An automated production monitoring method based on big data and blockchain

A big data and blockchain technology, applied in the direction of comprehensive factory control, device for coating liquid on the surface, foam dispersion/prevention, etc., can solve problems such as easy generation of bubbles, uneven color on shoe uppers, and inconvenient bubble elimination. , to achieve the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

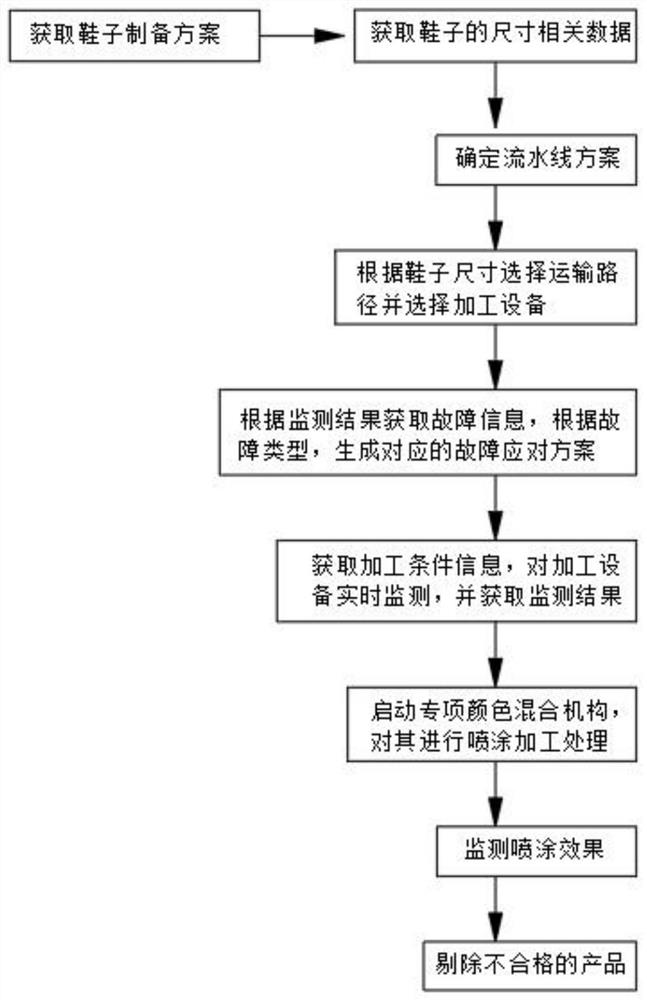

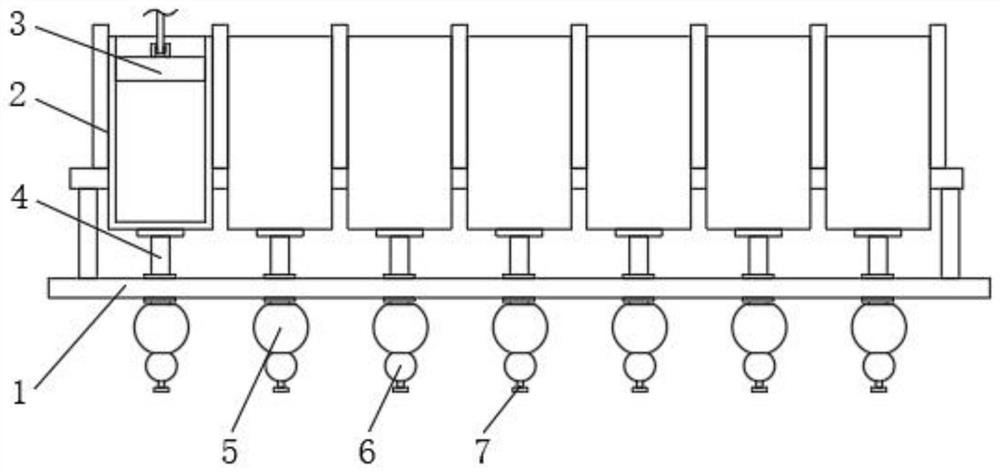

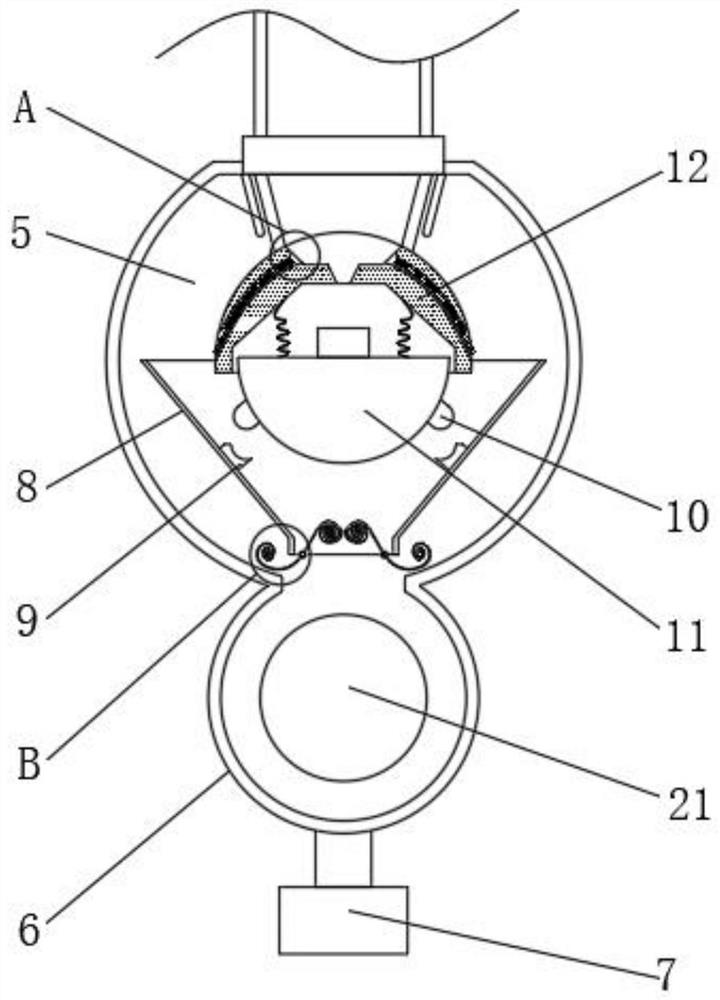

[0049] see Figure 1-7 , an automated production monitoring method based on big data and blockchain, the automated production monitoring method comprising:

[0050] S1: Determine the preparation plan of the shoes through big data, and obtain the relevant data of the shoe size, and select the assembly line plan according to the size of the shoes;

[0051] S2: Determine the assembly line plan, select the corresponding transportation path and select the processing equipment according to the size of the shoes, and the transportation path adopts the conveyor belt with the model HBLT50-1.51MISUMI for batch transportation;

[0052] S3: Through big data analysis, monitor the internal faults of its equipment, obtain fault information according to the monitoring results, and generate corresponding fault response plans according to the type of fault;

[0053] S4: Obtain the processing condition information according to the processing equipment, monitor the processing equipment in real t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com