A wiper elastic support part, a wiper joint base and a wiper

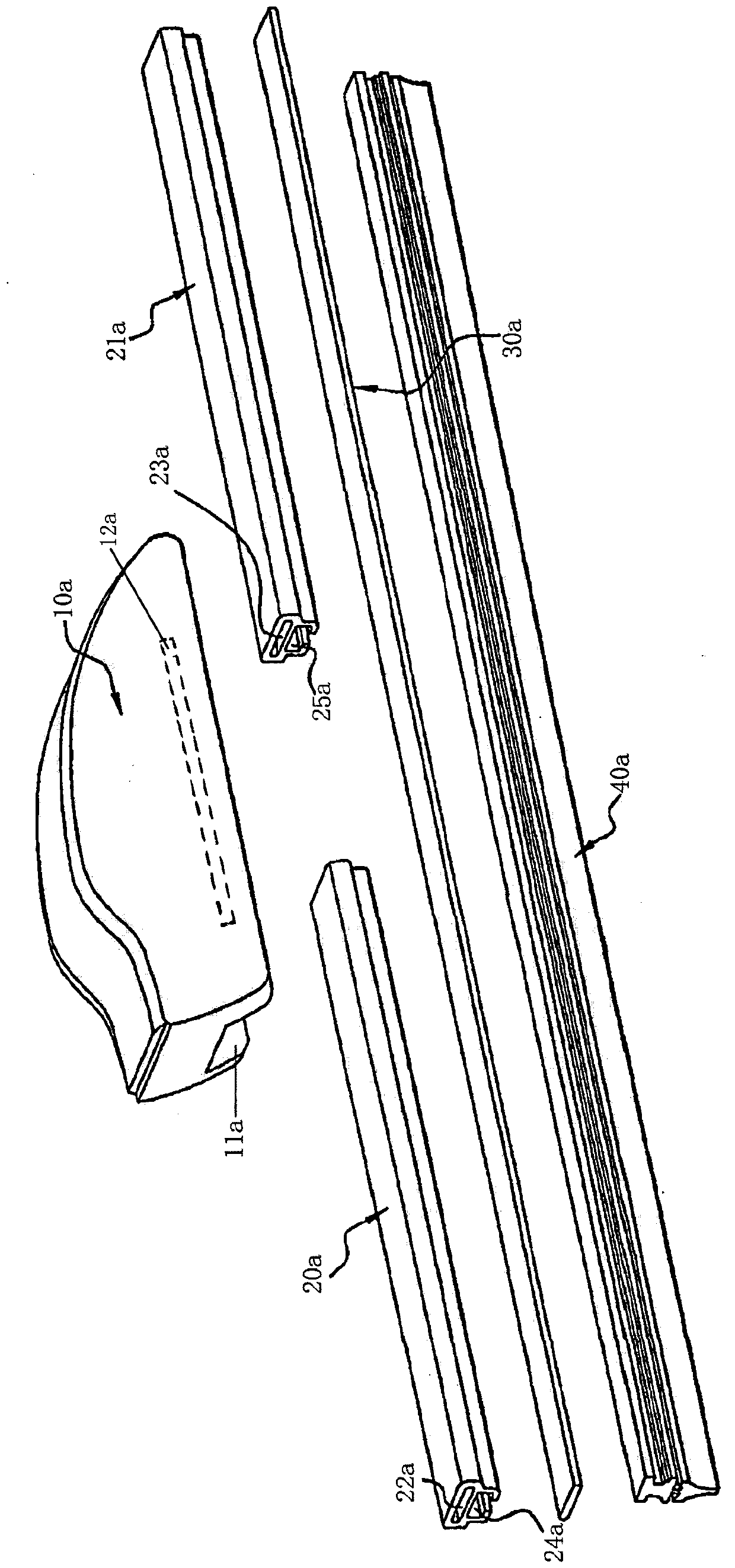

An elastic support and wiper technology, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems such as the influence of the wiper strip 40a on the wiping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

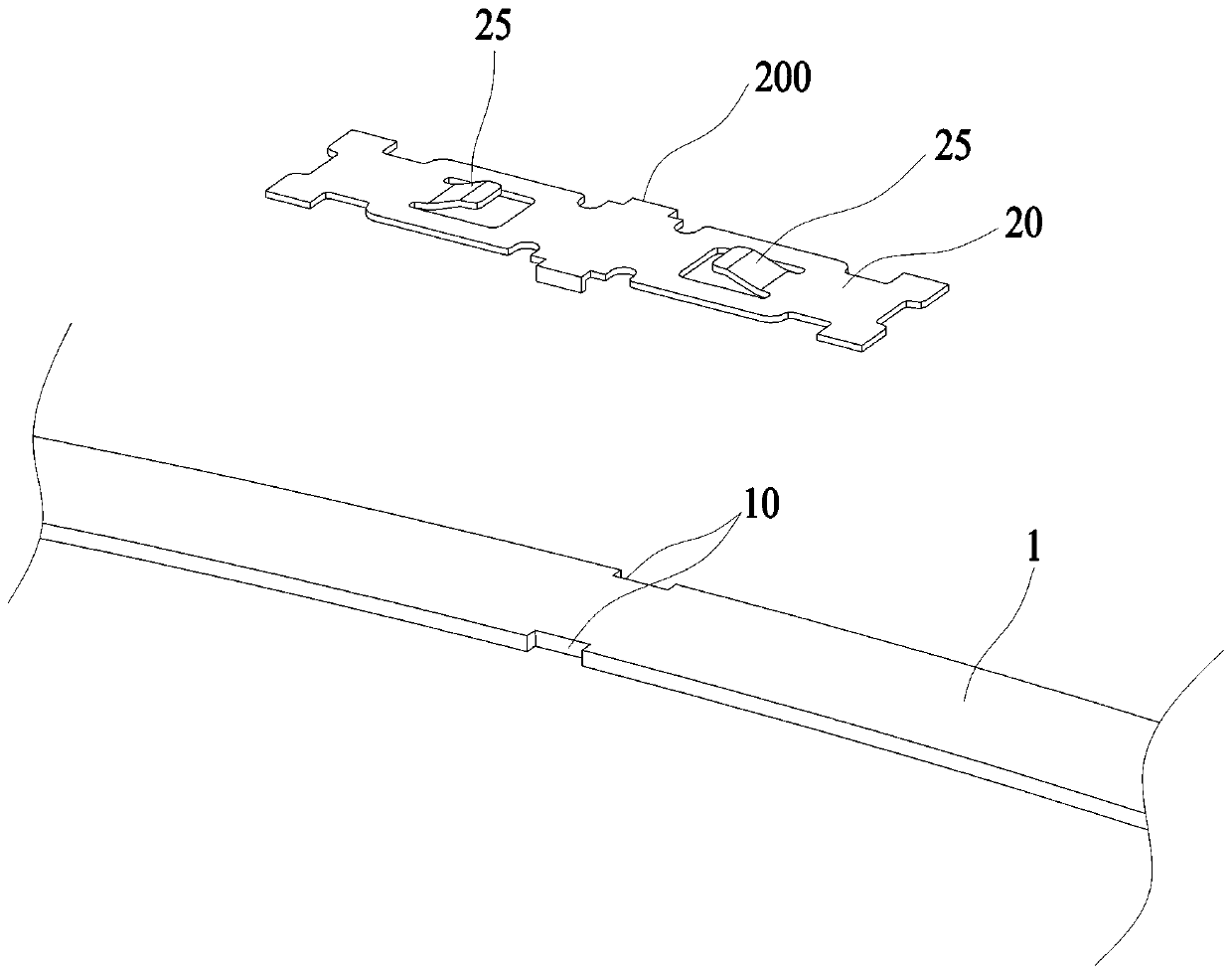

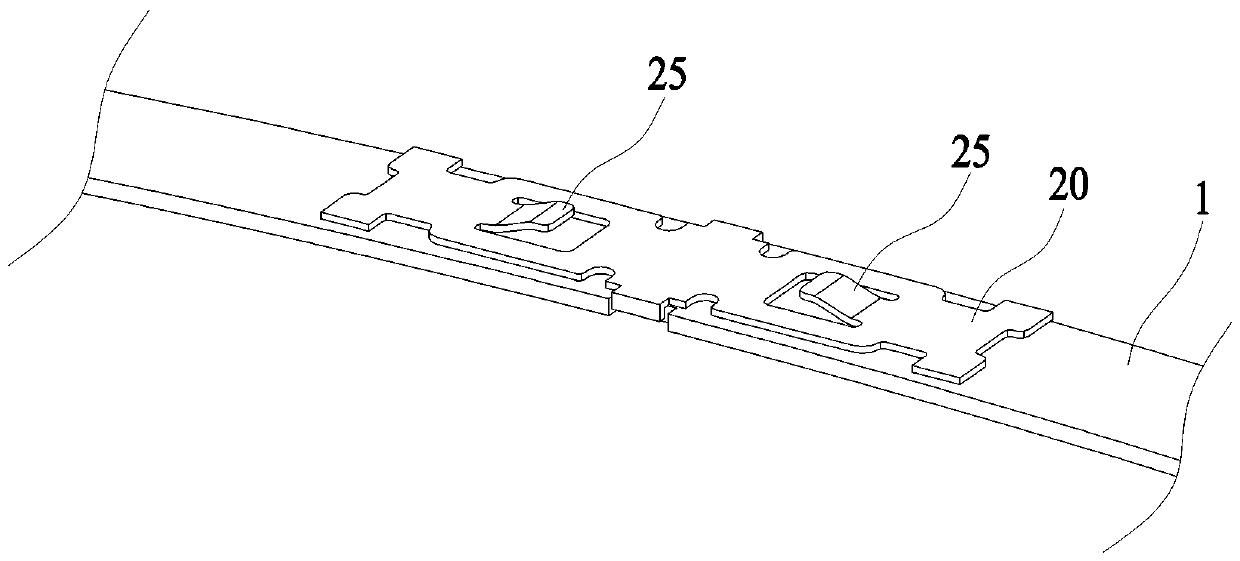

[0052] Such as figure 2 , 3 As shown, a wiper elastic support member 1, the wiper elastic support member 1 is a sheet body, the upper surface of which is additionally provided with a positioning elastic piece 20, the positioning elastic piece 20 is in the shape of a sheet, and its upper surface has stoppers 25, 26, The limiting portion is a pair of upturned flaps 25, 26, and the longitudinal sections of the two upturned flaps 25, 26 are in the shape of a figure-of-sight or an inverted figure-of-sight (inverted figure-of-sight is not shown). The middle part of the two sides of the positioning elastic piece 20 forms a first bent portion 200 downwards, and the wiper elastic support member 1 opposite to the first bent portion 200 forms a corresponding fixing notch 10, and the positioning elastic piece 20 passes through the aforementioned The first bending portion 200 of the wiper is engaged with the fixing notch 10 of the elastic supporting member 1 of the wiper.

no. 2 example

[0054] Such as Figure 4 , 5 As shown, the structure of this embodiment is basically the same as that of the first embodiment, and only the second bending part 210 is formed downward on the two sides of the positioning elastic piece 21, and is located at the front and rear ends of the two sides. The wiper elastic supporting part 1 opposite to the part 210 forms a corresponding fixing notch 11 , and the positioning elastic piece 21 is engaged with the fixing notch 11 of the wiper elastic supporting part 1 through the aforementioned second bending part 210 .

no. 3 example

[0056] Such as Figure 6 , 7 As shown, the structure of this embodiment is basically the same as that of the first embodiment, only the third bending portion 220 is formed downward at the front and rear ends of the positioning elastic piece 22, and the wiper elastic support member opposite to the third bending portion 210 1 forms a corresponding fixing notch 12, and the positioning elastic piece 22 is engaged with the fixing notch 12 of the wiper elastic supporting member 1 through the aforementioned third bending portion 220.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com