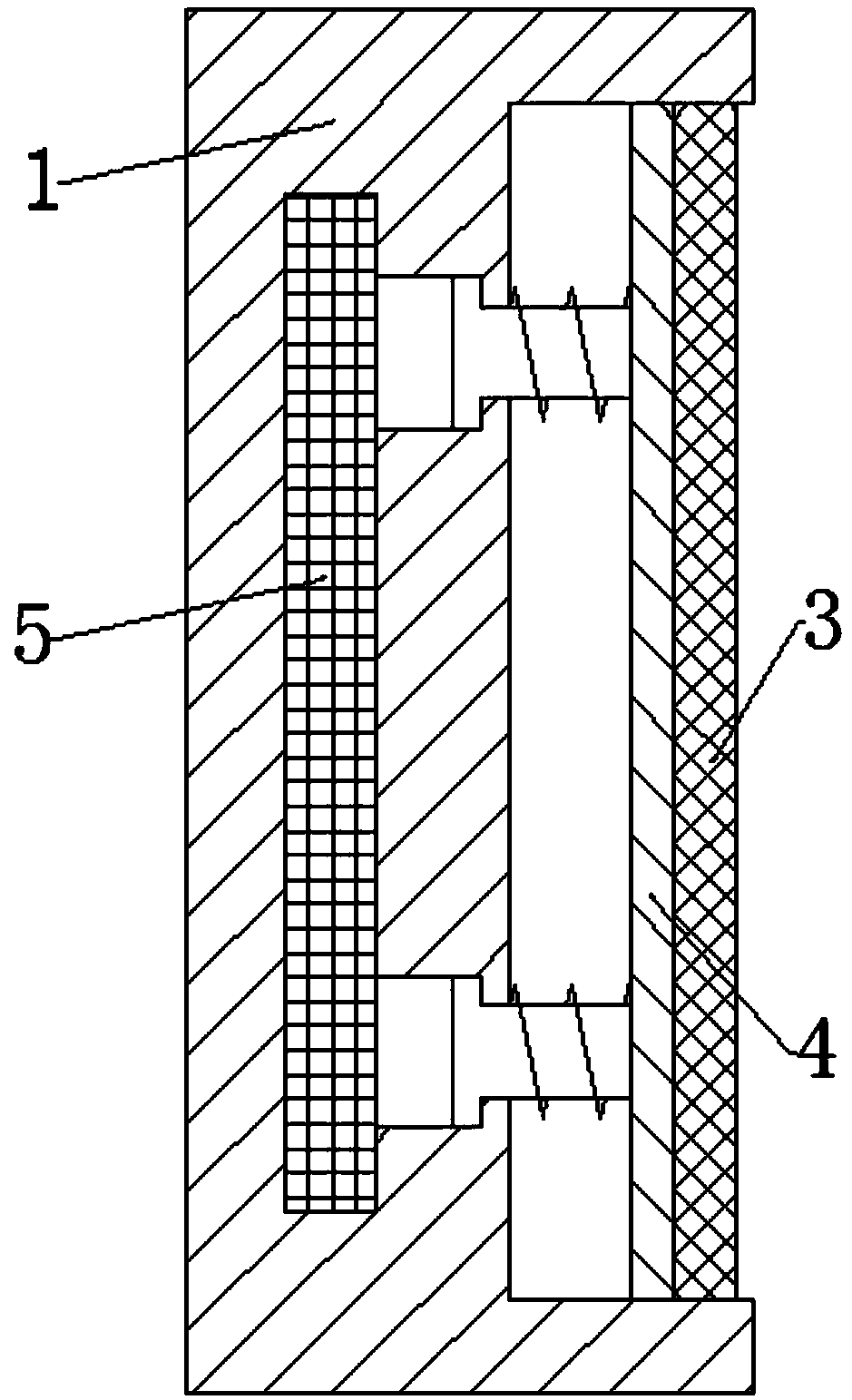

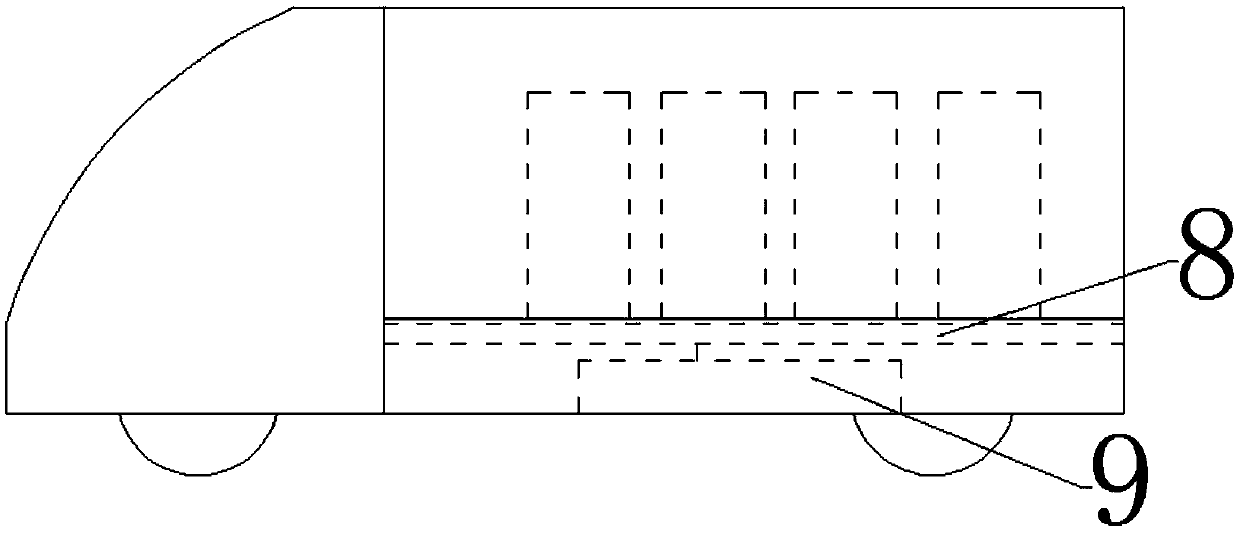

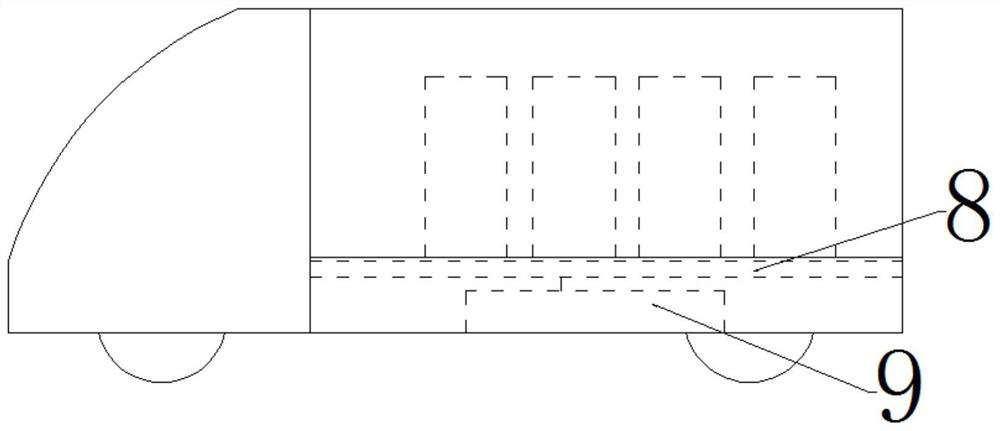

New energy source logistics vehicle for preventing cargoes from being collided

ActiveCN109664811ABuffering effectAvoid colliding with each otherLoad securingLogistics managementNew energy

The invention discloses a new energy source logistics vehicle for preventing cargoes from being collided and relates to the field of logistics devices. A transfer box is provided with an anti-collision device; the anti-collision device comprises a buffering device and a fixing device; the fixing device is mounted on an inner wall and a separation plate of the transfer box; the buffering device ismounted on an outer wall of the transfer box; the buffering device comprises buffering cotton, a mounting plate, a guide column, a buffering spring and an electromagnetic suction disc; a groove matched with the mounting plate is formed in the outer wall of the transfer box; the buffering cotton is mounted at one side of the mounting plate; the other side of the mounting plate is fixedly connectedwith the guide column sleeves with the buffering spring; a guide sleeve, which is in sliding connection with the guide column in an inserting manner, is arranged at the bottom of the groove; a limiting block is arranged at an inserting end of the guide column; a limiting ring matched with the limiting block is arranged at the outer end part of the guide sleeve; the limiting block is made of a magnet material; the electromagnetic suction disc opposite to the guide column is arranged on an inner wall of the transfer box; under a working state, part of opposite magnetic poles of the electromagnetic suction disc and the limiting block are the same; the collision to the cargoes is effectively avoided.

Owner:安徽共生众服供应链技术研究院有限公司

Buffering stop structure and corresponding packing case

ActiveUS8711299B2Reduce manufacturing costBuffering effectNon-linear opticsLiquid-crystal displayEngineering

The present invention relates to a buffering stop structure and a corresponding packing case. The buffering stop structure is disposed at a connecting corner between adjoining side surfaces of a corresponding case main body. The case main body is used to load a liquid crystal display (LCD) panel. The buffering stop structure comprises a fixing portion, a connecting portion and a case buffering portion. The manufacture cost of the buffering stop structure and the corresponding packing case of the present invention is lower, and the buffering effect thereof is better, so as to solve the problems of the packing case of existing technology that has higher manufacture cost and may cause environment pollution.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

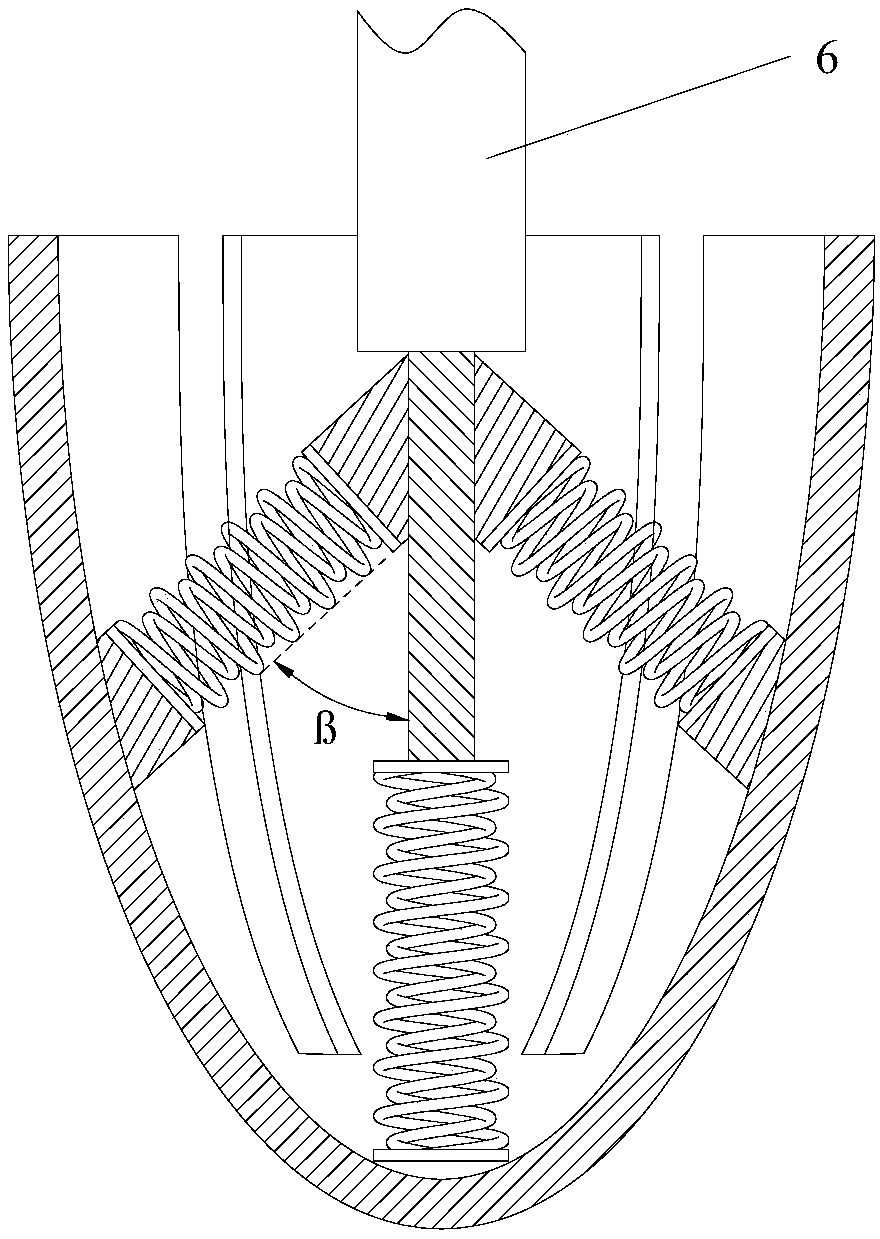

Bridge construction method and bridge structure

InactiveCN113356031AReduce load strengthReduce metal fatigue strengthBridge structural detailsBridge erection/assemblyMagnetic tension forceBridge type

The invention discloses a bridge construction method and a bridge structure, and belongs to the technical field of bridge construction. The bridge structure comprises a bridge body, a bridge pier column is arranged below the bridge body, and the end, close to the bridge body, of the bridge pier column is fixedly connected with a bridge type connecting frame; the end, close to the bridge body, of the bridge-shaped connecting frame is fixedly connected with a lower-layer connecting platform. According to the method, through mutual cooperation of structures such as the damping support, the damping inner shaft, the supporting spring, the tooth-shaped plate, the insection surface, the adapter shaft, the winding coil, a permanent magnet base, the permanent magnet and the electromagnet, the multi-frequency-band buffer effect can be achieved, the buffer effect can be achieved, and the buffer force of the supporting spring can be assisted through the magnetic force effect, the load strength of the supporting spring is reduced, the metal fatigue strength of the supporting spring is relieved, the damping coefficient under buffering is automatically changed according to the change of the vibration frequency generated when the bridge body is subjected to external force, and deviation from a preset frequency sensitive area can be effectively avoided.

Owner:陈颖

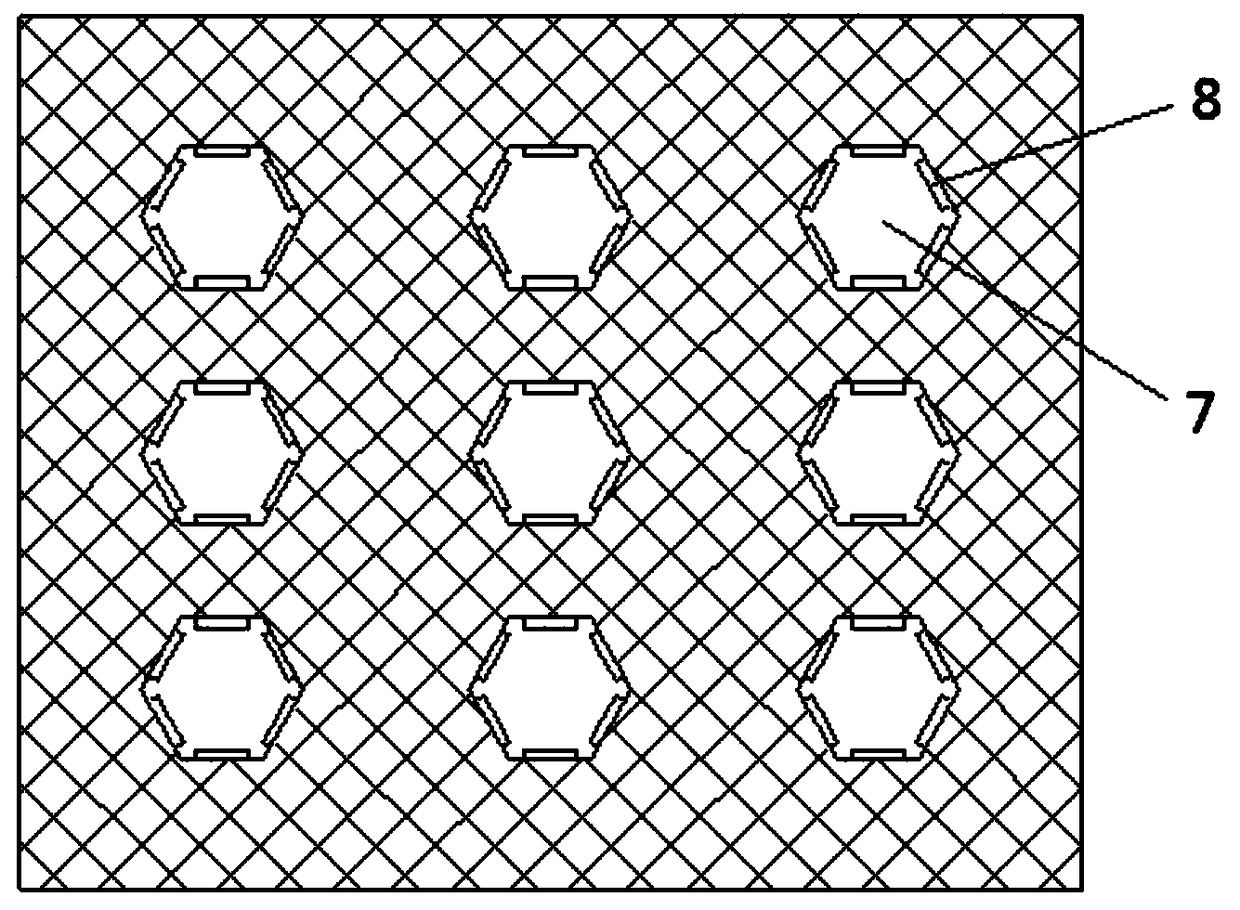

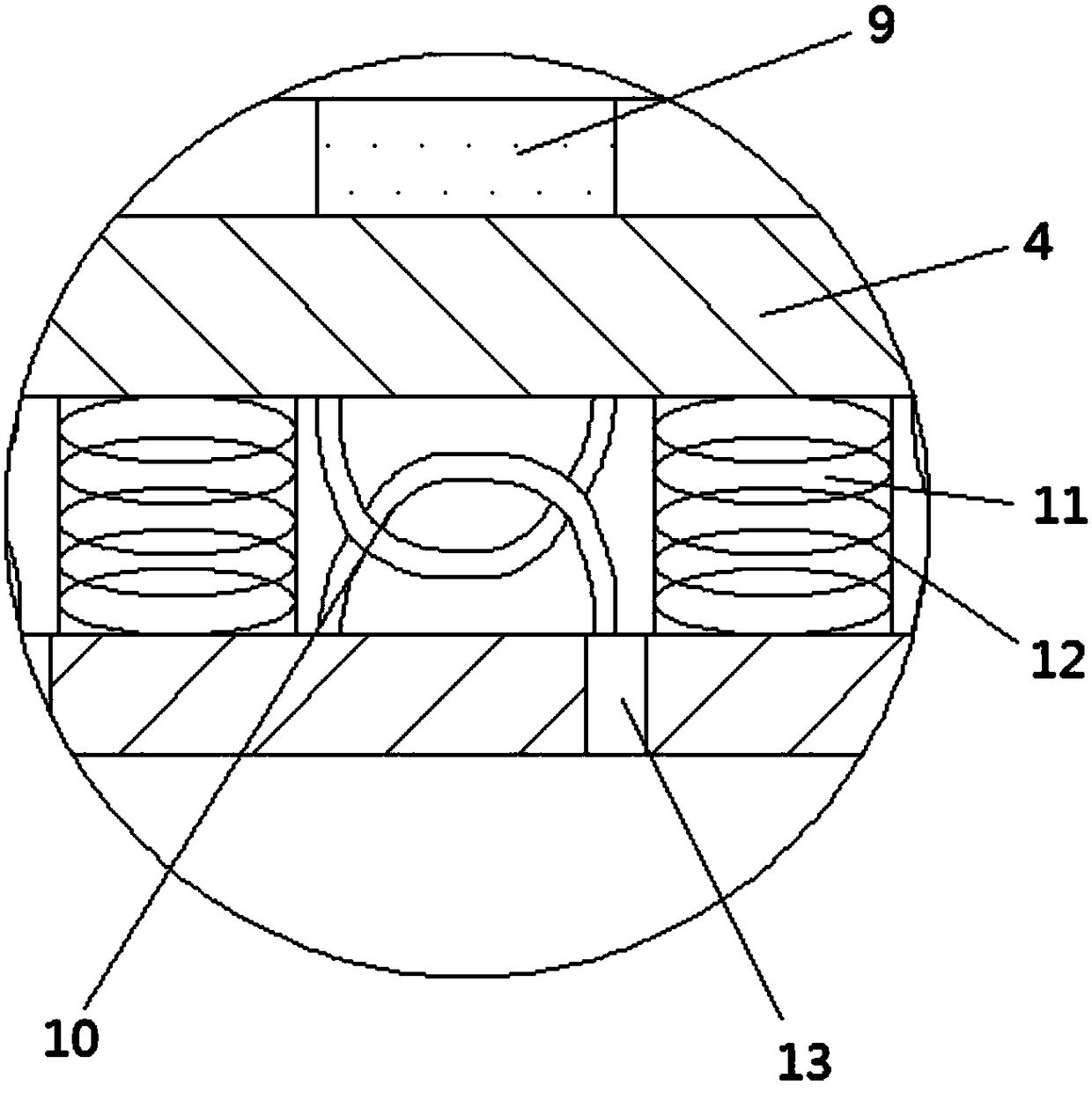

Outdoor fireproof antibacterial PVC carpet

InactiveCN108209466AImprove experiencePlay a double cushioning effectSynthetic resin layered productsFloor carpetsCushioningPolyvinyl chloride

The invention discloses an outdoor fireproof antibacterial PVC carpet. The outdoor fireproof antibacterial PVC carpet comprises a wool layer, wherein an antibacterial layer, a fireproof layer, a polyvinyl chloride layer, a cushioning layer and an anti-skid layer are sequentially arranged at the inner side of the wool layer; uniformly distributed regular hexagonal through holes are formed in the antibacterial layer, and an antibacterial block is arranged on each side wall of each regular hexagonal through hole; the fireproof layer comprises multiple flame retardant woven straps distributed at equal intervals; elastic fiber rods and a spring are distributed in the cushioning layer at intervals, and a fixed soft cover is sheathed outside the spring; and through slots distributed in a staggered manner are formed in the anti-skid layer, and anti-skid stripes are formed on the lower surface of the anti-skid layer. The outdoor fireproof antibacterial PVC carpet disclosed by the invention hasthe advantages of good fireproof performance, good antibacterial effect, good cushioning performance and high safety performance.

Owner:安吉艺科装饰材料科技有限公司

Falling object prevention device for building construction management

InactiveCN114856226AImprove buffering effectAchieve fixationBuilding material handlingConstruction managementMechanical engineering

The invention discloses an anti-falling object device for building construction management in the technical field of building construction, which comprises two groups of steel rods, two groups of steel rods and two groups of steel rods, a thick anti-falling net; the two sets of steel rods are sleeved with the two sets of connecting rings respectively, fixing structures used for fixing the connecting rings to the steel rods are arranged on the two sets of connecting rings, when the size of a falling object is large, the falling object directly falls onto the thick anti-falling net, and when the size of the falling object is small, the falling object falls onto the thick anti-falling net. The falling object finally falls on the fine anti-falling net; the impact force of a falling object falling on the thin anti-falling net acts on the thin anti-falling net, so that a connecting block vertically moves on a vertical rod through a second spring to finish buffering, when the second spring stretches out and draws back, a third spring is driven to stretch out and draw back to finish further buffering, meanwhile, a sliding block slides in a sliding groove, a fourth spring and a fifth spring stretch out and draw back, and the falling object is prevented from falling off. And meanwhile, the air bag deforms along with the air bag, so that the buffering effect can be further improved.

Owner:郑西跃

Motorcycle parts processing equipment

ActiveCN108015645BHas a cushioning effectBuffering effectGrinding drivesBelt grinding machinesElectric machineryStructural engineering

The invention belongs to the technical field of mechanical element machining devices, and discloses motorcycle part machining equipment. The motorcycle part machining equipment comprises a machine frame, a fixing mechanism and a grinding mechanism, wherein the fixing mechanism comprises an upper supporting block and a lower supporting block; mounting grooves are formed in the upper supporting block and the lower supporting block, and air bags are arranged in the mounting grooves; the grinding mechanism comprises a driving part and a grinding part, the driving part comprises an air tank, a partition plate is arranged in the air tank, and the air tank is divided into an air inlet cavity and an air exhaust cavity through the partition plate; a push rod is arranged on the side, close to the air exhaust cavity, of the partition plate; the grinding mechanism comprises a mounting table, and a grinding head and a motor are arranged on the mounting table; a supporting rod and a magnet layer arearranged on the mounting table; and the machine frame is further provided with an emergency stop mechanism, the emergency stop mechanism comprises a power supply, a conductive disc and an electromagnet, and the conductive disc is rotationally connected with the machine frame. The motorcycle part machining equipment solves the problem of high machining cost due to low machining efficiency caused by the facts that two devices are needed when a camshaft is ground and debugging between the two devices needs a long period of time cost in the prior art.

Owner:宁波江北珂达汽车技术有限公司

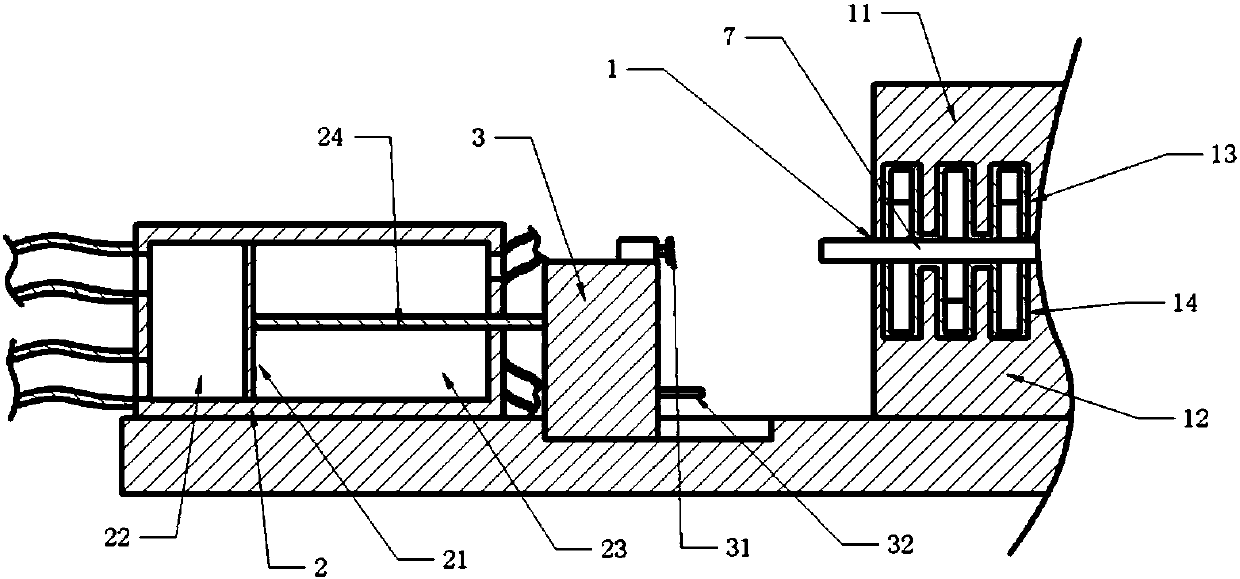

Projection lamp

ActiveCN106287585AEnsure safetyEasy to fixLighting heating/cooling arrangementsProtective devices for lightingElastomerAgricultural engineering

The invention relates to a projection lamp. The projection lamp comprises a casing, wherein a circuit board and a lens assembly are arranged in the casing; the casing comprises a casing front cover and a casing rear cover, the casing front cover comprises a first end cover and an inner side wall integrally arranged with the first end cover, and the casing rear cover comprises a second end cover and an outer side wall integrally arranged with the second end cover; the end part, opposite to the first end cover, of the inner side wall is in a first shape, and a seal washer is arranged between the casing front cover and the casing rear cover and has the first shape; an elastomer is arranged on the inner side wall and deforms inwards to enable the inner side wall to enter the casing rear cover more easily when the casing front cover and the casing rear cover are matched; meanwhile, the seal washer abuts against the inner surface of the second end cover to form a first chamber for mounting the lens assembly and the circuit board.

Owner:上海康耐司信号设备有限公司

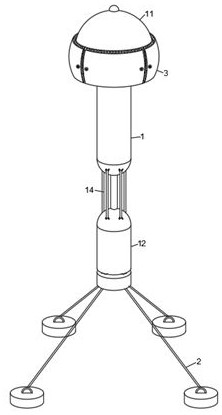

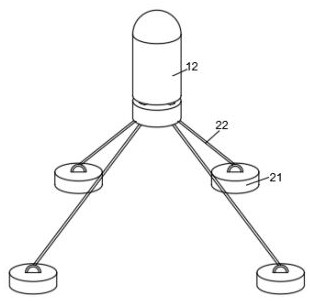

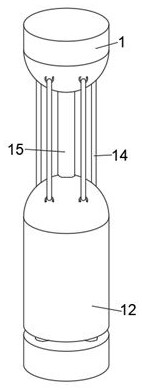

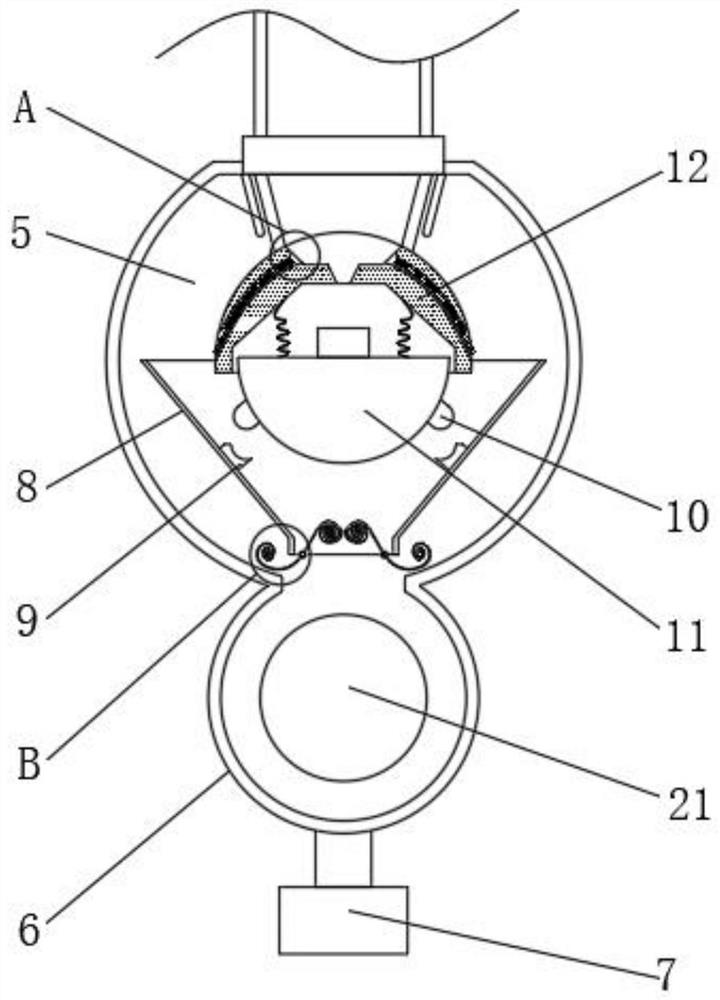

Wave energy power generation device of ocean buoy

ActiveCN114313105AExtended service lifeReduce maintenance timeHydro energy generationBuoysWave powerElectric generator

The invention provides a wave power generation device of an ocean buoy. The wave energy power generation device of the ocean buoy comprises a buoy cylinder, a buoy ball, a turbine generator, a controller and an electricity storage box. A traction assembly; the protection assembly is used for preventing garbage in the sea from colliding with the buoy ball and the buoy cylinder under the action of sea waves for protection, and the protection assembly is arranged around the buoy ball; the connecting assembly used for connecting the protection assembly and the buoy ball is installed on the buoy ball; the auxiliary floating assembly is used for inflating to assist floating of the buoy cylinder when the buoy ball is damaged, and the auxiliary floating assembly is mounted in the buoy cylinder. The buoy cylinder can conduct wave power generation through the turbine generator, when the buoy cylinder cannot float due to the fact that the buoy ball is damaged and leaks water, the buoy cylinder can float again for use through the auxiliary floating assembly, the service life of the device is prolonged, the maintenance time is shortened, and the working efficiency is improved.

Owner:SECOND INST OF OCEANOGRAPHY MNR

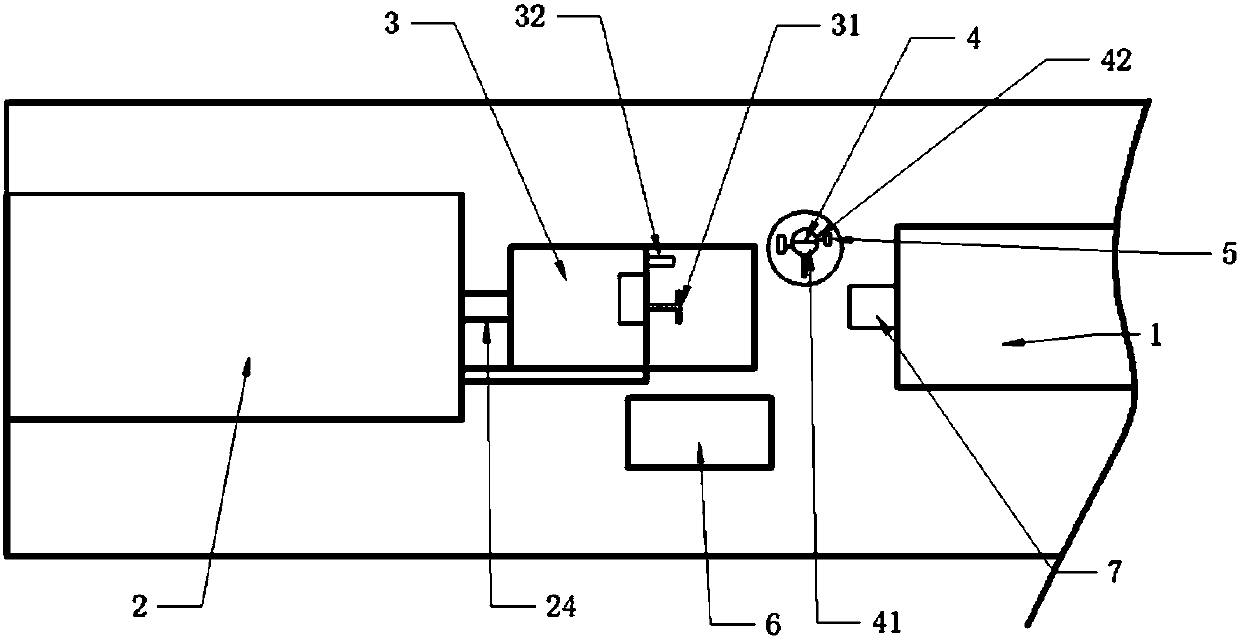

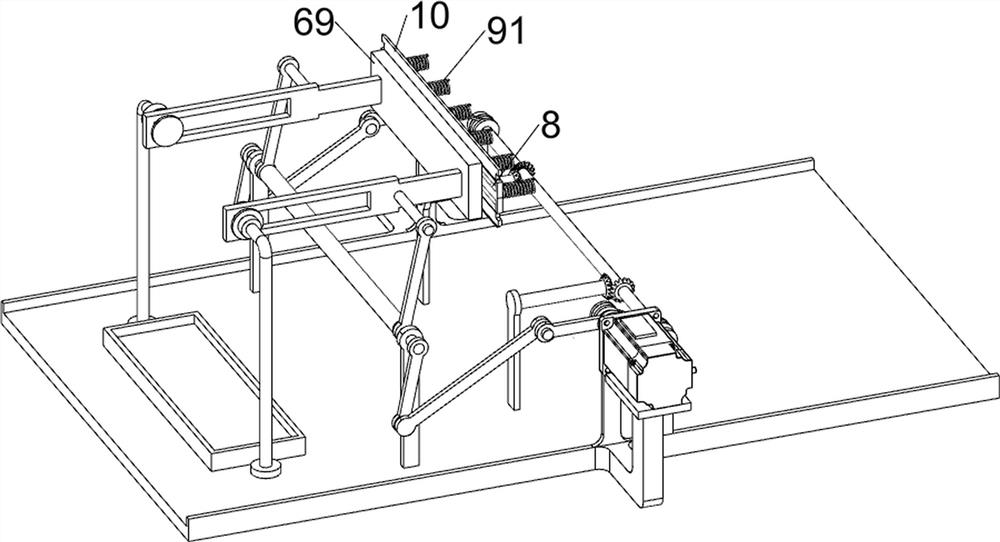

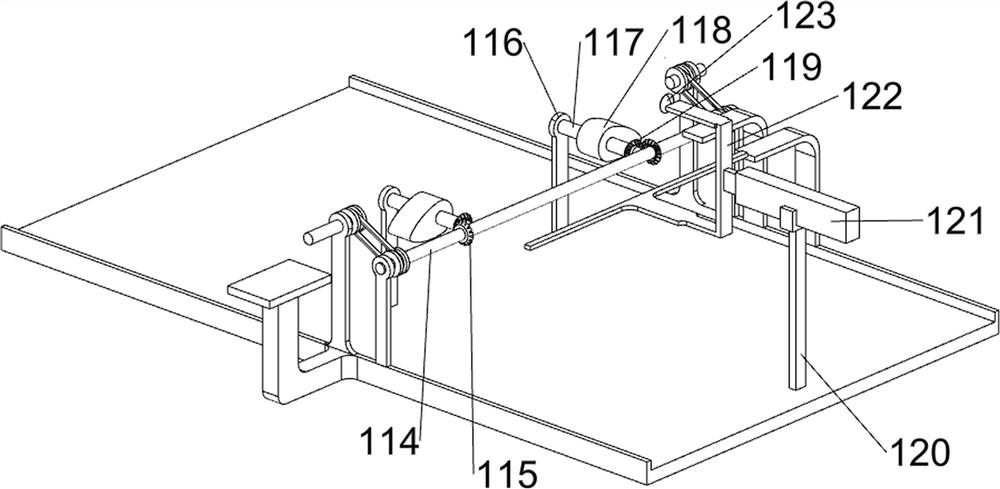

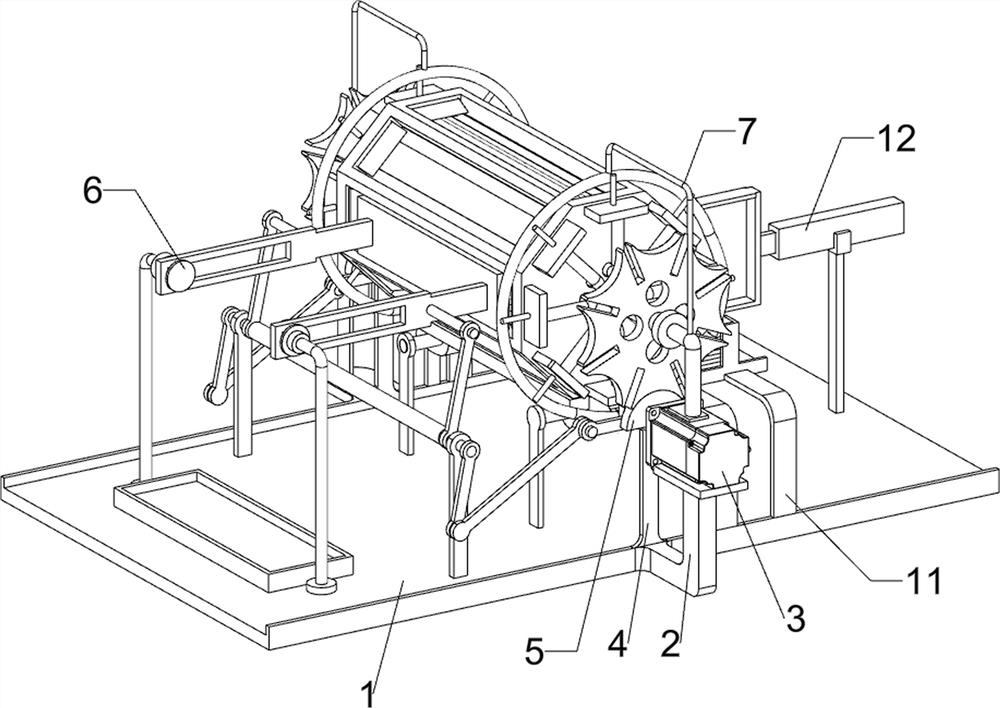

A device for printing colored dents on cardboard

ActiveCN112026370BBuffering effectImprove protectionTypewritersOther printing apparatusCardboardManufacturing engineering

The invention relates to a printing device, in particular to a device for printing colored dents on cardboard. The technical problem of the present invention is to provide a device for printing colored dents on cardboard that can fix the cardboard during printing and can produce a certain buffering effect during printing. A device for printing colored dents on cardboard, comprising: a base, the first support base is fixedly connected to the middle of the top side of the base; a servo motor, the servo motor is installed on the first support base Top: the first bearing seat, the first bearing seat is symmetrically installed in the middle of the top of the base. The present invention achieves the effect that the cardboard can be fixed during printing, and a certain buffering effect can be produced during printing. The cardboard is intermittently pushed to the lower part of the drum by the push plate, and the continuous rotation of the cam can The cardboard is pushed between the sliders on the front and rear sides, so that the sliders fix the cardboard.

Owner:佛山市金利澳环保科技有限公司

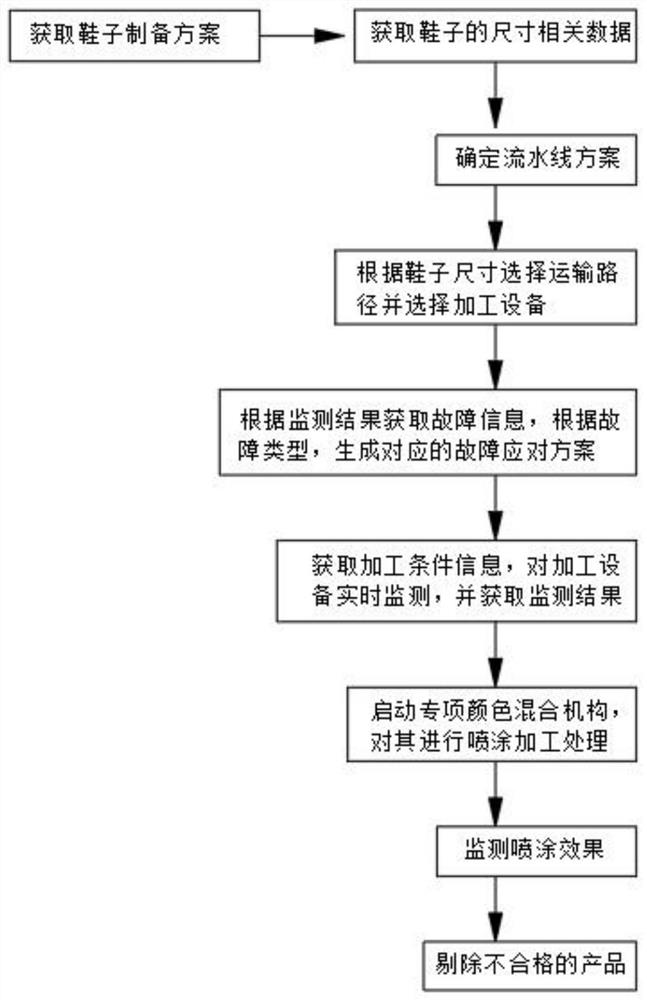

An automated production monitoring method based on big data and blockchain

ActiveCN112317270BGood removal effectEasy to guideLiquid surface applicatorsSpraying apparatusFiberProcess engineering

The invention discloses an automatic production monitoring method based on big data and block chain, which belongs to the field of automatic production monitoring. An automatic production monitoring method based on big data and block chain is formulated according to the size and type of shoes. The corresponding processing scheme is convenient for real-time monitoring of the processing quality. Through the setting of the telescopic buffering effect of the fixed block, the buffering effect can be effectively played, and the generation of air bubbles can be reduced, and the criss-crossing fiber strips can effectively remove the dyes. Bubble impurities, the inner material is PMMA defoaming wire, which can effectively guide and guide air bubbles, so as to facilitate the removal of air bubbles in the dye. It is guided to the inside of the adsorption block, and the excess dye solution can be effectively collected through the set adsorption block.

Owner:GUANGDONG INNOVATION TECH FOR NEXT GENERATION IND INTERNET CO LTD +1

A new energy logistics vehicle that can prevent goods from colliding

ActiveCN109664811BBuffering effectAvoid colliding with each otherLoad securingLogistics managementNew energy

The invention discloses a new energy source logistics vehicle for preventing cargoes from being collided and relates to the field of logistics devices. A transfer box is provided with an anti-collision device; the anti-collision device comprises a buffering device and a fixing device; the fixing device is mounted on an inner wall and a separation plate of the transfer box; the buffering device ismounted on an outer wall of the transfer box; the buffering device comprises buffering cotton, a mounting plate, a guide column, a buffering spring and an electromagnetic suction disc; a groove matched with the mounting plate is formed in the outer wall of the transfer box; the buffering cotton is mounted at one side of the mounting plate; the other side of the mounting plate is fixedly connectedwith the guide column sleeves with the buffering spring; a guide sleeve, which is in sliding connection with the guide column in an inserting manner, is arranged at the bottom of the groove; a limiting block is arranged at an inserting end of the guide column; a limiting ring matched with the limiting block is arranged at the outer end part of the guide sleeve; the limiting block is made of a magnet material; the electromagnetic suction disc opposite to the guide column is arranged on an inner wall of the transfer box; under a working state, part of opposite magnetic poles of the electromagnetic suction disc and the limiting block are the same; the collision to the cargoes is effectively avoided.

Owner:安徽共生众服供应链技术研究院有限公司

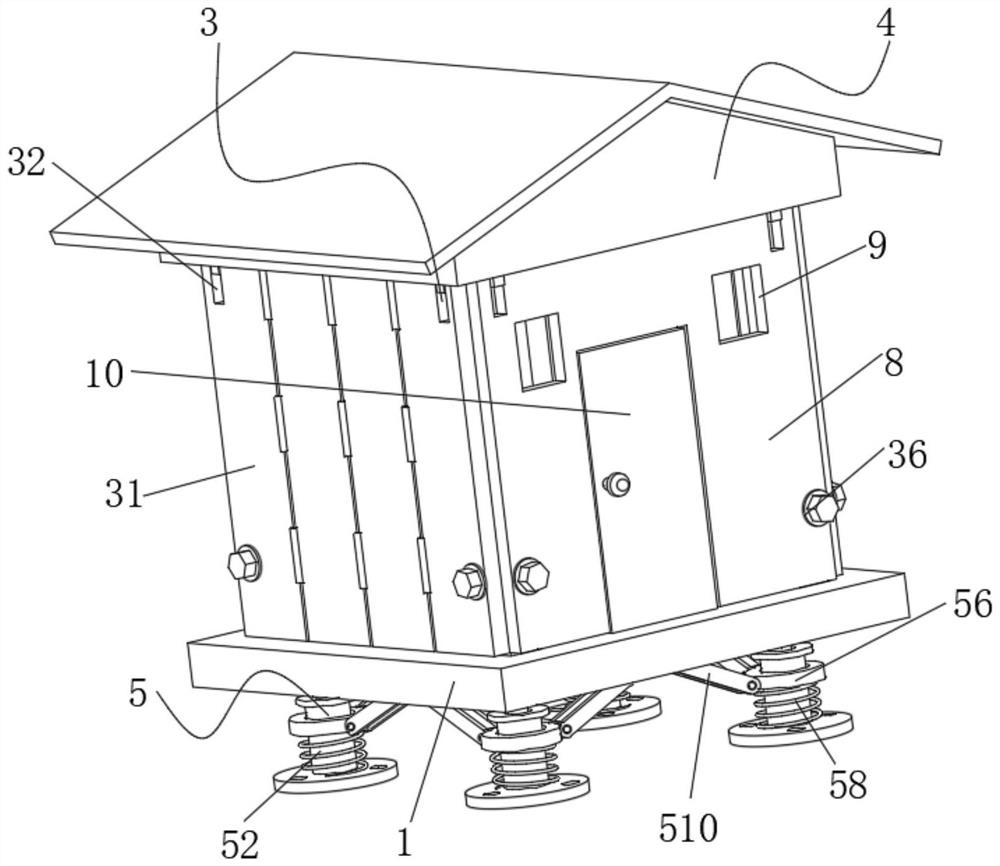

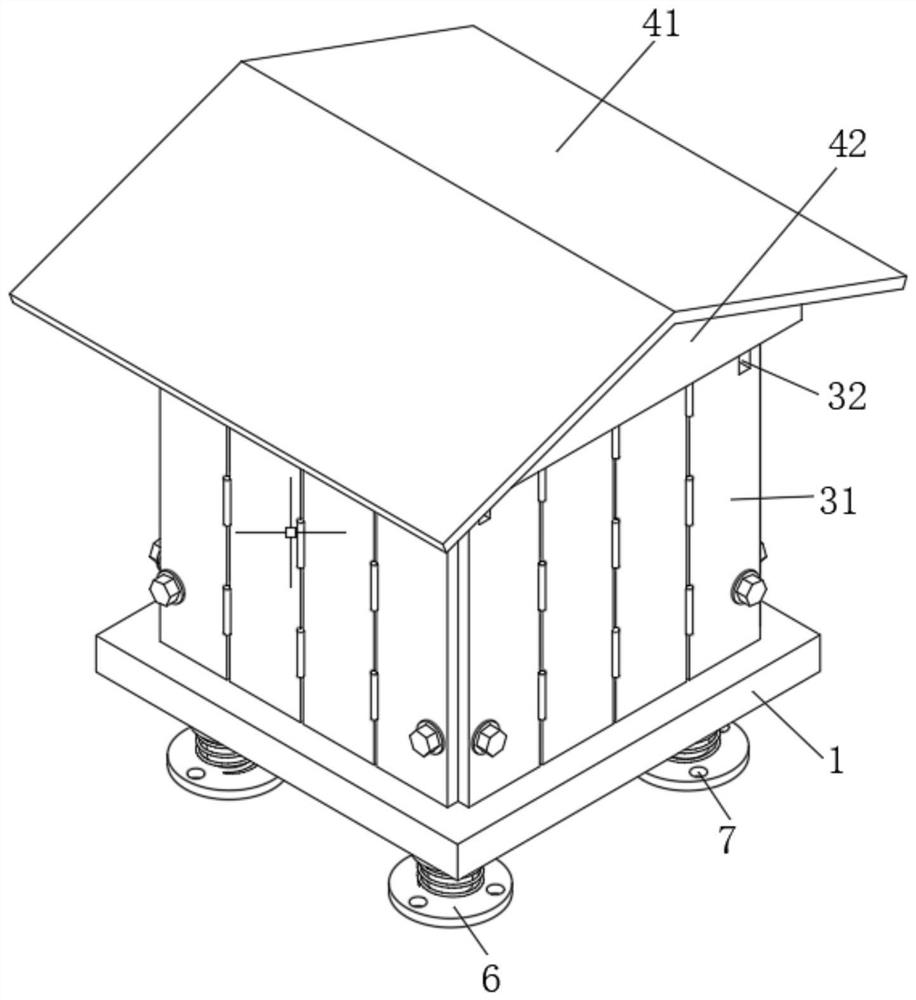

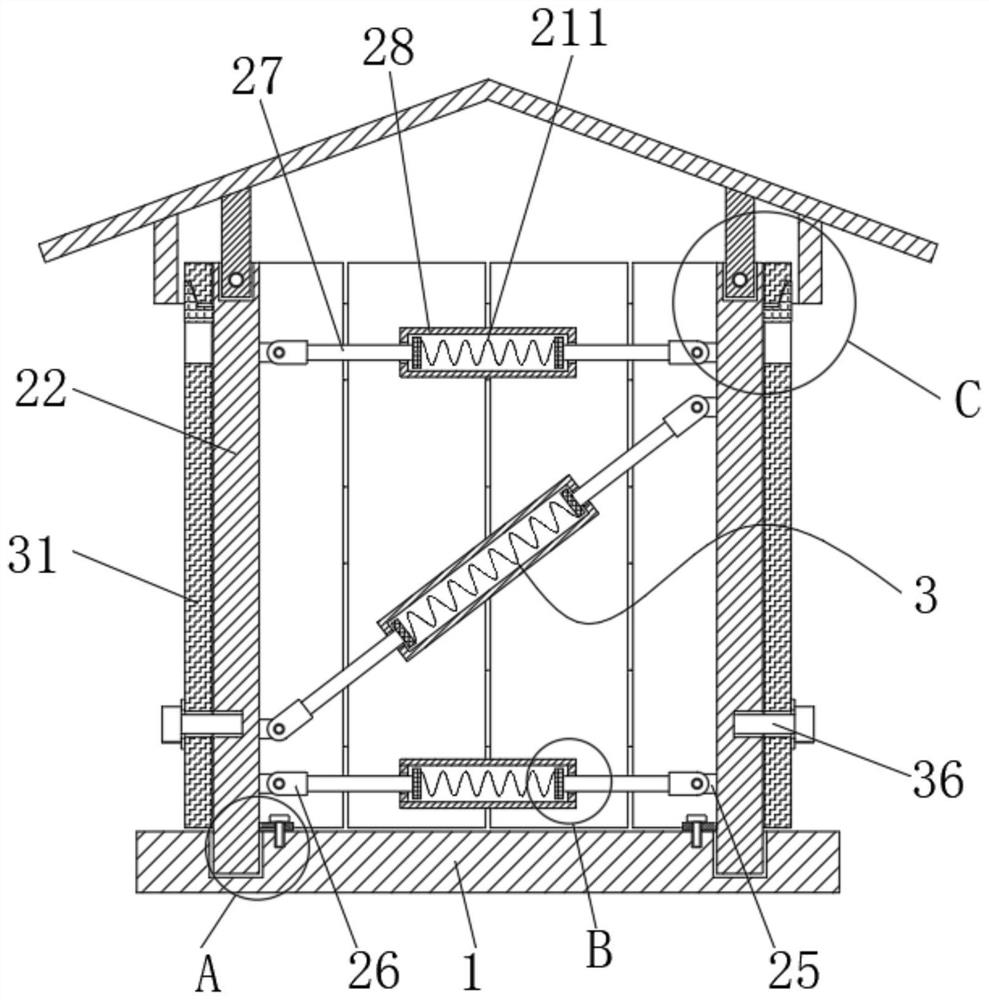

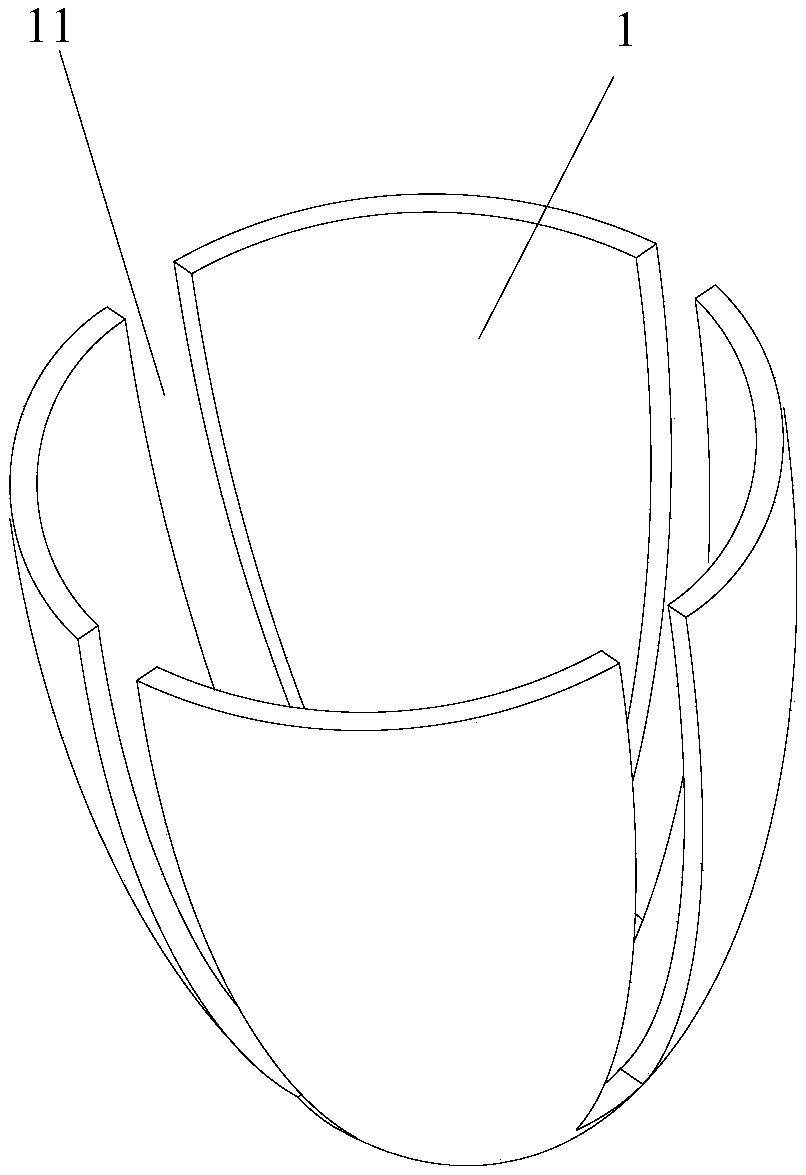

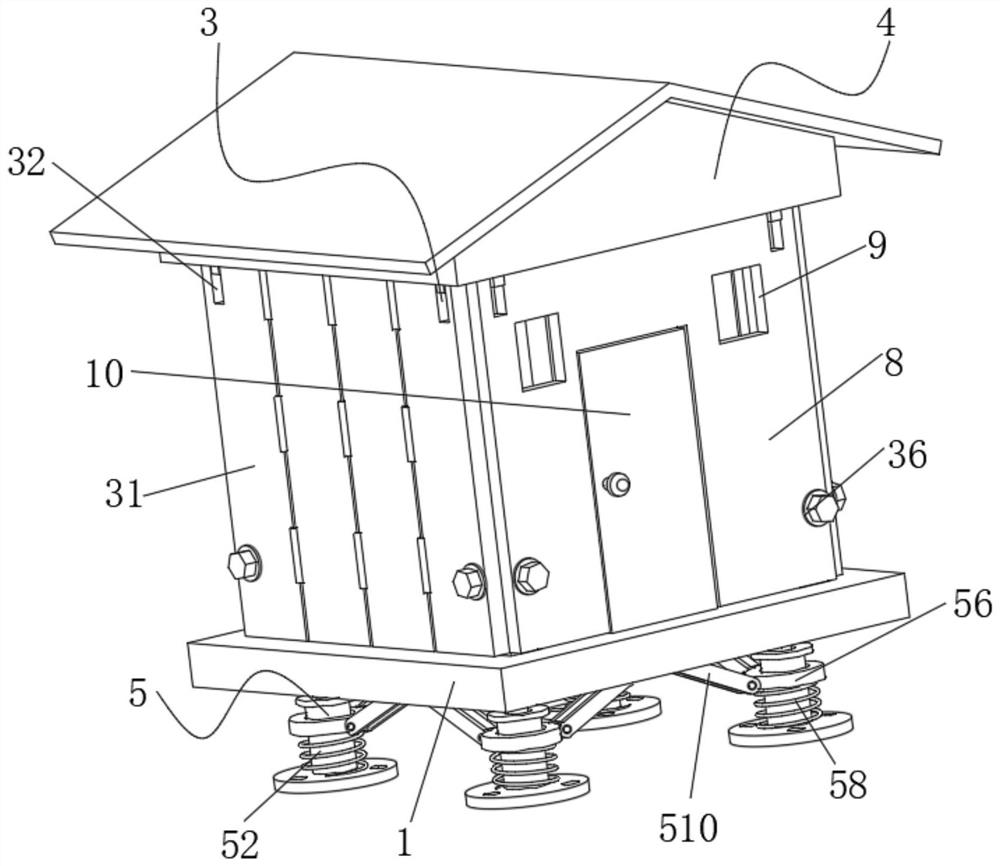

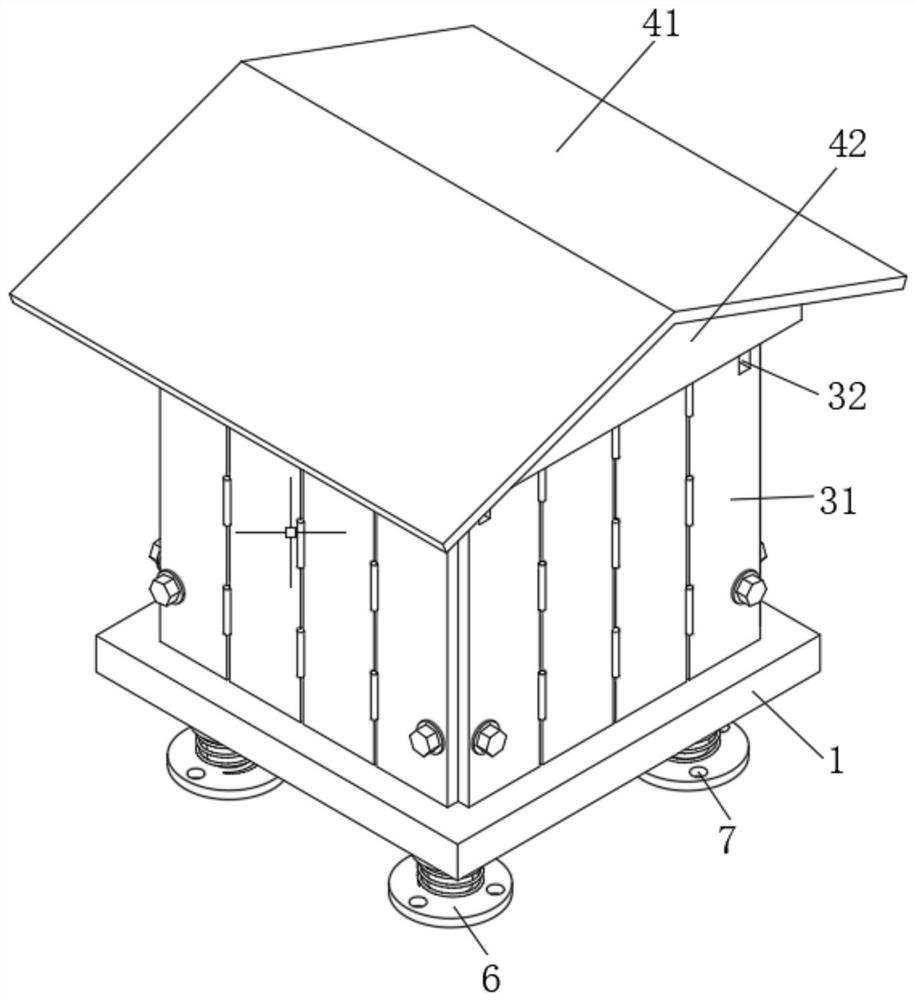

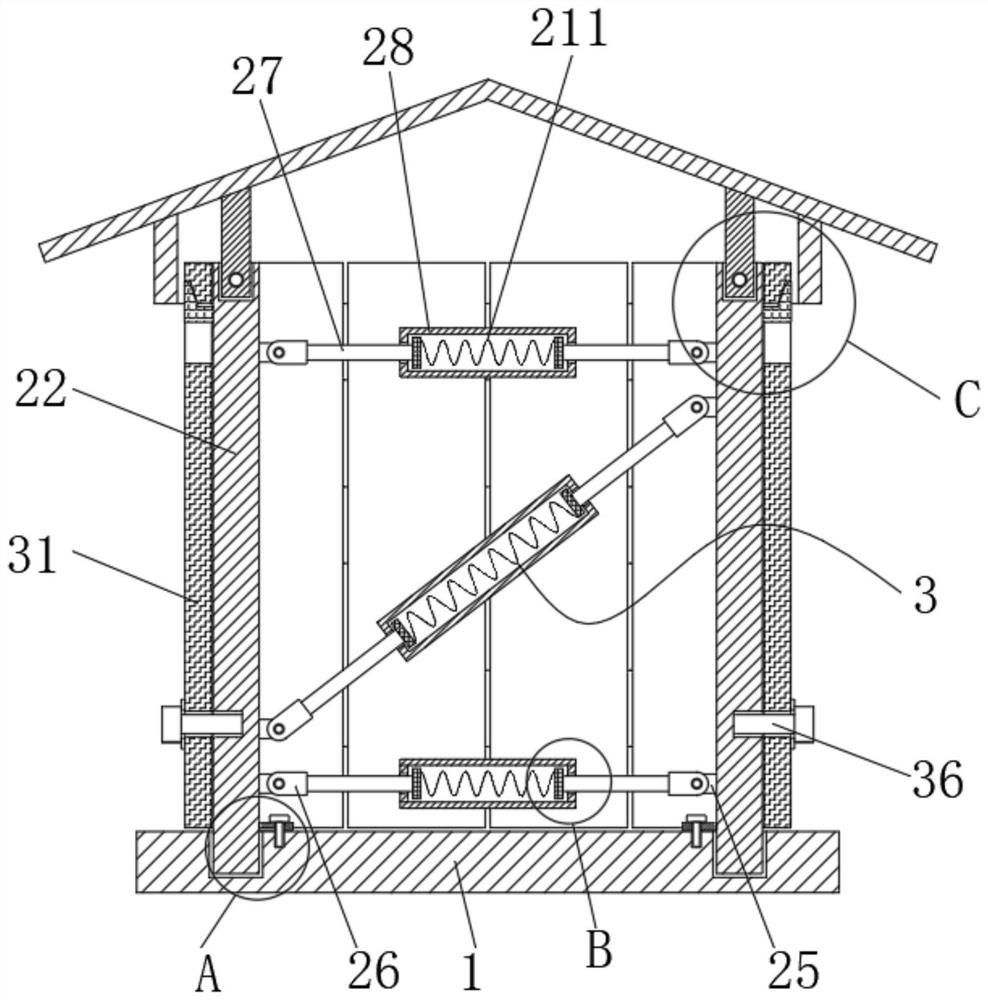

Stainless steel bungalow

PendingCN114658262AExtended service lifeImprove efficiencyProtective buildings/sheltersDwelling buildingEquipment useStructural engineering

The stainless steel bungalow comprises a bottom plate, a first buffering assembly, a connecting assembly, an eave assembly and a second buffering assembly, the first buffering assembly is arranged on the outer wall of the top end of the bottom plate, the connecting assembly is arranged on the outer wall of the first buffering assembly, and the eave assembly is arranged on the outer wall of the top end of the first buffering assembly; a second buffer assembly is arranged on the outer wall of the bottom end of the bottom plate. First inserting grooves are formed in the four corners of the outer wall of the top end of the bottom plate, and supporting beams are inserted into the first inserting grooves. By means of the first buffering assemblies, the frame composed of the four supporting beams has the buffering effect, the supporting beams are not prone to being broken and damaged in an earthquake, the service life of the equipment is prolonged, the protective plate is stably fixed through the connecting assemblies by means of a small number of second bolts, the equipment installation efficiency is improved, and the second buffering assemblies are arranged, so that the service life of the equipment is prolonged. The equipment is further buffered, the damage to the equipment is reduced, and the equipment is relatively safe and stable to use.

Owner:山东舜博金属制品有限公司

Conductive rubber and its application and surface selective metallized rubber product and its preparation method

ActiveCN103187117BMeet the use requirementsBuffering effectConductive layers on insulating-supportsInksChemical treatmentChemical plating

The invention provides conductive rubber and an application thereof. The conductive rubber comprises a rubber substrate and an ink layer that is printed on at least partial surface of the rubber substrate, wherein the ink layer contains a metallic compound, and the metallic compound is one or more than two of nanometer copper oxide, nanometer cuprous oxide, titanic oxide as shown in Formula I (TiO2-sigma), and a compound as shown in Formula II (M<1>M<2>pOq). The invention further provides a rubber product with a selectively metallized surface, and a preparation method of the rubber product. The rubber product comprises the conductive rubber and at least one metal layer, wherein the metal layer is positioned on the surface of the conductive rubber with the ink layer. Electroplating or chemical plating can be conducted on the conductive rubber, without any physical or chemical treatment, so that a refined conductive line is formed, and a using requirement in a shielding case with small size and complicated structure can be met.

Owner:BYD CO LTD

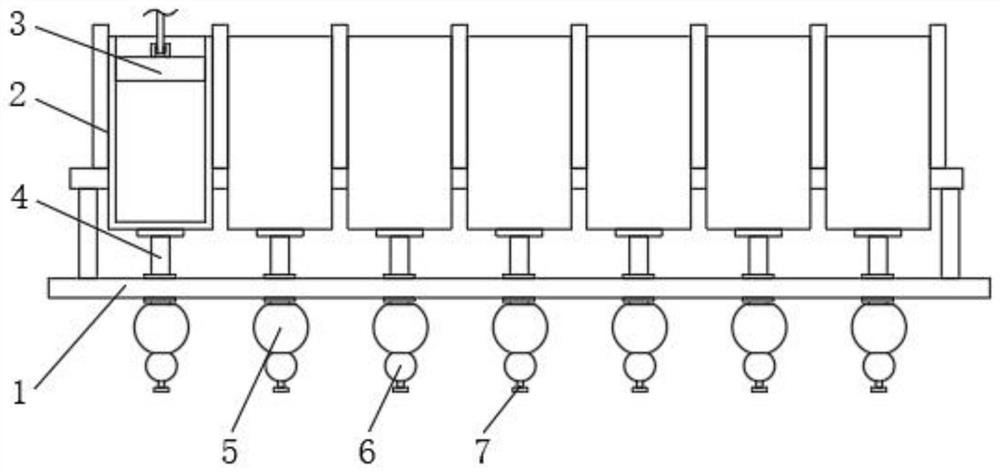

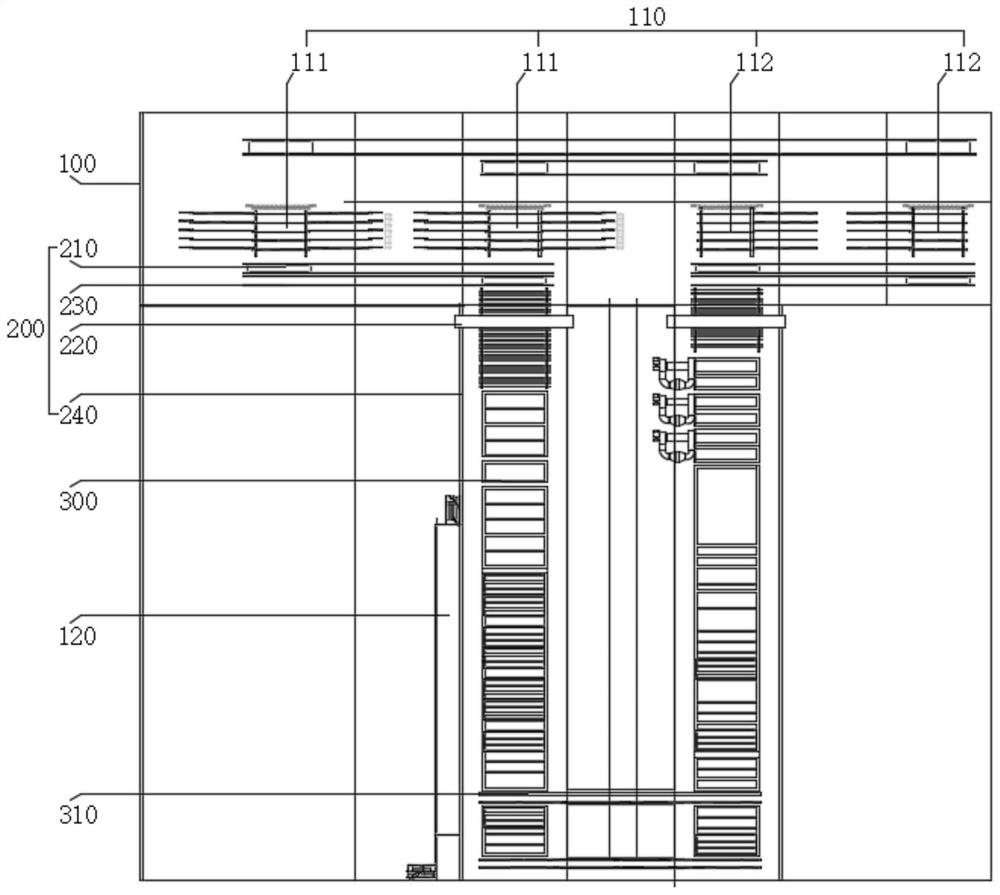

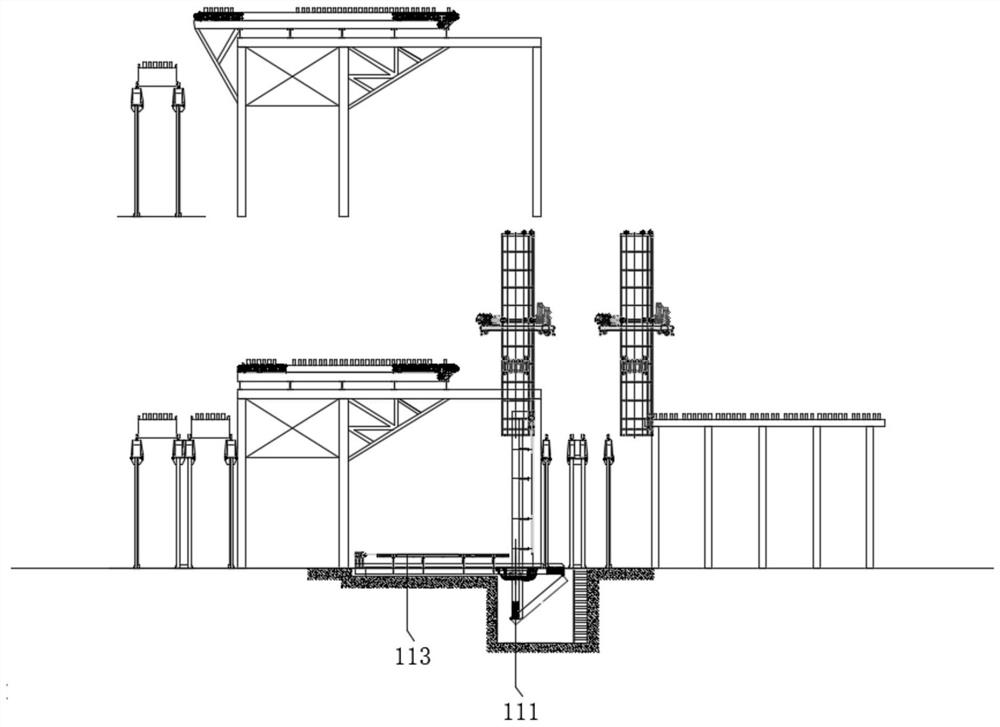

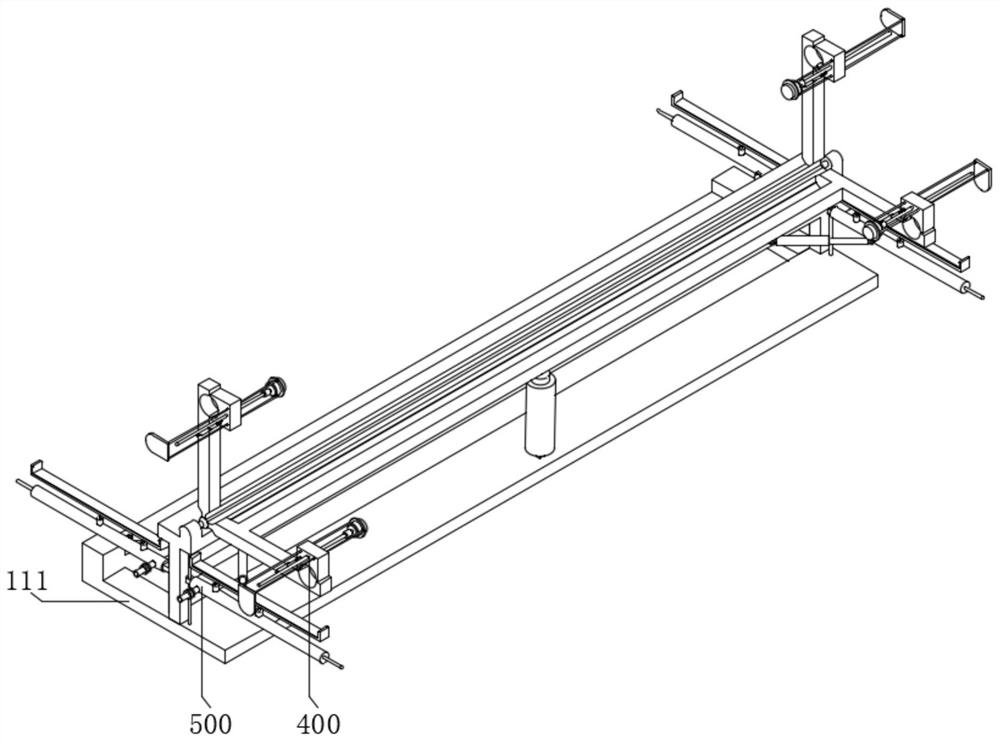

Intelligent vertical oxidation electrophoresis production line

ActiveCN114182324BImprove work efficiencyShorten the timeAnodisationElectrolysis componentsElectrophoresesControl engineering

The embodiments of the present application provide an intelligent vertical oxidation electrophoresis production line, which relates to the technical field of vertical oxidation electrophoresis production equipment. The intelligent vertical oxidation electrophoresis production line includes: a production plant, a conveying mechanism and a processing pool. The production plant is provided with a double-station loading and unloading structure, and the double-station loading and unloading structure has two loading stations and two unloading stations; the feeding mechanism includes a straddle car and a feeding The production plant is equipped with an over-crossing rail and a driving rail, the over-crossing vehicle is slidably arranged on the surface of the over-crossing rail, and the material conveying vehicle is slidably installed on the surface of the driving rail; the treatment pool group set in the production plant. This application can achieve the purpose of cyclic feeding and reduce the time required for feeding through the cooperation between two feeding stations, two unloading stations, multiple straddle carriages and multiple feeding cranes. , By improving the efficiency of loading and unloading, the production capacity can be increased.

Owner:肇庆智得智能设备有限公司

Model airplane with anti-collision block

The invention discloses a model airplane with an anti-collision block, comprising a buffer block mounted on the airplane, wherein the buffer block is provided with a first buffer body and a second buffer body, and the first buffer body is provided with a connecting post; the buffer block is provided with buffer grooves, four buffer grooves are arranged alternately with four second buffer bodies, and the second buffer bodies are located between two adjacent buffer grooves. The present invention achieves buffering in a plurality of directions of an aircraft through a first buffer body and a second buffer body, the aircraft is effectively protected, wherein the first buffer body and the second buffer body constitute a three-dimensional multi-degree-of-freedom buffer body, and the buffer blockutilizes the buffer groove arranged on the buffer block to make itself have certain buffer effect, thereby forming multiple buffer effects with the first buffer body and the second buffer body.

Owner:范翰臻

Stainless steel warehouse

PendingCN114575650ANot easy to break and damageHas the effect of wind and rain protectionProtective buildings/sheltersShock proofingStructural engineeringSS - Stainless steel

The stainless steel warehouse comprises a bottom plate, a first buffering assembly, a connecting assembly, an eave assembly and a second buffering assembly, the first buffering assembly is arranged on the outer wall of the top end of the bottom plate, the connecting assembly is arranged on the outer wall of the first buffering assembly, and the eave assembly is arranged on the outer wall of the top end of the first buffering assembly; a second buffer assembly is arranged on the outer wall of the bottom end of the bottom plate. First inserting grooves are formed in the four corners of the outer wall of the top end of the bottom plate, and supporting beams are inserted into the first inserting grooves. By means of the first buffering assemblies, the frame composed of the four supporting beams has the buffering effect, the supporting beams are not prone to being broken and damaged in an earthquake, the service life of the equipment is prolonged, the protective plate is stably fixed through the connecting assemblies by means of a small number of second bolts, the equipment installation efficiency is improved, and the second buffering assemblies are arranged, so that the service life of the equipment is prolonged. The equipment is further buffered, the damage to the equipment is reduced, and the equipment is relatively safe and stable to use.

Owner:山东舜博金属制品有限公司

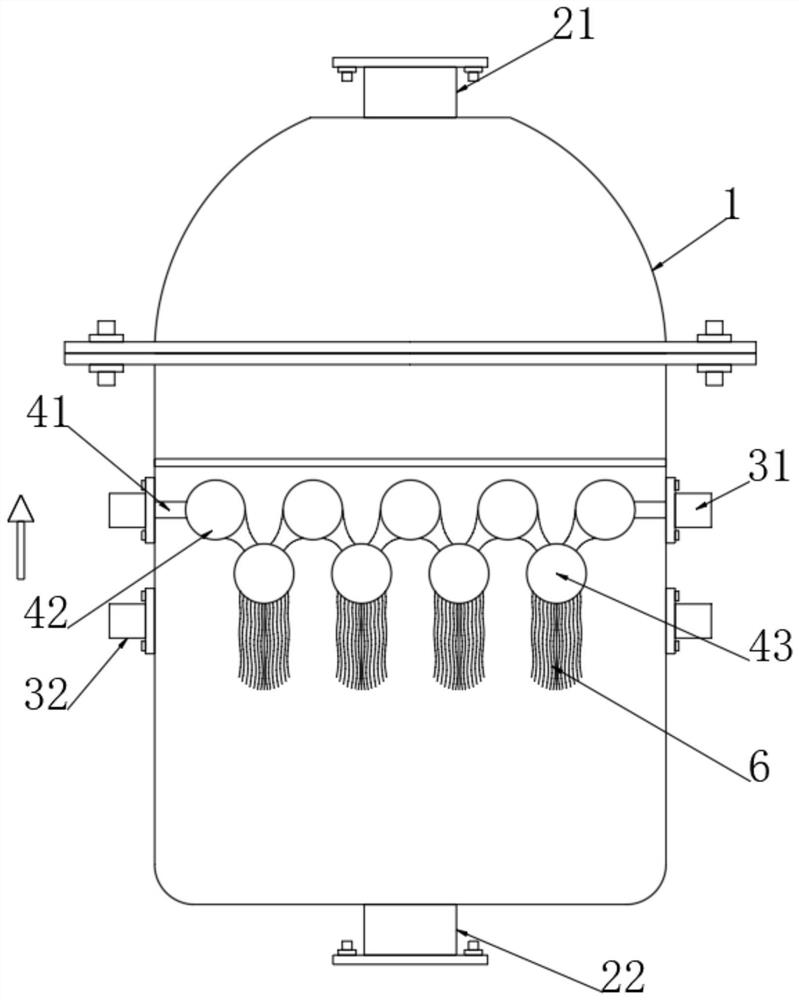

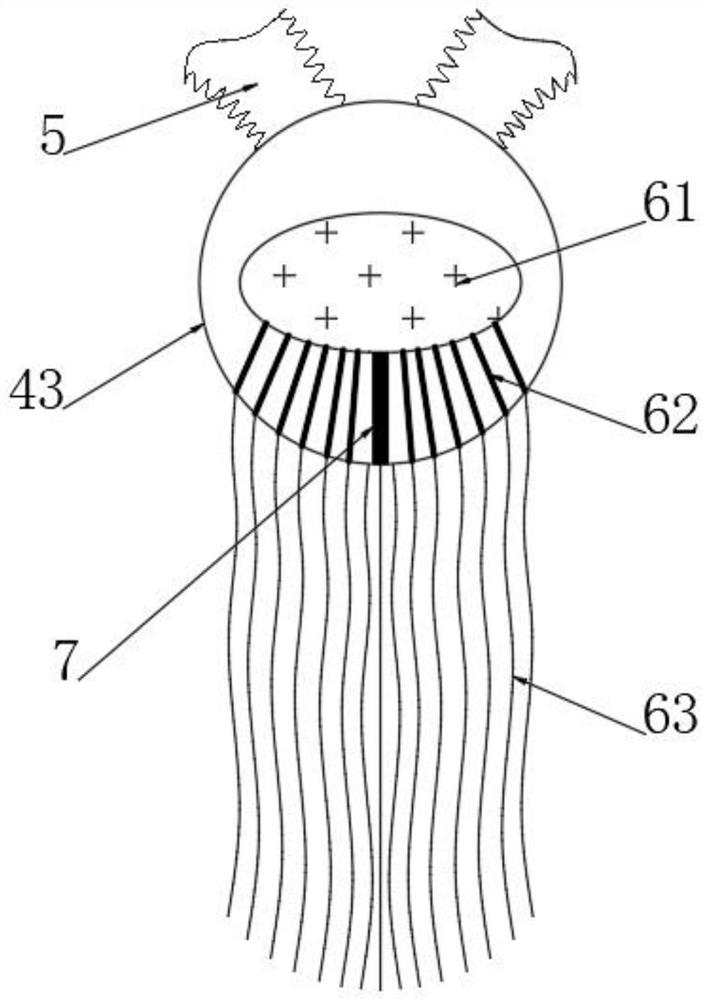

Flue gas treatment device of ice net type high-temperature alloy smelting furnace

InactiveCN113181732AImprove cooling effectGood effect of cooling and removing impuritiesIncreasing energy efficiencyWaste heat treatmentFlue gasCooling effect

The invention discloses a flue gas treatment device of an ice net type high-temperature alloy smelting furnace, and belongs to the field of waste gas treatment of high-temperature alloys. According to the flue gas treatment device of the ice net type high-temperature alloy smelting furnace, a filter screen and a water cooling channel in the prior art are combined through the arrangement of a heat removal ice ball net, so that when flue gas penetrates through the heat removal ice ball net, the effects of intercepting, adsorbing and cooling impurities in the flue gas are achieved at the same time. Compared with the effect of water cooling outside a flue gas exhaust pipeline or equipment in the prior art, the contact area between the heat removal ice ball net and the flue gas is larger, the distance between the heat removal ice ball net and the flue gas is closer, then the flue gas cooling effect is remarkably improved, and meanwhile, the effect of a heat gathering and ash catching string is matched, under the impact action of the flue gas, the plurality of water seepage floating ropes can be in a flying state and are interwoven with the plurality of adjacent water seepage floating ropes, so that a layer of impurity interception and adsorption barrier with a wet surface is formed below the heat removal ice ball net, and the cooling and impurity removal effects on the flue gas are better.

Owner:曹高博

Driving type hydraulic oscillator for well drilling

InactiveCN112127795AImprove the fixed effectEasy to disassembleEarth drilling toolsVibration drillingEngineeringStructural engineering

The invention discloses a driving type hydraulic oscillator for well drilling. The driving type hydraulic oscillator comprises an upper shell and a lower shell, wherein a shaft sleeve is fixedly arranged at the top of the upper shell; a cleaning shaft fixedly penetrates through the shaft sleeve; a handle block is connected to the top end of the cleaning shaft; a cleaning rod is mounted at the bottom of the cleaning shaft; a cleaning brush is connected to the cleaning rod; an anti-collision mechanism is fixedly mounted at the bottom end of the cleaning shaft; and a cleaning mechanism is arranged on the outer top wall of the upper shell. According to the driving type hydraulic oscillator, the handle block is held by a hand to pull the upper shell, then the cleaning shaft is driven to move upand down, the cleaning rod moves up and down to drive the cleaning brush to move, and then the lower shell is cleaned.

Owner:侯江伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com