One-sided feeding top hydraulic supporting gyratory crusher

A gyratory crusher and hydraulic support technology, applied in grain processing and other directions, can solve the problems of increasing equipment height, large feeding space, increasing feeding particle size, etc., and achieve the effect of reducing the difficulty of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

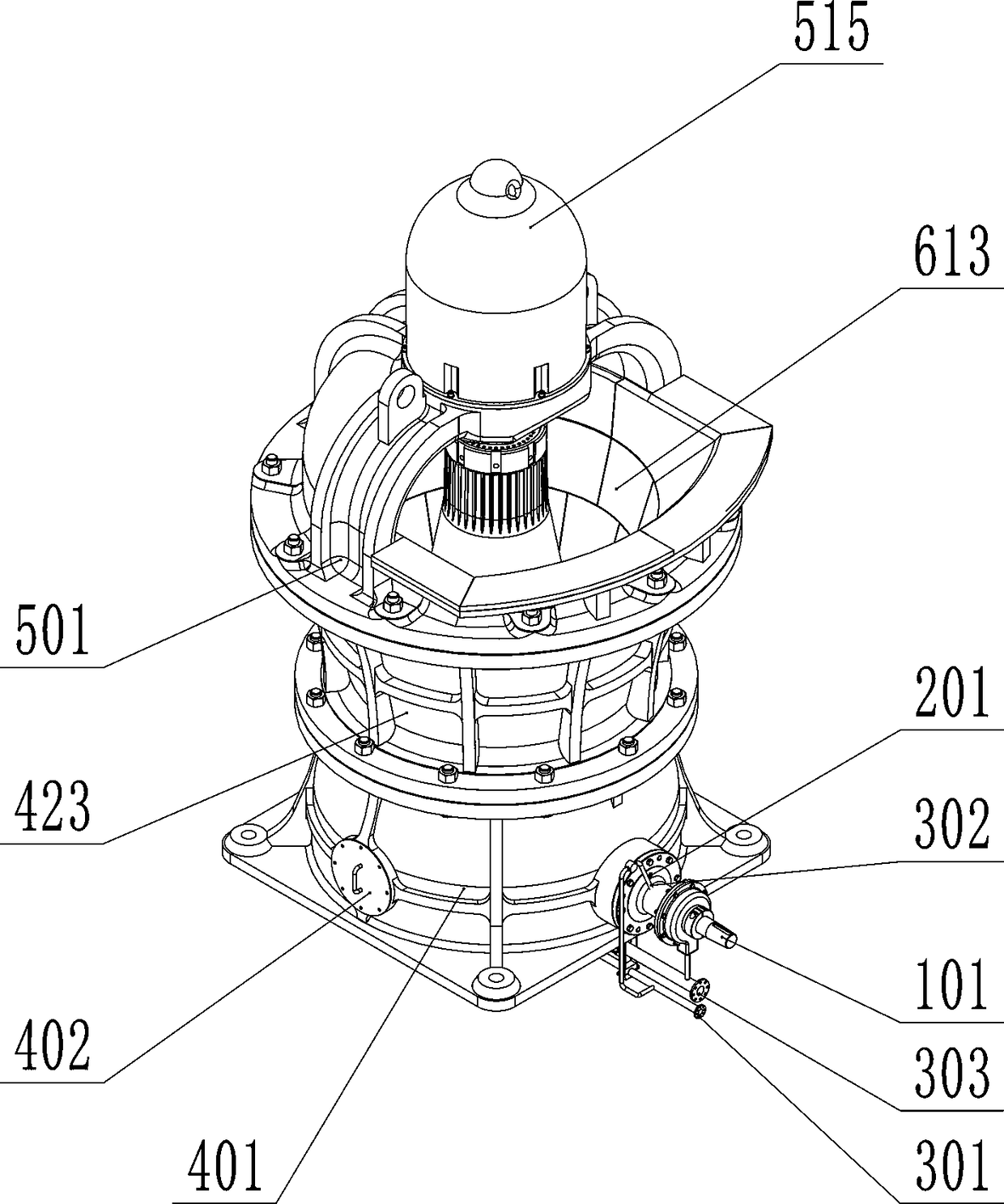

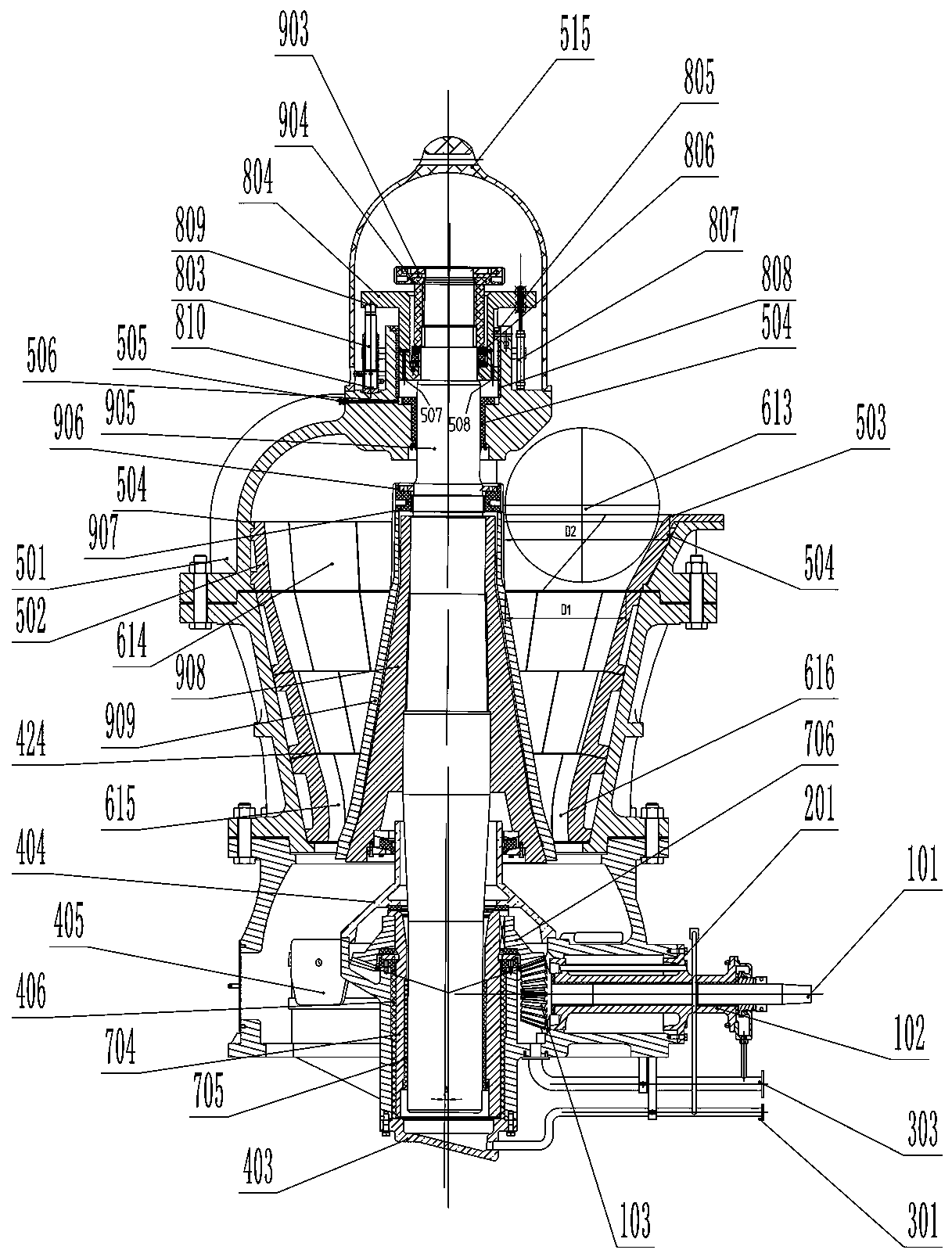

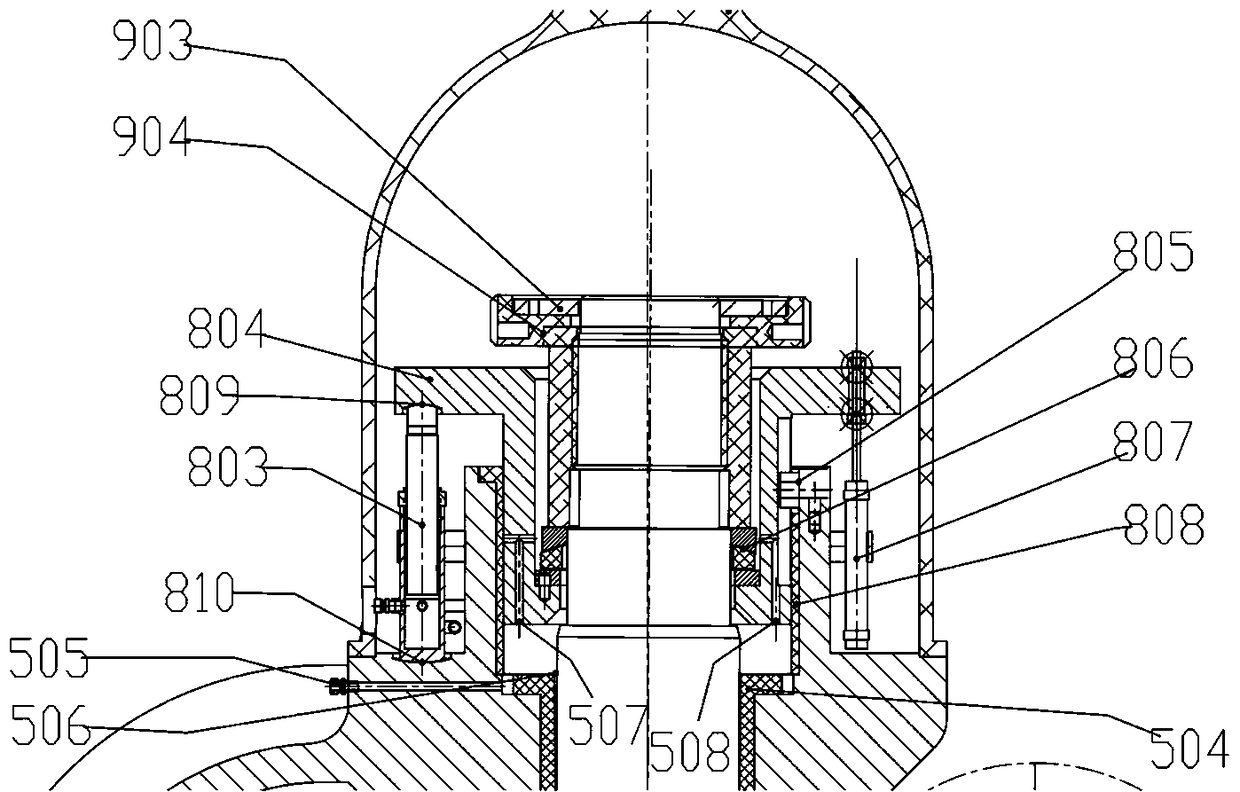

[0025]Embodiment 1: A gyratory crusher with unilateral feeding and top hydraulic support, including an upper frame assembly, a middle frame body assembly, a base assembly, a pinion transmission assembly, a large gear eccentric sleeve assembly, an upper hydraulic support lifting suspension assembly, a dynamic cone assembly. The upper frame body 501 and the middle frame body 423 , and the middle frame body 423 and the base 401 are fitted together through the taper surfaces respectively, the bolts are locked, and the base is installed on the base 1003 via the bolts. The transmission shaft frame 102 and the base 401 are connected by bolts, and the transmission shaft frame 102 is embedded with a sliding bearing, which limits the position and degree of freedom of the transmission shaft 101 and the pinion 103, and only allows the rotation of the rotation 101; the rotational power is input through the transmission shaft 101 , the transmission shaft 101 is rigidly connected to the pini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com