Motorcycle parts processing equipment

A technology for processing equipment and parts, applied in the field of motorcycle parts processing equipment, can solve the problems of high processing cost, long time required for debugging and use, low processing efficiency, etc., to achieve high processing accuracy and avoid worker injuries. Or pollute the environment and avoid the effect of excessive grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further detailed explanation through specific implementation mode below:

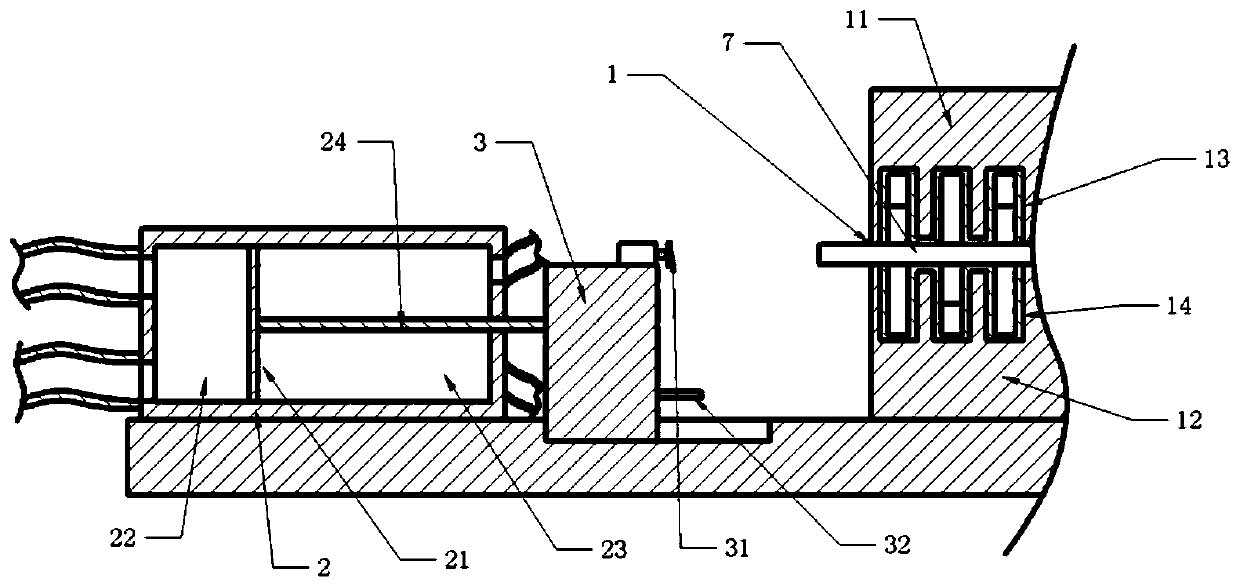

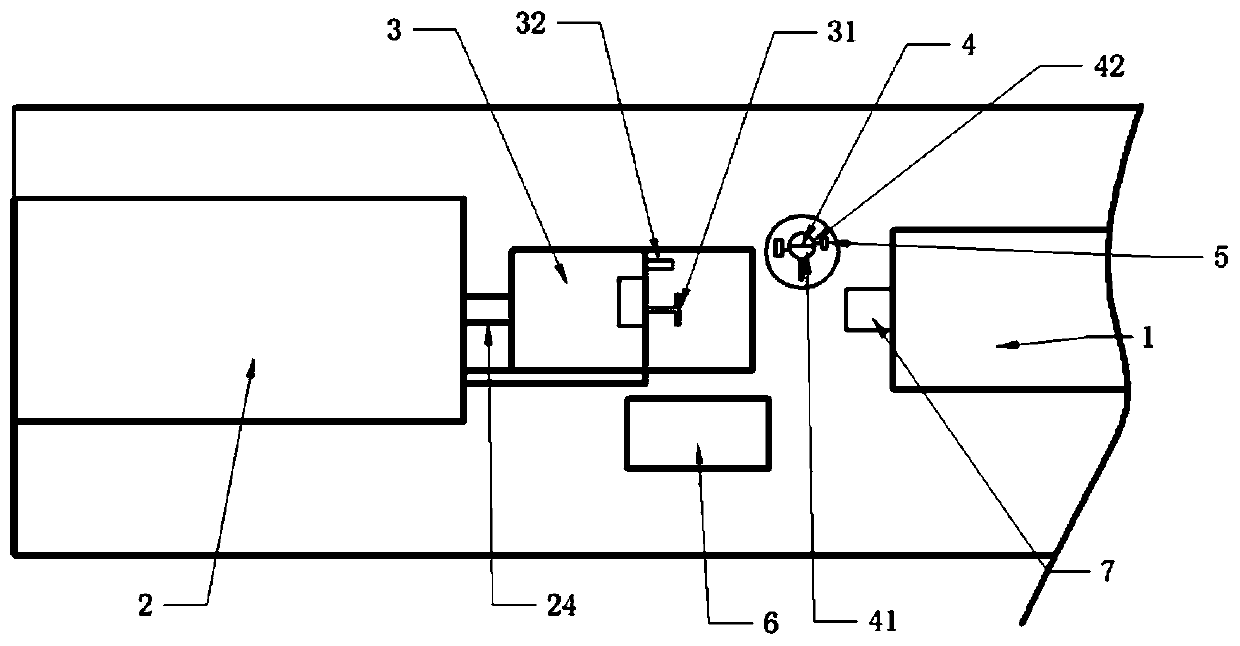

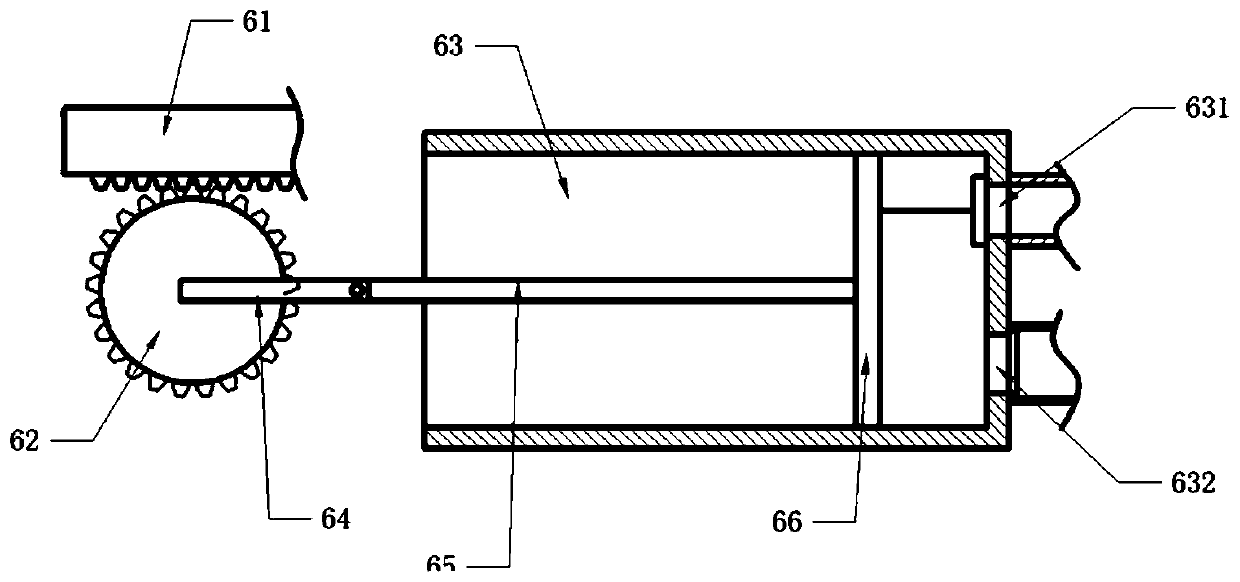

[0030] The reference signs in the accompanying drawings of the description include: fixing mechanism 1, upper support block 11, lower support block 12, installation groove 13, air bag 14, air box 2, partition 21, air intake chamber 22, exhaust chamber 23, pushing Rod 24, mounting table 3, grinding head 31, pole 32, conductive plate 4, conductive part 41, insulating part 42, push rod 43, electromagnet 5, dust removal mechanism 6, rack 61, gear 62, dust removal box 63, Air inlet 631, air outlet 632, fixed rod 64, linkage rod 65, slide plate 66, camshaft 7.

[0031] The embodiment is basically as attached figure 1 Shown:

[0032]The motorcycle parts processing equipment includes a frame, a fixing mechanism 1 is provided in the middle of the frame, a grinding mechanism is provided at both ends of the frame, and a dust removal mechanism 6 is provided below the grinding mechanism. Fixing mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com