Conductive rubber and its application and surface selective metallized rubber product and its preparation method

A technology of conductive rubber and rubber products, which is applied in applications, cable/conductor manufacturing, and conductive layers on insulating carriers. It can solve problems such as the inability to meet the requirements for the use of shielding shells, and the difficulty in forming fine conductive patterns. Low cost, reduced production cost, wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

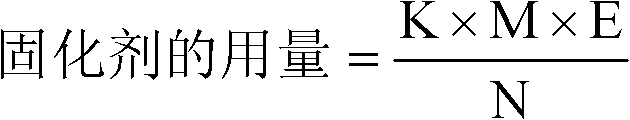

Method used

Image

Examples

Embodiment 1

[0136] (1) 80 grams of CuO and 80 grams of Fe 2 o 3 Mix well, and carry out ball milling in a ball mill with ethanol as a medium for 12 hours. After the ball mill product is dried, in a mixed atmosphere of hydrogen and nitrogen (wherein, the volume ratio of hydrogen and nitrogen is 2:1) , roasted for 5 hours, and ball-milled the roasted product to an average particle size of 80nm. The prepared product is CuFeO 3.98 .

[0137] (2) 100 g of the compound prepared in step (1), 15 g of polyvinyl butyral (commercially purchased from Kuraray Co., Japan, trade name Mowital) and 20 g of toluene were uniformly mixed to obtain an ink composition.

[0138] (3) The ink composition prepared in step (2) is printed on the surface of the rubber substrate (formed by vulcanized styrene-butadiene rubber) with an inkjet printing method, and dried at a temperature of 120° C. for 3 hours, thereby An ink layer (thickness: 15 μm) was formed on the surface of the rubber substrate.

[0139] (4) ele...

Embodiment 2

[0141] (1) 80 grams of CuO and 80 grams of Fe 2 o 3 Mix evenly, carry out ball milling in a ball mill with ethanol as a medium for 12 hours, after the ball milling product is dried, at a temperature of 800°C, in a mixed atmosphere of hydrogen and nitrogen (wherein the volume ratio of hydrogen to nitrogen is 1:1) , roasted for 6 hours, and the roasted product was ball-milled to an average particle size of 100 nm. The prepared product is CuFeO 3.9 .

[0142] (2) 100 grams of the compound prepared in step (1), 20 grams of binder (commercially purchased from Eastman Company of the United States, trade name CAB381-0.5), 100 grams of n-heptanol, 2 grams of dispersant (commercially purchased from Germany BYK company, trade mark is DISPERBYK-165), 0.2 gram defoamer (commercially purchased from German BYK company, trade mark is BYK-051), 0.4 gram leveling agent (commercially purchased from German BYK company, trade mark is BYK-333) and 0.5 g of hydrogenated castor oil (commercially...

Embodiment 3

[0146] The same method as in Example 2 was used to prepare the ink composition and selectively metallize the surface of the rubber substrate, except that no epoxy resin binder was used in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com