Flue gas treatment device of ice net type high-temperature alloy smelting furnace

A technology for superalloy and flue gas treatment, applied in waste heat treatment, furnace, furnace components, etc., can solve the problems of low efficiency and long time for waste gas treatment, and achieve the effect of improving the cooling effect and the effect of cooling and removing impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

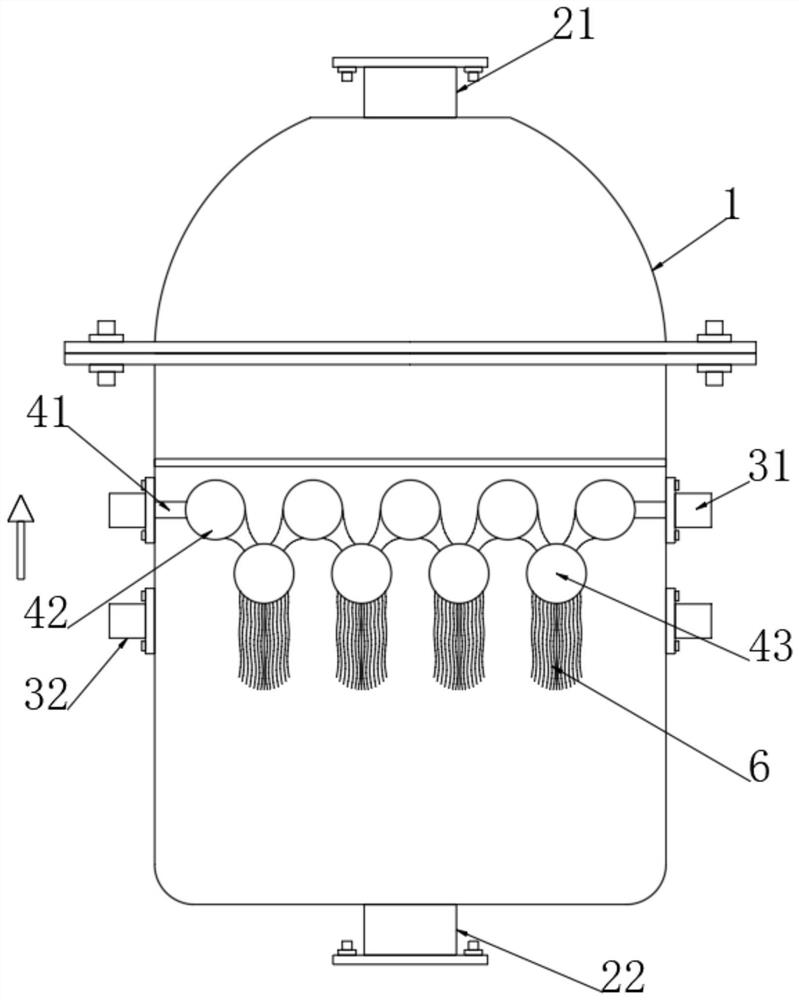

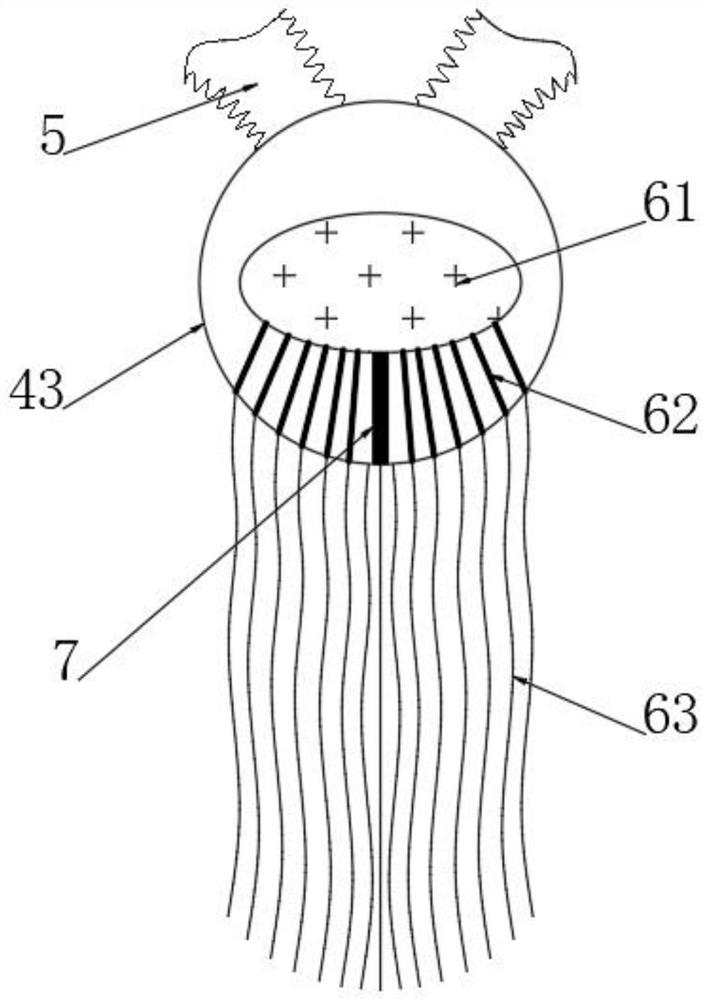

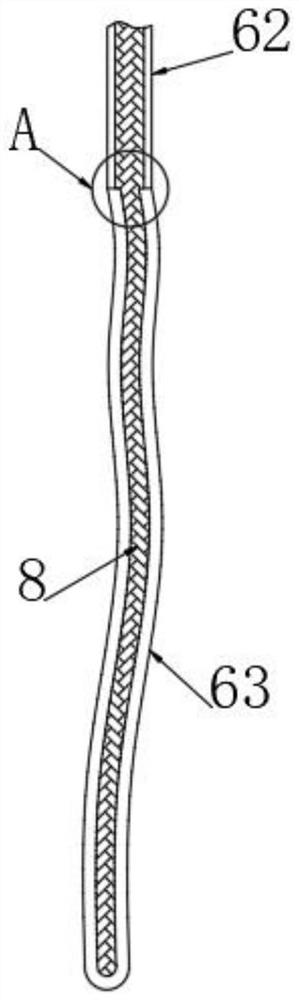

[0043] see figure 1 , a flue gas processor of an ice net type superalloy smelting furnace, comprising a device body 1, the upper and lower ends of the device body 1 are respectively fixedly connected with an exhaust hole 21 and an air intake hole 22, and the exhaust hole 21 and the air intake hole 22 All communicate with the inside of the device body 1, and the left and right ends of the device body 1 are fixedly connected with water inlet holes 31 and inflation holes 32. 1 communicates with each other, the device body 1 is fixedly connected with the limited top net, the limited fixed net is located above the deheated puck net, and the distance between the two is not greater than half of the length of the elastic tube 5, the smoke generated in the melting furnace of the superalloy The gas is passed into the device body 1 through the air inlet 22, and the flue gas impacts the deheated ice hockey net, causing it to move upward. The limit top net effectively ensures that its upwa...

Embodiment 2

[0050] The outer end of the up-going hot ice ball 42 is fixedly connected with a plurality of evenly distributed extra balls 9, the extra balls 9 communicate with the up-going hot-ice ball 42, and the plurality of extra-balls 9 can effectively increase the contact area between the up-going hot-ice ball 42 and the flue gas, so that the The cooling effect of the flue gas is better, and at the same time, the effect of intercepting impurities in the flue gas is better. The hot ice ball 42 is made of hard material, and the extra ball 9 is made of elastic material with rough surface. , a certain buffering effect can be produced between a plurality of additional balls 9 and the limit top net.

[0051] The main difference between this embodiment and Embodiment 1 is the material of the hot ice puck 42 and the extra ball 9 with a characteristic structure in addition to the hot ice puck 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com