Workshop across material transfer equipment

A technology of over-span and material, applied in the field of over-the-cross material transfer equipment in workshop, it can solve the problems of small size, complicated and cumbersome transfer process, inconvenient transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

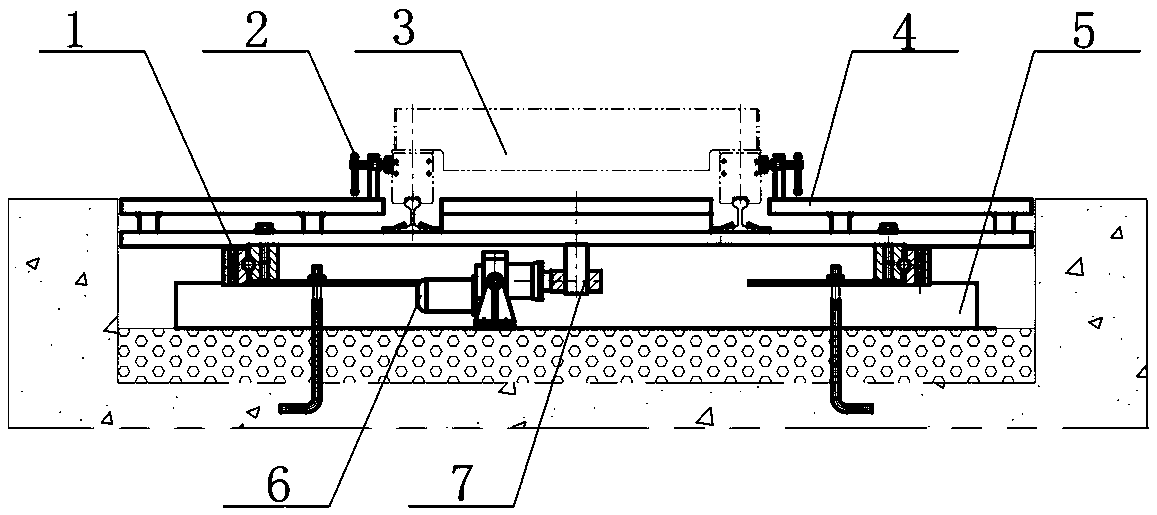

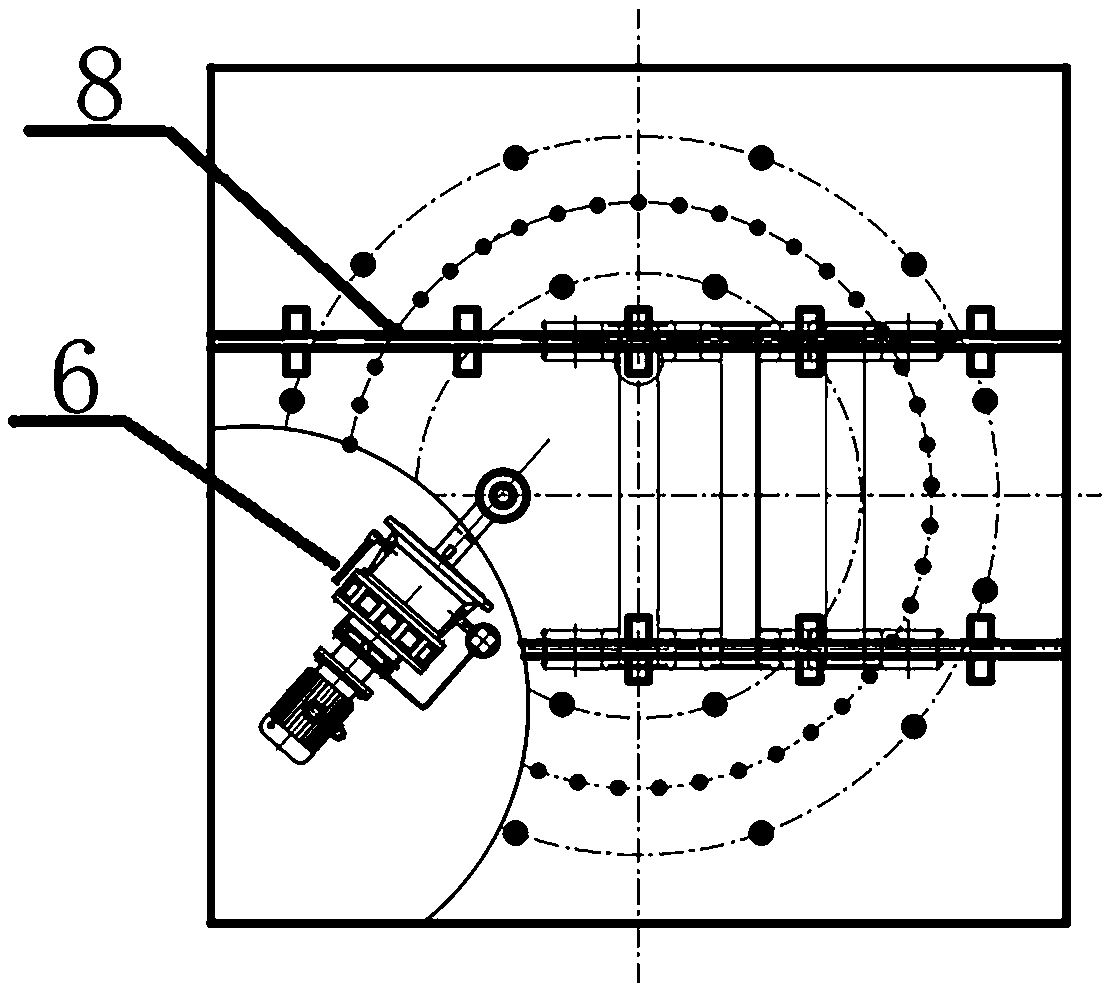

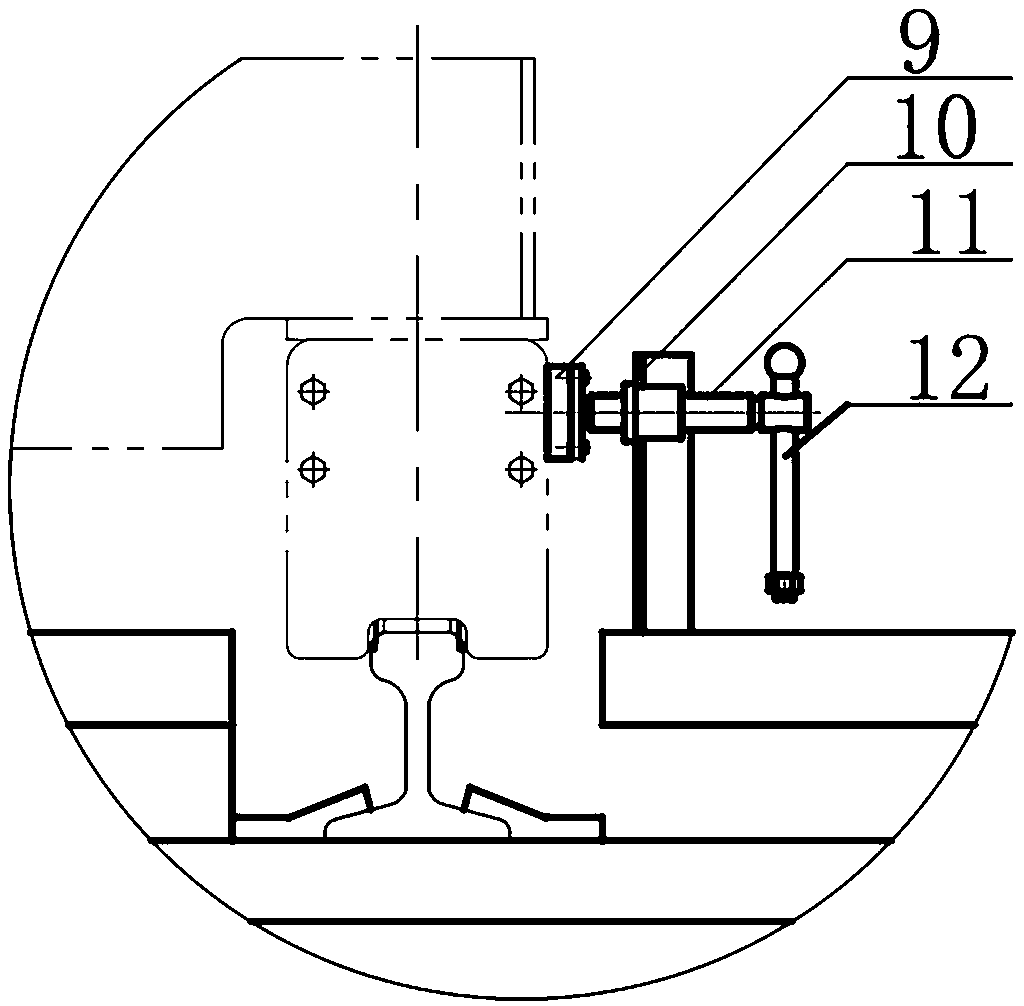

[0016] as attached Figure 1-5 As shown, the cross-span material transfer equipment in the workshop includes a docking track 8, a turntable 4, a slewing support 1, a fixed seat 5, an electro-hydraulic push rod 6, and a hinge shaft 7; the docking track 8 is set on the turntable 4, and the turntable 4 passes through the The slewing support 1 is placed on the fixed seat 5, and the electro-hydraulic push rod 6 is installed on the lower part of the turntable 4 through the hinge shaft 7, wherein the hinge shaft 7 is installed on the non-central part of the turntable 4, and the controller controls the electro-hydraulic push rod.

[0017] The rotation angle of the turntable 4 is controlled by the telescopic length of the electro-hydraulic push rod 6, and the transfer vehicle 3 docked on the docking track 8 on the upper side of the turntable 4 is adjusted to enable the transfer vehicle 3 to realize cross-span transfer. The electro-hydraulic push rod 6 is used to push the eccentric part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com