Four-directional rotation shaft structure based on modular assembly

A rotating shaft and modular technology, applied in the direction of pivot, shaft and bearing, pivot connection, etc., can solve the problem of not being able to ensure the modularity of the rotating shaft structure at the same time, it is difficult to meet the modular product shape, and the modular product shape is single and other issues, to achieve the effect of rich shape design, ingenious structural design, and high modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

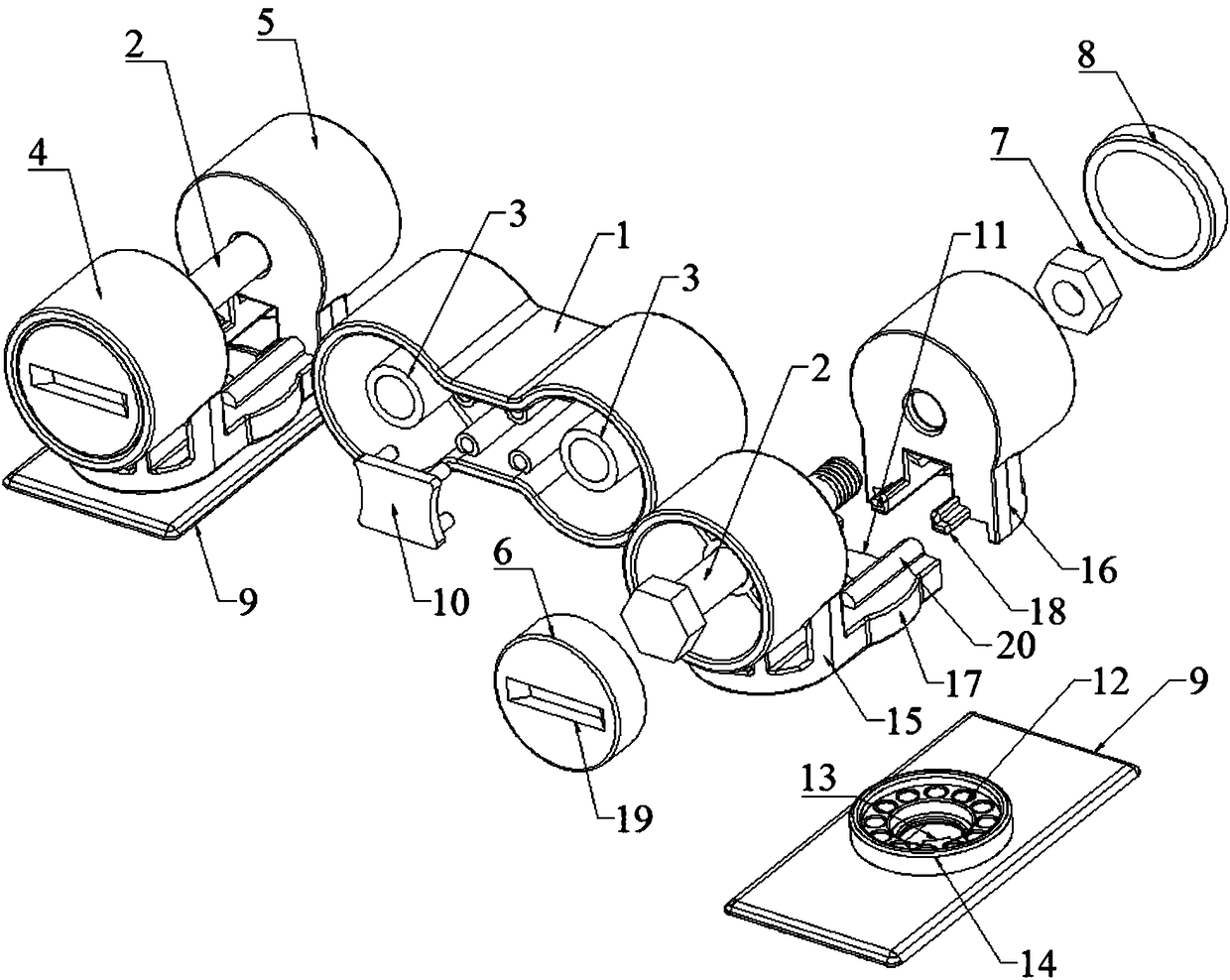

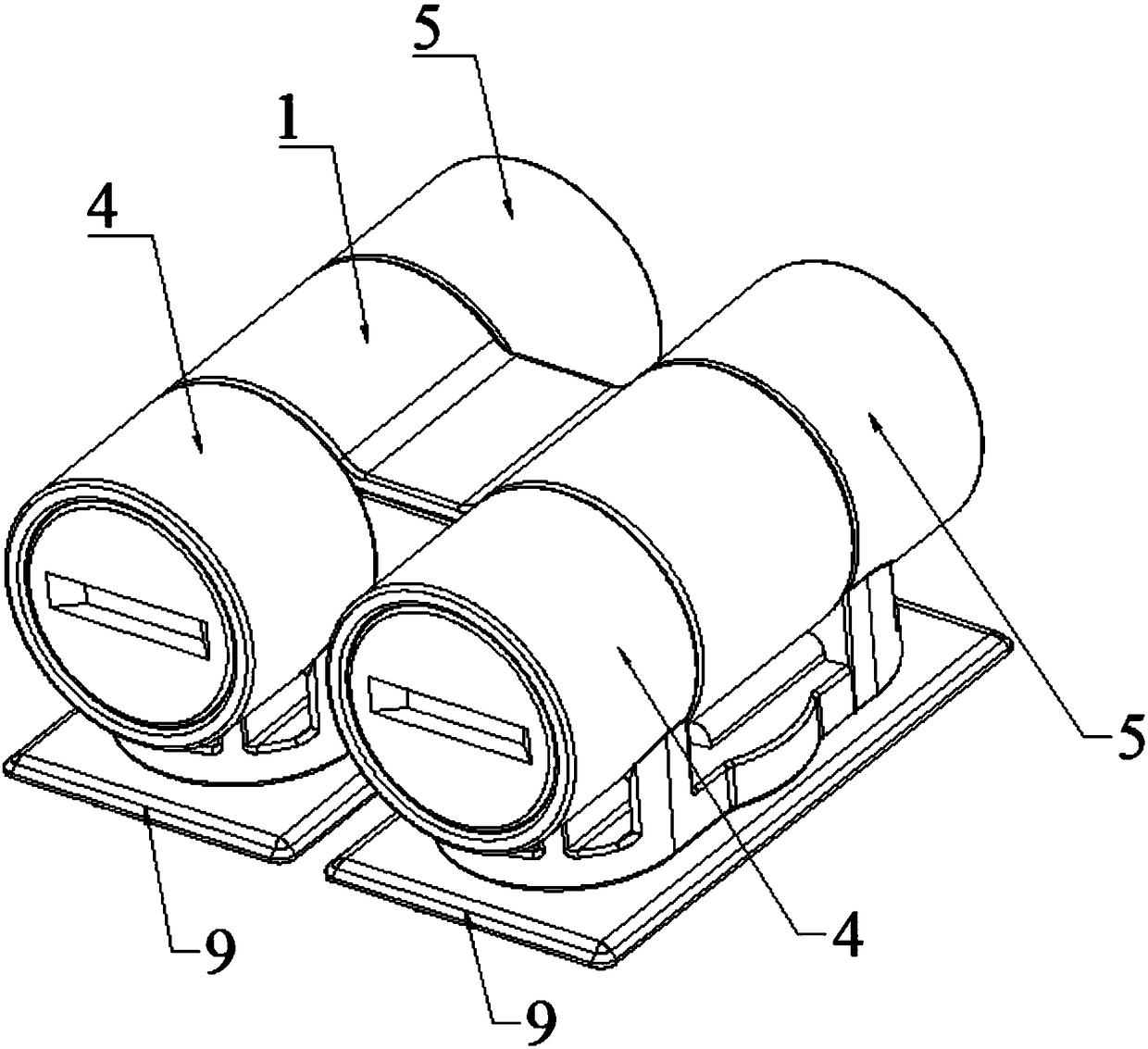

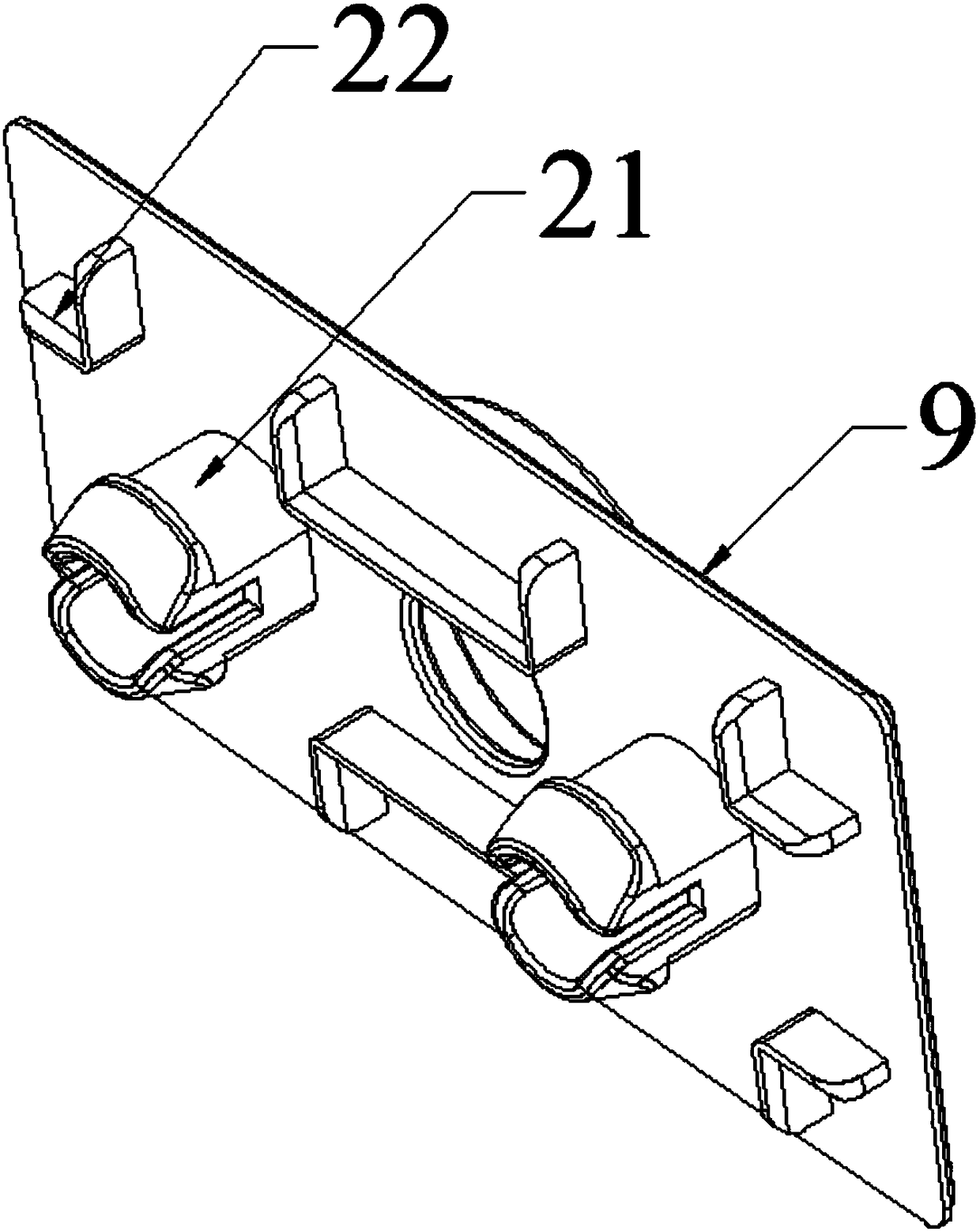

[0025] Such as Figure 1-Figure 4 As shown, the present invention provides a four-way rotating shaft structure based on modular assembly, including a co-directional shaft 1, the co-directional shaft 1 is a hollow shell with one side open and the cross-section of the hollow shell is 8 font, the codirectional shaft 1 is composed of a middle shell and an arc shell connected to both ends of the middle shell, and the inside of the codirectional shaft 1 is a connected cavity, and the centers of the two ends of the codirectional shaft 1 are A bolt shank 2 is movably socketed (the center of the circle is the center of the arc shell), and the bolt shank 2 is located in the direction of the axis of the circle center at the end of the coaxial shaft 1 (the axis of the circle center is the axis of the arc shell), Preferably, a rotating sleeve 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com