Variable-diameter self-adaptive rotary cutting type banana bunch cutter

A technology of rotary cutting and cutting blades, which is applied in application, food processing, food science, etc., can solve the problems of unfavorable banana storage, transportation and fresh sales, low level of mechanized application, and low operating efficiency, so as to reduce manual physical exertion, Reduce the number of operators and improve aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

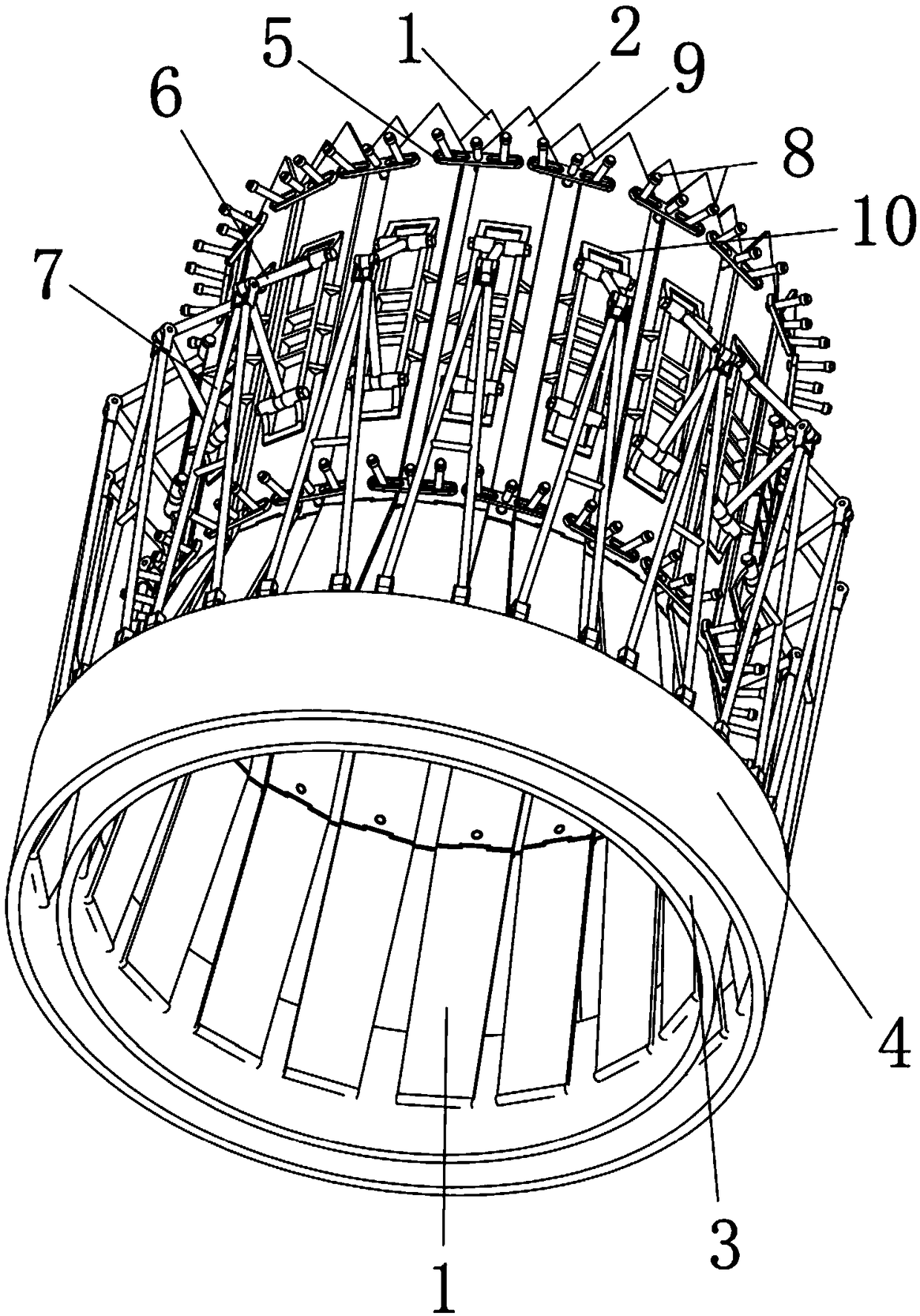

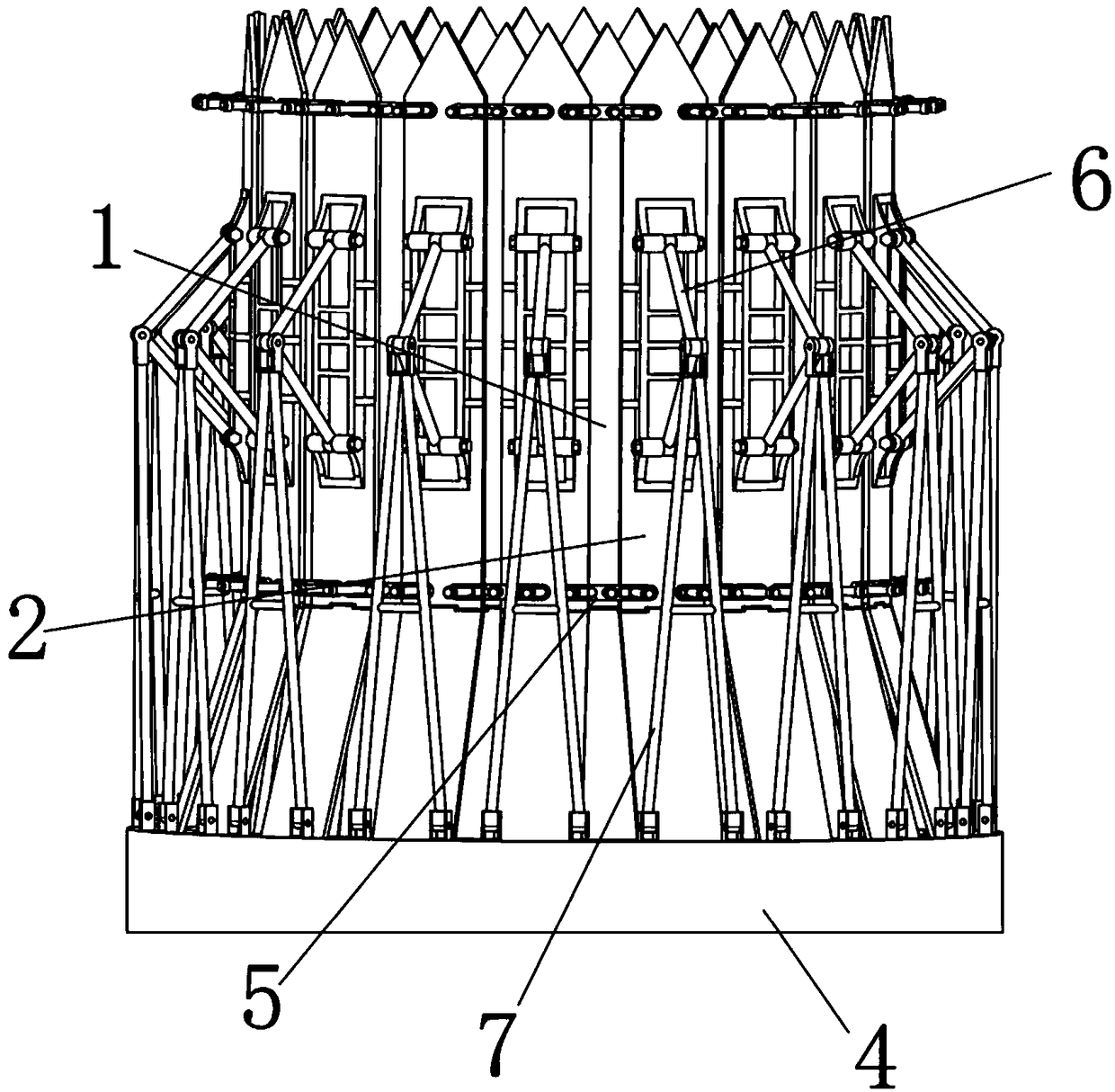

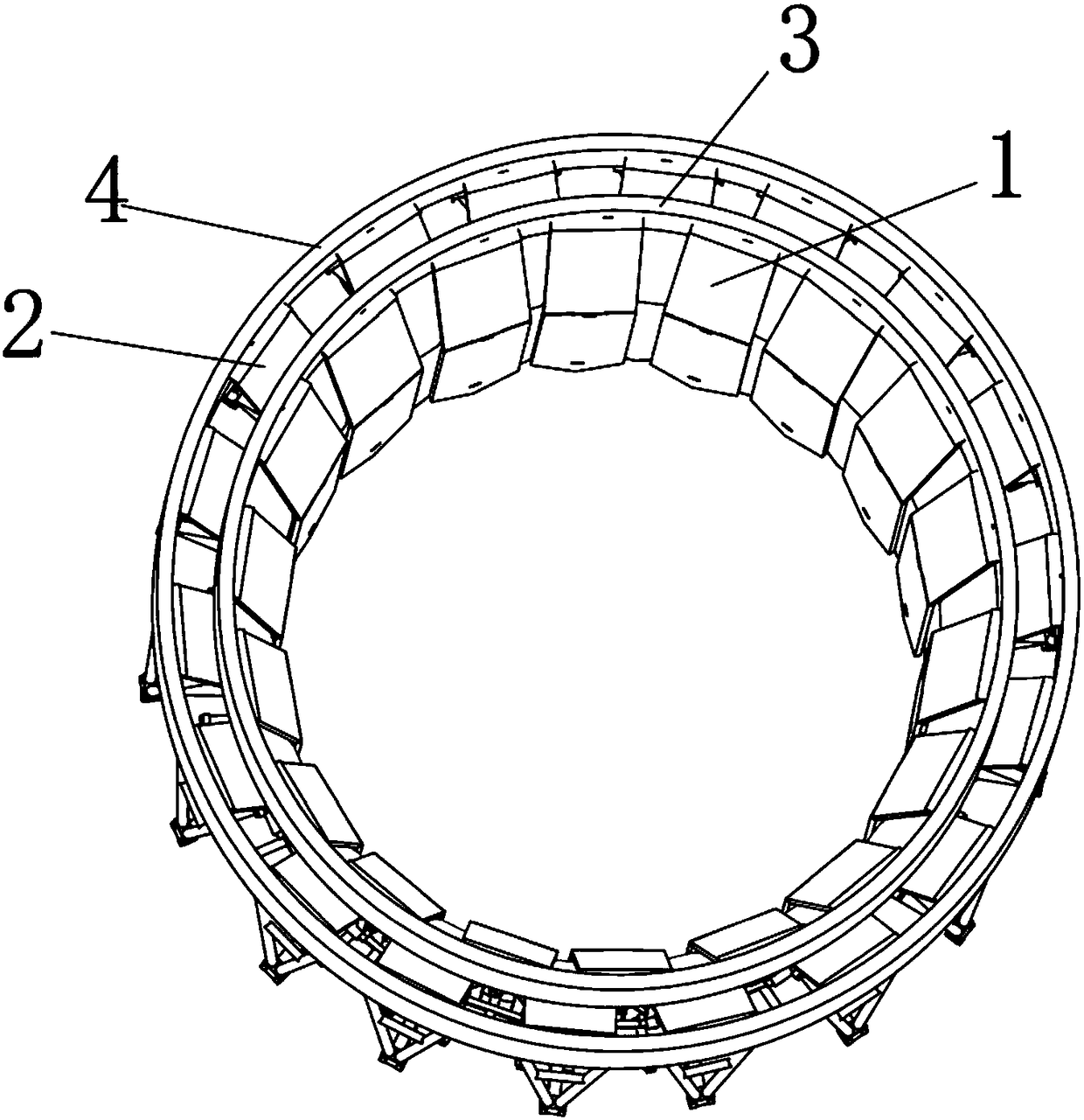

[0020] see Figure 1 to Figure 3 As shown, the variable-diameter self-adaptive rotary cutting banana comb cutter provided in this embodiment includes a double-edged inner cutting blade 1, a double-edged outer cutting blade 2, an inner annular knife holder 3, an outer annular knife holder 4, and a connecting piece 5. Double-joint linkage mechanism 6, A-shaped pull-rod mechanism 7; wherein, the inner annular knife holder 3 and the outer annular knife holder 4 have the same circle center, and the double-edged inner cutting blade 1 has multiple pieces slidingly installed inside On the annular guide groove of annular knife rest 3, constitute the inner annular enveloping structure that can envelop the banana fringe bar, and described double-edged outer cutting blade 2 has many slices that are slidably installed on the annular guide groove of outer annular knife rest 4 to form an env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com