A device for printing colored dents on cardboard

A cardboard and colored technology, applied in printing devices, printing, typewriters, etc., can solve the problems of no cushioning effect, cardboard damage, and cardboard cannot be fixed, etc., to achieve good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

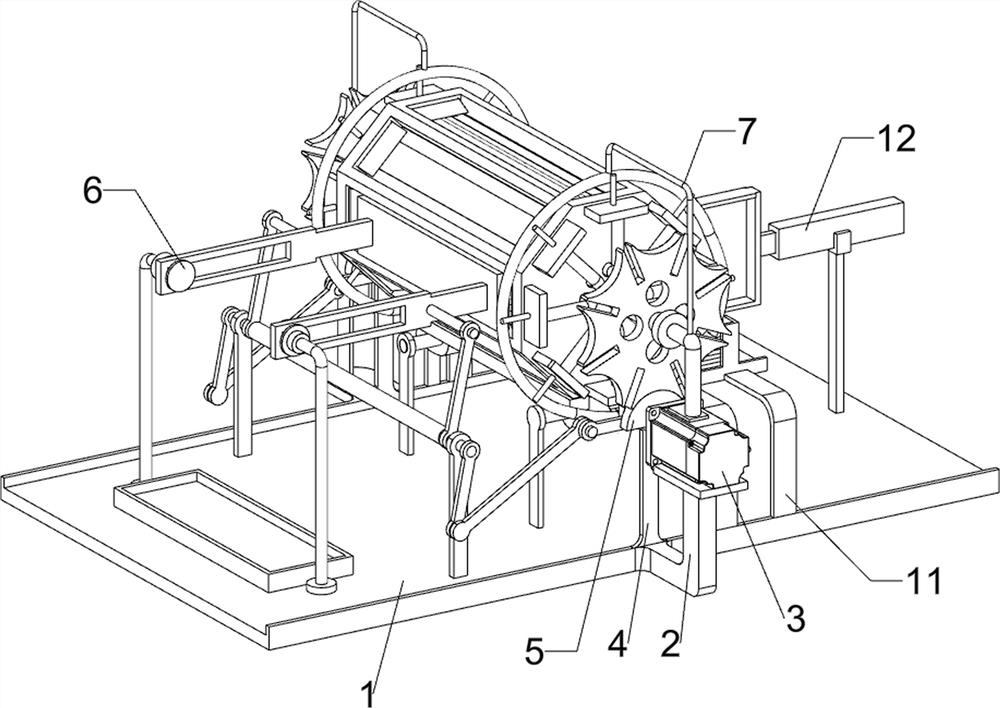

[0028] A device for printing colored indents on cardboard, such as Figure 1-5 and Figure 8-9 As shown, it includes a base 1, a first support seat 2, a servo motor 3, a first bearing seat 4, an intermittent rotation mechanism 5, an imprint mechanism 6, a clamping mechanism 7 and a feeding mechanism 11, and the middle of the front side of the top of the base 1 is fixed. Connected with the first support seat 2, the top of the first support seat 2 is installed with a servo motor 3, and the middle of the top of the base 1 is symmetrically installed with a first bearing seat 4, and the first bearing seat 4 on the front side rotates with the output shaft of the servo motor 3 connection, the output shaft of the servo motor 3 is provided with an intermittent rotation mechanism 5, the intermittent rotation mechanism 5 is connected with the first bearing seat 4 on the rear side, and the left side of the top of the base 1 is provided with an imprint mechanism 6, which is connected to th...

Embodiment 2

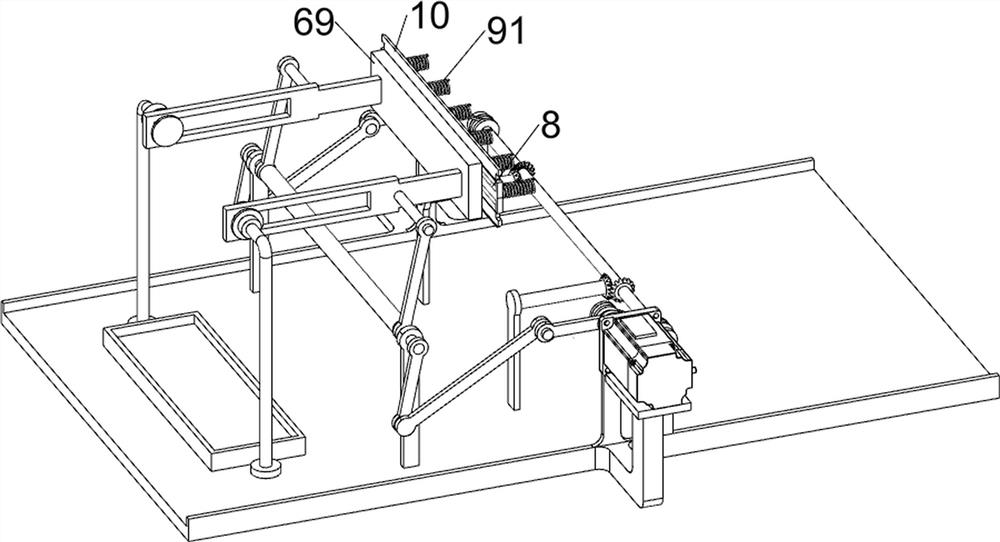

[0039] On the basis of Example 1, such as Figure 6-7 and Figure 9 As shown, also include pressing plate 8, second spring 9, slide plate 10 and the 3rd spring 91, all slide type is provided with pressing plate 8 in the chute on the rotating cylinder 53, all connect between pressing plate 8 rear sides and rotating cylinder 53 There are a plurality of third springs 91 , a slide plate 10 is slidably provided on both sides of the pressing plate 8 , and a plurality of second springs 9 are connected between the inner side of the sliding plate 10 and the pressing plate 8 .

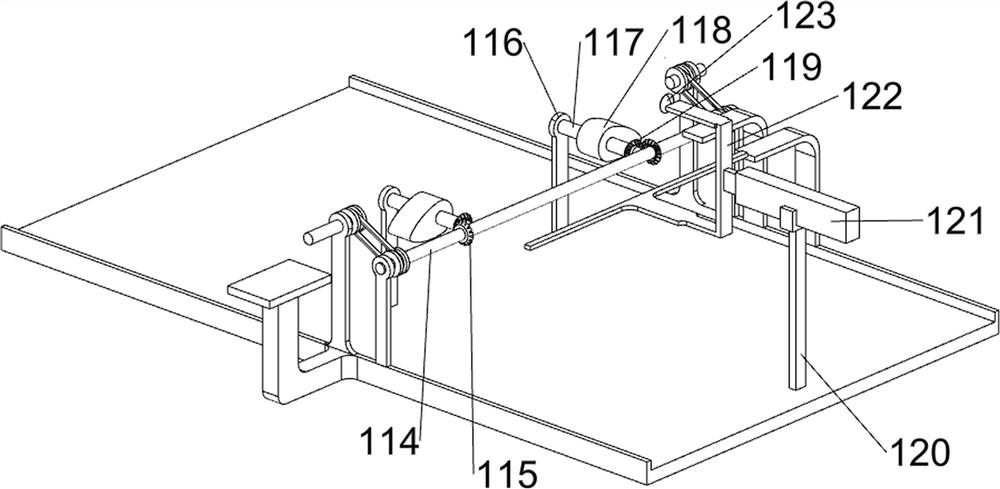

[0040] Also includes a pusher mechanism 12, the pusher mechanism 12 includes a second fixed rod 120, a cylinder 121, a push plate 122 and a suction cup 123, the top of the base 1 is fixedly connected with the second fixed rod 120, and the top of the second fixed rod 120 is equipped with Cylinder 121, the piston rod left end of cylinder 121 is connected with push plate 122, and push plate 122 is in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com